Bonding technology

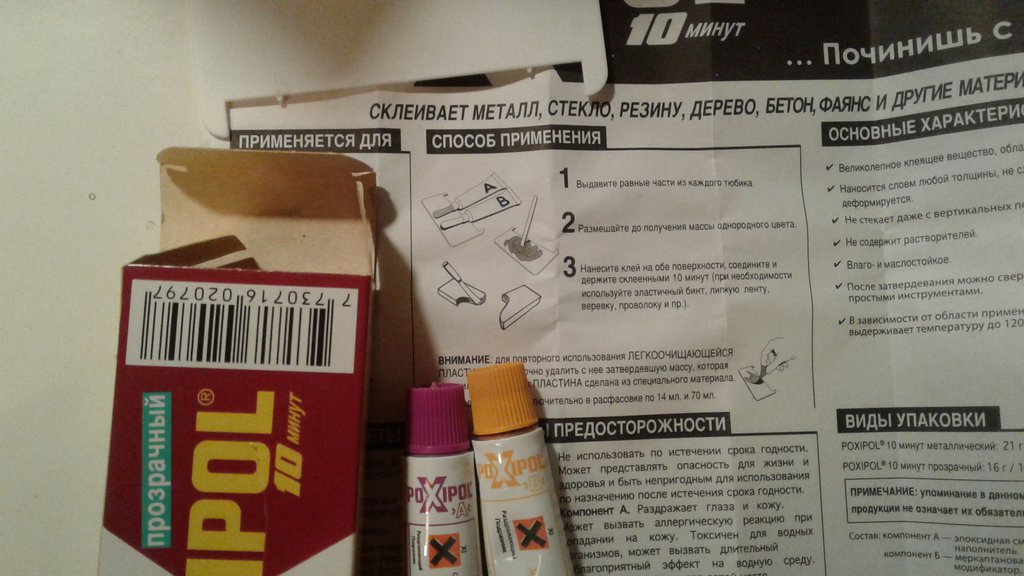

You do not need a professional construction education or extensive experience to work with glue. There is nothing complicated in the implementation of installation operations. Using the mixture, you can glue brick, concrete, metal, fiber cement, granite, marble, ceramics, glass, porcelain-faience, wood and some types of polymers other than those indicated on the package. Instructions for using Poxipol are as follows:

- 1. The surface to be treated is cleaned of foreign objects and treated with an antifungal liquid. No primer is required.

- 2. Dilute the required amount of glue, and prepare all the tools that may be needed in the process.

- 3. Smear only the surface of the element to be connected with glue and press it firmly in the right place. It is enough to hold for 1-2 minutes.

- 4. On average, hardening lasts 10-12 hours, but experts recommend not touching the treated area for at least one day, so that the glue is fixed as much as possible.

- 5. After complete solidification, any manipulations can be performed with the element, such as painting, drilling, grinding, curly cutting. According to its properties, the glue joint will be stronger than brick, concrete and any cement mortar.

The technological operation is very simple, but you shouldn't forget about safety measures

It is very important to use protective gloves during work, since if it comes into contact with the skin, it will no longer be possible to wipe off the glue. If you use it to glue two fingers together, then only surgical intervention will help to separate them painlessly.

So the matter is very serious and you should not neglect the safety requirements.

Use temperature and other application features

Poxipol is excellent for metal. The composition has the characteristics of fast curing. The temperature of use can vary from 20 to 24 ° C. After a 10-minute break, the composition will change color to transparent and harden without changing its own volume. The area to be treated will reach its maximum strength in a day, which is true if the temperature in the room changes from 21 to 25 ° C.

By means of the polarity ratio, the thermal input in the component can be controlled very precisely. Thus, the heat input can be controlled perfectly. You keep the original material properties by minimizing heat input. You reduce component distortion and avoid extensive reorganization.

You compensate for material tolerances due to the good gap bridging capability. Do you want to reduce your thin wafer production costs while increasing quality? Thus, even in poor conditions, these tracks can be laid safely.

