Advantages and disadvantages

The advantages of polyurethane foam, in principle, are all on the surface. It is difficult to imagine modern construction or renovation work without this material. First of all, this substance is simple and convenient to use, while it has excellent adhesion to many building materials, which makes it universal. The filling capacity of the material also remains undoubtedly.

Since the pressure after Macroflex expansion remains minimal, the foam distribution is very accurate. In this case, losses are reduced to zero. After curing, the foam turns into a solid building material with a cellular structure, the mechanical strength of which is high. In addition, the sealant does not conduct sound and helps to retain heat.

Since the pressure after Macroflex expansion remains minimal, the foam distribution is very accurate. In this case, losses are reduced to zero. After curing, the foam turns into a solid building material with a cellular structure, the mechanical strength of which is high. In addition, the sealant does not conduct sound and helps to retain heat.

In addition to the fact that the polyurethane foam is resistant to moisture and does not age, there is no doubt about its safety for humans. The material is completely non-toxic, both in liquid and solidified form. The composition does not contain propellants that can harm human health. The smell of this material is completely absent after hardening.

However, any building material may have its drawbacks. Polyurethane foam makroflex 750 ml, the presented technical characteristics of which are no exception. For example, it is rational to use it only for rather impressive seams (up to 40 cm), since minor defects look more jewelry work. In addition, "Macroflex" is not frost-resistant, it can be destroyed under the influence of sunlight. In this case, it is not desirable for the frozen foam to be in water, since the liquid, getting into the pores, can destroy the structure.

If you plan to use foam in an aggressive environment, then this point is also undesirable. This is due to the vulnerability of the foam structure under the influence of various destructive substances, such as hail, snow, exhaust gas, too sharp a drop in temperature or pressure. At the same time, it is unacceptable to use only foam for fastening, say, a window block, since under the influence of the external environment it can somewhat change its properties.

Rules for the use of "Macroflex"

To obtain a perfect result, you only need to apply the foam according to the technology indicated by the manufacturer.

Preparation for use

Before use, the balloon is brought into the room and kept at room temperature for at least 12 hours. Immediately before work, the cylinder is shaken for 15 seconds, then the protective cap is removed and the pistol is screwed on. In the working position, the cylinder should be upside down. The release of foam is controlled by pulling the trigger of the gun.

Before starting work, prepare the base or abutting surfaces. They must be clean, free from dirt, dust, construction debris.

It is important that the base is not icy or covered with snow, while its slight moisture is allowed, which even enhances adhesion

All contact surfaces adjacent to the workers are covered with foil or pasted over with masking tape. If the substrate is not even, a concrete solution is applied to it in advance according to the level, otherwise the strength of the masonry will decrease.

Foam application "Macroflex"

Working with foam does not require special skills and abilities. The composition needs only to be evenly applied to the base, periodically shaking the balloon. When erecting a brick or block wall, foam is sprayed in two continuous strips up to 4 cm wide, retreating from the edge of the elements by 3-5 cm.If a thin wall of 0.5-1 bricks is being built, only one strip is made in the middle.

Sheet materials are glued as follows: foam is applied to the seamy part of the material in spots with a step of 15 cm, stepping back from the edge by 5 cm, then immediately connected or leaned against the walls, other structures, pressed firmly. Hold the sheets or panels for 5 minutes, then proceed to work with the next element. The seams are rubbed 2 hours after the completion of the installation.

When installing the window sills, apply foam-cement in three strips to the fixing part of the product. After the window sill is put in place, pressed on top with a load, left for an hour. To check the evenness, use a level, correcting the position of the window sill within 2-3 minutes. Steps and prefabricated staircases are mounted in the same way. When sealing seams and holes, take into account that the foam will expand strongly in the future, therefore they are not completely filled.

Briefly about the Makroflex brand

Makroflex was originally a Finnish company. Joined Henkel in 2003. Henkel Makroflex is now a worldwide supplier of polyurethane foams.

The entire range of TM Macroflex is certified by quality management in accordance with ISO9001, ISO14000, OHSAS18000 standards.

