Features of the cladding

The procedure for working with different mixtures from Ceresit is different. The packaging for each type of glue contains instructions for use. After mixing, the solution should stand for at least 5 minutes, after which it is mixed again. A spatula is used for application, a notched float for leveling.

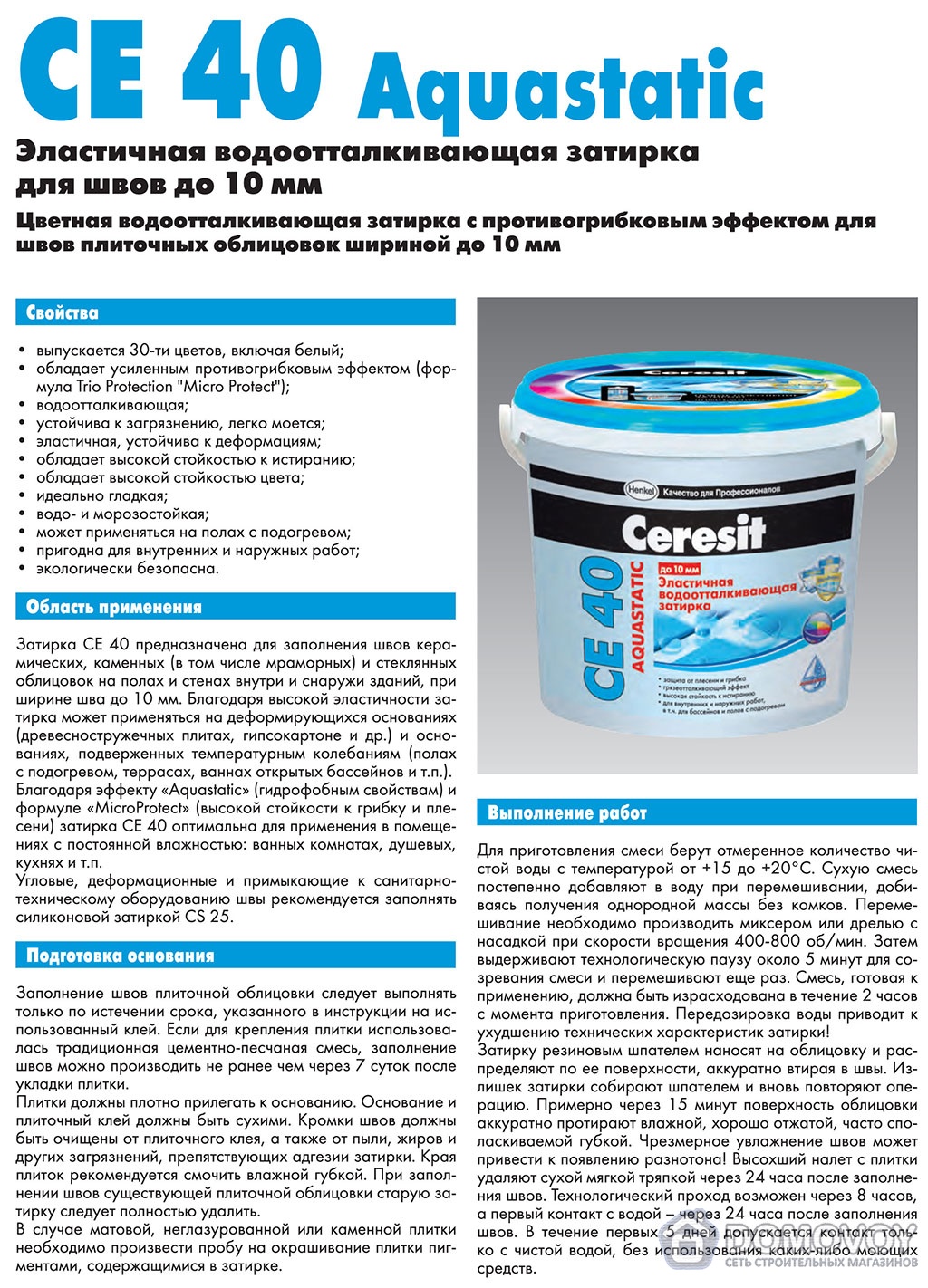

After fixing, the position of the plates can be corrected for another 10 minutes. Do not use Ceresit of the CM series for grouting, for this purpose the CE line is better suited.