Poxipol glue, the instructions for use of which should help you avoid mistakes, has insulating properties. However, this is true if you mix the ingredients until smooth. As additional positive features, excellent sag resistance should be highlighted. The tensile strength is 8 MPa. Adhesives have varying degrees of resistance to chemicals. For example, the composition perfectly withstands the effects of water and the external environment. The mixture will cope somewhat worse with hydrochloric and sulfuric acids, mineral oil, as well as gasoline and toluene.

In the case of a self-adhesive bituminous coating, the undercoat is designed so that it is laid on a suitable substrate after the release of the release film. The use of cold seam adhesives is mainly done with. Temperature sensitive substructures and parts.

... In the design of the system, self-adhesive strips can be used as a vapor barrier, sealing layer or top layer.

Poxipol scope

The table is segmented from single, flat sonotrode units. Any shape and weld lines can be created over the entire weld surface. The sonotrode table fits into the machine and can be used universally across the entire range of formats thanks to simple changes to the welding tool. The different product contours are displayed through welding tools and not through sonotrodes.

Features and scope of glue

Poxipol glue of the Uruguayan manufacturer Fenedur JSC is a two-component adhesive based on epoxy resin, a universal means for bonding a variety of materials. Cold welding, which is Poxipol glue, gives results as in conventional welding: after drying, a strong adhesive seam is formed, literally soldering the surfaces together.

A unique feature is the ability to subject the seam to various types of processing - threading, drilling, grinding, which will not violate the technical characteristics of the glue. To create a reliable joint, it is not necessary to subject products to strong pressing, squeezing. It is enough to ensure a state of rest and the absence of vibration, and the parts will be firmly fixed. Before use, both components of the glue are mixed with each other, and only then will the composition be ready for use.

The fields of application of Poxipol glue are varied. It can be used for restoration, repair, gluing, sealing, fixing products. The most popular use of glue among motorists is to seal a leak in a gas tank. Also in the garage it can be used for:

- repair of aluminum radiators of cars, motorcycles;

- restoration of the boat hull;

- body repair;

- strengthening the seams of the old vehicle.

Poxipol cold welding is suitable for materials such as steel, aluminum, alloys, wood, concrete, glass and ceramics, plastic. "Poxipol" perfectly glues rubber products, PVC without corrosive effect. It is not recommended to use glue only in relation to Teflon, polypropylene, polyethylene, and all other materials can be easily bonded with this cold welding.

Common cases of using Poxipol in everyday life:

- repair of handles of kitchen knives, other cutlery;

- restoration of household appliances;

- installation of hinges on furniture, additional fixation of cabinets, fasteners;

- placing the sink on the countertop;

- restoration of marble countertops, furniture made of metal and wood, plastic;

- repair of rails, crossbars, table and chair legs;

- repair of windows and doors made of wood, metal;

- fastening of hooks, dowels;

- restoration of water tanks at home and in the country;

- gluing sinks, bathtubs, mirror frames, sealing cracks;

- sealing of various areas in the bathroom, shower;

- repair of garden furniture, sculptures, monuments;

- restoration of carving on various objects;

- fixation of stone blocks, additional fixing of tiles;

- gluing drain pipes, drain channels;

- attachment of cuttings of garden tools.

Advice

Strict adherence to the rules of use and adherence to simple recommendations will help to quickly and reliably glue any surfaces and extend the life of damaged items.

- Smoothing the mixture after application should be carried out using a rubber spatula or a knife moistened with water.

- If the mass is poorly squeezed out, you can slightly heat the tube.

- In case of partial use of the material and the presence of a residual amount of glue for the next use, it is not recommended to replace the caps of the tubes in places.

- Prepare the mixture on an easy-to-clean plate.

- It should be remembered that Poxipol does not stick to Teflon, polypropylene and polyethylene surfaces.

- To join complex surfaces, a thin layer of toluene-free contact adhesive must first be applied to each of the parts. This applies to steel, bronze, copper and chrome plated products. Cold welding can be started after the auxiliary composition is completely dry.

