Method of application and consumption

Foam glue is applied to the thermal insulation boards immediately before their installation on the surface to be insulated.

Foaming adhesive can be applied in two ways: from a balloon or using an assembly gun. The second option is more convenient and allows better control of foam consumption.

- Place the cylinder in a vertical position on a flat surface, remove the protective cap. If you have an assembly gun, align the cylinder valve with the gun bridge. Shake the can for 20-30 seconds.

- Glue is applied along the perimeter of the slab, retreating from the edges by 1.5-2 cm, in strips 3 cm wide. Another strip is applied in the center of the slab from top to bottom. After application, it is necessary to wait 5 minutes for the foam to expand as much as possible under the influence of oxygen from the environment.

- The thermal insulation board is tightly applied to the wall, fixed in place. You can move the plate for 10-15 minutes until the adhesive is fully set. When moving the stove, do not pull it off the wall. The gap between the plates should not be more than 3 mm.

- After installing all the plates, the joints between them are filled with foam. Large gaps are filled with pieces of expanded polystyrene. Excess foam after drying (at least 24 hours) is cut off with a knife. Fresh glue is best removed with a specially designed “TechnoNicol Foam Cleaner”.

Applying the product to polystyrene foam

Foam consumption, according to the manufacturer, is 1000 ml per 10-12 sq. meters of the insulated surface. One cylinder with a volume of 750 mm is enough for an area of 8-10 sq. meters, and 400 ml - for 4 sq. meters. Please note that the degree of evacuation of the contents of the cylinder, that is, the actual volume used for the 500 PROFESSIONAL is approximately 95%, and for the XPS formulation it is slightly less - 85%.

A few words about penoplex

To begin with, let's bring some clarity to the concepts. What is penoplex, which will be discussed in the future?

Rigid polystyrene-based insulation can be divided into two large groups. Although the initial raw materials are the same, differences in production technology result in materials with rather serious differences in some technical and operational characteristics.

According to one of the technologies, polystyrene granules swell under the influence of temperature and steam, becoming air-saturated balls. This mass is poured into a compact in predetermined forms, the balls literally stick together, forming the material that is known to everyone under the name of ordinary white foam.

Foamed polystyrene granules and insulation boards obtained as a result of pressing them.

The technology captivates with its simplicity and low cost, which, in principle, predetermines the mass production of foam (there are probably small enterprises in any more or less large city), affordability, and, accordingly, the popularity of this insulation.

Meanwhile, he has quite a few very serious shortcomings. Many of them can be eliminated during the production of insulation using a different, more advanced technology.

This technology involves the complete melting of the raw material with the subsequent introduction of a foaming agent into it. The resulting foamed mass is passed under pressure through the forming nozzles of a special extruder. And then, solidifying, it forms a strip of the required thickness, which is further cut into blocks of standard sizes.

Extrusion line for expanded polystyrene insulation boards.

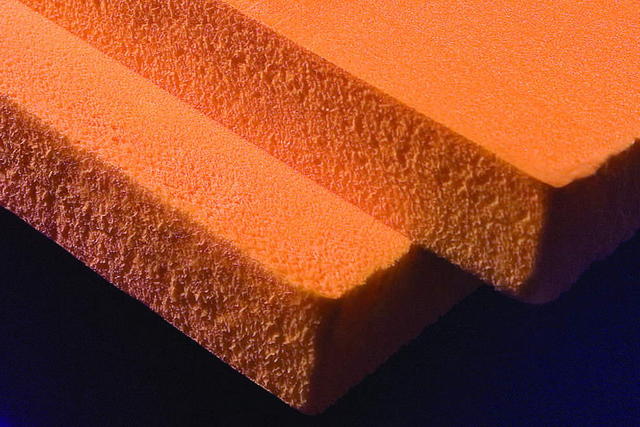

As a result of such processing of raw materials, a homogeneous gas-saturated mass is obtained, each cell of which is isolated from the neighboring ones.This gives an even predetermined density, a pronounced low coefficient of thermal conductivity, increased durability, resistance to mechanical stress, temperature extremes and moisture, more noticeable resistance to fire. In short, the material is more perfect. True, this also affects its cost - it is not an example more expensive than ordinary foam.