The glue dries out within 24 hours, after which you can continue further work, load the surface and grout the joints.

Professional advice

It is necessary to carry out work with Ceresit at a temperature of +5 +30 degrees. The optimum humidity is 60%. In other conditions, the exposure time and the consumption time of the glue change.

Ceresit products contain cement and give an alkaline reaction in contact with water. Therefore, you need to take care of your personal safety.

It is important to protect the skin and mucous membranes from getting the finished mixture. If this happens, you need to rinse the area under running water.

In case of irritation, burns, allergies, you should consult a doctor.

When choosing an adhesive for substrates that are not indicated in the instructions for individual products, it is better to stop at the Ceresit CU line. If you have any doubts about the use of the composition for individual substrates, you can consult a professional or test the glue yourself on a small area.

Scope of application

Each Ceresit tile adhesive has its own areas of use. In particular, CM 9 Plus is best suited for small ceramic tiles on non-deformable substrates. CT 84 is a polyurethane adhesive suitable for expanded polystyrene and other mineral substrates.

Ceresit CM 11 tile adhesive is indicated for ceramics for external and internal facing work. CM 14 Extra is produced for porcelain stoneware and ceramics. Ceresit CM 17 glue is produced for those cases when increased elasticity is important. CM 16 is better for fixing all types of slabs inside and outside the yard. Ceresit CM 117 glue is most often used for facade tiles.

The most common representative of Ceresit CM 11 is used for the following coatings:

- Ceramics, porcelain stoneware, clinker, piece and natural stone.

- Parapets, stairs, floors, terraces, roofs.

- Anhydrite coatings, gypsum.

- Young concrete.

- Deformable coatings (with the addition of elasticizers).

- Pools and bulk water tanks.

CM 11 is perfect for regular exposure to moisture and liquids. It is used for cladding with a water absorption of 3% and a size of no more than 30x30.

Application area:

Cerezit glue CM-11 is intended for fixing ceramic and stone tiles with water absorption of more than 3% (size 30x30cm) on non-deformable mineral substrates, on walls and floors, inside and outside buildings, in civil and industrial construction.

It is allowed to use CM 11 glue for fixing tiles with water absorption of less than 3% (porcelain stoneware, clinker, stone, etc.) only inside buildings on unheated floors that meet the requirements of SNiP-88.

In the case of deformable substrates, heated screeds and other difficult substrates, it is recommended to use highly elastic CM 17 glue or CM 11 glue prepared with the addition of CC 83 liquid elasticizer.

Ceresit CM 11 glue with the addition of CC 83 elasticizer is recommended for use:

-

for fixing tiles with water absorption of less than 3% (porcelain stoneware, clinker, stone, etc.) on floors during outdoor work and on walls;

-

on heated screeds;

-

on plinths, parapets, external staircases, entrance lobbies, floors of balconies and terraces, operated roofs, etc.;

-

in open, as well as in sufficiently large covered tanks and pools;

-

on deformable substrates (chipboard, gypsum plasterboard, OSB and other boards);

-

on ceramic (including glazed) facings for external and internal work;

-

on durable paint coats with good adhesion;

-

on gypsum and anhydrite bases;

-

on lightweight, cellular and "young" ("age" from 1 month) concrete.

