Polyurethane sealants

Polyurethane sealants are an elastic, adhesive, sealing compound on a polyurethane base that retains its elasticity for a long time. This sealant can be used for gluing and sealing almost any material: metal, wood, stone, lacquered sheet, plastic, ceramics, concrete.

Polyurethane sealants have good adhesion and guarantee strong adhesion of surfaces, which is not destroyed even during strong earthquakes up to 5 points.

• Resistant to corrosion.

• Hardens on reaction with moisture.

• Give in to coloring, easily varnished.

• Have quick adhesion.

Due to the fact that polyurethane sealants contain harmful corrosive substances, it should be remembered that when working with them, they should not be allowed to come into contact with open skin areas.

They are sold in standard original packaging with a weight of 310 ml, also in cardboard boxes or in a 600 ml aluminum bag.

What it is?

The current acrylic adhesives are a suspension of certain polymers dissolved in water or organic compounds. In the process of gradual evaporation of the solvent with the polymer, some modifications occur, which leads to the solidification of the substance and its acquisition of special rigidity. Depending on the components included in the composition, this glue can be used in various fields for specific purposes.

The most common area of application is construction, as the substance can bond most building materials, including metal, glass and even polypropylene surfaces. The main characteristics make it possible to use it in industrial production, as well as for domestic purposes, and the grip will be strong and reliable regardless of conditions.

The main advantages of acrylic adhesives.

- Easy to use. Uniform distribution over the entire bonded surface and fast setting.

- Very high adhesion to all materials. These properties allow the adhesive to be used on uneven surfaces.

- Moisture resistance, as well as ensuring a good level of tightness. Resistance to weathering associated with bad weather conditions is considered a huge plus.

- High level of elasticity.

In the process of working with various types of mixtures, the disadvantages of this glue were also identified. One of the most common disadvantages is considered to be insufficient thickness of the applied adhesive seam.

It is important to understand that of all types, only latex acrylic glue is odorless and non-toxic. All other varieties are toxic to some extent and have a pungent unpleasant odor.

Long-term use of adhesive without respiratory protection can damage the mucous membranes.

Types and technical characteristics

The glue in question is made from a synthetic substance - acrylic. Compositions based on it can be one-component and two-component. The first ones are already ready-to-use substances; in the second case, the composition must be diluted with water.

According to the basic substance and the method of hardening, acrylic-based adhesives can be of several types.

- Cyanoacrylate adhesive is a one-component transparent adhesive and can be used for a variety of materials. It is characterized by a very fast adhesion.

- Modified acrylic glue - a mixture of acrylic and solvent is widely used in construction.

- Acrylic compound that hardens only when exposed to UV waves of the required length.It is used when gluing glass, mirrors, screens and other transparent materials.

- Latex-based acrylic adhesive is the most popular substance, odorless, absolutely harmless and fireproof. This is the most versatile repair and assembly compound capable of interlocking any textures. Therefore, they use it when laying linoleum and other floor coverings. Due to its water resistance, it is used in bathrooms and other places with high humidity.

- Water-dispersible acrylic glue has the safest composition, hardening after moisture evaporation.

- Acrylic tile adhesive is used for fixing ceramic tiles, artificial flexible stone, quartz sand and other facing materials.

What is polyurethane adhesive

This type of adhesives quickly gained popularity after their appearance on the market. Polyurethane adhesive is a composition based on polyurethanes, polymers with high film-forming ability. After hardening, the mixture is resistant to aggressive chemicals and the external environment. The adhesive mixture, subject to the technology, glues together almost any material: metal, glass, ceramics, PVC, wood, rubber. The composition is practically odorless, viscous viscous consistency. The color of the glue in the finished state depends on the components (it can be amber, white, gray).

Composition

The basic components of polyurethane adhesives are aliphatic or aromatic isocyanates and hydroxyl-containing oligomers, oligoesters. To initiate hardening in two-component compositions, water, alcohols, aqueous solutions of alkali metals and organic acids are used. Rarely do modern adhesives use solvents to balance and adjust components. Surfactants (surfactants) are added to the polyurethane glue for better wetting of materials when gluing. Some adhesives additionally contain synthetic resins.

Specifications

In modern construction and renovation work, polyurethane adhesive mixture is considered one of the ideal compositions for work. Most brands are safe for human health, easy to use (applies to one-component types), easily withstand extreme loads, have anti-corrosion properties and retain their strength for many years. As with any chemical mixtures, the main thing is adherence to the application technology. General specifications for polyurethane adhesives:

- Durability. While maintaining stable temperatures and the stipulated mechanical loads, the dried composition retains its bonding properties for up to 30 years (depending on the manufacturer's composition).