Even with the naked eye, a significant difference in the structure of extruded polystyrene foam from ordinary white foam is visible.

Extruded polystyrene foam (EPS or XPS) is also supported by the fact that, due to the higher complexity of the technology and the need for special expensive equipment, large enterprises are mainly engaged in the production of such insulation, and not semi-handicraft workshops. That is, the likelihood of purchasing a low-quality or even dangerous material for use in housing construction that does not meet either GOST or even TU is much lower.

Due to its numerous advantages, a higher level of safety of use, and despite the "loss" in affordability, EPS is becoming more and more in demand. The zealous owner will choose him.

One of the leaders of the domestic market in the production of insulation materials based on extruded polystyrene foam is the Russian company "Penoplex". Its products are in great demand and are well known both on the territory of the Russian Federation and abroad.

Insulation boards of the Penoplex company are of a corporate orange color.

The range of the company includes slabs that can be used on almost all construction sites.

Of course, Penoplex is not the only manufacturer of such thermal insulation. Many well-known companies (for example, TechnoNikol or Knauf) also offer such heaters in their assortment. But it so happened that, at least among domestic builders, the name of the company "Penoplex" has become a household name, slightly transformed. And now very often all plates of extruded polystyrene foam are called penoplex.

How to predict the consumption of foam glue?

One important question remained unclear for us - how to calculate how many cylinders of glue-foam will need to be purchased to perform a particular volume of masonry work.

As already emphasized earlier, there is no unity in the assessment of material consumption among manufacturers. Therefore, it is necessary to rely more heavily on the "empirical" way of calculation. Yes, it will turn out to be more accurate: nevertheless, the difference depending on the size of the blocks can be considerable - if the area of the masonry or the volume of the acquired aerated concrete is equal

So, if the sizes of the blocks are known, it is not difficult to calculate their number. The "pattern" of stripes for different wall thicknesses is also known. That is, if you wish, you can determine the total length of all strips of glue-foam that will be applied when laying the wall.

Despite the difference in the estimates of the consumption by the manufacturers, and the differences in the declared characteristics, the base material of the glue-foam, polyurethane foam, is obtained from similar components, has approximately the same coefficient of expansion after release from the cylinder. In terms of volume and filling of cylinders, this is also an approximate parity. And if you listen to experienced craftsmen, then a standard cylinder, regardless of the manufacturer, is capable of giving about 80 running meters of glue with a strip thickness of about 20 mm. It would probably be more correct to count all the same about 75 meters - with a margin for purging and for the possible absence of the composition from an almost completely empty cylinder.

Having "on hand" the above data, it is already easy by simple division to calculate the recommended number of cylinders for laying.

All this algorithm is implemented in the online calculator offered to the reader's attention.

It's easy to work with him.

- First of all, it is necessary to indicate the size of the blocks from which the masonry will be carried out.Since the dimensions are standardized, you just need to select the desired values from those listed in the appropriate input fields.

- Next, you should choose "from which stove to dance": either from the area of the wall being erected (minus the area of openings, door and window openings), or from the volume of purchased aerated concrete blocks. After selection, the corresponding fields will become available for specifying either area or volume.

- Finally, when purchasing any building materials, a reserve is traditionally made for various unforeseen circumstances, or, frankly, not insufficient experience of a novice master. The calculator also takes this circumstance into account - the calculation can be carried out without taking into account the reserve, or lay 5 or 10% of the reserve.

The calculation result will be shown by the number of cylinders. Rounding up, of course.

Calculator for calculating the number of glue-foam cylinders for gas silicate blocks

* * * * * * *

And in order to complete the review of adhesives intended for laying aerated concrete blocks, we offer a video in which experts are trying to conduct a substantive comparative analysis of competing materials.