It is interesting: TechnoNICOL foam adhesive for expanded polystyrene - features of choice and application

Drying time table

I will give the drying time of tile adhesive using the example of popular cement-based compounds: from Ceresit and Unis.

| Adhesive name | Solution use time (in a bucket), hours | Working time (after application to the surface), minutes | Tile adjustment time, minutes | Grouting, hours |

| Ceresit CM 9 | 2 | 10 | 15 | 48 |

| Ceresit CM 11 Plus | 2 | 15 | 20 | 24 |

| Ceresit CM 12 | 2 | 20 | 30 | 24 |

| Ceresit CM 14 Extra | 2 | 20 | 20 | 24 |

| Ceresit CM 16 Flex | 2 | 25 | 25 | 24 |

| Ceresit SM 17 | 2 | 30 | 30 | 24 |

| Ceresit CM 115 | 2 | 20 | 25 | 24 |

| Ceresit SM 117 | 2 | 20 | 15 | 24 |

| UNIS XXI | 3 | 10 | 10 | 24 |

| UNIS Hi Tech | 5 | 25 | 15 | 24 |

| UNIS Belfix | 3 | 15 | 15 | 24 |

| Eunice Pool | 3 | 10 | 10 | 24 |

| UNIS Plus | 3 | 20 | 10 | 24 |

| UNIS Granite | 3 | 15 | 10 | 24 |

| UNIS 2000 | 3 | 10 | 10 | 24 |

With the addition of elasticizers (eg Ceresit CC 83), the time for using the mortar is reduced by about 25%, but the open time and the time for adjusting the tiles are increased. In this case, before grouting, it is better to wait twice the time recommended by the manufacturer.

Quick dry glue

There is a quick-drying tile adhesive that has a reduced setting and curing time:

| Name | Solution use time (in a bucket), hours | Working time (after application to the surface), minutes | Tile adjustment time, minutes | Grouting, hours |

| IVSIL EXPRESS + | 0,5 | 10 | 5 | 3 |

| Bolars Express Fast Hardening | 0,66 | 15 | 10 | 3 |

| Knauf-Schnelkleber | 0,5 | 15 | 10 | 3 |

| Founding Scorplix T-15 | 0,5 | 10 | 10 | 3 |

When working with such a mixture, it is important to knead the glue in small portions and apply full load on the coating after at least 24 hours.

Tile adhesive for outdoor work of the street frost-resistant

If the task is to put ceramic tiles outside the room, then it is better to use an option specially prepared for these purposes. It will contain all the necessary additives that will provide water repellency and the ability to withstand low temperatures. Such dry tile adhesives Ceresit CM include Ceresit CM 11, Ceresit CM 117.

Ceresit CM 11

Universal adhesive mixture designed for installation of tiles indoors and outdoors. It can also be used for installing porcelain stoneware inside buildings. It is used with veneers that have a water absorption of more than 3%. In this case, the size of the largest tile should be no more than 40x40 cm.

Ceresit CM 117

A universal building material that can be used for laying ceramic tiles of all types on any solid undeformed concrete, brick, cement screed surfaces.

The material has good water-repellent properties, frost resistance and strength characteristics, ensuring resistance to various mechanical influences.

Types of glue by area of use

The choice of glue is also necessary taking into account the operating conditions

Be sure to pay attention to this point. Any compositions are suitable for premises

But if you need glue for the floor in a seasonal dacha, in a bathhouse, in a gazebo, other objects on the street or in unheated rooms, you also need to pay attention to the temperature range. For such purposes, tile adhesive for external use is suitable.

So, here is what gradation according to special properties can be:

- for indoor use,

- formulations for external use,

- resistant to aggressive influences,

-

specialized with improved characteristics.

A few words should be said about specialized tile adhesive. These are formulations with polymer additives that change / improve the properties of cement. For example, a floor tile adhesive with improved adhesion is used when laying tiles on smooth substrates. Compounds remaining elastic after drying - for laying tiles on wood, etc. In the bathroom or shower, the kitchen needs increased resistance to moisture. Here you will need to look for a moisture-resistant tile adhesive. When laying outdoors - on a porch, terrace, in a gazebo, in an unheated summer cottage - frost resistance will be needed. There are also such compositions. In principle, any problem today has a solution. You can find tile adhesive even if you want to lay tiles on tiles.

