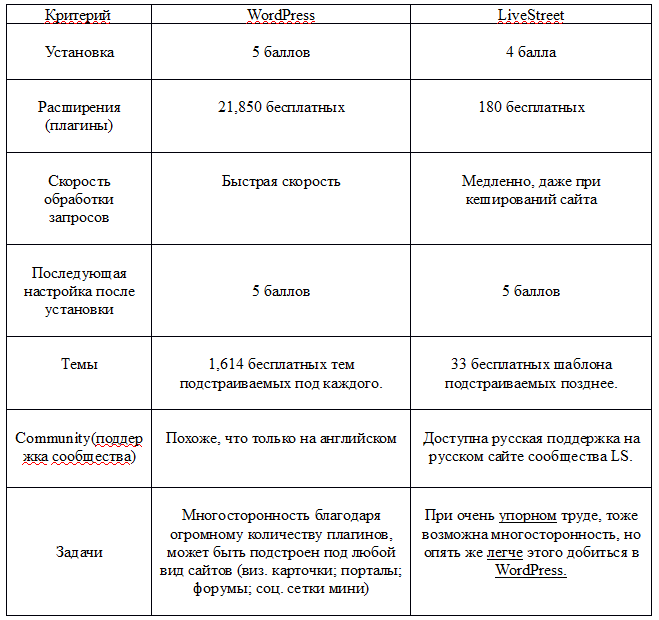

Features of the adhesive composition

Gluing is one of the best joining methods because unlike mechanical fasteners it does not leave marks. In addition, the load is more evenly distributed, and not concentrated in the place of the fastener - the latter often leads to deformation.

