Varieties

There are about 25 Titebond adhesives that are widely used in industry. The following four one-component compositions are considered the most popular in our country.

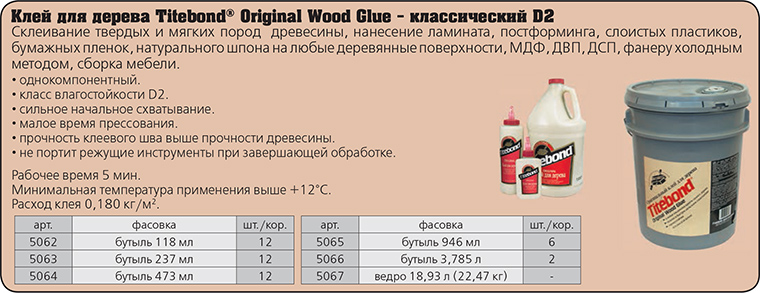

Original wood glue

Comes on sale in containers with a red sticker. Suitable for restoration, renovation, production of musical instruments. When dry, it does not change the woody qualities, does not distort the sound, and becomes hard. In addition, it can be used to assemble furniture.

Specifications:

- viscosity - 3200 mPa * s;

- dry residue - 46%;

- acidity - 4.6 pH;

- minimum temperature of use - +10 С;

Not recommended for outdoor use.

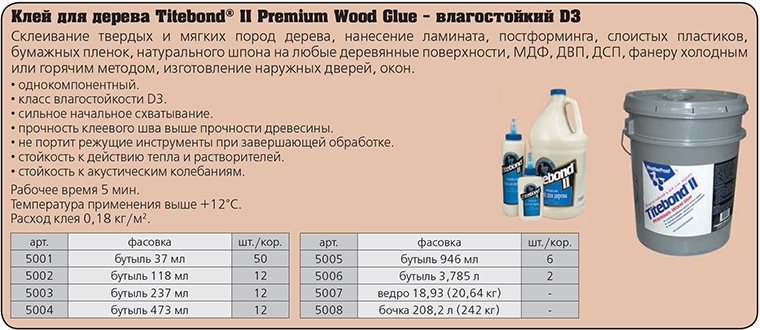

Titebond 2 Premium

Has a blue label. Suitable for gluing all types of wood products. Suitable for gluing joints and joints. Allows you to work with laminate, chipboard, fiberboard, veneer, plywood and paper film. Good for restoring furniture, gluing various boards. Differs in excellent adhesion at a short pressing interval.

Physical properties of the glue:

- viscosity - 4000 mPa * s;

- dry residue - 48%;

- acidity - 3 pH;

- minimum temperature of use - +12 C;

- consumption per 1 m2 - 180 g.

This type of adhesive is resistant to heat, solvents and acoustic vibrations. After using such glue, the products will not stick out at temperatures from -30 to 50C. The dried composition has a creamy transparent tone.

