Additional Tips

Despite the absence of toxic components in the composition of the UR-600 glue, it is necessary to glue, especially surfaces of a large area or using a hot method, in a ventilated room. For this, it must have natural or artificial ventilation.

Work should be done with gloves to protect the skin from exposure to acetone. It is more convenient to work with the composition with flute brushes, the size of which depends on the size of the treated area. At the end of gluing, the tool is washed in acetone and dried. Hands are washed thoroughly with soap.

Containers with underused glue are stored in a tightly closed container at a temperature of +10 to +25 degrees in a room where children and pets cannot access. During storage, the proximity of open fire, heating devices, direct sunlight is not allowed, since polyurethane rubbers are flammable.

Crystallization of the composition, if the shelf life is not expired, does not affect the adhesive properties. The container with glue is placed in a water bath with a temperature of up to 70 degrees. After 10-60 minutes (depending on the amount of the composition), the glue is mixed with a wooden / glass stick until smooth.

"UR-600" surpasses other adhesives in the quality of the seam for PVC and rubber products. The peculiarity of the composition allows them to create monolithic joints, which is successfully used in the repair of boats, boots, bags. This is explained by the fact that polyurethane rubbers are part of rubber and polyvinyl chloride. The presence of acetone in the glue softens the structure of the original products and promotes the adhesion of homogeneous substances.

Share link:

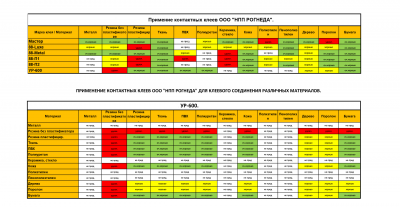

Applications of glue

Universal one-component glue UR-600 is widely used in industry. It is in demand in the manufacture of footwear, since it reliably holds together materials such as rubber, natural and artificial leather, nubuck, suede, hard and plasticized PVC, polyurethane, thermoplastic elastomer, thermoplastic elastolan. The glue is used in shoe repair shops, in everyday life for self-restoration of old shoes.

UR-600 is no less in demand in the furniture industry. With its help, fabric and other materials are attached to frame bases, parts are connected, and joints are strengthened. The tool has found application in the automotive industry, construction, and the production of leather goods. To increase adhesion and strength, it is introduced into the composition of various cast products, for example, glue can be involved in direct casting of shoe soles. At home, the tool helps in the repair, manufacture of products from:

- paper;

- cardboard (including construction);

- plastic of different types;

- fabrics;

- polyurethane;

- fiber materials;

- plexiglass;

- rubber;

- TPE with a high oil content;

- metals;

- various non-porous materials.

UR-600 glue is suitable for PVC boats, bags, fishing boots, rubber products, because it is waterproof, very durable, does not lose its qualities for a long time.

Main characteristics

A distinctive feature of the company's products is quality. The company produces everything you need for gluing various materials, namely:

- powder and ready-to-use glue for all types of wallpaper;

- special primers;

- liquid for removing old wallpaper;

- docking glue in tubes.

The packages contain detailed information on the application. Products are produced in a wide range of weights. They have a long shelf life.

Important: the special characteristics of the product, based on the content of special additives, make it possible to use it in rooms with high humidity levels.

