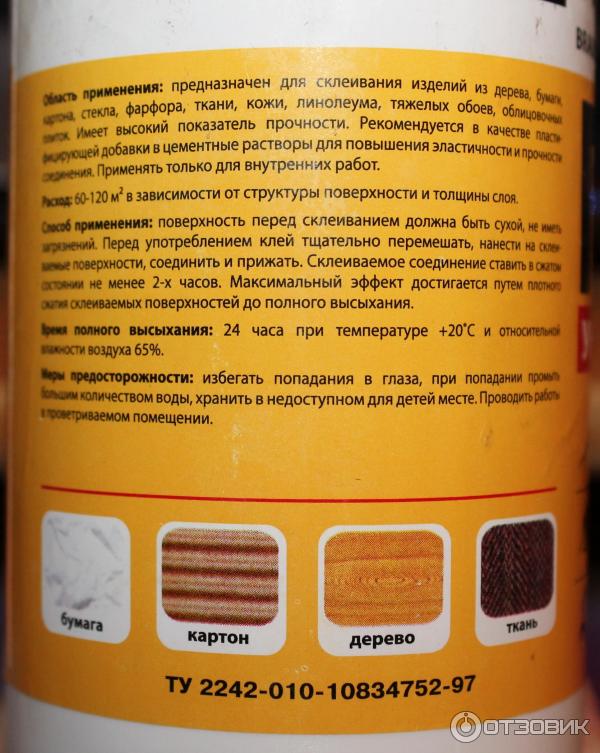

Scope of use

The tool is most widely used in children's art. PVA is very popular in schools, kindergartens, circles, developing studios. The child does not need special clothing to work with it. You can remove stains in a regular washing machine. The glue will easily hold together paper, cardboard, threads, fabric, etc. When mixed with gouache, glue is painted on canvas, because such paint will be resistant, will not fade.

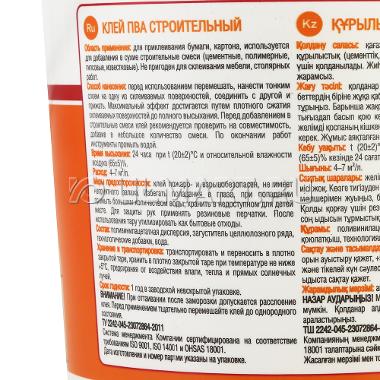

PVA is used in construction work: from gluing wallpaper to installing parquet, laminate, tiles. The adhesive is suitable for impregnating wood to make it water-repellent. When 5-10% PVA is added to a conventional cement mortar, the ability of the latter to waterproof significantly increases, as does plasticity, adhesion to the base. Add 70 g of PVA per 10 liters of the bulk to the plaster. This helps to dry the coating quickly and also allows the mortar to adhere better to the wall.