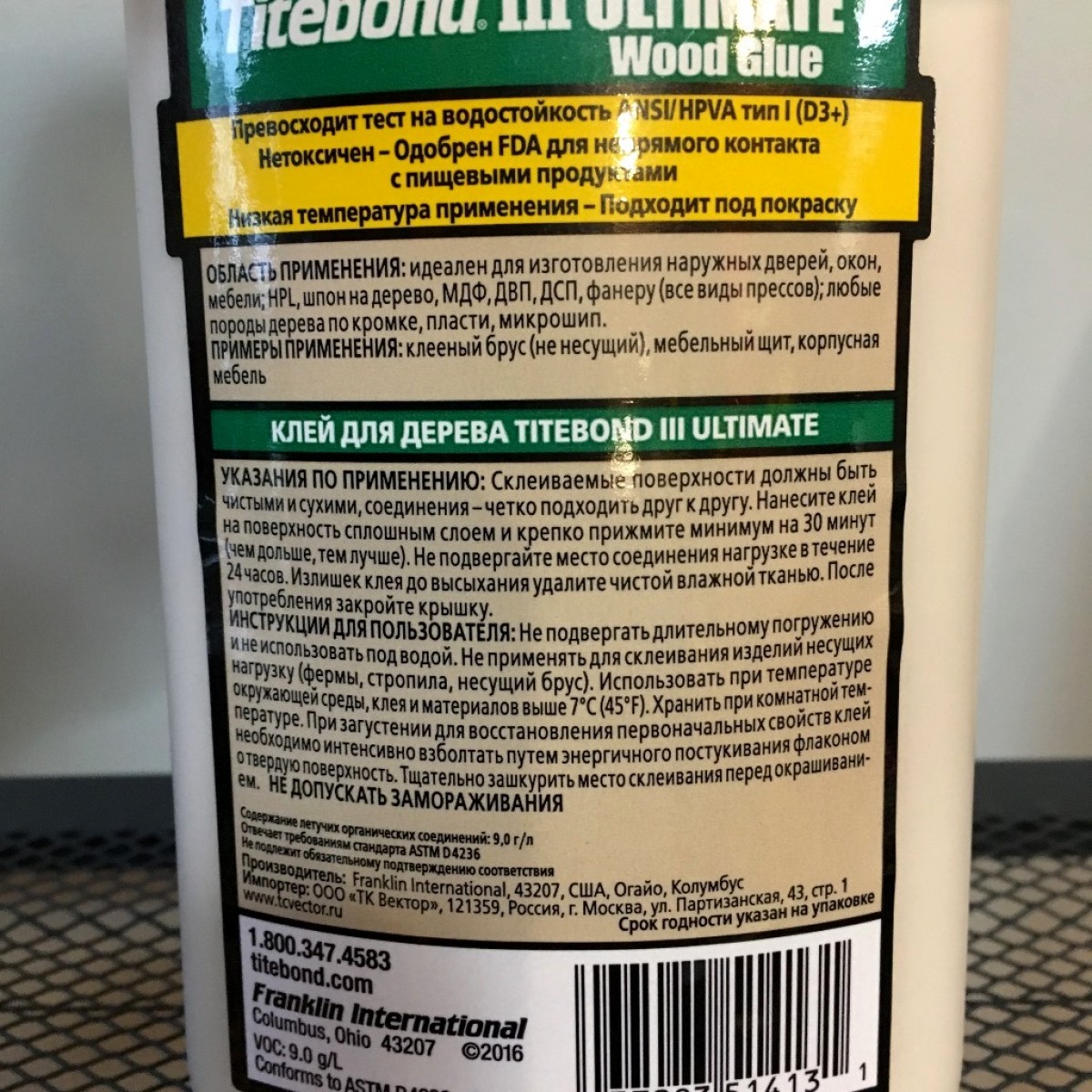

Titebond 3 Ultimate

Water-dispersible adhesive, sold in containers with a green label. The consistency is creamy and opaque in appearance. Prepared with water. Designed for fiberboard, chipboard, veneer, plywood, MDS, wood and plastic. Suitable for indoor and outdoor use. Differs in particularly good moisture resistance.

Titebond 3 Ultimate is non-toxic. It can be used for things used to store food, as well as those that directly interact with food.

The adhesive can be used hot or cold. In the first case, the speed of the surface setting process is increased by heating the glue joint or the wood itself.

Composition properties:

- viscosity - 4200 mPa * s;

- dry residue - 52%;

- acidity - 2.5 pH;

- density - 1.1 kg / l;

- consumption per 1 m2 - 190 g;

- drying time - 10-20 minutes;

- the minimum temperature of use is +8 C.