General requirements

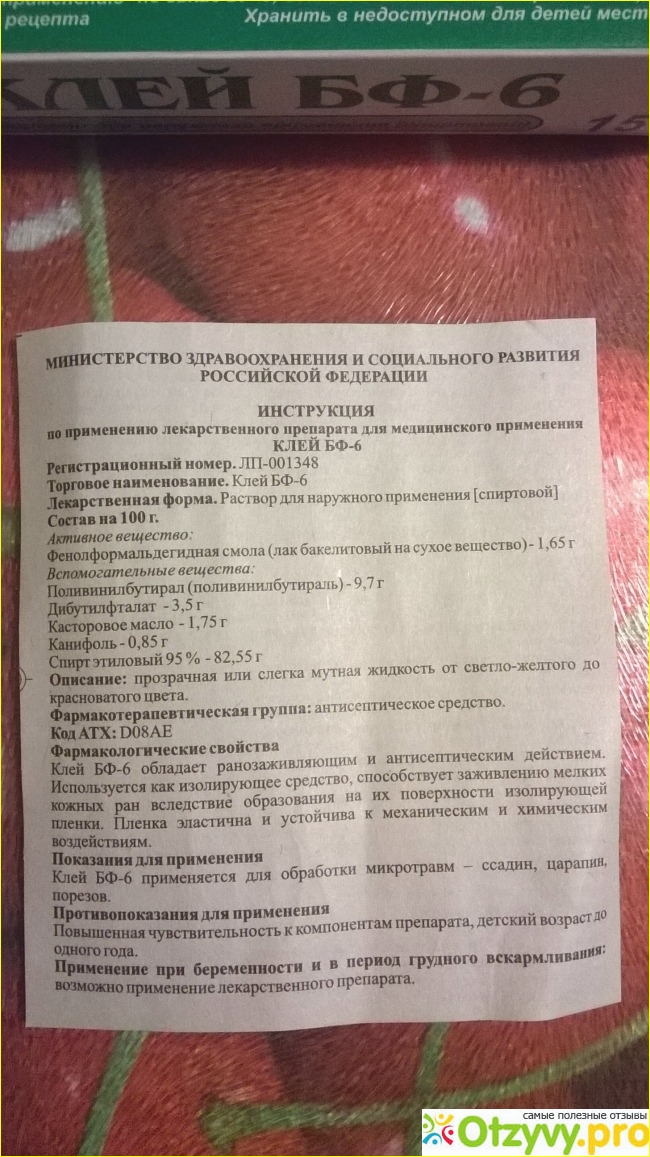

For gluing natural and artificial leather, as well as suede, you need a composition that, first of all, has the following characteristics:

The substance should not leave visible traces on the surface - this is important to preserve the appearance of the repaired product.

Only elastic glue will work as the leather stretches.

For repairing leather items, a compound with sufficient adhesion is required.

The absence of a strong unpleasant odor is desirable.

The shorter the setting time, the more convenient it will be to work with small parts; if it is necessary to glue a large surface, then it is better if the composition remains sticky for a longer time.

The glue must be safe for health.

Tips for using glue

The instructions indicate that in the rooms where work with the UR-600 is carried out, it is imperative to organize good ventilation. To protect your hands, you can use gloves or apply IER-1 paste to the skin, which forms a strong film. When all actions with the product are completed, hands should be washed with soap and water in the usual way.

The glue should be stored in a closed container at + 10 ... + 25 degrees, excluding the ingress of light, away from heating devices, sources of fire, protecting from the access of children and animals. The sun's rays and moisture should not come into contact with this product, even if the container is tightly packed. Sometimes the glue will crystallize if stored improperly. It is not necessary to throw it away, it is enough to lower the container into water with a temperature of +70 degrees, and then mix the composition.