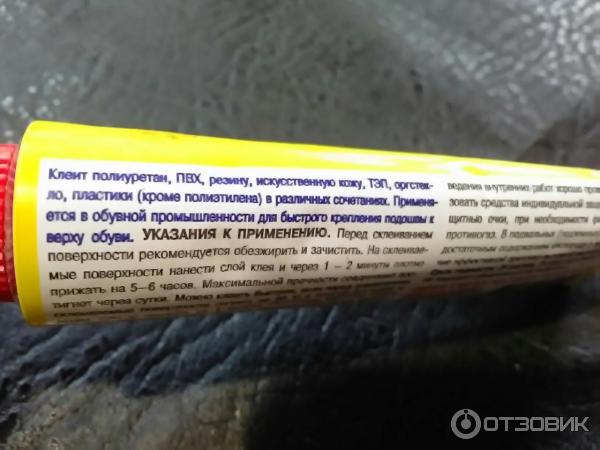

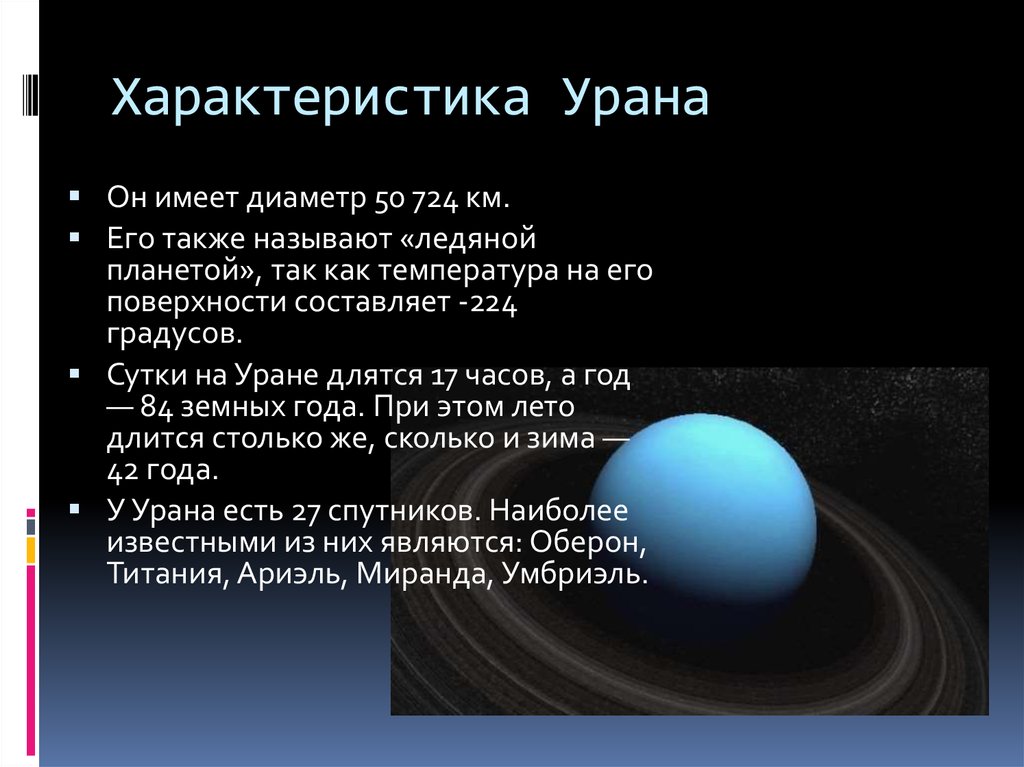

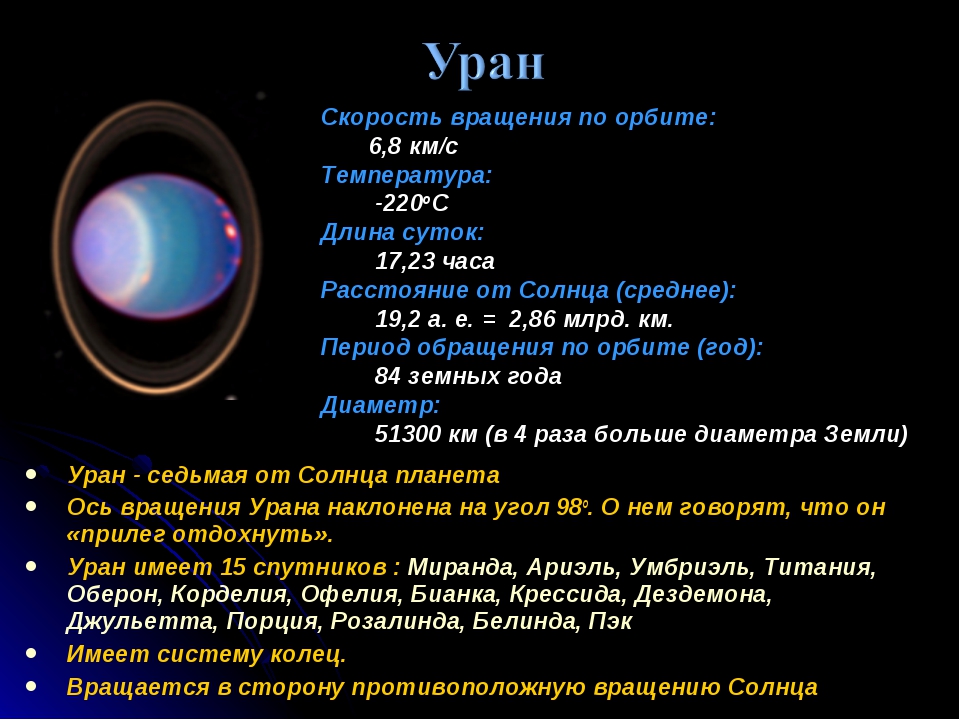

Clay Uranus

The composition is intended for use in everyday life: for gluing PVC materials, polyurethane parts, repairing shoes and rubber products. The seam formed during gluing is strong, but retains elasticity and flexibility. When the connected parts get wet, the strength of the seam decreases by only 20%. In addition, the seam remains practically invisible and does not affect the appearance in any way.

Shoe repair

Composition characteristics:

- the strength of the seam during delamination reaches 5–6 kN / m;

- the same value when gluing leather and polyurethane is 2-3 kN / m;

- mixture viscosity - 200 s;

- mass fraction of dry residue - 18%;

- the shelf life of unopened containers is 24 months.

Another option, which is a kind of competitor to polyurethane Uranium, is nairite glue. It is based on chloroprene rubber. It is intended for gluing leather, rubber, foam rubber, wood. The main advantage of the Nairite composition is the strength of the seam, the delamination index reaches 62 N / cm in a day. The second advantage is very high water resistance. Nairite is used not only to repair boots, but even boats and wetsuits, so the danger of leakage is negligible.

Boat repair

Solution composition

The composition of the CMC glue consists of shavings formed as a result of the processing of wood material at the plant.

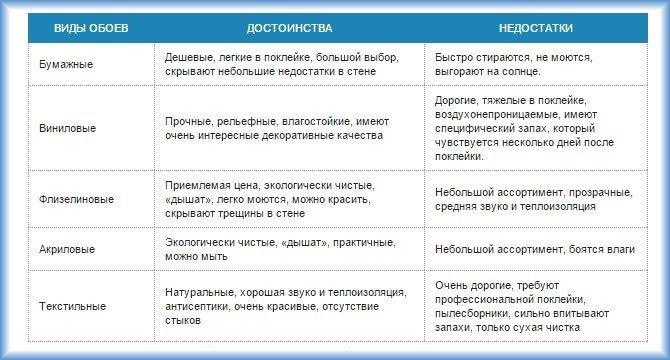

The prepared solution has high adhesion to many surfaces (concrete, stone, wood, plaster, etc.), except metal. Wallpaper sticks of different quality, gravity. Before buying, the outgoing material is assessed, since for heavy wallpaper it is better to take a more concentrated product.

The composition of the solution: glue powder - 55 percent, sodium chloride - 20 percent; moisture - less than 12 percent. The finished solution will be obtained after 2 hours. To prevent the mixture from spoiling, it is worth adding potassium-aluminum sulfate.

Interesting video about the topic:

disadvantages

- Low calorific value. Not the least reason why bituminous coal has lost the palm in the rank of "fuel number 1" is that oil and gas are much more energy intensive. In other words, burning 1 kg of oil or methane releases approximately one and a half times more heat than burning the same amount of the best anthracite.

- Impact on the environment. Burning coal, which is almost pure carbon, releases huge amounts of carbon dioxide into the atmosphere, which is known to be one of the most important greenhouse gases. To reduce the load on the planet's atmosphere, some countries must completely abandon its use. In particular, these are Russia, China and the United States - the largest consumers.

- Large financial costs. The coal industry has been in decline over the past few decades. The equipment is aging, and the financial assistance from the state is weakening every year. As a result, a large number of mines are being closed around the world.

- The difficulty of mining. Most of the coal deposits are located at great depths underground, sometimes several hundred meters. Practically everywhere manual labor of miners is widely used, and during its extraction methane and coal dust are formed, which, at the slightest spark, can cause a fire.

- High danger to life. Mine accidents happen all the time.The reasons are different: low technological discipline, disregard for safety rules, and increased complexity of mining. There are plenty of fatalities. The number of victims can sometimes go up to several hundred. For example, in Germany in 1962 in a mine located in the Saarland, 298 miners died. In Turkey, an accident in 1992 claimed the lives of 270 miners. In China, after another disaster, they were forced to close a thousand mines that did not meet safety requirements.

How to charge an AGM battery

Before you start charging the battery, you must carefully study the manufacturer's recommendations, which are indicated in the accompanying documentation. Batteries made using AGM technology completely "painlessly" endure a deep discharge (even reusable), but they have a very "negative attitude" towards exceeding the value of the charging current and voltage. How do I charge an AGM battery correctly? Today, two main algorithms are used:

- Two-stage, in which at the first stage the current is set - from 10 to 20% of the capacity value; as well as the voltage (as a rule, it is about 14.4-14.8 Volts), which in the second stage is reduced to 13.2-13.6 Volts. It is this mode that is considered the most useful for extending the "life" of the battery.

- Single-stage: voltage - 13.4-13.8 Volts, current - 10-30% of the rated capacity. This option for restoring the energy characteristics of the battery can only be recommended to owners of the simplest chargers.

Advantages and disadvantages

Compared to classic analogs, AGM batteries have a number of advantages:

- For such devices, there is no need for any preventive maintenance during the entire period of operation.

- High resistance to vibration loads allows them to be used on any vehicles.

- Absolute operational safety. Due to the fact that the electrolyte is inside in a bound state, that is, even if the case is mechanically damaged, it does not leak out.

- Products tolerate deep discharge well, after which they can be easily charged to full capacity.

- They can be installed in almost any position (vertical, horizontal or at an angle).

- Significantly less time is needed to charge the product (compared to liquid counterparts).

- Long service life (subject to all the rules recommended by the manufacturer).

Disadvantages:

When using AGM batteries, it is necessary to regularly check the health of the vehicle's electrical equipment. For example, a faulty voltage regulator relay can significantly reduce the life span of such a battery (and in the worst case, render it completely inoperative).

- The need to use special devices for charging, equipped with current and voltage regulators.

- Higher cost (compared to standard models).

- Store batteries only when charged.