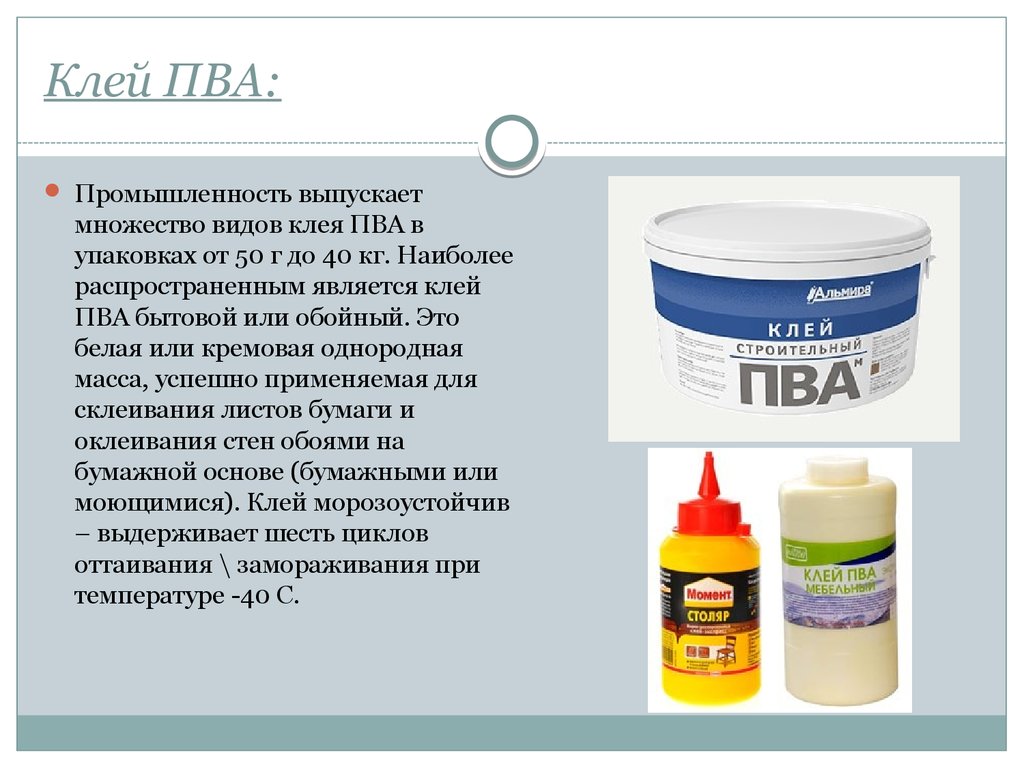

Types of polyvinyl acetate glue

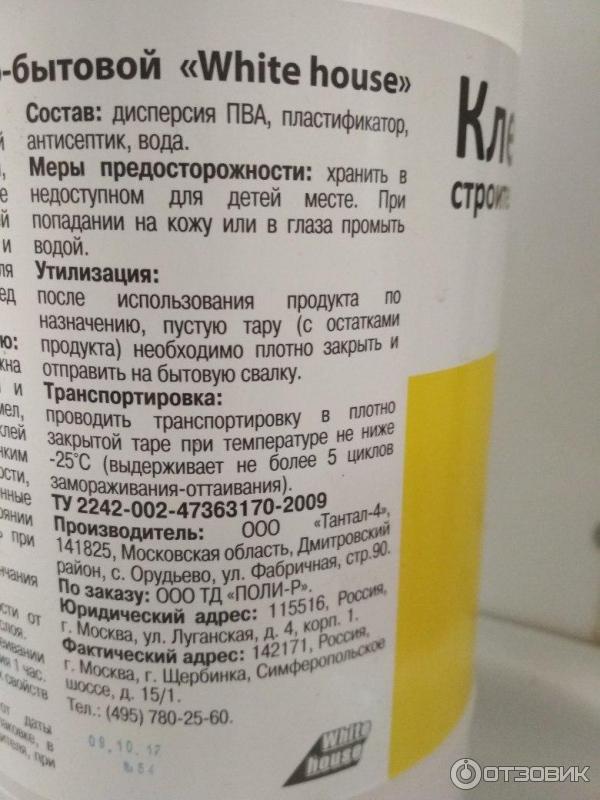

Any polyvinyl acetate adhesive is a homogeneous, viscous mass, white or cream in color. Conditionally, it can be divided into household and construction, depending on the composition of the adhesive base, this or that type is used in various fields.

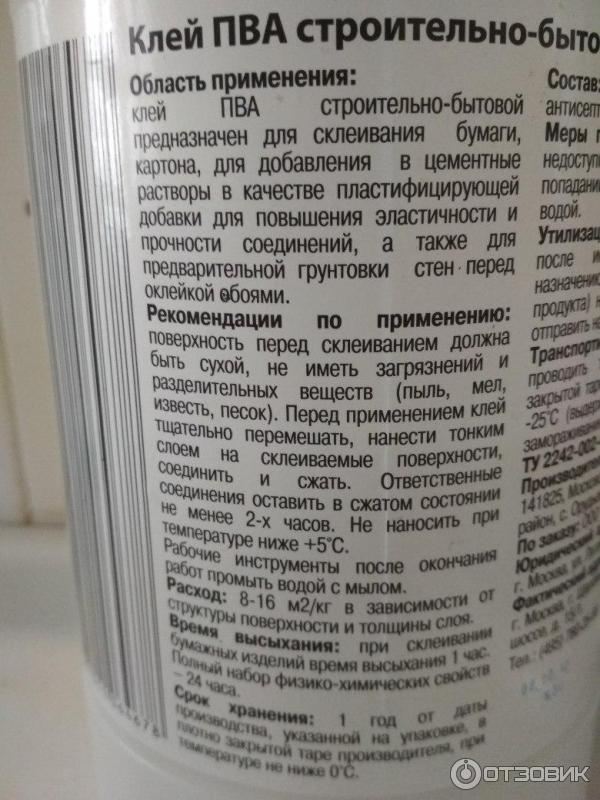

- Household polyvinyl acetate adhesive for paper or various paper-based products (including wallpaper). Frost resistance at t -40 ° C, no more than 6 cycles.

- Stationery polyvinyl acetate (PVA-K) for household needs and creativity, most often it can be found in a schoolboy or student's pencil case. It adheres well to paper, cardboard and other paper-based products. It has minimal water resistance and frost resistance, which determines its narrow specialization.