- When gluing smooth, pore-free elements, it is recommended to clean the working areas with sandpaper or fine sandpaper. This will increase the adhesive properties of the materials and ensure their reliable connection.

- It should be borne in mind that the composition becomes transparent only 10 minutes after application. At the same time, the volume and shape of the layer does not change.

- The recommended temperature for cold welding is 20-25 degrees. A higher temperature decreases the time for complete drying, a lower temperature increases.

Poxipol cold welding will help to quickly repair any product, maintain its presentable appearance and ensure high reliability of the connection.

You will learn more about working with Poxipol cold welding by watching the following video.

The consistency of the glue and its differences

By structure, two types of epoxy glue can be distinguished:

- Liquid glue is a gel squeezed out of a tube. Very simple and easy to use. You just need to squeeze the gel out of the tube and apply it to the surfaces to be glued. During operation, time is saved on mixing and preparation of the solution.

- Plastic mass - similar in consistency to dough or plasticine, sold in tubes. The necessary part of the plastic is cut off from the common piece and moistened with water. After that, you need to knead the product with your hands for a few seconds and apply to the parts to be glued.

There are also modified epoxy glue compositions, their hardening temperature ranges from +60 to +120 degrees Celsius. This material is used for bonding metals and non-metals that are resistant to oils, fuels and other organic solvents.

Hot-hardening agents with temperatures from +140 to +300 degrees are considered especially strong. Such compositions are heat resistant and have high electrical insulating characteristics.

In addition to epoxy compounds used in production and industry, there are a number of universal epoxies used in everyday life:

- Moment is one of the most recognizable modern brands. Sold in any hardware store at a very affordable price. Packing of goods is convenient for any craftsman: tubes with epoxy gel, plastic masses of 50 grams or reusable large-volume packages. The shelf life of such a product after opening the package is only a few months in a dry place with a temperature of no more than +25.

- "Contact" is ideal for gluing products that will subsequently be exposed to moisture. It is used for sealing joints in plumbing, pipe joints, gluing light shelves and decorative elements in the bathroom. The glue hardens in 2-3 minutes.

- "Cold welding" - suitable for joining metal elements, copes with the task for a few seconds. The mating level of the surfaces is identical to the effect after classical welding. After hardening, the edges of the metal product remain even, which is an additional advantage.

- EDP universal glue - used for fixing various surfaces, from glass and porcelain to metal. Experts say that this particular composition is optimal in quality and composition.

Top best

The stores have a large selection of epoxy compounds from foreign and domestic manufacturers:

- Contact - transparent epoxy adhesive. Contains: poly epoxy resin, hardener. For use in household repairs. The seam turns out to be resistant to an aggressive environment (exposure to oil, gasoline, water), does not shrink in any way, does not distribute. Perfectly fills vacuums, cracks.After drying, the product can be operated at temperatures from –30 degrees to + 150 degrees. Glass, metal, wood, porcelain are subject to gluing.

- Moment Super Epoxy is an epoxy adhesive with many functions. It has a colorless structure, has superpowers, sticks together almost all materials, does not distribute or shrink when dried. Suitable for outdoor use. After drying, you can paint over, drill, etc. When the parts are mixed, curing begins after five minutes, and after an hour, high reliability is achieved. Do not use with polyethylene, teflon, polypropylene and surfaces that will come in contact with food.

- TechnoNIKOL is a two-component thixotropic epoxy adhesive. The seam turns out to be strong for bending, compression. Provides high adhesion to smooth surfaces. It is used for the repair of concrete structures, columns, curbs. Fills voids, gaps, cracks. Connects bearing and repaired concrete elements. Available in metal and plastic containers.

- G / Flex is an epoxy resin designed for permanent and hydro-resistant bonding of fiberglass, ceramics, wood. Has an elasticity higher than conventional epoxy or polyester resin, but thicker and tougher than sealants. Used for connections that will absorb stress, increase, contraction, ripple, shock. After connecting the elements, the working time is 45 minutes at room temperature. Curing occurs after 7 hours, after a day, the elements to be glued can be used.