General rules of application

The surfaces to be glued are cleaned before applying the glue-foam. Remove dust, bitumen, grease, dirt. They work only with dry aerated concrete blocks.

Ultraviolet radiation affects the properties of the glue, therefore, after hardening, it is covered with a protective layer, a layer is applied on top:

- gypsum;

- paints;

- sealant.

Masonry

Glue-foam "Macroflex" is used to connect blocks of partition walls. The product is not intended for load-bearing walls. The masonry is made in blocks of the correct shape of the same size. Deviations in dimensions should not exceed 1 mm. Foam should not be used if the blocks are hollow. The base for the first row is leveled. It should be flat, strictly horizontal. Controlled using a building level. Glue-foam is applied to the ends of the block (vertical, horizontal) in strips, retreating from the edge of 3-5 cm. It is necessary to remove the unsuccessfully placed element within 1 minute.

During work, 3 minutes are taken as a reference point, this is the time during which several operations need to be performed:

- apply glue to all surfaces of the block;

- install it in place;

- easily tap the block from above to align it horizontally;

- check the horizontal level.

A wall folded with Macroflex glue-foam can be plastered after 2 hours.

Gypsum panels

First prepare the surface of the wall (ceiling). Remove remnants of previous finishes, wallpaper, paint. Prime if the surface quickly absorbs moisture, then proceed to the main work:

- put the panel on a flat surface;

- retreat from the horizontal edge 5 cm;

- squeeze out the first strip of Macroflex glue-foam, leading it parallel to the edge;

- apply subsequent strips in 15 cm increments, observing parallelism;

- place the last strip 5 cm from the edge.

For a quick and high-quality application of glue-foam, it is worth purchasing a specialized (professional) model of a gun. When installing a gypsum panel, you need:

- apply glue;

- install the panel in 3 minutes;

- press down the panel to the main surface, adjusting its position;

- hold for 5 minutes until the foam holds the materials together.

After 2 hours, you can start the next stage of work.

Window sills

Clean the surface of the window opening. Dirt and oil stains impair adhesion. You can remove them with white spirit. Squeeze glue foam onto the prepared window sill. Apply it in parallel stripes. For a firm fixation, 2-3 extruded tapes are enough.

Stair steps

When fastening steps to wooden spacers, the glue strips are applied parallel to the edge. For a narrow step, 2 spacers are enough. The wide one requires 3, 2 at the edges, one in the middle. When applying glue, a standard distance of 10-15 cm is maintained between the strips. Within 3 minutes, the step is set in place, aligned, pressed. So that it does not rise up, they put a load weighing at least 10 kg on it. They remove it after 60 minutes.