- Decrease in starting efficiency (according to reviews of AGM batteries) at very low ambient temperatures (minus 30 degrees and below).

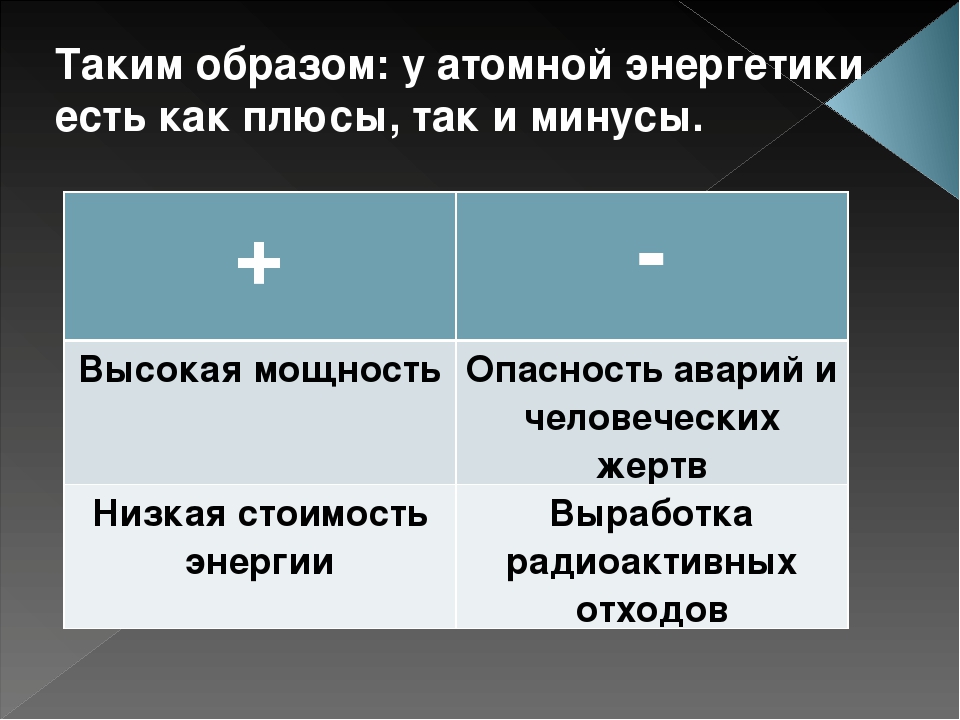

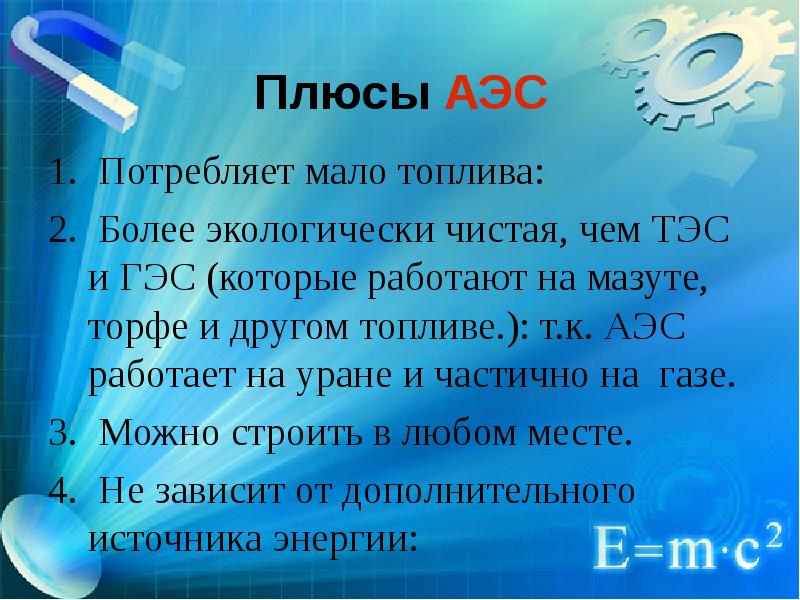

The benefits of fusion energy

- More environmentally friendly power generation. The "side" results of a thermonuclear reaction are elements such as helium-4 (an inert gas, non-toxic) and tritium, which can be used as fuel. The use of "secondary tritium" will reduce the fuel component, which means that energy will be cheaper.

- Relative availability of synthesizing materials (fuel). Deuterium can be easily obtained from sea water. Lithium is a fairly common element in the earth's crust. It is possible to reproduce tritium in fusion reactors.To start and operate a thermonuclear reactor during D-T fusion, only the three above substances are needed.

- Fusion plants, in comparison with power facilities that use oil products and coal, do not harm the environment by emitting greenhouse gases or aerosol pollutants.

- Thermonuclear fusion does not belong to chain reactions, because of this it is subject to more stable and simple control. A thermonuclear installation, unlike a thermonuclear bomb, cannot explode due to personnel errors or equipment breakdowns. Due to the design features of the thermonuclear power plant and the small amount of fuel used, the explosion of the reactor core is impossible.

- Safer use of the power facility. The operation of a fusion reactor is much safer than a nuclear one. If it is damaged, the melting of the core and the release of radioactive substances does not occur, since during operation the thermonuclear fusion reaction must be fed with the base fuel or energy.

KMTS glue types

There are several types of kmts, each of which is for a specific application:

- "1-Chips" - glues a light type of washing wallpaper with a paper base.

- "1" - released for lightweight paper-backed wallpapers.

- "N" - an economical option for paper, textile materials.

- "Extra fast" - for gluing canvases to concrete, plastered bases, used as a primer.

- "Super-Max" - glues all types of paper sheets on concrete surfaces.

- "Mini-Max" - used for gluing light washable wallpaper with a paper base.

- with PVA - glues all textile, paper materials to concrete, wood, plastered surfaces; not used for painted walls, as low adhesion; has a color indicator, which is very convenient when applied to the canvas.