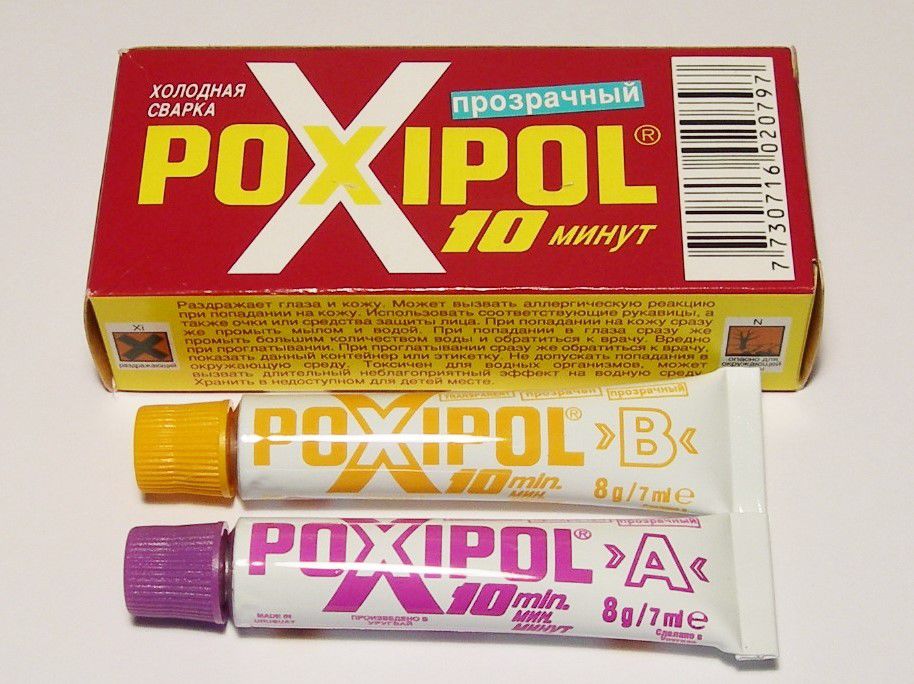

- Poxipol - two components. Consists of oligomers. The package contains two tubes. The contents are mixed in equal proportions before use. When mixed until smooth, a white adhesive is obtained. Bonds ceramics, metal, wood, concrete, plastic, glass, rubber. It hardens when exposed to water or oils. The seam can be corrected for the first 10 minutes after application. Complete hardening occurs in a day.

Instructions for the use of glue

For reliable fixing of parts, it is important to prepare well both bonded surfaces. First, they remove dirt, debris, dust off

Further, degreasing is carried out by washing with soapy water, wiping with acetone, alcohol, special degreasers (depending on the type of material). Before applying the glue, you need to make sure that the surface is completely dry - this way the adhesion will be much higher.

Glue preparation method

It is necessary to mix the two components of Poxipol glue strictly before work, otherwise the composition will quickly harden and deteriorate. It is necessary to perform the following actions:

- put the required amount of component A (epoxy resin) on a plate or in a disposable cup;

- add the same volume of composition B (hardener), that is, the proportion will be 1: 1;

- mix the glue well so that it becomes homogeneous, you should not devote a lot of time to the process.

At the end of the work, the tray plate must be cleaned by scraping off the glue residues, it is reusable and will be useful for the next application of Poxipol.

Bonding products "Poxipol"

After the glue has reached a uniform consistency without lumps, you can start bonding the parts. One of the working surfaces is well coated with glue, then strongly pressed against the second part. Withstand 60-120 seconds for initial setting, if necessary, adjust the position of the parts during the first 5-10 minutes. The product is left for a day, after which it can be used.

Useful tips for using Poxipol are as follows:

- to seal joints, pits, cracks, and other defects, it is better to use a small construction trowel or knife dipped in cold water, with which the glue is spread;

- when repairing leaks on containers, tanks, the composition is also applied with a spatula, but already a little thickened, or they take opaque plastic-like glue with their hands, stick to the problem area;

- if small steel shavings are introduced into the glue, the mass will become more resistant to mechanical stress and will be able to withstand even the vibration of the products;

- the most favorable temperature for working with glue is + 18 ... + 22 degrees, in which case the composition hardens evenly;

- often it is required to apply two layers of glue, in this situation you need to wait until the first is completely dry and only then do the second.