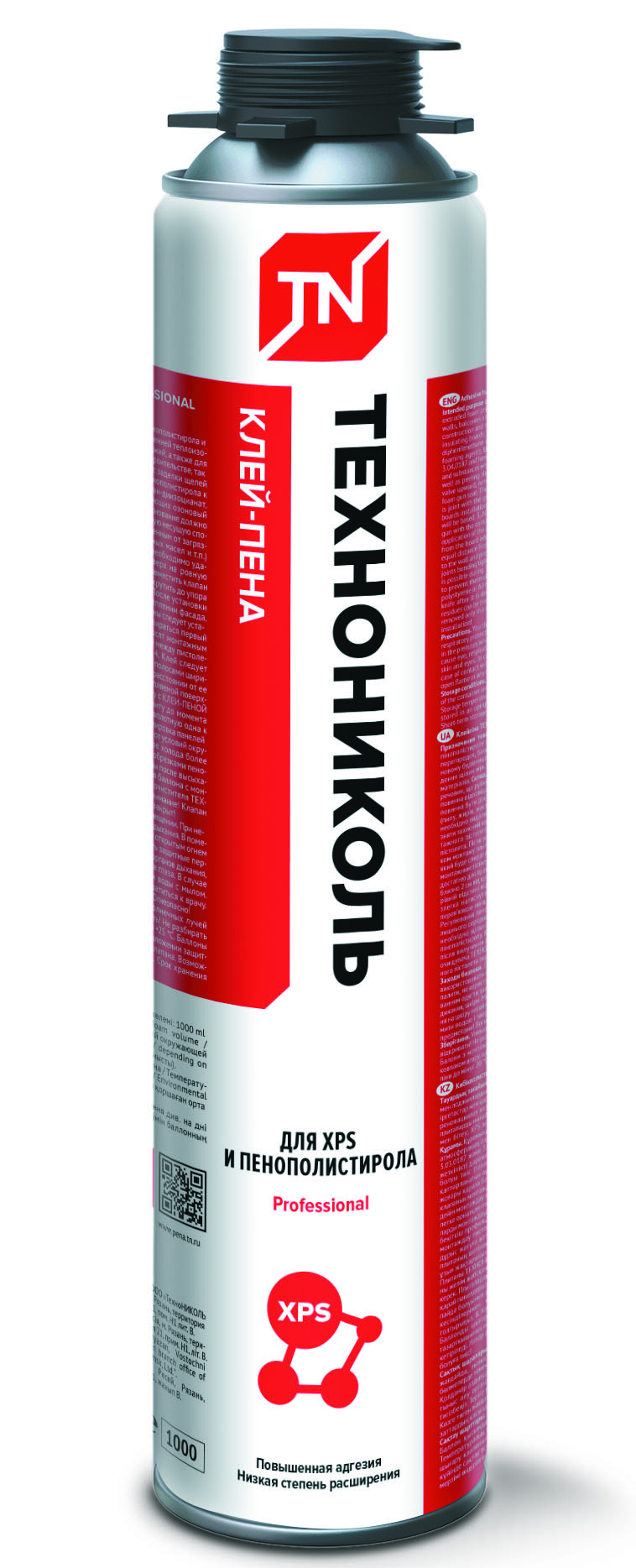

Features and characteristics

Glue-foam "TechnoNICOL" is a one-component polyurethane adhesive, with the help of which the installation of expanded polystyrene and extrusive boards is carried out. It has high adhesion rates, which makes it suitable for concrete and wood substrates. Due to special additives, the polyurethane foam is fireproof. It can be used to insulate surfaces with insulating plates and seal joints between them.

Installation fire-fighting foam adhesive for expanded polystyrene is characterized by ease of use and reduced time for insulation. It is suitable for working with aerated concrete, plasterboard, glass-magnesium sheets, gypsum fiber. This material is produced in metal cylinders with a capacity of 400, 520, 750, 1000 ml. The consumption of the composition is directly related to the volume of the binder. For example, for professional glue with a volume of 1000 ml, it is 750 ml.

Adhesive properties allow for temporary bonding of XPS and EPS boards. It provides for fixing to cement plaster, mineral surfaces, chipboard, OSB.