How to use correctly

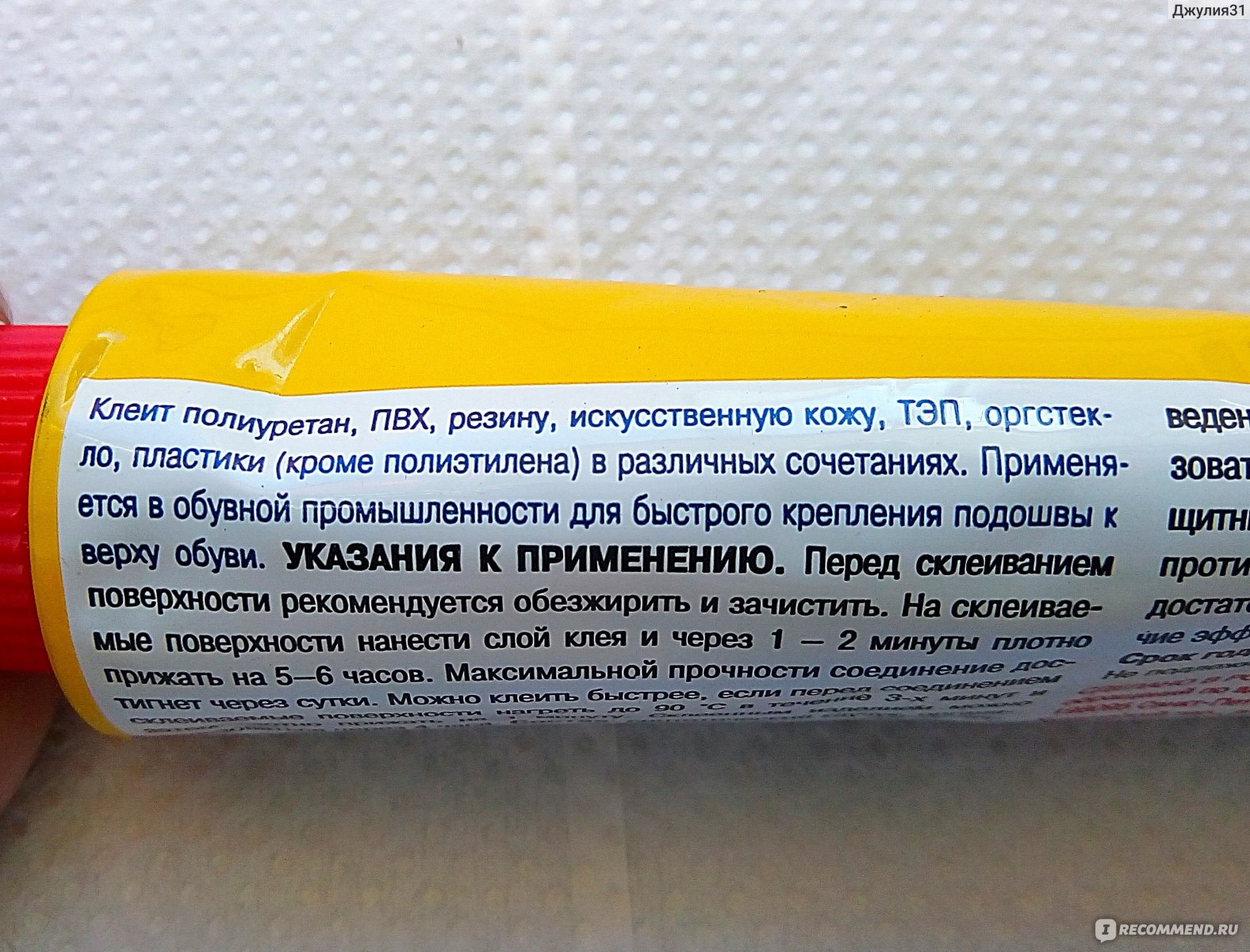

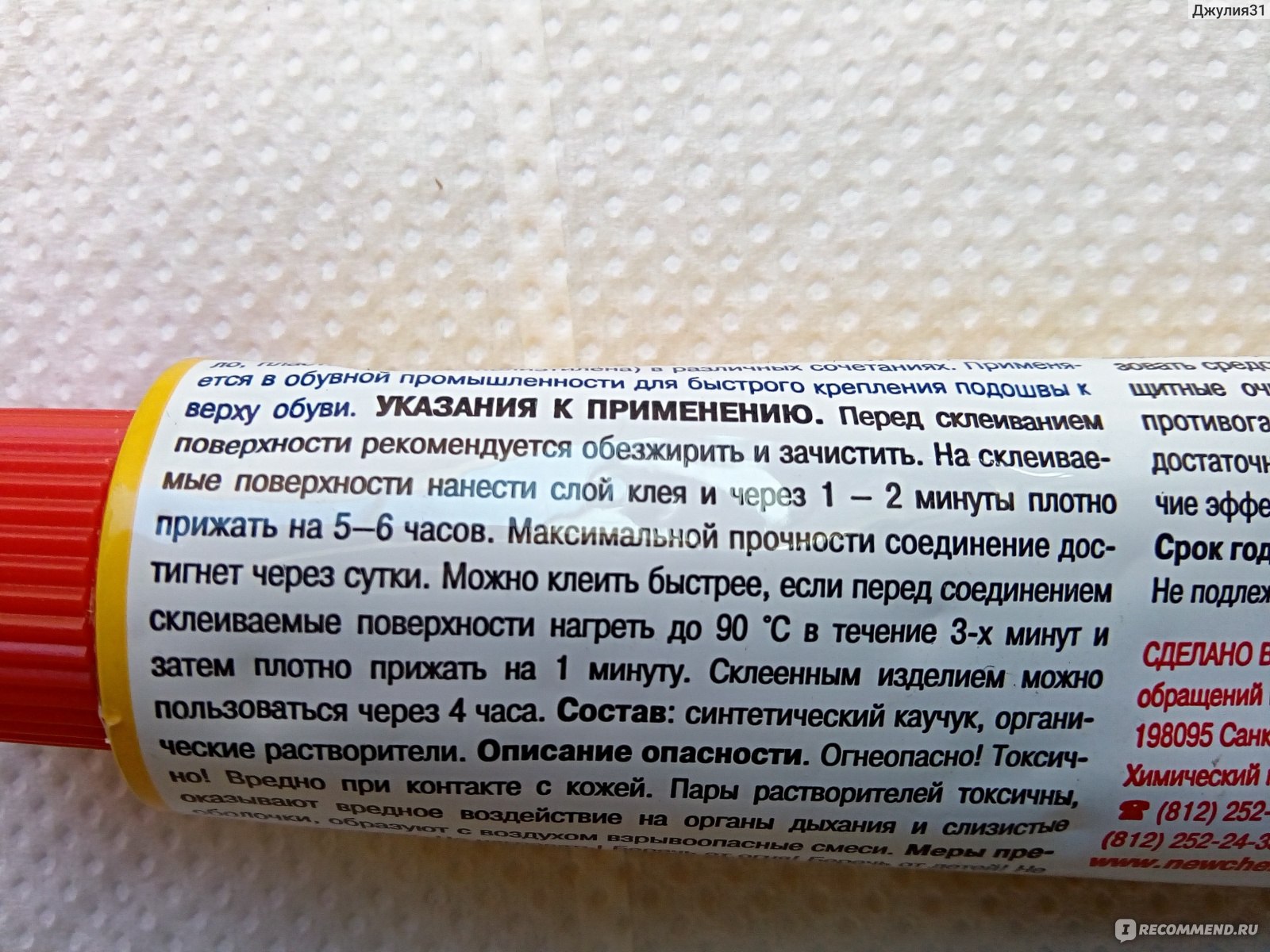

Despite the fact that it is quite simple to use Uranus glue, a number of rules must be observed when using this composition:

- It is recommended to apply at a temperature of +17 degrees and a relative humidity of 80% (in such conditions, the most durable connection is created);

- do not use for gluing products made of polyethylene;

- before each use, it is necessary to degrease the surface to increase adhesion;

- do not apply the composition to metal products, since the glue has a low level of adhesion to such material;

- it is necessary to glue objects in well-ventilated areas;

- avoid contact of the adhesive with mucous membranes and skin.

It is recommended to store Uranium glue at temperatures from -30 to +30 degrees. In other conditions, the composition begins to crystallize. However, after hardening, you can restore the previous properties of this product. To do this, just open the tube and leave the glue for a day at room temperature.

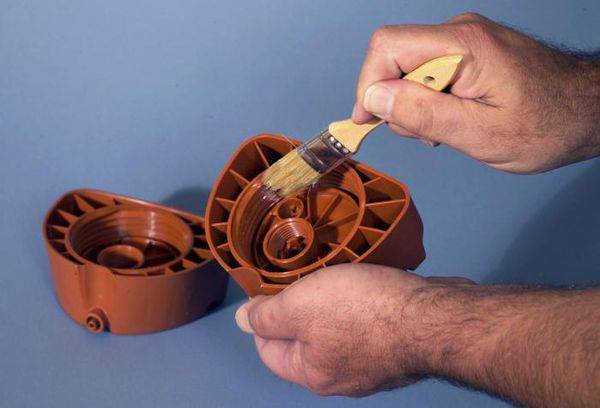

There are two ways of gluing materials using "Uranus": hot and cold. In both cases, a seam of the same strength is created. The difference between these methods lies in the working conditions and the rate of consumption of the composition. It is recommended to use a spatula, stick or brush to create an even layer.

Before starting work, it is also necessary to prepare acetone. This liquid will be required to remove excess glue from products or from the skin. The surface can be degreased with acetone. If a rubber boat is being repaired, then it is necessary to prepare a nylon thread for stitching large holes.

In some cases, before starting work, you need to sand the surface with sandpaper. This allows you to increase the level of adhesion and, as a result, the strength of the connection. Such processing will be required, in particular, when restoring rubberized products. When working with polyurethane, this method does not give the indicated effect.

Cold method

The cold welding method is more popular, since it does not require special preparations (except that the surface must be degreased with acetone or alcohol) or additional devices. For gluing materials "Uranus" is applied in a thin layer and kept for two minutes.

At the end of the specified period, both parts of the product are forcefully pressed against each other. To create a reliable connection, it is enough to hold the material for two minutes. But in order to increase the strength of the seam, it is recommended to place the product to be glued under the press for at least 6 hours. The glue hardens completely within 24 hours after application. That is, the repaired products cannot be used until the end of this period.

Hot method

The hot method is considered to be more effective, as it allows you to quickly achieve a strong connection. To glue the materials, in this case, you need to apply the prepared composition in an even layer on a degreased surface.

Next, you need to warm up the product for three minutes at a temperature of 90 degrees. To do this, you can use a regular or construction hair dryer. The latter allows you to more accurately adjust the heating temperature. Using a regular hair dryer, the appliance should be kept for more than three minutes.

At the end of the specified period, the materials to be glued must be pressed tightly against each other and held for a minute. Next, you need to leave the product to dry completely. This process takes no more than four hours, after which you can use the item. During this time, the heated glue gains sufficient strength and is able to withstand the above loads.

p> Share link:

Gluing

One of the effective methods of joining parts used during assembly of a product is gluing. The connection using adhesives, in contrast to mechanical ones, does not damage the product, since it does not penetrate into the material. With adhesive bonding, the load is evenly distributed over the entire area. When mechanically it is concentrated at the attachment point. This can adversely affect the appearance of the product: its deformation is often observed.

Bonding technology is common in the electronics, automotive, aerospace, construction and woodworking industries. In addition to industry, Uranus glue is widely used in everyday life. It is effective for repairing shoes (they can be used to glue the sole or heel), leather goods (repairing bags, belts), household and office equipment.

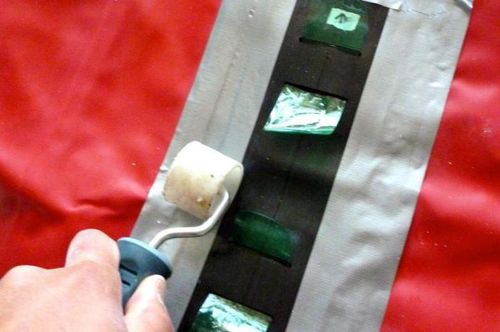

Due to its high adhesive capacity, the Uranus glue provides a gentle bonding method - the product does not deform, and the colorless seam does not spoil its appearance. The aesthetics of such a connection is possible if you use a brush, roller or special spatula.

Recycling problem

At the moment, huge stocks of DU have been accumulated in the world. At the same time, an industrial technology for its complete utilization has not yet been developed. Under such conditions, European companies prefer to operate according to a very simple scheme. Formally, they simply send the DU to Russia for processing. Meanwhile, such an operation is considered even more expensive than the costs of disposal of this substance and its storage. The benefit for companies in this case is that after additional enrichment, only 10% of the raw materials imported into Russia are returned to Europe. 90% remains on the territory of our country.

According to the legislation, it is impossible to store DU from other countries in Russia. To get around it, foreign depleted uranium is simply transferred into federal ownership. To date, Russia has accumulated about 800 thousand tons of such waste. At the same time, 125 thousand tons were brought from Europe.

In the United States, DU is treated as radioactive waste. In Russia, depleted uranium is defined as a valuable energy raw material, excellent for fast-neuron reactors.

How to properly prepare the glue: procedure

The package contains information with a detailed description of the method for diluting the powder:

- A container of the required volume is prepared (a plastic bucket is often used).

- Water is measured and checked for temperature (optimally 25 degrees).