Remains of glue in the tubes do not need to be thrown away, they can still be used in the future.

It is only important not to swap the caps, screwing them in the correct order. If the epoxy resin in the package thickens a little, put the tube in hot water or on a closed heating battery before use.

Adhesive Precautions

Epoxy can negatively affect the skin, mucous membranes, causing irritation and allergic reactions. The hardener is even more harmful to the skin, it must not be allowed to come into direct contact with the body. If any component or their mixture gets on the skin, wash it with plenty of soap and water. Eye contact or swallowing requires urgent medical attention!

After drying, the composition is harmless to humans, but safety measures must be observed while working with it: wear glasses, gloves, a respirator, and ventilate the room well. It is better not to use expired glue. It should be stored only out of the reach of children and animals. It is strictly forbidden to repair elements of gas equipment with Poxipol!

Poxipol cold welding provides exceptional bonding performance across a wide range of products. It will become an indispensable tool at home, in the workshop, for repair work. The effectiveness of the glue has been proven in practice, it does not lose its popularity among users.

Scope of application of the polymer composition

When choosing the type of cold welding, be sure to take into account the nature of the material to be processed. The field of application of cold welding is very wide. If we consider the maintenance and repair of a car, the following areas are distinguished:

- connection of various metal surfaces;

- soldering of flowing pipes, gas tanks;

- sealing cracks in plastic tanks;

- repair of parts and pipes of the exhaust system;

- manufacture of plugs for threading.

Cold welding for plastic

For the processing of plastic surfaces, less serious requirements are put forward compared to metal surfaces. Therefore, Poxipol two-component adhesive meets softer requirements. For comparison, the maximum operating temperature is 93 ° C, and the strength of the joint is 2.4 MPa.

The choice of composition for plastic should be correlated with the working conditions of the material. For example, for vibro-loaded materials, a composition with increased bursting and shear pressure is chosen.

WATCH THE VIDEO

Technical characteristics of Poxipol

- Cold welding creates a seam that resembles the quality of a metal weld joint.

- The glue is easy to apply, it keeps its shape, does not spread, does not form drips even on vertical surfaces, does not increase in volume.

- After drying, it does not dry out, does not deform.

- The composition does not contain solvents, does not emit a strong odor, you can glue children's toys.

- In the open air, it is not toxic, but the glue line should not be in constant contact with water in open reservoirs, since it can harm their inhabitants.

| Characteristic | Value, description |

|---|---|

| Connection strength | 993 N |

| Cutoff voltage | 22 Mpa |

| The term that the mass retains its plasticity | Up to 10 min. |

| How long does Poxipol dry | 1 hour |

| Time before the start of operation | The surface / part must dry for at least a day. |

| Consumption for 1 sq. M. | 0.2-0.3 kg |

| Withstands exposure to chemicals | Water, precipitation |

| Withstands well exposure to chemical elements | Hydrochloric, nitric, sulfuric, phosphoric, acetic acid, sodium hydroxide, mineral, vegetable oil, plasticizers, toluene, gasoline |

| Heat resistance | The metal composition can withstand temperatures up to +80 ° C, transparent - up to +60 ° C. |

| Operating temperature | Should not exceed +120 ° C, otherwise the seam will burn out. |

It is impossible to glue under water, but after 10 minutes. after applying Poxipol, the glued object can be immersed in liquid. Detachment will not occur. The composition is non-flammable. The listed properties are possessed only by a properly combined epoxy with a hardener.

Application area

Instructions for use and technical characteristics of this glue are fully posted on the manufacturer's website. It describes in detail in what areas it can be applied, what properties it has.