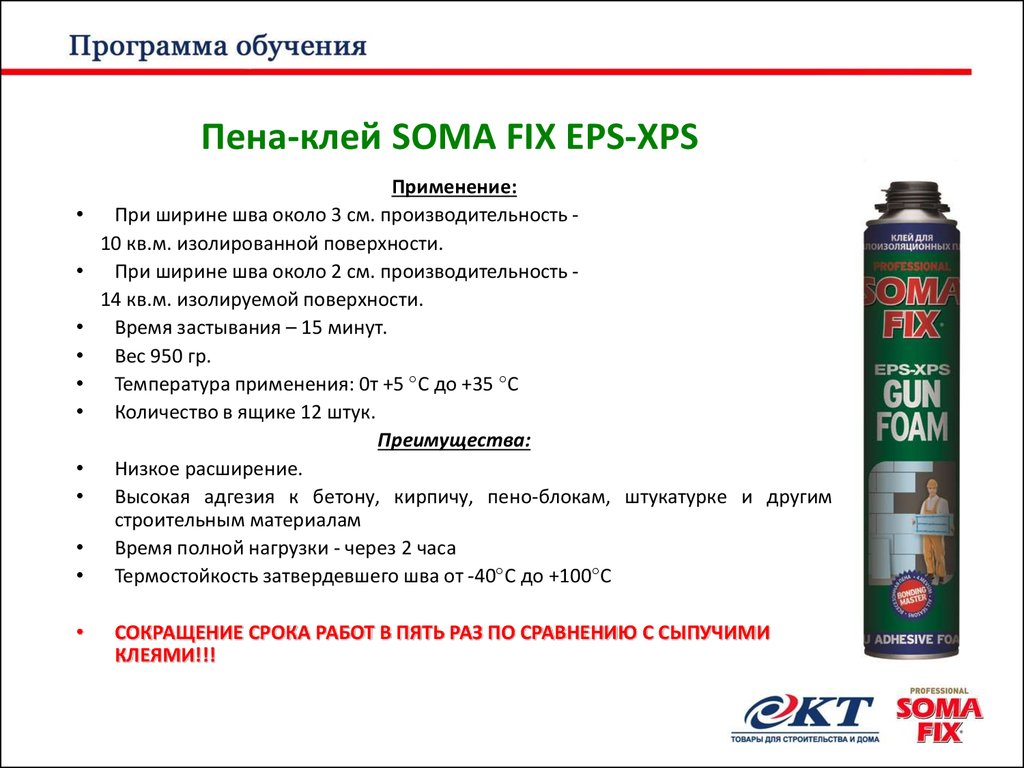

The technical characteristics of the glue-foam are as follows:

- consumption depends on the volume of the cylinder and is 10 x 12 sq. m with a volume of 0.75 liters and 2 x 4 sq. m with a volume of 0.4 l;

- material consumption from the cylinder - 85%;

- peeling off time - no more than 10 minutes;

- initial polymerization (solidification) time - 15 minutes;

- full drying time, up to 24 hours;

- the optimal level of humidity during work is 50%;

- density of the composition after final drying - 25 g / cm3;

- the level of adhesion to concrete - 0.4 MPa;

- thermal conductivity level - 0.035 W / mK;

- the optimal temperature for work is from 0 to +35 degrees;

- adhesion to expanded polystyrene - 0.09 MPa.

Storage and transportation of the cylinder is carried out exclusively in an upright position. The storage temperature can vary from +5 to + 35 degrees. The warranty period during which the adhesive foam can be stored is 1 year (in some varieties up to 18 months). During this time, the temperature regime can be reduced to -20 degrees for 1 week.

This is interesting: Features of metal siding under a tree

What is foam glue

The Technonikol product is a mixture of glue and foam. It is a modern assembly and construction material that combines all the positive aspects of foam sealants and construction adhesives. Purpose - installation, gluing of heat-insulating plates during the implementation of external insulation of structures, porous blocks, external seams of structures. Adhesive foam is suitable for performing internal insulation work in apartments and country houses, when it is necessary to seal the joints between the walls, to use it when fixing and installing drywall, glass-magnesium sheets, OSB, wood, plastic, etc.

The product has a number of advantages over analogues:

- immunity to moisture and mold, decay;

- moderate consumption;

- slight adhesion;

- low thermal conductivity;

- weak susceptibility to negative weather external factors;

- affordable price;

- availability for sale;

- excellent recommendations from specialists in the field of construction;

- long shelf life with preservation of the original properties;

- low fire hazard;

- ease of use.

What is the difference from polyurethane foam

Polyurethane foam or glue-foam? It is difficult for an uninformed person to figure it out. To understand the difference between these materials, you need to compare them. Polyurethane foam is a polyurethane sealant. Purpose - installation. Additionally, it has sound and heat insulating properties. Used when installing doors, filling gaps, sealing seams. It can be used to fix building materials, but the expansion it gives when solidifying makes fixing problematic.

Foam adhesive is a polyurethane adhesive. Its main function is to connect parts. It differs from polyurethane foam in its qualities.Its adhesive ability and adhesion is several times better than polyurethane foam. This is achieved through special additives. The foam adhesive does not expand. The increase in volume is minimal. In order to evenly glue the panel to the wall with mounting foam, additional fixation is needed. Otherwise, the foam, expanding, will lift the slab. When working with foam glue, no fixing devices are required. The panel is simply attached to the wall and pressed.