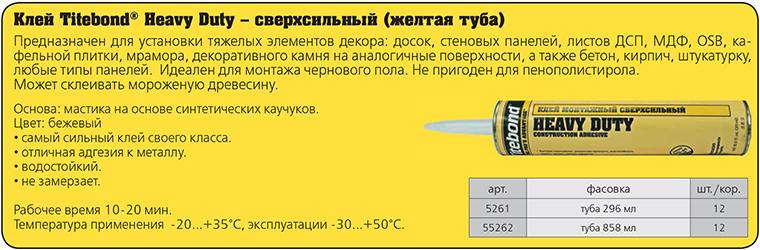

Heavy duty

Super strong assembly adhesive, sold in a yellow tube. It contains artificial rubber, which makes it possible to glue wet, frozen wood products. The glue seam does not change from physical impact, does not collapse, is not susceptible to the formation of fungus.

In addition to wooden surfaces, it allows gluing slate, ceramics, organic glass, fiberglass, artificial and natural stone. Suitable for use in the interior and exterior of buildings, installation of floor coverings, repair and production of garden equipment, creating decorative elements, installing mirrors.

Properties:

- viscosity - 150 Pa * s;

- dry residue - 65%;

- density - 1.1 kg / l;

How to use correctly

Working with Tytbond glue does not require special skills and knowledge. When using it, the main thing is to clearly follow the instructions. Work must be carried out only at positive temperatures.

Surface preparation

The surface of materials prepared for gluing must be dried, cleaned from dust, grease, oils and other contaminants using solvents. It is not recommended to apply Titebond to painted surfaces, therefore old paint must also be removed.

Working with glue

Mix the glue thoroughly, apply it to the surface of both parts with a brush and squeeze them well, excluding movement. During the drying period (10-20 minutes), remove the excess with a damp cloth. If necessary, reposition the parts until the glue dries.

Precautionary measures

It is necessary to work in ventilated areas using protective equipment (especially for allergy sufferers).If the adhesive comes into contact with the mucous membrane of the eyes, it is necessary to rinse the eyes with running water for a quarter of an hour. If dizziness or nausea occurs, go outside quickly. In case of contact with skin, remove as soon as possible and wash with soapy water.

Keep out of the reach of babies.

Varieties

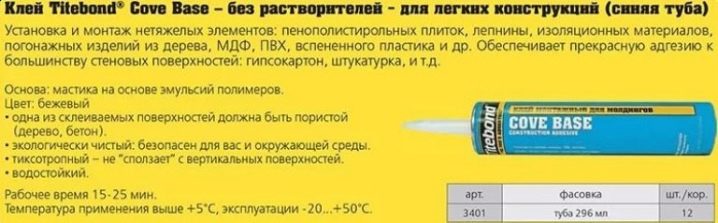

Solvent Free Cove Base

This compound helps to adhere PVC and rubber finishing structures, as well as acoustic tiles.

The underlying surface can be drywall sheets, putty, paint and varnish materials and wallpaper, as well as ceramic tiles. Having come into contact with the surface, the glue prevents the attached materials from sliding down. It does not form vapors harmful to health, does not catch fire, fully complies with the regulatory requirements adopted in the Russian Federation and the United States.

Its physical characteristics:

- state of aggregation - mastic of moderate viscosity;

- color - beige;

- shelf life - 2 years or more;

- frost resistance - acceptable for operation in Russia

The glue itself and the materials to be joined must be warmed up to +5 degrees.

After drying, the composition is removed with a sharp knife blade. The mixture should be applied strictly on one side, its choice is arbitrary. Do not use glue without the inclusion of a solvent to join parts that are under water for a long time.

Instructions for use

You can start working with the product only at freezing temperatures indoors or outside buildings. For all types of adhesives, preliminary surface preparation is very important: in the presence of dust, sawdust, and other contaminants, the degree of adhesion may decrease. In addition to such contaminants, grease, oil stains, and old paint should be removed. For this purpose, the following methods are used:

- grinding with a special machine, sandpaper;

- the use of a scraper;

- rinsing with household or professional detergents;

- wiping with degreasers, solvents.