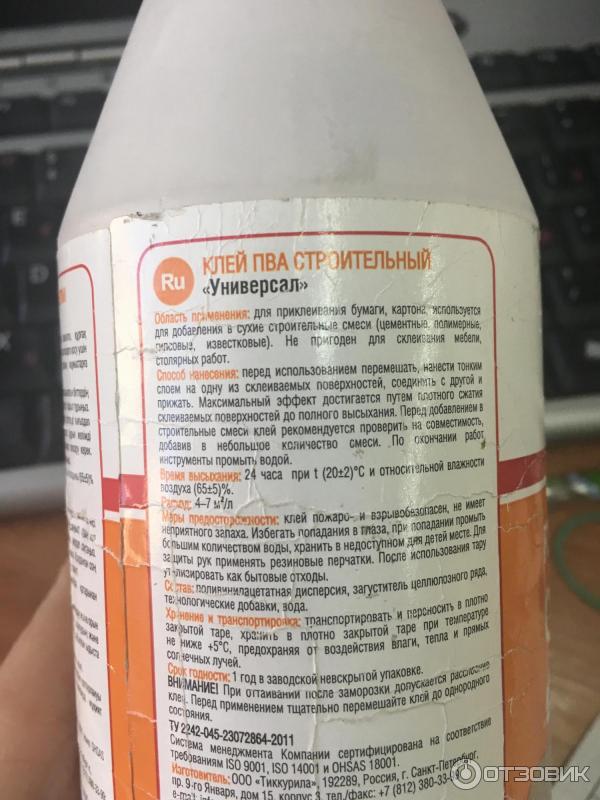

- Universal polyvinyl acetate (PVA-MB) has a wider range of applications. Frost and moisture resistant. They can glue paper, cardboard, leather, fabric, stick them to wood, glass or metal surfaces. It can be used in construction, as an auxiliary substance. Adding PVA-MB to a primer or putty increases the adhesive properties of the material. Frost resistance at t -20 ° C, no more than 6 cycles.

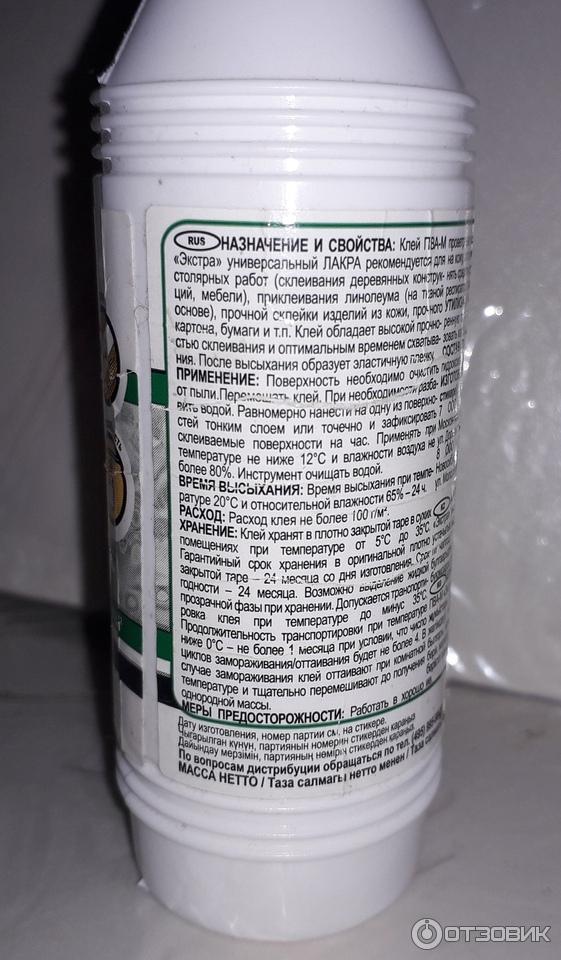

- PVA super glue (PVA-M). They can glue all paper bases, porcelain, fabric, leather, wood products (chipboard, MDF), as well as linoleum, parquet, tiles. Application in the construction industry is due to the minimum pressing time, the adhesive sets quickly and guarantees maximum adhesion in a short time. Frost resistance at t -40 ° C, no more than 6 cycles.

- PVA dispersion. An aqueous polymer solution stabilized with polyvinyl alcohol has high adhesion. Moderately toxic, with low frost resistance. It is widely used in construction as an additive in mixtures and mortars. The production of packaging, household chemicals, paints, fabrics, footwear is also not complete without the use of dispersion. She can glue wood and a dense paper base (photographs, cardboard, etc.), fabrics.

Mode of application

The most important point when using PVA is surface preparation:

- Clean the bonding area from dirt, remove all dust, dirt and other debris. The substrate must be dry.

- Degrease with acetone or other solvent.

- Prepare the site for applying the adhesive. A smooth surface must be sanded or a "concrete-contact" mixture should be applied to create locking joints, and a rough surface, on the contrary, should be sanded.

- Follow the instructions carefully when diluting the mixture. Any deviation will reduce quality and reduce adhesion.

- Use a brush or roller to apply the composition.

- Remove excess adhesive mixture with a dry cloth.

- When connecting wooden structures, observe the pressing time; it is better to leave them under the load until they are completely dry.

PVA glue is a versatile product used for gluing various materials. It is an emulsion of polyvinyl acetate in water with the use of additives. Differs in a characteristic weak smell.

Preparation of a composition for whitewashing trees using PVA glue

For whitewashing trees in spring, a composition with PVA glue is perfect. This will help protect the plants from pests. Usually the same recipe and mixing ratio is used. Casein glue can be added to PVA glue, this allows you to make a moisture-resistant composition that will be resistant to precipitation.