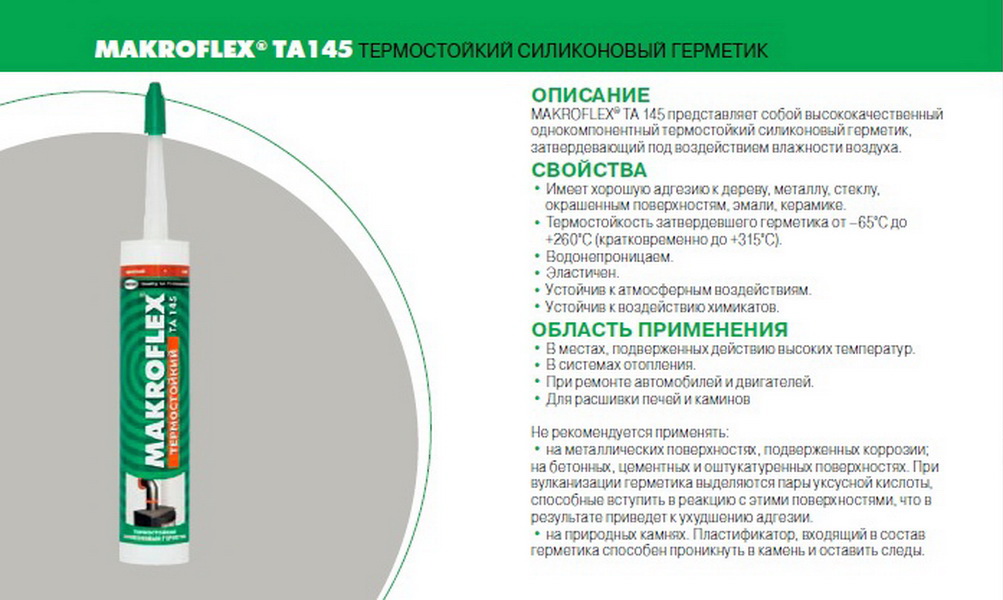

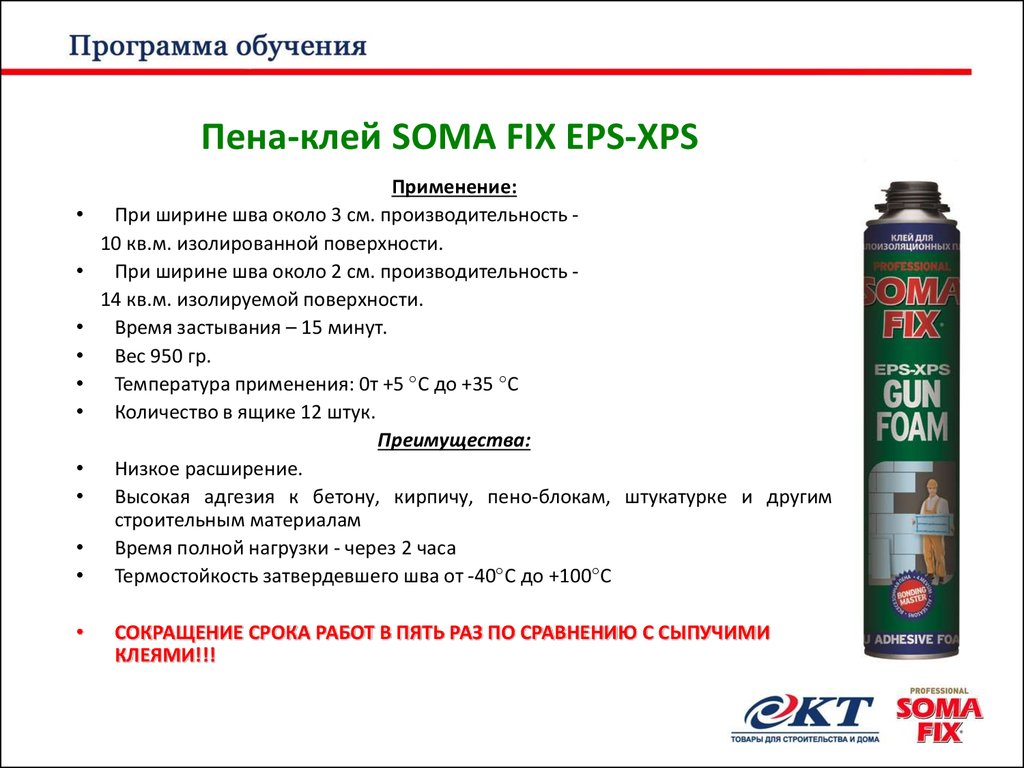

In addition to assembly foams, the assortment has been expanded with a wide range of sealants, adhesives.

Every year the company develops, manufactures, delivers goods that meet the latest standards, consumer requirements for quality, ease of use, environmental friendliness.

Makroflex: household or professional

There is an opinion that beginners should use household foam in their work. This is partly true. For such work as sealing small cracks, installing small products, household foam is used. It makes no sense to buy a professional one for this type of work. As for professional foam, it is applied to the surface by means of a pistol, which allows more accurate metering of the volume and control of the substance consumption.

The main difference between household and professional foam is shrinkage.

The main difference between household and professional foam is shrinkage.