- Strength. Polyurethane compounds have high elasticity, which allows them to withstand thermal expansion of materials (temperature differences up to 40 degrees Celsius) or physical movements within acceptable limits without rupture.

- Moisture resistance. The hardened adhesive mixture does not pass or absorb moisture (if the installation is observed, it completely seals the seams). The same feature prevents mold, pathogenic fungi and organisms from developing.

- Drying time. After application to the substrate, one-component glue retains its properties for up to 60 minutes, and two-component glue - up to 2 hours.

- Strength curing period. Depending on the composition and the materials to be glued, the final state is reached after 2-3 hours (for example, when repairing shoes) and up to 48 hours when laying ceramic tiles, parquet, gluing wooden parts.

- Fully cured mixture and parts can be used at temperatures up to 150 degrees Celsius and above. The lower limit is –60 degrees, which is ideal for use in all regions of Russia.

Application

Polyurethane adhesive is used in all areas of construction, production and repair.Such distribution was achieved due to excellent characteristics while adhering to gluing technology, minimal toxicity of most brands, ease of use for non-professionals. At the same time, 1-component and 2-component glue practically does not differ in efficiency. Where are polyurethane adhesives used:

- production and installation of metal-plastic windows, composite materials;

- production of sandwich panels;

- in mechanical engineering for fixing elements of the skin and hull;

- installation of ceramic and tiles in residential or technical premises;

- laying parquet boards and laminate;

- gluing mosaics (marble, onyx, slate);

- bonding foam insulation, foam, fiberboard, chipboard, MDF;

- household use: repair of shoes, minor breakdowns of plastic, glass, wood, etc.

Rules and application features

There are two main ways of using adhesive mixtures.

Hot gluing

For a more reliable fixation of materials, people use the hot gluing technique. In this case, the composition is preheated with a building hairdryer. Only after warming up, it is applied to the surface to be glued.

Cold bonding

With cold gluing, the composition does not need to be preheated. It is applied in its original form to the coating. However, before this, the surface must be prepared. It is cleaned of debris, traces of dirt and degreased. With cold gluing, the adhesive layer dries for about 8-10 hours.

What it is

Acrylic adhesive is a water-soluble product. It is produced without the addition of solvents, so its base is considered natural. The mass has a liquid consistency of a transparent shade, but there are varieties with a yellowish tint.

This tool is widely used due to a number of advantages:

There are no toxic compounds in the composition, it is safe for the body and the environment.

Suitable for joining different surfaces, in different combinations, providing a secure fit.

The consistency of the product helps it to be evenly distributed over the plane, aligning the base, which is important when gluing uneven elements.

The water-resistant composition facilitates the use of the adhesive as a sealing agent.

Withstands adverse, aggressive environments, therefore it is widely used for outdoor work.

Assortment, product availability, mass transparency.

There are varieties with a yellowish tone, which is important to consider when buying for transparent surfaces. Also, quick-drying types do not leave time for adjustment, correction

The unpleasant odor disappears after complete drying.

Nairite glue brands and their features

Today there are several types of shoe glue. "Nairit" is among the most popular, respected by many masters.

The following brands also stand out, besides the first naturally:

- Nairit-1. An adhesive composition, which is famous for its high strength of the finished joint. Manufactured on the basis of chloroprene rubber. The adhesive mass is easy to use. After applying the first layer, there is enough time for the parts to be glued. You can use two ways to connect individual elements - cold or hot. If the first gluing option is used, you must wait a day before using the finished product. If the work is carried out according to the second method, it is allowed to wear shoes after 4 hours.

- Rapid-5. An adhesive made on the basis of chloroprene rubber. Used when joining leather, rubber, plastic.

- Glue Sar-30E nairite. Adhesive mix from an Italian manufacturer. According to experts, this glue is considered the best among similar products. Suitable for gluing leatherette, natural leather, rubber, various types of fabric. If the materials were glued with a hot method, the finished product can be used after 3 hours.

- Anles.This glue is made by a domestic manufacturer. Used to repair genuine leather or leatherette shoes.

Each of the brands presented above has differences in characteristics and methods of use. To familiarize yourself with the features, you must read the instructions for use.

Characteristics and properties

Nairite glue from different manufacturers has some differences in characteristics. However, it is permissible to indicate average numbers:

- The color of the glue mass is yellow-brown shades.

- Viscosity - 2600 mPa · s at a temperature of 22 ° C.

- Reaching maximum strength is about 200 minutes.

- Heat resistant up to 75 degrees Celsius.