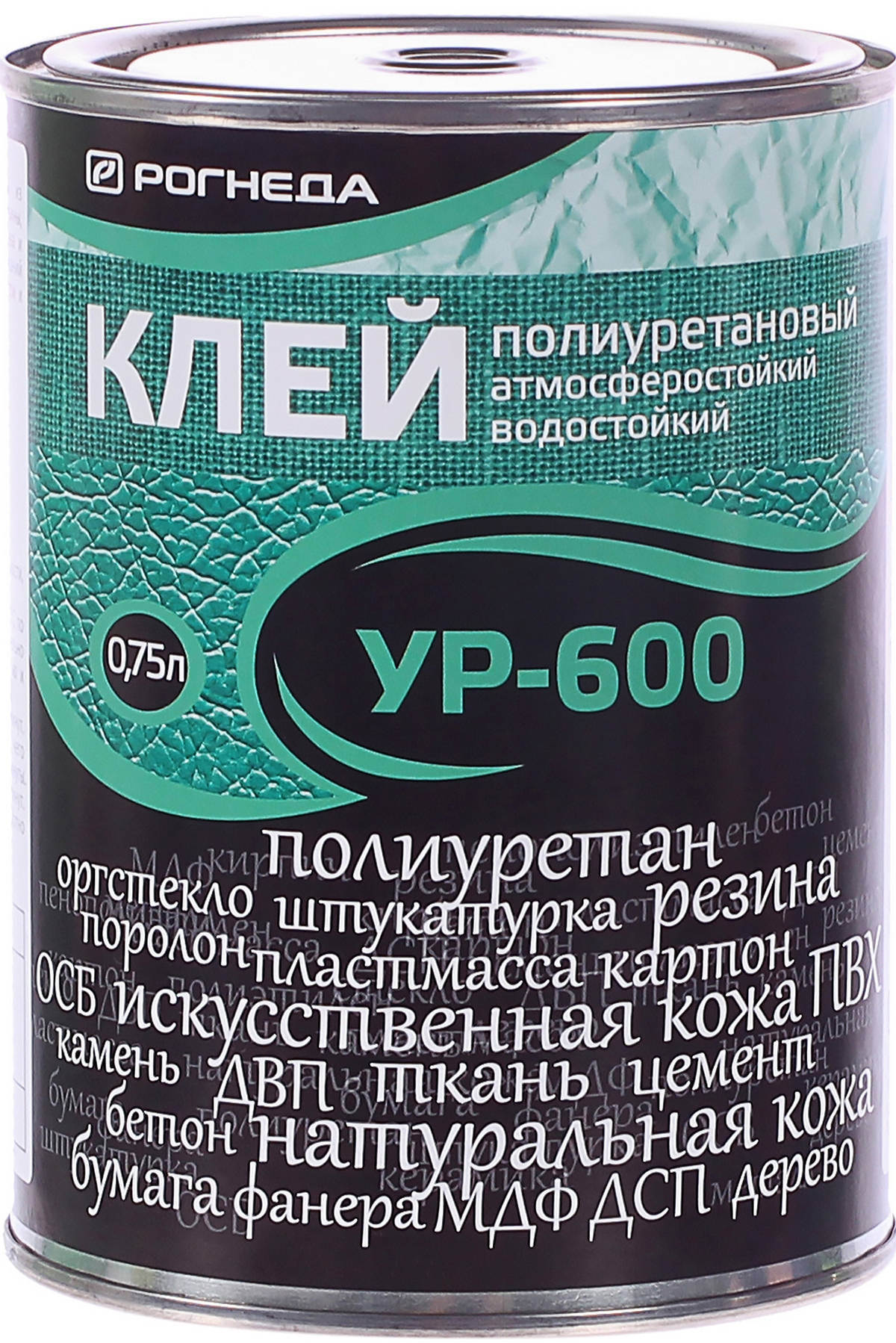

Description and purpose of the adhesive

Glue "UR-600" is a solution of polyurethane rubbers in ethyl acetate and acetone in a 1: 1 ratio without other additives. The adhesive is transparent and does not leave any marks when dry. "UR-600" is used in the manufacture of:

- furniture;

- cars;

- plastic windows;

- in the production, repair of footwear and leather goods;

- for household needs.

The glue firmly connects the products:

- made of PVC;

- rubber;

- leather (natural and artificial);

- plastic;

- polyurethane;

- plexiglass;

- paper;

- cardboard;

- fabrics;

- Fiberboard;

- Chipboard;

- thermoplastic elastomer;

- metal.

Packaging from 750 milliliters to 20 liters is convenient for use at work and at home.

General description and purpose of the composition

KS glue is a viscous mass, the color of which depends on the added mineral. It can be white or yellowish, grayish. The main substance in the composition is sodium water glass. The substance began to be used in construction at the beginning of the 19th century. Produce liquid glass by fusing soda with quartz sand. The classic production method is to dissolve silicon in alkalis.

A feature of sodium water glass is that it:

- glues any materials;

- adheres well to minerals;

- not afraid of sudden temperature changes;

- resistant to precipitation.

Adhesive based on water glass is used for working with various surfaces. The composition hardens gradually, and differs in strength after hardening. Both natural stones and ceramic and glass tiles are glued together.

What glue can be used to glue porcelain

For the repair of porcelain items, a variety of adhesive solutions have been created that allow you to firmly connect the breakaway parts to each other. In most situations, after restoration, you can continue to use the product as intended.

STANGE

Stange waterproof glue is specially designed for working with porcelain. The composition forms a strong bond that is resistant to external influences. Fast setting and drying makes it easy to bond small parts.

Cosmofen ca-12

One-component glue "Cosmofen CA-12" is a liquid transparent solution of low viscosity. After connecting the parts, gluing occurs instantly, and the seam formed is resistant to weathering and temperature changes.