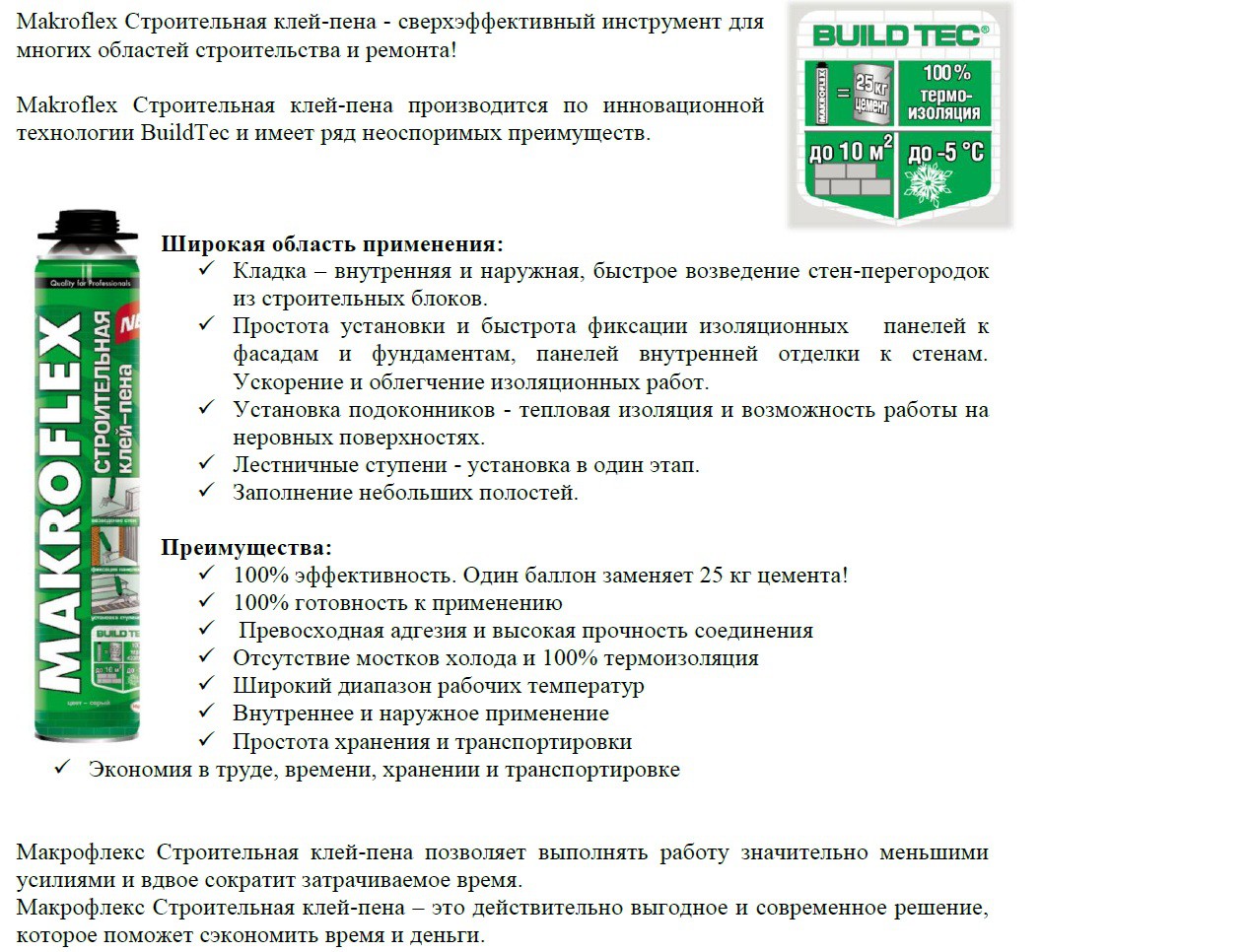

Description and purpose

Polyurethane is the basis of a product designed for fixing expanded polystyrene boards. With the help of foam glue, the insulation plates are fixed on the inner and outer walls of the house. No special skills are required for installation work. A non-specialist can work with a construction tool.