- Density - 0.85 g / cm³.

Sometimes the composition is diluted with additional components to improve its technical characteristics.

Advantages of glue

Any adhesive has a number of strengths and weaknesses. Before you start using mixtures, you need to familiarize yourself with the pros and cons.

The benefits of nairite include:

- High heat resistance.

- The elasticity of the adhesive mass does not decrease even with decreasing temperatures.

- Resistance to prolonged exposure to moisture, acids.

- Long shelf life.

- High adhesion rate.

- Fast absorbency.

- Possibility of gluing various materials.

- The skin does not shrink after the adhesive mass dries.

- High bond strength.

Disadvantages of glue

The disadvantages of almost every nairite adhesive composition include toxicity, long drying time. Analogues dry out much faster. Nairite glue has no other significant drawbacks.

Where is applied

Thanks to nairite glue can be used for connections of various parts, it is used during various, wide range of repair work. This is a repair of clothes based on artificial and natural leather, rubber, plastic parts, decorative elements joining. In auxiliary operations, such as gluing insoles with half insoles and the like.

Scope of the material

The presence of the listed properties is due to the wide scope of the material's applicability. It is used for many purposes in the implementation of external and internal construction work at residential, administrative, economic and industrial facilities. Also, glue is the most important raw material in the manufacture of sandwich panels and other elements that consist of several different materials. This approach is most widespread in the production of insulating parts and decorative items for interior decoration.

There are several models of glue that differ slightly in composition and are specially designed to maximize market coverage. One-component polyurethane parquet adhesive can be used on regular or warm floors. In both cases, the result will be exactly the same. If all the manufacturer's recommendations are followed, the positive effect of the repair is guaranteed.

It is necessary to work with glue in special protective gloves and goggles. Despite the absence of toxic substances in the composition, contact of the material on open skin areas may cause irritation or allergies. Glue is applied using a special curly spatula, which can be bought at a tool store. In case of insufficient ventilation of the work area, professionals also recommend the use of respirators to protect the respiratory system.

Adhesives manufacturers

A large number of polyurethane-based adhesives are sold in stores. Domestic and foreign manufacturers provide such products to the market. Here are the most popular brands:

- Anles. The range of the company includes about 10 polyurethane adhesives for industrial and household use. The adhesives "ADV", "Vilad", "Polyurethane", PVC Fix and others have earned the respect of users.All of them are used for gluing PVC, rubber-fabric products, polyurethane, thermoplastics, leather, glass, metal.

- "Titanium". Several canned adhesives are produced under this brand for professional and home use. Especially known is the foam glue "Universal" - a one-component composition for external and internal work, quick-drying, with high fire resistance. Another good composition is Bonolit "Formula of heat". This glue is so strong that it is used for masonry blocks, the construction of external and internal walls, as well as partitions. It serves as an alternative to conventional cement mortars.

- Desmokol. It is widely used in shoe factories, reliably holds rubber and polymer materials. Available in small tubes, cans and even 200 liter barrels.

- Kenda Farben. The company presents on the market a very high-quality polyurethane compound SAR 306, which has high thermal stability. It is used for gluing PU, TPE, and various rubber products. The addition of a special hardener increases the adhesion of other difficult-to-bond materials.

- Sika. This Swiss brand produces a whole line of polyurethane-based products. Especially known is the polyurethane sealant Sikaflex, which has high tensile strength, resistance to moisture, chemicals and physical stress.

- Inov. A cold-curing polyurethane binder of this brand from the People's Republic of China is used for laying seamless coatings, the production of rubber plates, rubber crumb, rolls.