The solution is intended for both domestic and industrial use. The versatility of the adhesive allows it to be used with most types of porcelain. Cosmofen CA-12 is suitable for gluing small parts where express fixing is required. It is not recommended to use this solution for surfaces with a porous structure, parts in an aqueous environment and in situations where it is required to create a plastic adhesive joint.

It is also important to consider that the composition can be used to glue chemically treated and painted aluminum surfaces.

RAPID

The adhesive solution produced under the Rapid brand is actively used for working with many materials, including porcelain. The composition is distinguished by a pronounced odor, which disappears only a few minutes after gluing. Seizing occurs instantly, which is very convenient when working with small products.

Thanks to the economical consumption, even small packaging lasts for a long time. Rapid glue is supplied in tubes of different sizes, from which it is easy to squeeze out the required amount of substance.

EPOXY GLUE

Epoxy Glue is based on epoxy resin, which forms a pasty consistency and high viscosity. The solution is suitable for repair and maintenance work. After application, the glue instantly sets and is suitable not only for joining parts, but also for filling cracks, holes, roughness. Epoxy Glue retains its qualities at ambient temperatures ranging from -50 to +154 degrees, which allows it to be used in any conditions.

How to do the job correctly

Before proceeding with gluing, it is recommended to prepare the primer mixture and apply the liquid with a brush or roller. This will strengthen the base of the surface to be treated. In order for the solution for gluing wallpaper to turn out to be monotonous, without clots and lumps, it is necessary to mix it thoroughly.

The glue is applied in a thin layer to one of the surfaces. The canvas is firmly pressed against the wall, trying to combine the joints and patterns. If this cannot be done immediately, you can correct the position of the wallpaper within 10 minutes. Glue is added to dry building mixtures in a ratio of 1:10. It should be remembered that they may be incompatible. To avoid spoilage of a significant amount of the product, it is better to prepare a little solution first. Lump formation indicates incompatibility.

Purpose

Glue 4508 is intended for gluing various parts of products:

- textile;

- rubber;

- rubberized;

- cardboard;

- paper.

- damaged bicycle and car cameras.

Rubber glue

Technical characteristics of glue 4508 allow it to be used in shoe repair. Adhesives 4508 are used for the manufacture and repair of rubber boat structures.

And:

- Fishing costumes.

- Boot.

- Leather goods.

The 4508 glue helps to give the garments elastic, strong seams that do not allow moisture to pass through, is palpable.

As a result, you will receive products:

- With sturdy waterproof seams.

- Excellent tack.

- With elastic connections.

Choosing an adhesive for ceramics

Ceramic products are also repaired with specialized glue. A number of companies are engaged in the production of solutions, whose products are distinguished by such characteristics as setting speed, the ability to operate in difficult conditions, and resistance to weathering.