Work should only be done in a well-ventilated area. Due to the environmental friendliness of the composition, it is possible not to use special respiratory protection, but for allergy sufferers, people with hypersensitivity and lung diseases, masks (respirators) are required. If dizziness is observed, you should immediately leave work and go out into fresh air. If the glue gets on the skin, wash it well with soap, otherwise there is a risk of irritation and redness. When the product gets into the eyes, they are washed well (at least 10 minutes), if necessary, consult a doctor.

Titebond glue is one of the highest quality and most convenient products that does not need to be diluted, but can be used ready-made. It has the highest moisture resistance among similar compositions, it is economical, therefore it is most often used by professionals.

The only one-component adhesive to meet the toughest ANSY TYPE II moisture resistance standard

- Provides strong initial tack and short pressing times

- Provides a higher bond strength than the wood itself

- Non-abrasive: does not damage cutting tools during finishing

- High resistance to heat and solvents

- Resistant to acoustic vibrations

- Remove with a damp cloth until dry

Physical properties

- The foundation:

cross-linked polyaliphatic emulsion - State:

viscous liquid - Colour:

creamy, after drying, translucent creamy - Dry residue:

48% - Viscosity:

4000 mPa * s - Acidity ph:

3 -

Flash point:

100 ° C -

Freeze resistance:

stable - Shelf life:

24 months in original packaging at 20 ° С -

Moisture resistance class:

D3

Directions for use

-

Application temperature:

+ 12 ° C -

Operating temperature:

-30 ... + 50 ° С - Consumption:

180 g / m2 - Work time:

10-20 minutes depending on conditions. Work surfaces must be dry, free of oil, grease, dirt, peeling old paint and any other materials that reduce adhesion - Cleaning:

it is cleaned with water until it dries. After drying, the excess is removed mechanically

Peculiarities

- Freezing does not change the structure of the glue, but causes it to thicken

- After long-term storage, stir the glue thoroughly before use to restore its properties.

- Meets the requirements of ASTM C557 (USA) and AFG-01 D3498 of the American Plywood Industry Association, DIN EN204 D3

Use for underwater connections

Precautionary measures

Use only in well ventilated areas. May cause skin irritation. If dizziness or other unpleasant effects appear, you need to go out into the fresh air, consult a doctor. If any glue gets in your eyes, rinse them with running water for 15 minutes. If the adhesive comes in contact with the skin, wipe it off and wash the skin with soapy water. Keep the adhesive out of the reach of children! Use only for its intended purpose.

Packaging

Store and transport at t> 5 ° C.

In carpentry work, a tool is often needed that allows you to connect parts without nails and self-tapping screws. This is glue Titebond

, in the production of which a different basis is used: the components can be proteins, polymers, synthetic rubbers, polyurethanes, aliphatic resin.

How to use epoxy glue: instructions

The gluing process takes place in 3 stages:

- cleaning surfaces;

- preparation of glue mixture;

- gluing surfaces.

First of all, a thorough preparation of the parts with which to work is carried out, since the finished glue will need to be applied immediately before it hardens. The surfaces are cleaned with ordinary sandpaper, then degreased with a special solution and after complete drying, you can go directly to the glue hardener.

Steps for preparing epoxy glue:

- Squeeze the resin out of the tube into a container.

- Add hardener as directed. Typically, 1 part solvent contains 10 parts resin. An overdose of hardener is allowed 1: 5.

- Mix the glue ingredients by hand.

- Apply the glue composition to the surface of the part and press firmly against the other, fixing the position for 10-15 minutes. The exact time of action of the hardener must be found in the instructions, since some manufacturers may make minor changes to the composition. In a few hours, the product will be completely ready for use.