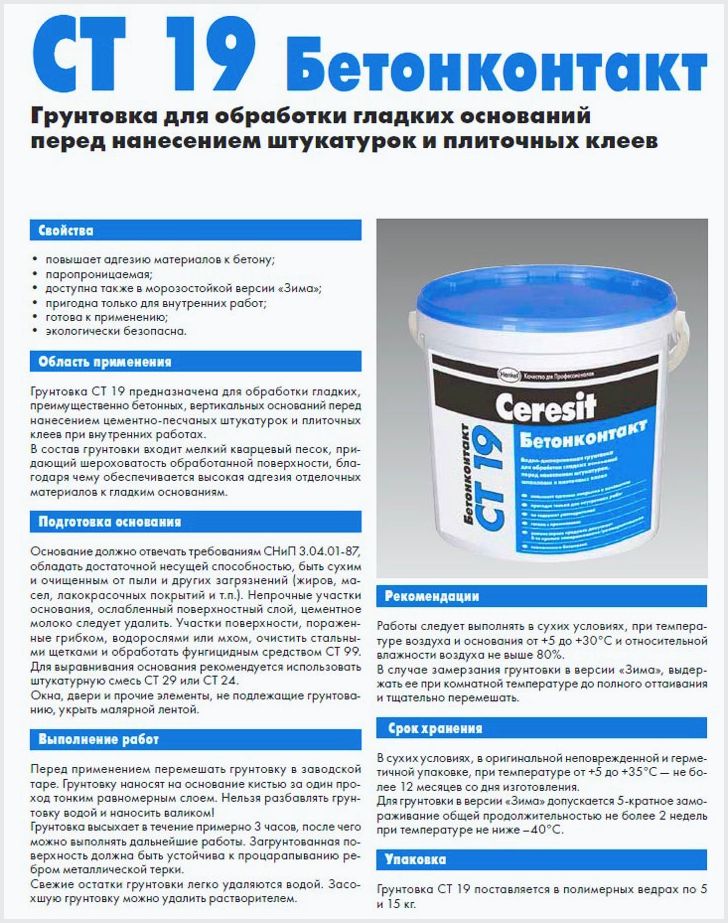

- Henkel. Products from the Ceresit line are high quality adhesives for tiles and other materials. The most famous polyurethane adhesive is Ceresit CT 84 - a means for fixing window sills, filling gaps between expanded polystyrene plates, aerated concrete blocks, for fixing thermal insulation. Also on sale is the Moment Crystal glue from Henkel - a transparent polyurethane gel for all types of materials, except for Teflon and polyethylene.

- Polinor. Polynor Stik glue is a one-component composition for fixing extruded polystyrene foam, aerated concrete, panels, mineral wool. It can be used for sealing joints and open areas, for attaching decorative elements.

- Soudal. Soudal brand produces polyurethane adhesive Soudabond Easy - a professional composition in cylinders for fixing mineral wool, cork, gypsum board, glass wool, foam blocks and fiber-cement boards.

- "Lighthouse". Glue "Super NN" of this manufacturer is intended for banner fabric, leather, laminate and parquet, all types of plastic, polyurethane, as well as rigid PVC and ABS. Before use, it is imperative to clean the bases with Cosmofen solvents.

Also polyurethane-based adhesives are produced by the companies "Neomir", "Rastro", "Kleon", Adesiy, Bostik, Duayen and others. The funds have different prices and volumes, but, for the most part, are of good quality. You can get excellent polyurethane glue at any hardware and hardware store.

Manufacturers of glue KMTS

In hardware stores, in the markets, there are Russian, imported TMs for sale. The price of the former is much lower, but the technical characteristics are not inferior.

Famous manufacturers:

- Pennant 75B is produced in Russia. The finished solution has a high viscosity, water-retaining qualities. Suitable for all types, types of wallpaper on all surfaces, including metal. No toxic substances, safe. Packing in bags.

- Carbocel produces a universal CMC product for all types of canvases. It is an environmentally friendly product with high levels of solubility. Highly effective filler-free product. Available in packages of 0.3 kg, 0.5 kg, 15 kg.

- Omega produces an adhesive based on carboxymethyl cellulose with the addition of antifungal components. Suitable for various wallpapers in structure, width.The solution is prepared within three hours, as a result, a homogeneous mass without lumps is formed. Shelf-life Unlimited.

- Polycell CMC-7 is a white fine-grained powder, readily soluble in water at any temperature. It is used in construction as a thickener for putties, increases the plasticization of mortars, adhesion strength.

- Malva produces glue designed for fixing multilayer wallpaper (foam), cloths on a paper, fabric basis. Fastening is carried out on painted, concrete, plastered, wooden surfaces.

Composition

Polymer adhesives should be:

- Tenacious;

- Elastic;

- Non-flammable;

- Electrically conductive;

- Heat conductive.

To make the glue non-flammable, antimony oxide or other additives are added to its composition. For thermal conductivity, boron nitride is added to the composition. The additive mixing technology is strictly observed, otherwise the mixture will lose its adhesion.

We are used to the fact that adhesives are sold in a liquid, ready-to-use state. But they are also sold in powder form. Such a powder is diluted with special solvents;

- You can also find granular glue. To bring it into working condition, the granules are heated at low temperatures;

- There is adhesive in the form of films with and without a closed adhesive part.

Polymer adhesives are constantly being improved, the increased interest in them is justified by their use in the construction of rocket launchers. And a mixture with multiple properties is extremely important.

Manufacturers

Most modern manufacturers of building mixtures produce a line of polymer adhesives. The products of different companies differ from each other in terms of technical characteristics and quality.