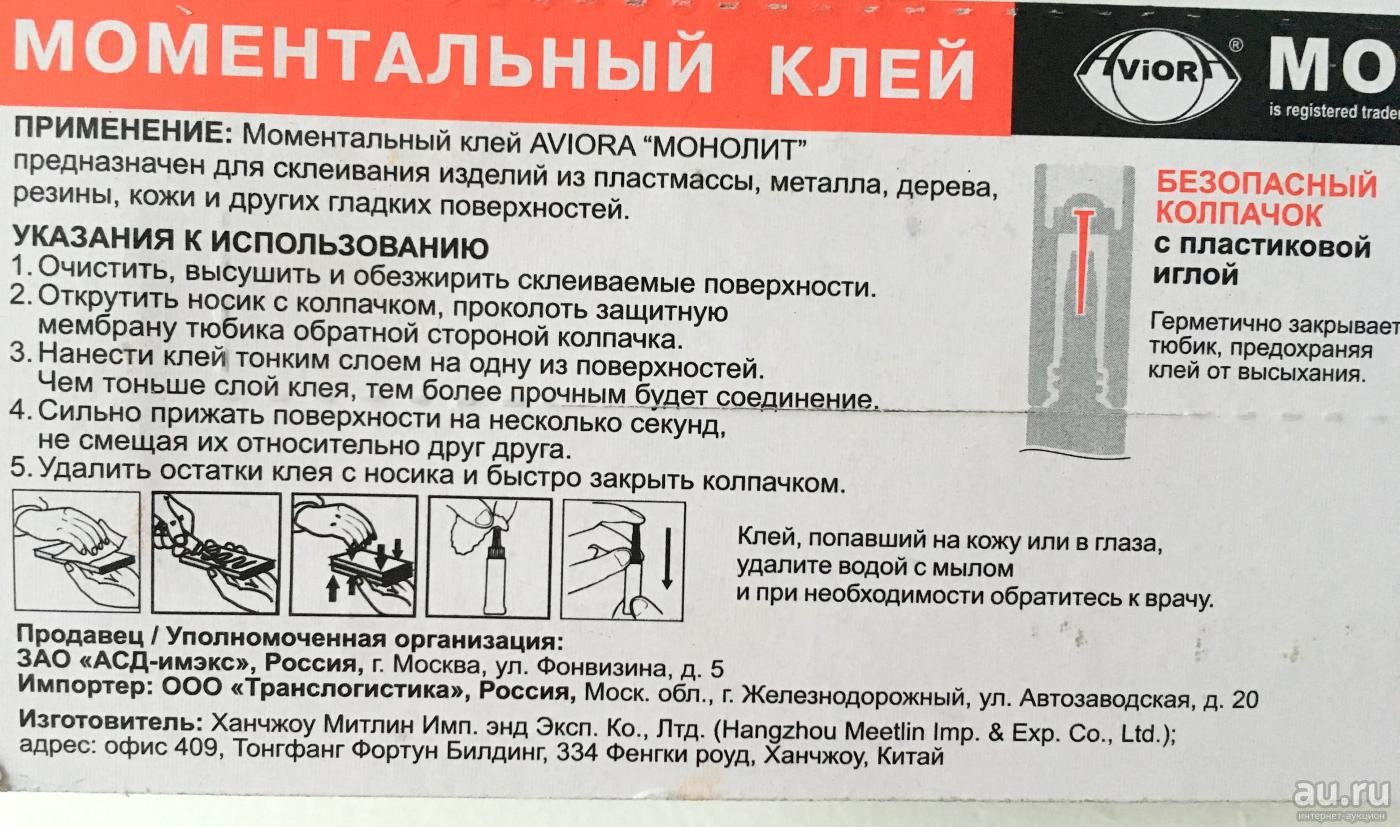

"Second"

Transparent glue "Secunda" got its name due to instant setting. The mortar connects the parts of the ceramic object securely and forms a strong seam.

"Super Moment"

Super-Moment glue is suitable for working with a wide range of materials, including the main types of ceramics. The main advantages of the composition include:

- fast adhesion;

- resistance to water and temperature extremes;

- economical consumption.

Cyanopan

According to its composition, Cyanopan glue is a monomer of ethyl or methyl cyanoacrylate in combination with a plasticizer. Cyanopan has fast adhesion and provides a strong bond between surfaces. The ability to penetrate the treated surfaces improves the protection of the ceramic and maintains the characteristics of the adhesive even in aggressive environments.

"Force"

Heavy-duty adhesive solution "Force" is a colorless consistency of ethyl cyanoacrylate with an effective fixing property of ceramics. The composition is safe for humans, but when using it, you need to adhere to the basic rules - work in a ventilated area and do not inhale the vapors of the solution.

"Monolith"

"Monolith" has a one-component composition, therefore it is easy to use and safe. The substance reliably connects surfaces and dries up in a few seconds. Monolith has a slow consumption and convenient packaging. By applying a drop of solution, you can treat a surface of 3-5 square meters. cm.

"Elephant"

The composition "Elephant" has all the necessary properties for a reliable connection of ceramic surfaces. The substance is appreciated for its quick setting and the formation of a strong seam.

Adhesive properties

Due to its suitability for a huge list of materials, including highly plasticized, the glue is considered universal. It compares favorably with analogs in that it retains its properties during abrupt changes in environmental conditions, practically does not react to external damaging factors.