Titebond Solvent Free - Green Tube (Solvent Free)

|

Product descriptionMultipurpose building glue Solvent Free Titebond (green tube)

Application areaDesigned for gluing: moldings, panels, foamed and rigid plastics, wood, metal, stone, wet ice cream processed saw-materials; for use in bathrooms, etc .; Physical propertiesType of: a mixture of polymer emulsions;State: medium viscosity mastic (130 Pa.s);Colour: beige;Dry residue: 78%;Density: 1.45 kg / l;pH: 4.0–6.5;Frost resistance: stable;Suitability: more than 2 years.Distinctive features:

Directions for use

Security measures:Avoid prolonged exposure of the eyes or skin to the adhesive. In case of contact with eyes, rinse with water for 15 minutes, if in contact with skin, wash with soap and water. If eye or skin irritation persists, seek medical attention. Keep the glue out of the reach of children! Use only for its intended purpose. |

Adhesive characteristics

Despite the possibility of professional use, the products of the series do not require special skills, knowledge during application.

They are easy to use, it is only important to carefully read the instructions. A common tool, including metal, is suitable for work, glue does not stick to metal, and all fixtures can be easily cleaned

Other properties and technical parameters of Titebond adhesives:

- After hardening, all adhesives become transparent, despite the initial dullness of the consistency. They can even be applied to delicate items.

- Means are resistant to freezing, after drying, the seam will withstand temperatures down to -35 degrees. Also, glued bases can be heated up to +40 degrees, but at +100 the seam area can catch fire.

- The bond strength will be very high, much higher than the wood itself. This ensures the durability of the glued products. The seam is resistant not only to the action of water, but also to the influence of solvents and acoustic vibrations.

- Adhesives are universal, they are suitable for all types of wood, as well as other compositions based on wood, combined materials, many types of plastics. Also, the means can effectively fasten paper, cardboard. Elastic compounds are suitable for use as sealants.

- All errors in work - stains, drips - can be washed off with water until complete solidification. This is very convenient for adjusting the glue line.

- The polymerization of the composition is fast (10-20 minutes), but still not instantaneous, and it is quite possible to correct the position of the parts. As the humidity rises and the temperature drops, polymerization may slow down. You can not work with the composition at temperatures less than + 10-12 degrees.

- It is not required to subject parts to strong compression, installation under a press. They will stick together even with a moderate degree of fixation, the adhesion will not decrease.

The most popular adhesives of the Titbond brand have a dry residue of 48%, their viscosity is 4000 mPa / s, and their acidity is 3 pH. Material consumption is 180 g / sq. cm.After opening, each product remains suitable for a long time (up to 2 years) if stored at a temperature of about +20 degrees. It is undesirable to apply the composition on painted surfaces, use it in rooms with too high humidity, poor ventilation.

Peculiarities

Titebond adhesive is intended for professional use. However, if you follow the instructions, it can be used in everyday life.

Depending on the type of substance, the composition of the components is also different.

Among the main components are aliphatic resin, synthetic rubber, polymers, polyurethane, protein, water. Standard packaging contains 473 ml of substance.

When working with glue, it is important to observe the temperature regime, humidity parameters, which are indicated on the manufacturer's packaging. It should be noted that when solidified, the adhesive emulsion forms a beige film.

The glue can be easily removed from the treated surface until it dries. After that, you will have to use the means at hand.

It should be noted that when the sticky emulsion hardens, it forms a beige film. The glue can be easily removed from the treated surface until it dries. After that, you will have to use the means at hand.

Varieties

There are about 25 types of wood glue, which are produced in series:

Original Wood Glue 5064

473 ml usually comes in a red bottle. It is used for working with musical instruments, as it does not affect the sound due to its solid consistency. Suitable for both wind and string instruments.

Titebond II Premium 5004

- a one-component, moisture-resistant adhesive, which has a blue packaging, is distinguished by a high setting speed, resistance to solvents and a shortened full cure period. The finished seam of the Titebond 2 adhesive is elastic. Usually this variety is used to make benches, garden furniture, mailboxes. The non-toxic composition allows it to be used for repairing various household items, even those that have indirect contact with food.