The use of PVA glue is also justified here for the reason that the composition is notable for its affordable cost. However, you should be prepared for the fact that the mixture is worse than the rest and will allow the trees to breathe. The second version of the solution is more difficult to prepare, you should purchase for it:

- clay;

- slaked lime;

- fungicide;

- PVA glue.

Before starting work, stir two parts of lime and one part of clay in a bucket. The latter is pre-soaked to dissolve the lumps. At the final stage, 300 g of oxide should be added, and after that - 100 g of glue.

3 Features of applying the composition and surface preparation

Before applying PVA glue to the surface, it should be thoroughly degreased, get rid of dust and dirt. Foreign particles and traces from adhesive materials will interfere with adhesion to the surface; maximum adhesion will not be achieved. In addition to being clean, also make sure the surface is dry. If you apply PVA glue on a flat and smooth surface, sand it with fine-grained sandpaper or a float. Grungy foam gypsum or foam concrete is pre-primed.

We dilute the concentrated PVA glue according to the instructions, and also take into account the peculiarity of the materials that we will fix. For example, for bonding sheets of fiberboard and plywood, the glue can not be diluted, but for other surfaces, the proportions are always different, indicated by the manufacturer. When applying glue to the wallpaper, carefully level the canvas on the wall with a dry cloth so that bubbles do not form on the surface.

When working with flooring, we use a notched trowel. It is convenient for them to level the adhesive, distributing it in an even layer and removing excess. When joining wood, cardboard and other cellulose materials, coat the joints with a thin layer, press them together for 1 minute, and then put them under the load. Acting according to this scheme, we get the connection as strong as possible. The drying time of polyvinyl acetate glue depends on the thickness of the application, however, complete polymerization occurs in a day.

Main characteristics

Wallpaper glue CMC is protected from the formation of mold, mildew, which will not show through on the wallpaper. If the composition includes sodium tetraborate, then you should not worry about the appearance of insects. Due to these characteristics, the powder is often added to putty mixtures, concrete mortars.

This product is produced at Russian and foreign enterprises.

Main technical characteristics:

- moisture content up to 12%;

- dissolves in water by 96-100%;

- infusion, swelling of components, activation of properties - 2-3 hours;

- ready-made it is used within a week.

The amount of added water depends on the density of the wallpaper: for thin material - 8 liters of water per pound of powder; for dense canvases - 7 liters of water per pound of powder.

In order for the glue to fully activate its properties, warm water is taken for dilution, the mass for swelling is left overnight.

General specifications

PVA glue Super M

Any type of PVA glue must meet specific quality standards. Regardless of the type of glue, they are common to everyone:

- The adhesive capacity must comply with GOST 18992-80 - 450 N / m;

- Frost resistance of the composition must withstand at least 4 cycles;

- The average shelf life is six months;

- Complete solidification should occur within 24 hours;

- The composition should not be toxic and moisture resistant.

Also an important parameter should be the ability to dissolve in water and acetic acid. This is necessary in order to remove the adhesive from the object, if necessary.

This is also a minus of PVA - if you need to restore parts that will interact with water or an acidic environment, it is better to use something else, because the glue in such a place will quickly lose its properties, and the object itself will fall apart again.

PVA glue: composition and technical characteristics

Polyvinyl acetate was first obtained in 1912 in Germany by the scientist Fritz Klatt, and a few years later the enterprising Farben set up the production of PVA on a commercial scale. Currently, the universal PVA glue, the composition of which is familiar to every school graduate, is the most popular in the world, its world production exceeds a million tons.

Polyvinyl acetate, the content of which in the glue reaches 95%, is obtained from vinalone, a synthetic fiber based on polyvinyl alcohol. Depending on the field of application, plasticizers are added to the dispersion, providing plasticity and frost resistance to the adhesive film. It can be diisobutyl phthalate, dibutyl phthalate, tricresyl phosphate, EDOS and other alcohols, esters. Their percentage is in the range of 1.5-5%, and the components of the glue are thickeners and targeted additives that provide adhesion strength to various surfaces.

Universal PVA glue has the following technical characteristics:

- low consumption, depending on the type of work and lying in the range from 100 to 900 g per square meter;

- adhesive capacity 450 N / m;

- complete drying time up to 24 hours;

- frost resistance for more than 4 cycles;

- average shelf life is 6 months.

The PVA dispersion is explosion and fire safe; when using plasticized glue, a small amount of acetic acid, EDOS plasticizer and vinyl acetate are released into the air.