It is necessary to pay attention to the issue of water temperature, with very hot water, the glue will weld, with cold water, clumping may appear

- Glue is poured into the water with constant stirring.

- After thorough stirring, it is left alone for two hours.

- After mixing, the mass is ready for use.

We recommend a video on the topic:

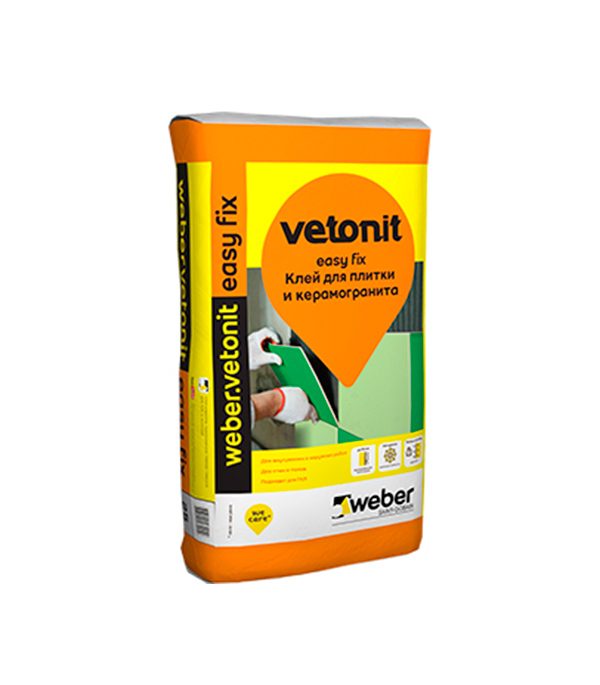

Standard formulations "Vetonit"

Adhesives from the group of standard ones are used for tiling floors and walls, if they do not have serious defects or other problems. Such bases include completely dried cement screeds, concrete floor and wall coverings, smooth brickwork. Only in this case will a sufficient level of adhesion of the adhesive to the surface be ensured. The mixture can be selected depending on the individual characteristics of the base material.

Vetonit Optima

This adhesive is the most widely purchased standard formulation. It can be applied to indoor and outdoor surfaces and is ideal for ordinary tiles and glass mosaics. The advantages of the mixture include good contact with concrete, brick, plaster, uniformity of layer hardening, economical consumption, excellent strength characteristics. "Vetonit Optima" is a self-leveling mixture, therefore, if there are moderate defects in the base, it is also allowed to use it.

Optima's technical characteristics are as follows:

- time for adjusting the position of the plates - 10 minutes;

- the suitability of the solution for work - 2 hours;

- adhesion - 0.5 MPa;

- layer thickness (maximum) - 1 cm;

- temperature during work - + 5 ... + 30 degrees;

- consumption - 1.29 kg / sq. m.

Easy Fix

"Vetonit Easy Fix" is distinguished by its resistance to the action of water, therefore it is most often used for finishing rooms with high humidity with medium format porcelain stoneware and tiles. The mixture is great for renovating bathrooms, saunas, showers. Among other things, the glue has increased frost resistance: it easily tolerates up to 100 freezing and thawing cycles, therefore it is suitable for outdoor use. In addition to cement, brick substrates, Vetonit Easy Fix is suitable for the following materials:

- cement-lime plasters;

- gypsum fiber, drywall;

- cement particle boards.

When applying Easy Fix glue, it is important to consider one feature. In order for the base to reliably connect to the tile, it is necessary to ensure the uniformity of the temperature of the surface, masonry, mortar within 48 hours

The technical characteristics of the glue are as follows:

- the pot life of the solution is 2 hours;

- correction time - 10 minutes;

- adhesive layer - 1.5 cm;

- adhesion - 0.6 MPa;

- consumption - 1.29 kg / sq. m;

- temperature during work - + 5 ... + 30 degrees.

Granit fix

This adhesive is intended for non-standard types of tiles: porcelain stoneware, mosaics, clinker, double-fired ceramics. Suitable for ordinary ceramic tiles. The glue is even more frost-resistant - withstands 150 freeze / thaw cycles. It is suitable not only for finishing floor and wall bases inside and outside the house, but also for installing underfloor heating systems and for spot gluing insulation. The adhesive mixture is very elastic, does not absorb water after drying, practically does not shrink, and has minimal fluidity.

Specifications:

- the color of the mixture is gray;

- the pot life of the solution is 2 hours;

- tile adjustment time - 15 minutes;

- adhesion level - 0.8 MPa;

- glue layer - up to 1.5 mm;

- consumption - 1.29 kg / sq. m;

- temperatures during operation - + 5 ... + 30 degrees.

How to use Uranus glue? Operating and safety instructions

These products are used primarily in everyday life.Effective glue "Uranus" for PVC, synthetics, household items. It can also be used to repair shoes. The main thing is that when working with this glue mass, it is necessary to fulfill a number of conditions prescribed by the instructions:

The air temperature must be at least 17 degrees.

Humidity should not exceed 80%. Otherwise, there is a decrease in the reliability and strength of the connection.

Glue "Uranus" (PVC, boats and shoes) is not intended for plastic and metal products. This is due to the low adhesion of the adhesive to such surfaces.

Before starting work, the surfaces of the products to be joined should be thoroughly degreased and cleaned.

Uranium polyurethane adhesive can be used in two ways - cold and hot.

When working with this glue, you need to remember that it is safe for humans when it dries, since it becomes an ordinary polymer. In its original form, it is highly toxic and fire hazardous.

Therefore, it is necessary to work with this glue in well-ventilated rooms, in which it is forbidden to smoke and use heating devices with an open spiral.

It is also important to protect your eyes and skin from getting this mixture on them. To work with Uranus glue, it is recommended to use personal protective equipment: goggles and gloves

If the product comes into contact with the skin, it should be washed off with acetone. After that, the affected area should be treated with plenty of water.

Application

Glue "Uranus" has become widespread both in industry and in everyday life. For what works it is applied:

- In industry - for quick adhesion of the polyurethane sole to the upper part of the shoe. It is also used for gluing leather and suede shoes.

- In everyday life, it is suitable for repairing shoes: it is convenient for them to glue the detached sole or heel. However, in case of serious damage to the shoe, it is better to contact the master.

- More than suitable for fixing accessories (bags, belts).

- With the help of "Uran", minor repairs of household appliances and office equipment are carried out.

- It is used to glue cuts and holes on rubber boats, as well as to repair other tourist equipment.

- Uranus glue has found application in the field of construction. It is irreplaceable in the installation of polyurethane foam products: ceiling plinths and polyurethane stucco moldings.