Recommendations

Do not rush while stirring. It is necessary to accurately assess the consistency of the solution. To do this, they are a little typed on a trowel, and then the tool is tilted. If the solution falls off in a piece, then you need to increase the amount of water.

The amount of liquid should be increased only during the initial mixing of the glue. After 2 stirring, if the glue thickens during operation or begins to clump, then you should not add water. It is advisable to use a mixer to mix the solution. This is necessary to restore its consistency for a while, which will help finish the work.

If the solution flows down, creeps, then some time is needed for partial setting, and the next portion is prepared with the required amount of liquid. If the adhesive holds firmly, then the mixture can be used.

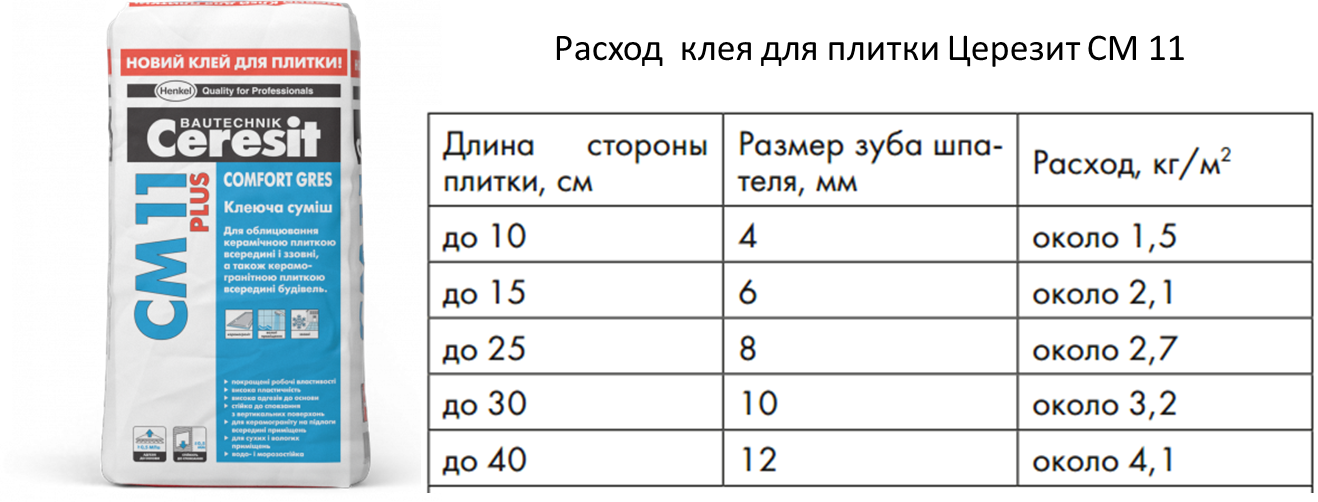

Main technical characteristics

"Ceresit CM 11", the technical characteristics of which should be read before purchasing the composition, can be used after mixing for 180 minutes. In order to know how much volume is needed to carry out the work, it should be noted that about 1.7 - 4.2 kilograms will be needed per square meter. The final figure will depend on the thickness of the layer to be laid, as well as the material at the base of the decorative finish of the subfloor.

It is important not only to choose the right adhesive composition, but also to observe the technology of its mixing. Thus, for 1 kilogram of the mixture, 0.24 liters of water will be needed.

And for 25 kilograms of dry composition, which is equal to one bag, you will need 5 liters of water. When laying, the master must observe the thickness of the recommended layer, which is equal to 6 millimeters. The open time is 15 minutes, which is why it is important to lay the tiles before the mixture sets. The master has the ability to correct the final position of the product after laying it for 20 minutes.