The glue is contact, that is, the adhesion of the parts to each other begins immediately after their contact. It is easy to use, because you do not need to mix it with hardeners, the composition is ready for application. The glue line will be elastic, therefore, it will not crack from movement and is suitable for products subject to vibration, dynamic loads. Other characteristics of the glue:

- even, smooth surface, which, after drying, has no color, suitable even for transparent, colored materials;

- inertness to the influence of aggressive chemicals: weak acids, alkalis, gasoline, petroleum products, oils;

- frost resistance, heat resistance, the ability to operate products with a glue seam at -50 ... + 120 degrees;

- moisture resistance, suitability for indoor use, in the air, in open places exposed to precipitation, with high humidity.

UR-600 glue is produced in a very convenient container, so you can always choose the right volume for home use (750-1000 ml) and for industrial use (up to 20 liters).

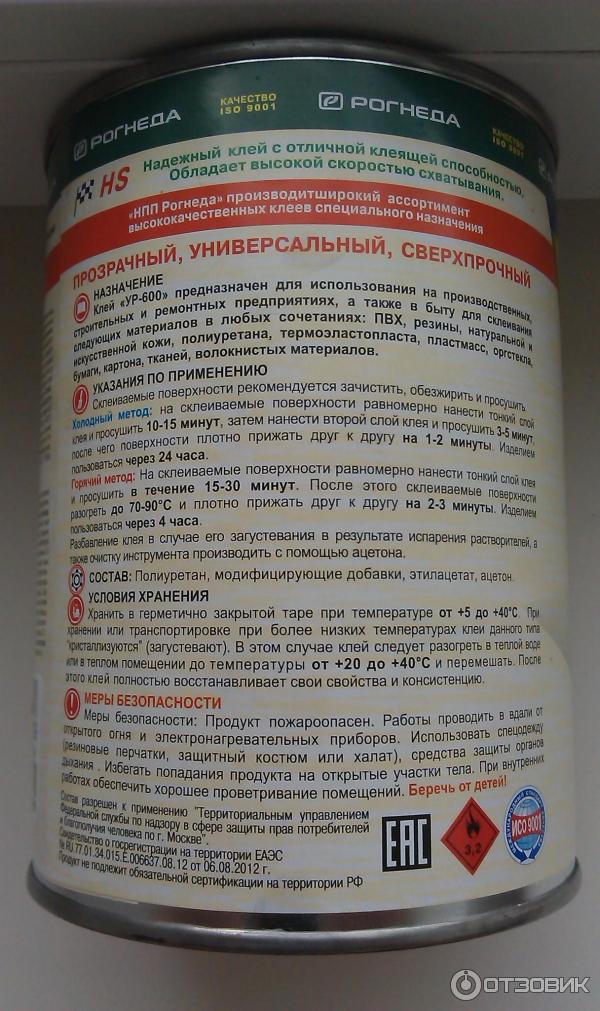

Technology of use

According to the instructions, you first need to prepare the base. To do this, remove all dirt, dust, clean off old coatings, rust, scale, using any convenient means: sandpaper on a bar, a grinder, spatulas. Further, both parts to be glued are degreased using any solvent and dried thoroughly. Rubber, leather, leatherette are sanded to improve adhesion.

Stopper brushes work well with glue. Application is possible in two ways (optional):

- Cold. Lubricate the surfaces to be glued with UR-600 glue, making an even thin layer. Leave for 10 minutes, apply the glue again in the same way, wait another 10 minutes. Then they press the parts together, hold for 2 minutes, as a result, a strong seam is created. You can use the item in a day.

- Hot. Apply glue to the surface, leave them in the air for half an hour. Both bases are heated up to +80 degrees with a building hair dryer or other devices, folded together, pressed with a press for 3 minutes. Usually the method is used for large-area bases. The product can be used after 4 hours.

After drying, the strength of the glue line will be approximately the same regardless of the method used, but the cold method leads to a much higher consumption of glue (2 times).

Composition and specifications

The glue is sold in packs of 15 milliliters. It includes acrylic, and therefore has a fairly thick consistency. The composition is used by service centers for the repair of mobile phones, computers. With its help, it is possible to glue the frames of touch screens and buttons.

The composition is highly resistant to external factors, but at the same time it penetrates poorly into porous structures. The tool can be used for fixing joints made of metal, glass, brick, vinyl. With its help, it is possible to fix ceramic elements, fiberglass, leather, rubber and wood. A distinctive feature of the composition is that when heated to 100 degrees, the glue seam retains its softness and plasticity. Thanks to this, it can be easily removed.