Polyurethane adhesive is applied in two ways: cold and hot. They differ both in the temperature of the surface and glue, and in the compression time of the parts to be joined.

Instructions for use (cold method):

- The adhesive is applied to both surfaces to be glued in a thin layer.

- After two minutes, the parts to be glued are compressed with force. It is advisable to leave them tightly pressed for 5-6 hours.

- The final gluing takes place after 24 hours.

The hot method is considered more effective because of the quick results:

- The glue is applied to the prepared surfaces with a spatula, roller or brush.

- Then the surfaces to be glued must be heated for 3 minutes to 90 degrees.

- Immediately press the parts tightly together for 1 minute.

- Complete drying - after 4 hours. After this time, it is already allowed to use the item.

Recommendations for working with Uranus:

The temperature for gluing is not lower than +17 degrees.

The importance of air should not exceed 80%, otherwise the bonding properties of the glue will not be fully revealed.

The surfaces must be pre-cleaned from dust, dirt and grease.

All work is carried out in a well-ventilated area.

When gluing, do not smoke and turn on heating devices with an open spiral.

Idea: use an ice cream stick to level the adhesive layer.

Do not allow the composition to come into contact with the skin and eyes. Be sure to use protective gloves and goggles

If the product does get on the skin, it is removed with acetone, and then the affected area is washed with plenty of water.

For an aesthetic look, the Uranus seam is applied with a brush, roller or spatula.

The adhesive is not suitable for metal products. This is due to the low level of adhesion to such surfaces.

How are objects heated at home? You can use a hairdryer or put the products on a battery, or heat them over an electric stove (the shoemaker method).

"Uranus" and other polyurethane adhesives dry quickly, so do not keep the tube open for a long time.

Uranus glue is a reliable companion for many repair work, from shoe repairs to installing a ceiling plinth and even fixing equipment on a hike. Subject to all working conditions, its use is safe for humans. And after drying, the glued objects will serve the owner for a long time.

Glue "Uranus": composition and method of application

Description and distinctive features of the adhesive

Glue "Uranus" is a one-component composition based on polyurethane. The main purpose of the product is to secure elastic materials. The glue is made from synthetic polyurethane rubber, which is mixed with additional components dissolved in acetone and ethyl acetate.

Uranium has the following properties:

- transparent, with a pinkish or yellow tint;

- homogeneous structure;

- solidifies exclusively on contact with air.

Uranus glue sets quickly. A firm bond is obtained in a few seconds after application. But it takes at least a day to completely dry the product. These shades disappear after the adhesive has hardened. The seam created with this product remains elastic, which is why this material is used for shoe repairs. Upon contact with water, the bond strength decreases by 20%.

Instructions for glue Uranus

There are 2 main methods of gluing. They differ not in the strength of the seam, but rather in the consumption of the composition and the working conditions. In the photo - glue for polyurethane Uranium.

glue for uranium polyurethane

Cold welding - implies the absence of heat treatment:

- the adhesive mass is applied to the surfaces to be joined;

- press the parts and place them under the load;

- do not withstand me for 8 hours.

The seam reaches its maximum strength after a day. This method is quite suitable for repairing rubber products - boats, shoes, according to reviews, but not suitable for gluing PVC parts.

PVC slide

Hot method - involves warming up according to the instructions:

- the parts to be connected are warmed up by a hairdryer, for example, up to 80C;

- a layer of glue is applied to the hot, degreased surface;

- the products are pressed tightly. Compression time is 1 minute.

Such bonding is more effective for plastic materials. The seam reaches its maximum strength after 5 hours.

Through a sieve

The simplest separation method is gas diffusion - "forcing" gaseous raw materials (uranium hexafluoride) through a fine-pored membrane, while different isotopes diffuse through the pores at different speeds. It was gas diffusion that became the first method that was used to obtain commercial quantities of uranium-235 at the first enrichment plants. In the United States, the development of gaseous diffusion for the Manhattan Project was led by Nobel Prize winner Harold Urey. In the USSR, until 1954, this direction was headed by Academician Boris Konstantinov, then he was replaced by Isaac Kikoin.

At first, as is often the case, the gas diffusion method seemed more accessible to implement. But it demanded huge expenditures of electricity - the Sayano-Shushenskaya hydroelectric power station and the first stage of the Beloyarsk nuclear power plant, as it now turns out, were built primarily for these purposes. In addition to the general high cost and low efficiency, the gas diffusion method was unsafe for workers - mainly due to high temperatures and noise in the workshops. Plus large volumes of chemically active mixtures under pressure, and these are potential emissions and environmental pollution.Meanwhile, an alternative to the gaseous diffusion method has been known since the end of the 19th century - this is the centrifugal method, which promises very significant savings: when in 1958 the plant in Verkh-Neyvinsk entered the design mode, it turned out that the energy consumption per separation unit is 20 (!) Times less than the diffusion method. method, and the cost price is half. True, numerous technological difficulties awaited the designers on the way to creating centrifuges.

Technologies

The great Russian: what Kulibin actually invented

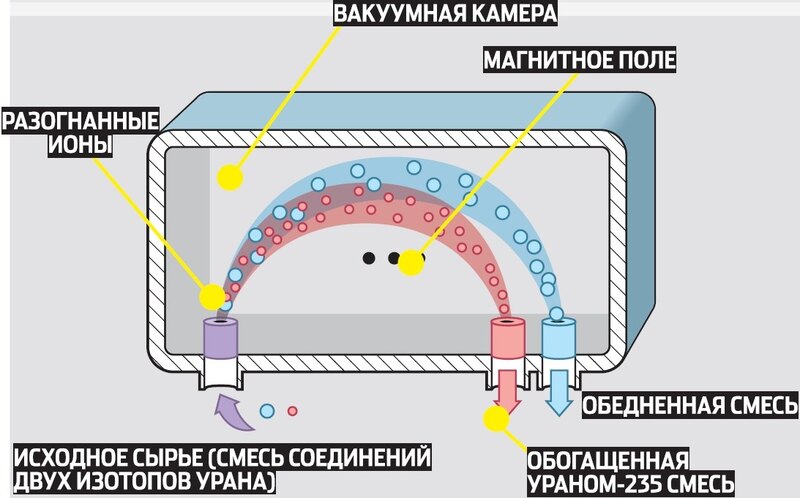

Electromagnetic separation. Based on the movement of charged particles (ions) in a magnetic field. Depending on the mass of particles, the curvature of their trajectory is different, and even a small difference in the atomic mass of the nuclei of uranium isotopes makes it possible to separate them. Such installations, called calutrons, were used in the American Manhattan Project because they made it possible to obtain a very high degree of uranium enrichment in a few passes. However, calutrons are very bulky, expensive to maintain, consume a lot of energy and have low productivity, so they are not currently used for industrial enrichment of uranium.