Tile adhesive for warm floors

It is often necessary to lay it on a heated floor. This is a serious factor that can lead to unexpected results in the future. This is due to the natural linear expansion under the influence of temperature, therefore, such a tile adhesive should have improved adhesive properties that remain even under high temperature conditions.

The brand offers the following types of mixes that can be used in underfloor heating systems. These include Ceresit CM16 flex and Ceresit CM 12.

Ceresit CM16 flex

High-quality cement-based adhesive with improved adhesive properties and good plasticity. It is perfect for interior and exterior cladding, which is ensured due to the presence of special hydrophobic and plasticizing components in the composition. With such a composition, grouting can be started after 24 hours with normal drying.

Ceresit CM 12

A composition specially developed by the brand, used for laying large ceramics or porcelain stoneware with dimensions of 60x60 cm and a considerable weight. The peculiarity of the material is that it is able to withstand many cycles of complete freezing and at temperatures down to -30 degrees.

If it is required to perform work on deformable substrates, then it is recommended to add CC 83 elasticizer to the mortar.

Main characteristics and their influence on the choice of adhesive composition

Felling tiles - the result of choosing the wrong brand of glue

For fixing porcelain stoneware outdoors, an adhesive with a high degree of frost resistance is required.

Facing with ceramic mosaic in the bathroom is carried out with moisture-resistant glue

- if the base is cellular concrete (gas and foam concrete), gypsum blocks and drywall, all types of cement-based blocks: cinder blocks, expanded clay concrete, etc .;

- when installing a warm floor, it prevents the tiles from peeling off as a result of temperature deformations from heating and cooling;

- for large-format slabs - provides a longer period for correcting the position of the tile after laying, which is very important when facing the surface with heavy large slabs of porcelain stoneware;

- when using glazed ceramic tiles - this is not directly indicated in the specifications, but in practice, the use of an adhesive with low elasticity can provoke the appearance of cracks on the glazed surface. Obviously, this is due to the occurrence of internal stresses from the influence of deformation of the base, which is directly transmitted to the cladding through inelastic glue.

Laying of ceramic tiles on a warm floor is carried out with an adhesive mixture with high elasticity

High spreadability of the adhesive mixture allows it to fill all the voids under the tiles

Laying ceramic tiles on a wall without a support strip is only possible with highly thixotropic compounds

The application of tile adhesive over a large surface area is allowed only with a significant period of open time of use.

The correction time of the laid tiles is an important indicator, especially if you are going to do the installation with your own hands.

Types of glue

Depending on the peculiarities of the application of glue for ceramics, the Ceresit brands are divided into different types. They also determine different areas of their application. For example, CM 115 can be used for external and internal work when installing tiles of any type. Possesses high adhesion and strength characteristics.

Therefore, all products of the presented brand should be divided into the following types:

- For outdoor use. It includes building mixtures, which include fine-grained selected sand, polymer binders, hydrophobic and plasticizing additives, which make the compositions resistant to water and plastic for applying glue in an even layer on tiles of various parameters. They also contain components that improve the resistance to low temperatures, ensuring sufficient strength and integrity of the screed or adhesive layer in case of repeated freezing.

- For interior decoration. It is more simplistic in terms of using specific components. The mortar, as a rule, is made on a cement base, provides acceptable adhesive properties and has good water repellency.

You should also divide the trains by destination:

- for tiles on ordinary surfaces;

- for tiles and porcelain stoneware on heated floors.

Tile features

Tile type

This is the material from which the tiles are made.

For example, for tiling with mosaics or natural light

with a stone, preference should be given to adhesive solutions based on white cement. V

otherwise, it will be difficult to give the surface a well-groomed look.