> The adhesive foam contains additives that increase adhesion, it is several times higher than that of classic polyurethane foam. Scope of glue-foam from the company "Macroflex":

- glue brick blocks;

- fix facing slabs made of stone, wood;

- fix plasterboard plates;

- glue window sills indoors and outdoors;

- fix thermal insulation materials to the facade, foundation.

Glue-foam is a new product. It was specially developed for bonding polystyrene and foam boards. Previously, agents with cement binders were used for this purpose. Aerosol polyurethane foam is used for gluing different materials:

- cardboard;

- plywood;

- GVL;

- Chipboard;

- drywall;

When using construction foam, work efficiency is increased. Operation of the product does not require additional equipment, water consumption, or energy consumption. There is no dirt or dust at the work site.

Types of glue-foam

This brand of foam adhesive is a one-component polyurethane adhesive. It allows you to mount products from extruded polystyrene foam and regular foam. The composition of the material is represented by various target additives, and isocyanate oligomers play the main role in it. They are able to actively displace propane and isobutane during the reaction with oxygen from the ambient air. Distinctive properties of glue-foam are as follows:

- providing good thermal insulation;

- reliable fixation with the base;

- resistance to mold, moisture;

- excellent wear resistance and long service life.

The insulating and adhesive qualities of the foam glue are at a high level. This allows you to use a tool for attaching expanded polystyrene to concrete, brick, wooden walls and other bases. It is widely used in works with plasterboard, aerated concrete, gypsum fiber, glass-magnesium sheet. There are two main types of "TechnoNIKOL" for expanded polystyrene, they are described below. Each product is sold in bottles of 400, 750, 1000 ml.

TechnoNIKOL 500 Professional - universal glue-foam

This product is the most popular in the series, it has excellent bond strength and high adhesion to any surface. It is widely used for XPS (Extruded Polystyrene Foam), including thermal insulation boards made of this material. Also, the foam can be used to seal the joints between the slabs during the arrangement of the insulation:

- roofs;

- foundation;

- basement;

- basement floor;

- outside the house;

- inside the house and apartment.

Foam glue is suitable for filling cracks in walls, fixing plastic, sheet metal, panels, drywall, mineral wool. The glue will fill any voids, cavities. It can also be used to glue tiles on the roof, decorative elements - plinths, cladding, stucco molding. The universal product is suitable for all types of substrates listed above, as well as for plaster, chipboard, tiles, porcelain stoneware.

The technical parameters of TechnoNIKOL foam are as follows:

- thermal conductivity - 0.035 W / mk;

- setting time with the base - 10 minutes;

- final drying - 24 hours;

- density of the finished adhesive layer - 25 g / cu. cm;

- the shade of the foam after hardening is blue;

- temperature during work - from 0 to +35 degrees;

- recommended humidity when gluing boards - up to 55%;

- adhesion to extruded polystyrene foam - 0.13 MPa, concrete and wood - 0.15 MPa, metal - 0.07 MPa.

Within the first ten minutes, you can change the position of the glued board, which is ideal for beginners.

TechnoNIKOL for expanded polystyrene

This material is designed for gluing polystyrene foam boards, it is perfect for arranging thermal insulation. The composition contains polyurethane, which tends to increase in size by 10%. With the use of this glue-foam, you can attach expanded polystyrene to buildings from the outside and from the inside, insulate basements and the foundation. It seals the joints between slabs, removes holes and voids.

The technical parameters of the product are similar, the difference is in the initial setting period. It is slightly larger than all-purpose glue (15 minutes). It also differs in the color of the finished layer (gray). If necessary, you can use "TechnoNIKOL" for expanded polystyrene and for fixing other materials, but the manufacturer recommends using it for its intended purpose.