PVA glue - use in everyday life and industry

Currently, PVA glue is used in various fields of activity. With its help, walls are wallpapering and laying ceramic tiles, PVA is used in labor lessons at school and as an additive in the glass industry. Depending on the purpose, various types of glue are used, among them the most common are:

- wallpaper glue based on PVA, intended for pasting with washable and paper wallpaper on various surfaces;

- universal PVA glue, used for gluing wood, cardboard and leather products, it is also part of the formulations of putties and primers;

- super PVA glue used for installation of floor coverings and for facing with ceramic tiles;

- Stationery PVA, used for gluing cardboard, papers, photographs, is the least toxic type of glue due to the absence of plasticizers;

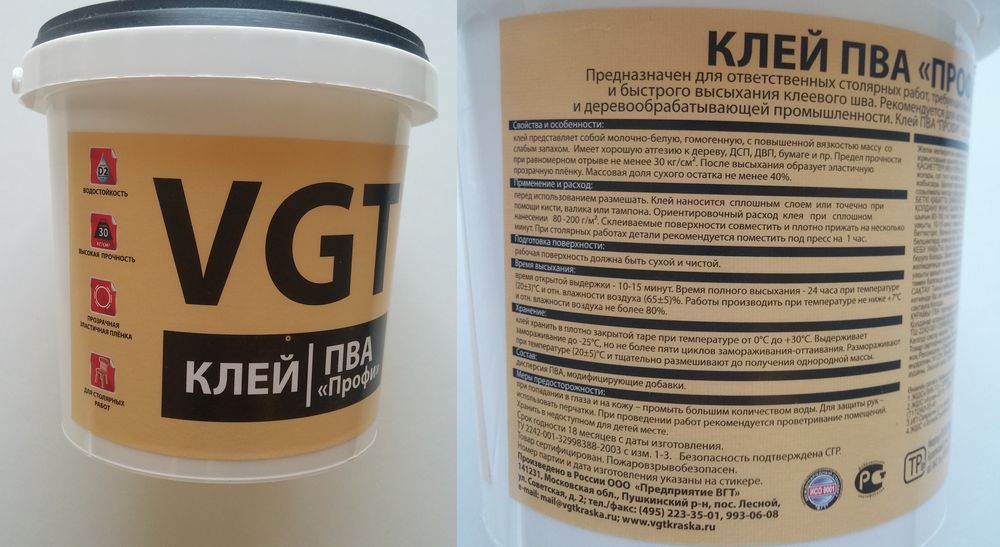

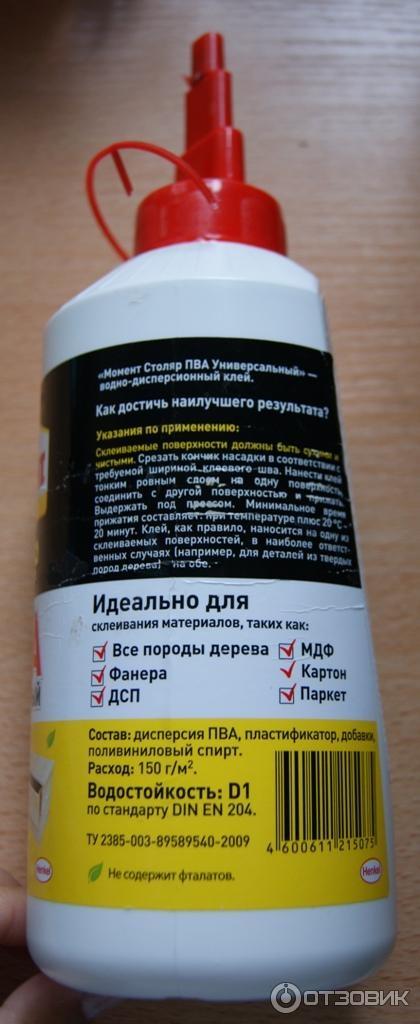

- PVA joiner's glue with high adhesion to wood materials and water resistance;

- homopolymer dispersion of PVA, characterized by maximum setting strength and used in the porcelain, textile, glass industry, in the production of building materials;

- PVA glue A moment that has a short pressing time and is used when installing parquet and laminate.