Titebond 3

- a product produced in green packaging, which is particularly durable and water resistant. It is suitable for gluing items in direct contact with food. There are no toxins and solvents in the composition, only safe polymers are taken as a basis. Titebond 3 glue can even be used for gluing items that will be used in subzero temperatures.

You can work with this composition by cold or hot gluing. The basis of the glue is a water-dispersion mixture, which makes the composition universal. With glue, you can glue not only wood, but also plastic with other materials. Consumption is 190 g / m². Polymerization times vary from 10 to 20 minutes.

Heavy duty

- a very strong compound that is suitable for bonding concrete, brick, fiberglass, ceramics, stone and even hardboard. A high degree of adhesion is ensured by the synthetic rubber included in the composition. With this glue, you can even work with wet and frozen wood.

The hardened seam has good elasticity, thanks to which vibration and mechanical influences are not afraid of it.

How to determine the quality of the adhesive?

Consider our advice. The most important indicator of the quality of the glue is its high adhesion capacity.

The higher this indicator, the better the glue. In second place is adhesion (sticking force), which ensures the most durable adhesion of various materials.

The most important indicator of the quality of the glue is its high adhesion capacity. The higher this indicator, the better the glue. In second place is adhesion (sticking force), which ensures the most durable adhesion of various materials.

An equally important characteristic is the drying time of the adhesive, which must be taken into account when laying floor coverings in rolls. The drying rate is influenced by the composition of the glue and the presence of organic or inorganic functional compounds in it.

The drying speed is influenced by the composition of the glue and the presence of organic or inorganic functional compounds in it.

The quality of the glue can also be judged by its elasticity. This makes Franklin flexible adhesives ideal for flooring applications.

The indicators of the moisture resistance of the adhesive composition play an important role when it comes to working with them in bathrooms, saunas, swimming pools and other rooms with high humidity.

As for wood flooring, it is necessary to choose an adhesive that does not contain water for their installation. This means that polyurethane glue is ideal for working with wood.

Types and characteristics of adhesives

There are polymer and polymer cement adhesives for flooring.

Tiles, artificial and natural stone are laid using polymer-cement adhesives. The glue-cement provides reliable adhesion of durable and hard materials.

Polymer adhesives are used for laying linoleum, wood, laminate, carpet. Adhesives of this type have high indicators of elasticity, strength, resistance to aggressive environments.

In addition to the above compositions, acrylic mixtures and PVA glue containing water are widely used for laying floor coverings. They are characterized by high adhesion and vapor permeability. The presence of liquid rubber in polyurethane mixtures and the absence of water make them versatile.

Before starting to work with flooring adhesive, you must carefully study all the technical characteristics and recommendations of the manufacturer, the type of material, and the operating conditions.

If the selected glue is suitable, then you can get to work. If you have any difficulties when choosing an adhesive, it is better to seek help from a consultant.

Where to buy quality flooring adhesive?

Our company Vector offers quality adhesives from the well-known manufacturer Franklin. In the catalog presented on our website, you can familiarize yourself with the range of products offered.

We offer favorable terms of cooperation: reasonable prices, prompt delivery, convenient payment. By contact phone you can contact us, get a free consultation and place an order. Call us!

Floor adhesives from Franklin Int. created for those who care about the quality of fixing materials. Parquet, linoleum, carpet, plywood, chipboard, MDF and other coatings will be securely fixed and retain their original appearance for a long time, thanks to a variety of unique adhesives from Franklin Int.

Floor adhesives from Franklin Int. are produced without solvents, which ensures safety for the environment, and a wide range of products meets the needs of professionals at all stages of installation and repair work: both rough and luxury finishing. Our specialists will help you to choose the necessary glue, taking into account the properties of the floor covering.