Perfect for home repairs in workshops, designing all kinds of crafts. Assembly, fixing, joining of furniture interiors made of wood or metal. It is especially recommended for objects experiencing rather heavy loads. Remember this. Let's say - slats and crossbars of beds, crossbars at stools. Legs of tables, chairs, armchairs.

Repair of wooden or metal doors and windows, hingeing. Leaky tanks, water tanks. Filling and repairing cracks in the sink, bathroom, toilet. Fastening handles of hand tools. Almost the entire list, from a heavy hammer to a light mop. Bonding marble and granite blocks.

For the restoration of stucco, concrete, plaster or marble monuments. Securing a variety of fittings. For supporting in walls to hang heavy objects. In summer cottage gardening, installation of fasteners for hanging objects, tools and massive decorations.

Patching radiators made of non-ferrous alloys and fuel tanks on cars or motor vehicles. Also other everyday things. Boat frames or car bodies. Reinforcement and joining of seams in vehicles. Restores threaded connections. Docking and renovation of garden furniture from basic materials used.

Restoration of vases, flower pots, large porcelain items, gardening fountains. Bonding of concrete pipes for gutters or storm gutters. Plastic drainage systems. As you can see, the possibilities are great.

Advantages and disadvantages

Among the advantages of Poxipol, users highlight the following:

- Versatility. The adhesive is suitable for restoring various objects and fixing various materials. But it is preferable to use Poxipol when working with metal, with which this product provides the most durable connection.

- Allows you to quickly restore damaged items. Poxipol eliminates the need to buy a new crane, as it provides durable metal adhesion for a long time.

- Ease of use. To glue the damaged parts, it is enough to mix the components from two tubes, apply to the fragments and connect the latter together, pressing for 2-3 minutes.

- Multiple layers of glue can be applied. This feature allows you to eliminate deficiencies after the completion of the repair.

- Transparent consistency. Due to this, after application, Poxipol remains invisible from the outside.

Poxipol has a wide range of applications and is non-toxic to both humans and pets. Among the disadvantages of the glue are low tensile strength, inability to withstand high temperatures and vibrations.

Security measures

"Poxipol", the temperature of use of which should not differ from the recommended one, is used in accordance with safety measures

It is important to avoid contact of the composition with the skin and eyes, as this can cause irritation. If this still happened, then it is necessary to wash the skin with a solution of soapy water.

In the hardened state, the material is not toxic.

Fast tool welding

The tools are only pushed in and out of the welding press.Setting up new products is a simple exercise. Instruments can be changed with a few hand movements. The annoying and time-consuming time to control the temperature of the instruments is no longer required. This is why the ultrasonic welding process is called the cold welding process.

No cold weld welding - optically perfect and stable welds result in high quality, very flat products with consistent optical quality. In thermal resistance welding, heat is supplied from the outside and therefore must be above the melting point of the material. This leads to overheating and depletion of food.

Advantages and disadvantages

The demand for Poxipol cold welding and a large number of positive reviews are due to a number of undeniable advantages of the material.

- The versatility of the tool lies in the possibility of gluing together materials of different structure and density.

- Ease of use and availability of material. The composition can be purchased at any hardware or hardware store, which makes it even more popular with consumers.

- The possibility of forming a layer of any thickness is due to the stability of the composition to deformation and the preservation of the original volume after drying.

- Due to its thick consistency, the composition is excellent for working on vertical surfaces.

- The absence of solvents in the glue makes it possible to use the composition in living quarters in the presence of children and animals.

- Resistance to water makes it possible to use the glue in rooms with high humidity. The product can be used with moderate exposure to sulfuric and hydrochloric acids, gasoline and toluene.

- The material does not leave marks after drying, which allows you to glue objects without fear of streaks and stains.

The disadvantages of Poxipol cold welding include a low melting point of 120 degrees, which significantly limits the scope of the glue. There is a small package for models Poxipol 00266 and 00267, which has a volume of 14 ml, as well as a long time for the complete drying of the product. Low tensile strength values exclude the use of glue for work with parts that are prone to vibration and shock. The disadvantages include the need for thorough preparation of working surfaces with mandatory degreasing and dust removal of parts.