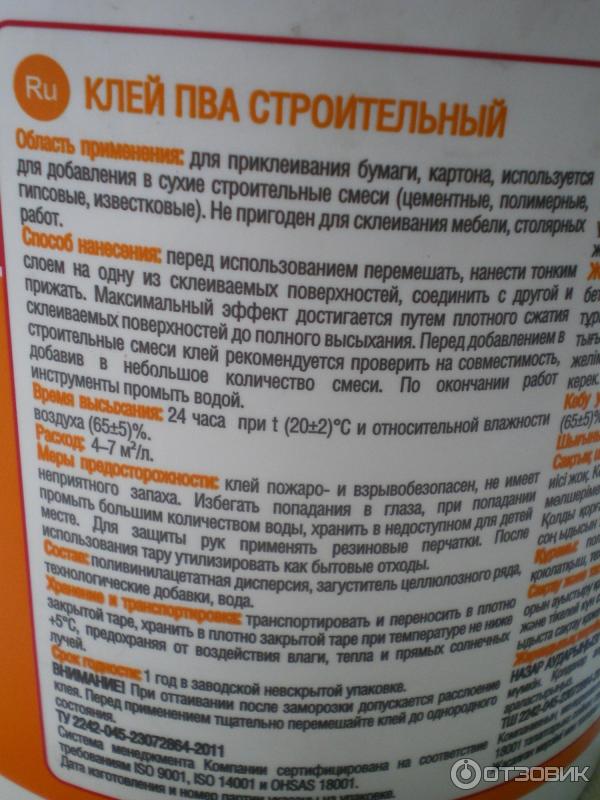

PVA construction glue - basic rules of work

PVA construction glue is used by both professionals and novice home craftsmen. For all types of work, there are uniform basic rules, the main of which is the mandatory degreasing of the surface. Also, cleaning the glued surfaces from dust will not hurt. It is better to apply PVA with a roller or notched trowel, and not with a brush.It is necessary to press down strongly bonded surfaces for 1-2 minutes, this will ensure good adhesion.

Safety, affordable price and environmental friendliness of the glue are one of the reasons for its popularity among the population. Even a popular toy "smart plasticine" is made of it, for which sodium tetraborate and dyes are added to PVA glue. Superiority over competing formulations is the main reason that adhesives manufacturers today are trying to improve the formulation of PVA, rather than invent new substances.

Polyvinyl acetate glue is a white suspension with a light, specific odor, water-based, perhaps the most common type of adhesives. Its popularity lies in its affordable price, versatility, environmental safety and ease of use. The scope of its application is large, from gluing paper to fixing wooden bases, tiles, foam and other materials.

What it is

Acrylic adhesive is a water-soluble product. It is produced without the addition of solvents, so its base is considered natural. The mass has a liquid consistency of a transparent shade, but there are varieties with a yellowish tint.

This tool is widely used due to a number of advantages:

There are no toxic compounds in the composition, it is safe for the body and the environment.

Suitable for joining different surfaces, in different combinations, providing a secure fit.

The consistency of the product helps it to be evenly distributed over the plane, aligning the base, which is important when gluing uneven elements.

The water-resistant composition facilitates the use of the adhesive as a sealing agent.

Withstands adverse, aggressive environments, therefore it is widely used for outdoor work.

Assortment, product availability, mass transparency.

There are varieties with a yellowish tone, which is important to consider when buying for transparent surfaces. Also, quick-drying types do not leave time for adjustment, correction

The unpleasant odor disappears after complete drying.

How to use PVA glue correctly?

In order for you to be able to fully appreciate all the advantages of this product, it must be correctly selected. PVA glue should have a thick structure, white color and a homogeneous mass. You can watch a photo and video review of PVA glue right in this article! You also need to remember that a high-quality product cannot cost mere pennies.

Having chosen a good glue, you should not rush to use it, because for this you should very carefully prepare the surface. The working surface must be completely free of dirt and all kinds of dust. If the surface has a porous and uneven structure, then it must be carefully treated with a primer or sandpaper.

Shake the glue with a brush before application. It is applied in a very thin layer, and then the surfaces are carefully pressed against each other. As already noted, the period for complete drying is 24 hours, therefore, for a good result, the surface should not be touched throughout the day.

The main varieties of PVA glue

Since the scope of application of PVA is determined by the type of its composition, among the varieties are distinguished:

- household (wallpaper);

- stationery (PVA-K);

- universal (PVA-MB);

- Super glue;

- building.

Household glue is used for paper and paper-based wallpaper. The properties of the composition make it possible to use it for wallpaper that is glued to plastered walls, concrete or wooden surfaces. In consistency, the composition is a milky-white liquid, which can have a beige tint and a faint odor. The composition is non-toxic, therefore it is safely used in residential premises. With prolonged use, the glue turns yellow. The composition has a shelf life: the glue, suitable for use, is liquid and homogeneous.PVA with an expired shelf life is taken in lumps, which makes it impossible to apply it to the surface. If the glue is expired, then when the composition is squeezed out of the container, a clear liquid will pour out first. The seam formed using household PVA can withstand a temperature drop of up to -40 ° Celsius.

The PVA superglue contains additives that increase its strength after polymerization. You can use the composition by repairing the surface laid with ceramic tiles. For several unsticked elements, it makes no sense to prepare a cement composition; it will replace it with PVA superglue, which can firmly fix the tile on the concrete surface. The substance, like the previous version, can withstand fluctuations up to -40 degrees, so its use is allowed in unheated rooms or on the street.

PVA glue - composition and technical characteristics

The world production of PVA glue exceeds the mark of one million tons annually. In its composition, polyvinyl acetate occupies the leading role - 95%, and the remaining 5% remain for all kinds of plasticizers, which give the formulations plasticity and good frost resistance, as well as additives that improve adhesion.

The technical characteristics of the universal PVA glue are in its low consumption - depending on the type of work, from 100 to 900 grams per square meter. The station wagon dries up within a day, withstands 4 freeze-thaw cycles, it is stored, on average, about six months without changes. The PVA solution is not flammable and not explosive; when used, it does not emit harmful substances into the air.