There is a special glue for fixing porcelain stoneware. His

the application is dictated by the peculiarity of this type of tile. It is distinguished by high

density, low water absorption, low adhesion ability. Insofar as

porcelain stoneware does not absorb glue, and at the same time has a significant weight,

then to fix it, you need to use special compounds. These include

glue for porcelain stoneware Werker, Hercules, Litoflex K 80 or tile adhesive Eunice

A plus.The general requirement for adhesives in this case is that it must be reinforced.

Tile dimensions

Professionals know that for the correct fixing of tiles

the thickness of the mortar to be applied should be equal to the thickness of the tile itself.

Accordingly, the size of the tiles plays an important role in the choice. But more importantly

thicknesses are geometric dimensions. This is due to the fact that the larger the tiles,

the more weight it has, which means that the fixing should be

the ability of the selected adhesive.

Thus, tiles with sizes from 100x100 to 300x300 mm are quite

will hold all-purpose adhesive. But for larger samples, a reinforced

tile adhesive. Of course, these requirements are important for wall cladding. For

floor tiles, such a requirement is insignificant.

Component selection

Analyzing the topic of how to properly dilute the tile adhesive, you should familiarize yourself with the choice of suitable components. The environment is of particular importance, eg temperature. Attention to detail affects not only the consistency and characteristics of the solution, but also the consumption of glue per 1 sq. m. The following points are important:

- Water. Most manufacturers believe that mixing should be done with clean water. But no one means that the liquid must be drinkable. The unsuitability of industrial water is the presence of impurities, acids and alkalis that affect the properties of the solution.

- Temperature. Preparation of the composition should be carried out at a temperature of 5 to 40 degrees. But the best indicator is the room rate - 18-24. In such conditions, the components react quickly, and it will not be necessary to prepare the solution for a long time.

- Temperature difference. The mortar that will be used during the laying of the tiles must be prepared from seasoned materials. This means that the water and the building mixture must have the same temperature. It is advisable that they were longer in the room, so that they were equal in warmth to the air.

Working at room temperature stabilizes the glue consumption per square meter. m. In the cold, the product deteriorates, and it is not so easy to calculate its amount. And in hot weather moisture quickly leaves the solution. Another important factor that affects product performance is the cleanliness of the mixing vessel.

Before performing work, the container must be cleaned thoroughly, removing the frozen remnants of the past with a solution, as well as removing plaque on the walls. During kneading in such a dish, there will be no chemical effect on the glue. The same requirement applies to the construction mixer and drill attachment. A clean container and stirrer reduces lumps for an even consistency.

What is good about Ceresit glue

Now let's take a closer look at the merits of Ceresit

In order to make sure of this as reliably as possible, you should pay attention to reviews about ceresit glue cm 11 from people who have already worked with it

All of them first of all note that this glue mixture is universal in use and there are no restrictions in its use.

She is not afraid of exposure to high and low temperatures, and also has an optimal degree of humidity.

After solidification, the presented solution is not afraid of long-term and short-term exposure to moisture, which is also its indisputable advantage.

Builders pay attention to the fact that, provided that it is used, it is possible to glue the tiles from top to bottom, and at the same time it will not slide along the horizontal plane.

Another advantage of this mixture is that there are no additives and substances harmful to humans in its composition.

First of all, a high degree of adhesion should be noted, that is, Ceresite can quickly and firmly adhere to a wide variety of surfaces, while it is only important that the surfaces are pre-cleaned.

This mixture is elasticized, which allows you to use it for outdoor work and use it with ceramic tiles with a high degree of moisture permeability.

He is not sensitive to high and low temperatures, and is also not afraid of their sudden changes.

When using this glue mass, "slipping" of the tile during its gluing in different directions is excluded.

The versatility of this adhesive mass has made it so popular today.

Please note that it can be used even on screeds equipped with heating systems.

In addition to all of the above, one cannot fail to note the complete safety of the presented glue, since it does not include any toxic components.

In the process of work, its consumption is minimal, however, the quality of adhesion remains at a high level due to the high degree of adhesion.