Tips & Tricks

Before gluing drywall to walls and ceilings, surfaces must be properly prepared. It is necessary to remove wallpaper, paint, peeling plaster. It is necessary to sweep away dust from the walls, ceiling, it is better to vacuum it. For better adhesion of the glue to the surface, it is primed. Immediately before pasting, the surfaces are moistened with water using a spray bottle.

The choice of adhesive depends on the condition of the surface to be smoothed. For smooth walls, choose a foam adhesive that has a small coefficient of expansion, for example, for expanded polystyrene. In case of significant defects, foam is used that can fill the cracks and recesses in the wall.

It is necessary to accurately calculate the amount of glue applied to the wall or sheet so that it does not squeeze out between the joints and does not complicate their further sealing in the future. It is impossible to lay electrical networks in the polyurethane foam due to its high flammability. In addition to igniting, when heated strongly, it gives off a large amount of toxic gases.

Share link:

Conclusion and recommendations

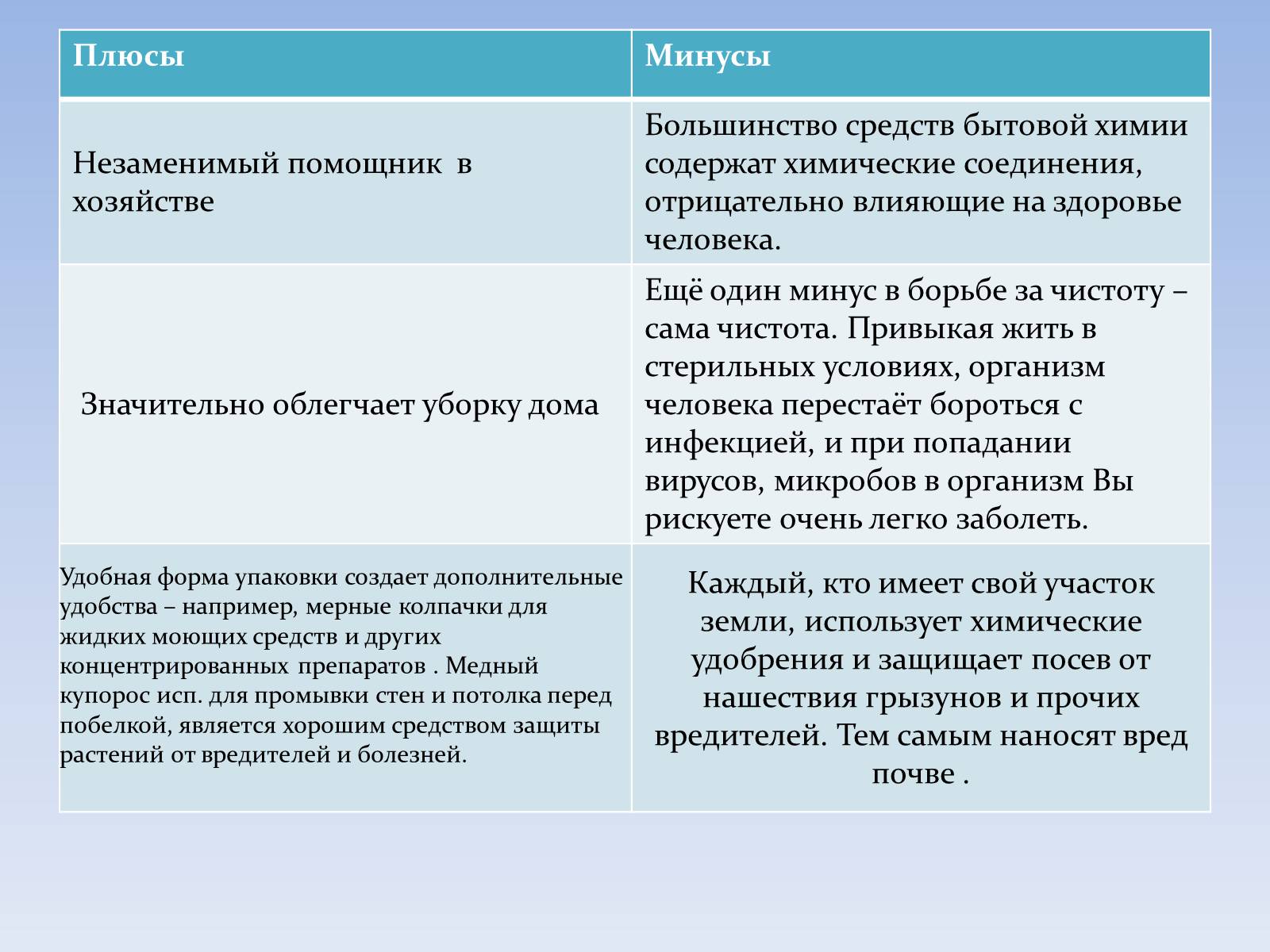

Household chemicals cause serious harm to human health, as they contain hazardous substances, albeit in small quantities. To reduce the negative consequences, you should adhere to the following rules:

To exclude the possibility of poisoning, household chemicals should be kept separate from food.

Detergents must not be exposed to direct contact with sunlight and open fire.

Household chemicals should be stored in closed containers and out of the reach of children.

When choosing a detergent, you should pay attention that it is hypoallergenic.

Preference should be given not to powders, but to gels, granular and liquid products.

To prevent the ingress of harmful substances into the body, when using household chemicals, protective equipment should be used, such as glasses, masks, rubber gloves, a respirator, and special clothing.

The recommended dosage and frequency of use should be observed.

Expired funds cannot be used for cleaning.

It is important to study the instructions for using each of the funds and familiarize yourself with the composition. If household chemicals are considered hypoallergenic, then they have been tested by dermatologists.

Try to limit the use of synthetic detergents as much as possible.

Pay attention to phosphate-free and eco-friendly products

Unlike synthetic ones, they have a lot of advantages and are safe for humans. Phosphate-free chemistry contains a small amount of surfactants, which is made possible by the advanced technologies that are used in its production.

It is worth paying attention to phosphate-free and eco-friendly products. Unlike synthetic ones, they have a lot of advantages and are safe for humans.

Phosphate-free chemistry contains a small amount of surfactants, which becomes possible thanks to the advanced technologies that are used in its production.