PVA glue is suitable for gluing a wide variety of surfaces. However, by adding certain components to the classic PVA, manufacturers have mastered special compositions that are effective in various fields of application. For example, wallpaper glue is produced specifically for gluing wallpaper, which provides adhesion between a wooden or concrete wall and paper.

The glue labeled "Super" is applicable on a different scale - it is used to glue not only wallpaper, but also linoleum, and even facing tiles. "Super" glues porcelain, leather, fabric, provides adhesion of such surfaces as chipboard. The universal adhesive is suitable for bonding various combinations of surfaces, for example, when you need to bond wood and tiles, cardboard and metal, linoleum and concrete. Joiner's PVA is used for gluing pieces of furniture into a single frame. Such a composition is characteristic in that, when solidified, it forms a translucent solid layer that tightly adheres to wooden surfaces.

Construction PVA is a dispersion designed to be added to a wide variety of mortars and formulations. To increase elasticity and durability, it is added to cement and lime mortars, plaster, primers. Sometimes it is used as a soil, but this solution is only suitable for cheap repairs, for example, in a utility room.

Homopolymer dispersion, which has the highest adhesion strength, is also referred to as a separate type of PVA. This dispersion is used in the textile industry, glass and porcelain industry, in the production of materials for repair and construction. "Moment", a type of glue that tends to quickly set in air, should also be included in a separate category. Most often, this is used when installing laminate or parquet flooring.

PVA is used in the tobacco industry - it is one of the components of the material from which cigarette filters are made. Textiles and fabrics are impregnated with emulsions with a low concentration of polyvinyl acetate in the textile industry, which are then used for sewing clothes - this gives them greater wear resistance, density, elasticity. On the basis of PVA emulsions, water-repellent mixtures are made, which also impregnate fabrics.

PVA has become an element of paint formulations practically from the moment of its invention.PVA-containing paints have high elasticity, wear resistance, cover well surfaces of stone, concrete, wood, plaster, metal. And in combination with plasticizers, such mixtures form a glossy film with increased tensile strength. Even pencils and corks are made using this glue, and the popular children's toy "smart plasticine" is nothing more than polyvinyl acetate with additives from dyes and sodium tetraborate.

Instructions for use

Precautions should only be taken if you have an allergic reaction to a specific group of repellents. The fact is that the plasticizer, dibutyl phthalate, in its pure form is used to repel mosquitoes, and its concentration in the PVA glue is super, rather high

To prevent possible reddening of the skin of the hands, we recommend using latex gloves. Otherwise, this glue is safe.

To understand how to glue with PVA glue with high quality, you must firmly master the following rules:

The surfaces to be glued must not be dusty.

Degreasing is the key to a quality seam.

Reliable fixation during the day is an important condition for polymerization.

Compliance with the temperature regime is the foundation of successful work.

After mastering the above rules, the instructions are pretty simple. The optimum temperature for gluing is 18-25 ° C. Please note that the parts themselves must be at this temperature, and not just the air in the room. The surfaces to be glued must be cleaned of all excess. This is best done with fine sandpaper. Moreover, the use of sandpaper will increase the surface roughness, which leads to an increase in the contact area and thereby improve cohesion.

The cleaned and sanded surface must be wiped with a highly volatile solvent. In addition to degreasing, this procedure will remove dust. The presence of dust dramatically reduces the adhesion of the glue to the part.

PVA dispersion is applied in a thin layer on both surfaces and left for 6-8 minutes. During this time, on each part, the glue penetrates into the thickness of the material by several microns and already begins the polymerization process. Then the surfaces to be glued are pressed against each other and securely fixed

Please note that, unlike solvent-based adhesives, when working with PVA, the fixing time is of decisive importance. The minimum time for reliable setting is 24 hours at a temperature of 20-25 ° C

Only after this time, the glue line acquires the declared characteristics.

Of course, if you glue the cardboard, then you don't have to wait that long. But when working with furniture, adherence to the aging period is highly desirable. When gluing wood, careful adherence to the instructions leads to a paradoxical effect - the glue seam of PVA super glue becomes stronger than the product itself. In other words, if the load is exceeded, the piece of wood itself will break, not the glue seam!

It is best to remove excess glue immediately after application. This can be done with a damp cloth. After drying and complete curing, only scraping with a knife or sandpaper is possible. The action of household solvents causes the polymer film to swell and does not lead to dissolution.

Composition and technical characteristics of PVA building glue

PVA construction glue is resistant to moisture, therefore, the content of acetone, which is responsible for this indicator, is increased in the five percent share of additives. For shorter curing times and for greater strength, crushed glass or porcelain is added.

The advantages of the composition include:

- low consumption;

- high strength indicator;

- drying speed;

- resistance to UV radiation;

- minimal shrinkage;

- fluidity.