Wood adhesives are very popular in furniture making and joinery. The masters consider the glue "Titebond" (Titebond) to be a quality tool, more precisely, its whole line, produced under this brand. The manufacturer - the American company Franklin International - monitors the quality of the products, and also guarantees the highest moisture resistance of the compositions among analogues.

About Titebond

Franklin International has been a recognized world leader in the design and manufacture of wood adhesives for 70 years. Franklin International has achieved a solid position in the market and professional recognition due to the quality of adhesives, competent technical support, work with customers and a flexible pricing policy.

Franklin International invests heavily in improving existing and developing new adhesive technologies to produce high quality wood adhesives. The firm's ongoing commitment to R&D enables it to bring the most advanced adhesive technologies and products to the market, Titebond Wood Glues.

Franklin International development stages:

- 1935 year. The first Titebond Liquid Hide Glue, formulated in a ready-to-use form.

- 1952 year.The first adhesives for professional woodworkers, Titebond Original, based on aliphatic resin.

- 1991 year. The first one-component, aliphatic polymer based adhesive, Titebond II Premium Wood Glue, which meets the ANSI / HPVA Type II (USA) water resistance standards, DIN EN204 D3.

- 2003 year. The latest development is the first one-component water-based adhesive Titebond III Ultimate Wood Glue, which has passed the ANSI / HPVA Type I (USA) water resistance test, approaching DIN EN204 D4.

Franklin International is constantly expanding its range of products with the Titebond Wood Glues brand used by professionals around the world. The company now produces more than 25 types of adhesives for industrial use.

Franklin International's history as an international leader in assembly adhesives begins in 1970 with the release of Titebond Construction Adhesive, one of the first adhesives to pass the rigorous tests of the American Plywood Association AFG-1.

Twenty years later, Franklin International launches the first solvent-free industrial adhesive that also meets this standard.

Construction and assembly adhesives Titebond today occupy a significant part of the market in Russia. The most common and versatile is Titebond Multi-Purpose (red tube). Titebond Heavy-Duty (yellow tube) is considered to be one of the strongest adhesives in its class. Titebond Solvent Free (green tube) is the only solvent-free adhesive in the industry that achieves Heavy-Duty strength.

A new series of high-quality industrial adhesives for wood produced by Franklin International is widely presented on the Russian market. These adhesives have a wide range of applications, are suitable for all types of presses, are economical and easy to use.

Franklin International's history as a leader in flooring adhesives also dates back to 1970, when the technology was first introduced to use safe chlorine-based solvents. 20 years later, Franklin International offers a new solvent-free industrial adhesive for flooring that is flexible after curing, opening a new generation in environmentally friendly adhesive technology.

In Russia, from a wide range of flooring adhesives, the universal Multi-Purpose Flooring Adhesive, Titebond Fingerblock natural parquet adhesive, and Urethane Wood Flooring Adhesive are well known. Recently, a new unique system of epoxy waterproofing Titebond Epoxy Moisture Control System was supplied to the Russian market. Besides the high quality, all of these products have a relatively low price tag.

All Franklin International products are perfectly adapted to the requirements of Russian stores.

Franklin International offers a unique sealant program under the Titebond brand. This program contains 11 high quality products that can be used for the entire spectrum of construction, installation, renovation work.

Today the Franklin International company continues to raise the bar of world standards for adhesives of all types: for wood products, for all installation and repair projects, installation of any floors, both rough and luxury finishing.

Scope of use

Titebond glue has a very wide range of applications:

- It can be used for gluing wood of any type, species, age.

- In everyday life, it is used for gluing laminate, cardboard, paper, plywood and others.

- In the woodworking industry, including for the manufacture of doors, decorative flooring, furniture.

- In the field of design - for the artistic decoration of interior items with wooden details.

- When carrying out repair work in the house. It can serve as an analogue of a sealant and provide water resistance to joints.

There are varieties of glue that have a narrow specialization. For example, glue for repairing musical instruments, means for restoring antiques, household items, wooden souvenirs.