When studying the characteristics of a particular product, it should be remembered that high-quality polymer glue should have the following qualities:

- high rates of elasticity;

- good electrical and thermal conductivity;

- fire resistance;

- a high degree of adhesion (adhesion) and the ability to firmly bond various surfaces to each other.

Before choosing the appropriate type of polymer-based solution, it is recommended that you familiarize yourself with the most famous manufacturers and study the reviews on their products.

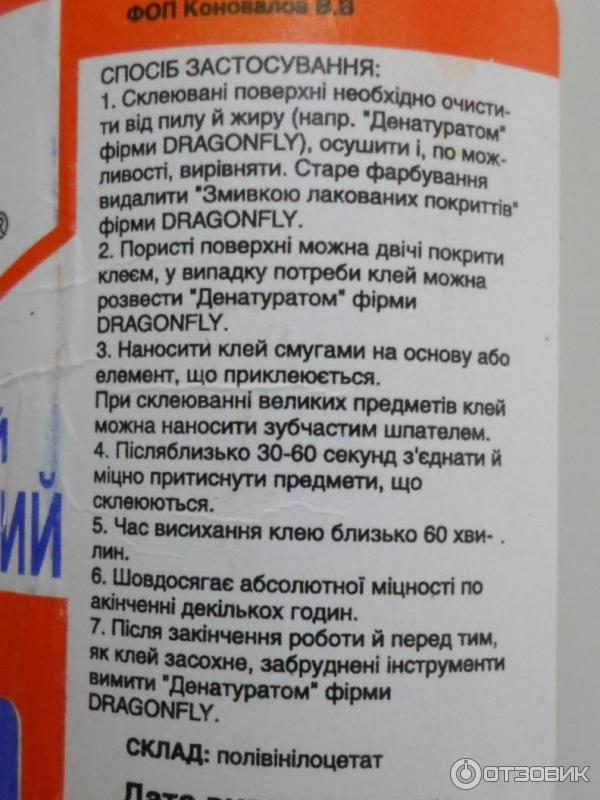

Dragon

The Polish company Dragon specializes in the production of construction chemicals and adhesive mixtures. This company has been supplying high quality products to the construction market since 1972.

The universal polymer-based Dragon glue is very popular in the Russian market. This composition can be used for both interior and exterior decoration. The mixture is resistant to water and temperature extremes. The time for complete setting of the bonded surfaces is thirty minutes.

Customer reviews of this product are in most cases extremely positive.

Consumers highlight the following advantages of Dragon glue:

- short drying time;

- high quality;

- effective bonding of a wide variety of materials;

- affordable price.

Hercules-Siberia

The Hercules-Siberia company specializes in the production of dry mixes for construction work. In the manufacture of products, the most modern foreign technologies and high-quality raw materials are used.

The company produces two modifications of polymer-based glue:

- universal;

- superpolymer.

Both types of mixtures are available in dry form. The maximum volume of a bag with a free-flowing mixture is 25 kg. The universal compound can be used not only for bonding various surfaces, but also for eliminating minor irregularities in walls and floors. Superpolymer modification is excellent for cladding various surfaces of tiles. It can be used for heated floors.

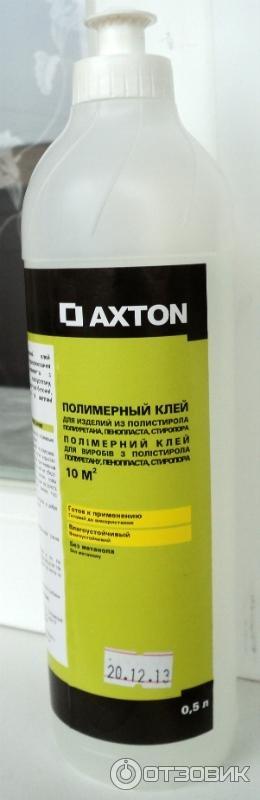

Axton

Products manufactured under the Axton trademark are manufactured for the Leroy Merlin chain of stores. Axton polymer-based adhesive mix has the highest performance characteristics.Such mixtures are used in the manufacture of metal structures, finishing and installation work, as well as for sealing joints.

Bostik

The Bostik company is one of the world leaders in the production of adhesive mixtures. The company produces compounds intended for both domestic needs and the field of professional construction. All Bostik products comply with international quality standards.

The polymer adhesive Polylex from the manufacturer Bostik is distinguished by a high degree of adhesion. The mixture can be used to bond materials such as ceramic tiles, paper, various types of fabrics, wood-laminated board, linoleum, plastic.