PVA consumption depends on the type of work performed. The minimum indicator is 0.1 kg per 1 m2, at the maximum value, the consumption reaches 0.9 kg per 1 m2.After polymerization, the adhesive is able to withstand a pull-off load of 550 N / m, which is sufficient for furniture products and finishing materials. The polymerization rate of the glue is influenced by the temperature of the parts and the air, as well as their humidity. Restrictions are imposed by the area of the glued surfaces. The average is 12 hours, it can be increased up to 24. The adhesive is resistant to sunlight, which is necessary for areas that are near windows or within the range of light. The adhesive can withstand up to six freeze-thaw cycles.

For quick drying of the adhesive

Often many are puzzled by what can be done with PVA glue to dry it quickly. To do a good job, you need to know how to dry the glue quickly. With fine paperwork and a thin layer of glue, it will completely dry after a maximum of 15 minutes.

On average, PVA dries for 24 hours. In order for the surfaces to be glued tightly to each other, it is necessary to press them well, for example, create a press from books or clamp them in a vice for several hours.

- To ensure good adhesion of surfaces, you must first thoroughly clean them from debris and dust.

- In order for the application to be uniform, it is necessary to degrease the surfaces with acetone or alcohol.

- It is best to use a brush or roller for working with PVA, as a thin layer will dry faster.

- To ensure fast drying, you must use a product from a trusted manufacturer.

- PVA dries faster when exposed to moderately high temperatures, so you can dry the product with a hairdryer, put it next to a heat source, or put it in the microwave for a few seconds.

2 Types of glue - what to use in everyday life and industrial purposes?

PVA glue has found its application in various fields of activity. Laying tiles, gluing wallpaper, gluing plastics, cardboard, paper, plywood, use as an additive in the glass industry. To get the maximum result when fixing certain materials, let's take a closer look at the varieties of this universal fixator.

Let's start with the simplest thing - PVA stationery glue. This glue is well known to schoolchildren, students and their parents, because it is used for gluing standard things that are used in everyday life: cardboard, paper, photographs. Stationery glue is absolutely safe, does not cause allergic reactions when it comes into contact with the skin, so even children work with it. Among the disadvantages of personalized PVA stationery glue, one can single out low resistance to moisture and negative temperatures.

PVA is used everywhere, hence a wide selection of grades and types

For industrial purposes and repair work, PVA construction glue is used. The list of basic materials that this composition can fix among themselves includes: paper, vinyl and fiberglass surfaces. The technical characteristics of the building glue make it possible to use it as an additive that increases the adhesion of building mixtures (putty, plaster, primer).

Specialized construction clamps are distinguished separately, for example, PVA wood glue. It is widely used by joiners to work with wood, has increased moisture resistance.

PVA-M super glue is designed to work with vapor-permeable materials. Thanks to this composition, the glue seam is as strong as possible, and its application does not require compliance with certain rules. Craftsmen use this glue to work with ceramic tiles, fixing joints of flooring, leather products, porcelain, fiberboard (chipboard), plywood, glass and wood. PVA-M super glue has an increased frost resistance of -40 ° C.

PVA dispersion is an additive to mortars that are used in the printing, footwear, textile and glass industries, as well as in the production of packaging, household chemicals and paints and varnishes.The reason for adding dispersion is to increase the adhesion and strength of the product. PVA glue is also used as a basis for the production of wallpaper glue, which fixes paper-based finishing material to various surfaces (concrete, plaster, wood, cement).

Dispersion PVA glue

And if you are at a loss as to which composition is suitable for your material, then it is better to stop at a universal PVA glue. It has a wide spectrum of action, which allows:

- glue fabric to wood, metal, glass surface;

- use as an additive for putty, primers and water-based cement mixtures;

- fix the floor covering (carpet, linoleum, tiles);

- to glue synthetic materials on a paper base, cork, vinyl;

- fix sheets of chipboard, fiberboard, MDF, decorative plastic.

Kiilto EcoStandard dispersion glue based on PVA (Finland)

The Finnish PVA brand already speaks of the high quality of the product and its reliability. The buyers were convinced of this more than once, as indicated in their comments.

The composition is suitable for laying linoleum, solid boards and working with other materials. Quite often, PVA glue emulsion is used to extend the life of the floor. Sometimes glue also helps when it is necessary to attach plywood to concrete with dowels.

Instructions for use

Before starting to work with glue, you should make sure that the temperature at this time and for the next three days will not be less than +15 degrees, and the humidity during this period will not exceed 80%.

The surface on which the dispersion mass is applied must be clean, dry, firm and even. If there is an unstable layer on the concrete surface, it should be removed by grinding.

The use of PVA takes place in several stages:

- Thorough mixing of the composition.

- Application of the mass to the desired area and even distribution.

- The overlap of elements on top of each other and their tight compression.

When working with parquet, it is allowed to sand it only 7 days after applying the glue.

It is also important to remember that when stains appear on the surface, remove with a damp sponge before drying.