Suggested brands of glue-foam for block masonry

It probably makes sense to look at the range of similar adhesives available in hardware stores. Just to compare the characteristics of different brands and the level of prices for them.

It is clear that it is difficult to consider all brands without exception, and, probably, it is not necessary. Let's take a look at the most popular among our builders - this will be enough to complete the overall picture.

| Illustration | Name and main characteristics of the glue | The approximate cost of a cylinder |

|---|---|---|

|

TechnoNIKOL is one of the most popular brands among domestic builders. Designed for laying load-bearing and self-supporting walls and partitions made of aerated concrete and ceramics. Application temperature - from -10 to + 35 ℃. Peel strength - 0.12 MPa, which corresponds to 1.2 kgf / cm² - an approximate parity with the calculated resistance of aerated concrete brand B2 in tension (1.22 kgf / cm²). Complete polymerization - after 24 hours. Evacuation of the contents of the cylinder - not less than 94%. The output of the glue-foam is up to 40 running meters with an average strip width of 30 mm. |

from 320 rubles | |

|

KUDO PROFF 28+ ABL - despite its unusual name, it is a Russian brand owned by Troll-Auto LLC. Foam adhesive based on polyurethane foam, a wide range of possibilities, including for the construction of self-supporting walls from aerated concrete blocks. Adhesion to aerated concrete - 0.3 MPa (3 kgf / cm²). Application is allowed at negative temperatures - up to -10 ℃. Polymerization - 24 hours. The block is laid in no more than 2-3 minutes. after glue application (open time). Correction possibility - 2 min. Consumption is indicated as "vague" - the balloon corresponds to a bag of dry glue or 1 m³ of masonry |

from 325 rubles. | |

|

PROFFIX 101 is a professional quality foam adhesive with a very wide range of possibilities in construction and decoration. Manufacturer's declared characteristics: - correction time - up to a minute, - initial setting - up to 3 minutes, complete polymerization - from 2 hours, depending on working conditions and material. The exit from the cylinder is from 100 to 300 running meters with a strip width of 10 to 15 mm. |

from 400 rubles | |

|

TYTAN PROFESSIONAL is one of the most popular formulations. Designed for the construction of load-bearing walls and partitions from high-quality blocks with geometry deviations of no more than 3 mm per 1 running meter. The tensile and shear strength of the bond after complete hardening is about 0.15 MPa. Open time - up to 1 min., Block position correction - up to 3 min. Complete readiness of the masonry - in 24 hours. The declared foam yield is up to 60 linear meters. |

from 390 rubles. | |

|

"CERESIT CT 115" is a product of a well-known European brand. The purpose is to praise internal partitions made of aerated concrete blocks. Application temperature - from -5 to + 35 ℃. Adhesion to aerated concrete - 0.3 MPa. The approximate consumption declared by the manufacturer is 1 cylinder per 10 m² of masonry made of blocks with dimensions of 600 × 200 mm and a thickness of 100 mm. |

from 300 rubles. | |

|

"YTONG DRYFIX" - glue for masonry partitions inside the building. Application temperature - from -10 to + 35 ℃. Open time - up to 3 minutes. Complete polymerization - after 12 hours (under optimal conditions). The declared yield of glue-foam is up to 110 linear meters of strip up to 15 mm thick. |

from 450 rubles | |

|

"PENOSIL Premium StoneFix 827" is a foam adhesive, in the characteristics of which it is specifically indicated that it is intended for. Application temperature - from -5 to + 35 ℃. Curing - within 5 minutes, full polymerization - 24 hours. Consumption in the list of characteristics is not specified by the manufacturer. |

from 280 rubles. |

You can see that despite the difference in brands, the approximate price level is equal. But the purpose of some formulations is clearly limited only by internal non-bearing partitions, which should be taken into account when choosing.

It is interesting that in matters of glue-foam consumption, manufacturers clearly do not adhere to any uniform units of measurement. But we will talk about consumption in more detail below.