Household foam doubles in volume. As for the secondary expansion of the professional, it is practically absent. The coefficient of shrinkage of professional foam is minimal: from 0 to 3%, which cannot be said about household foam, where the indicated indicators are 5-7%. Household is used once, professional - more than once.

Professional foam Makroflex 750 ml is used for:

- thermal insulation of roofs, heating systems or walls;

- filling cavities;

- creating partitions with soundproofing properties;

- in fire-resistant structures, as fire protection (Makroflex FR77 fire-resistant).

It should be remembered that the substance hardens in about 24 hours. In view of this, large voids cannot be filled in one go. Use multiple balls.

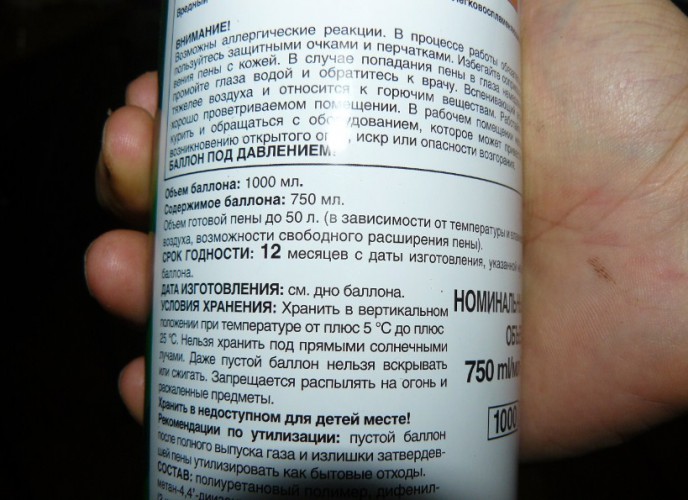

Polyurethane foam: composition

On the market, polyurethane foam is represented by one-component and two-component mixtures. At the same time, its overwhelming share belongs to a one-component sealant. Polyurethane foam GOST, composition and technical characteristics.

Foam contains two main components - MDI and polyols. Mixing in a pressure cylinder, they turn into a one-component liquid prepolymer. When exiting the container under the action of a propellant gas (propellant), the substance enters into a polymerization reaction with water molecules in naturally humid air.

Foaming occurs, the volume of the mass expands by 3 or more times, and the formation of a densely elastic, durable substance of a porous structure - polyurethane foam. It will take about 24 hours for the reaction to complete and fully cure.

In a two-component composition, an activator is added to the base (prepolymer). Being in one bottle, they are separated by a shutter and do not mix. When the lock is removed, activation and rapid polymerization occurs, independent of air humidity. The mass immediately begins to solidify already in the container. The process takes three to ten minutes. In this short time, you need to have time to use the entire composition.It takes 4 hours for the foam filler to harden completely. Considering the need for quick skillful manipulations, it is advisable for specialists to work with this product. Foam assembly technical characteristics and properties.

In addition to the base and a mixture of liquefied gases (propane-butane), various additives are introduced into the foam to impart certain properties (fire resistance, increased adhesion): stabilizers, plasticizers, surfactants, and others.

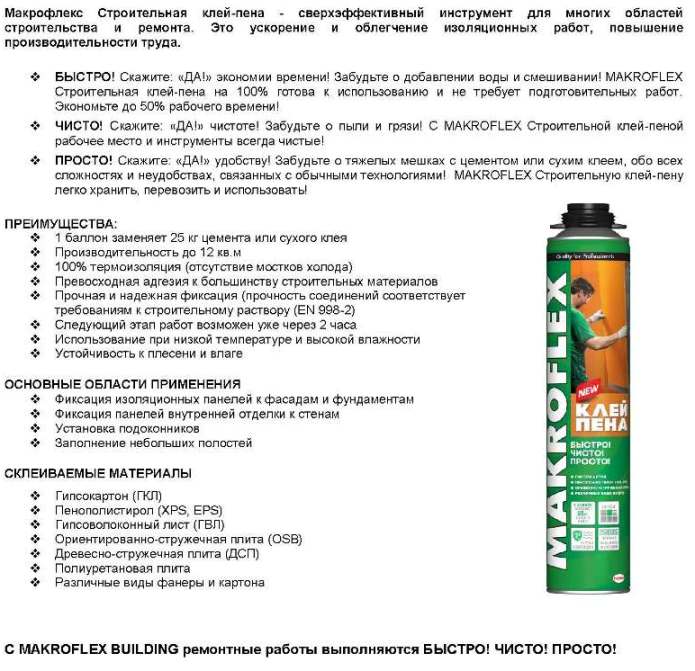

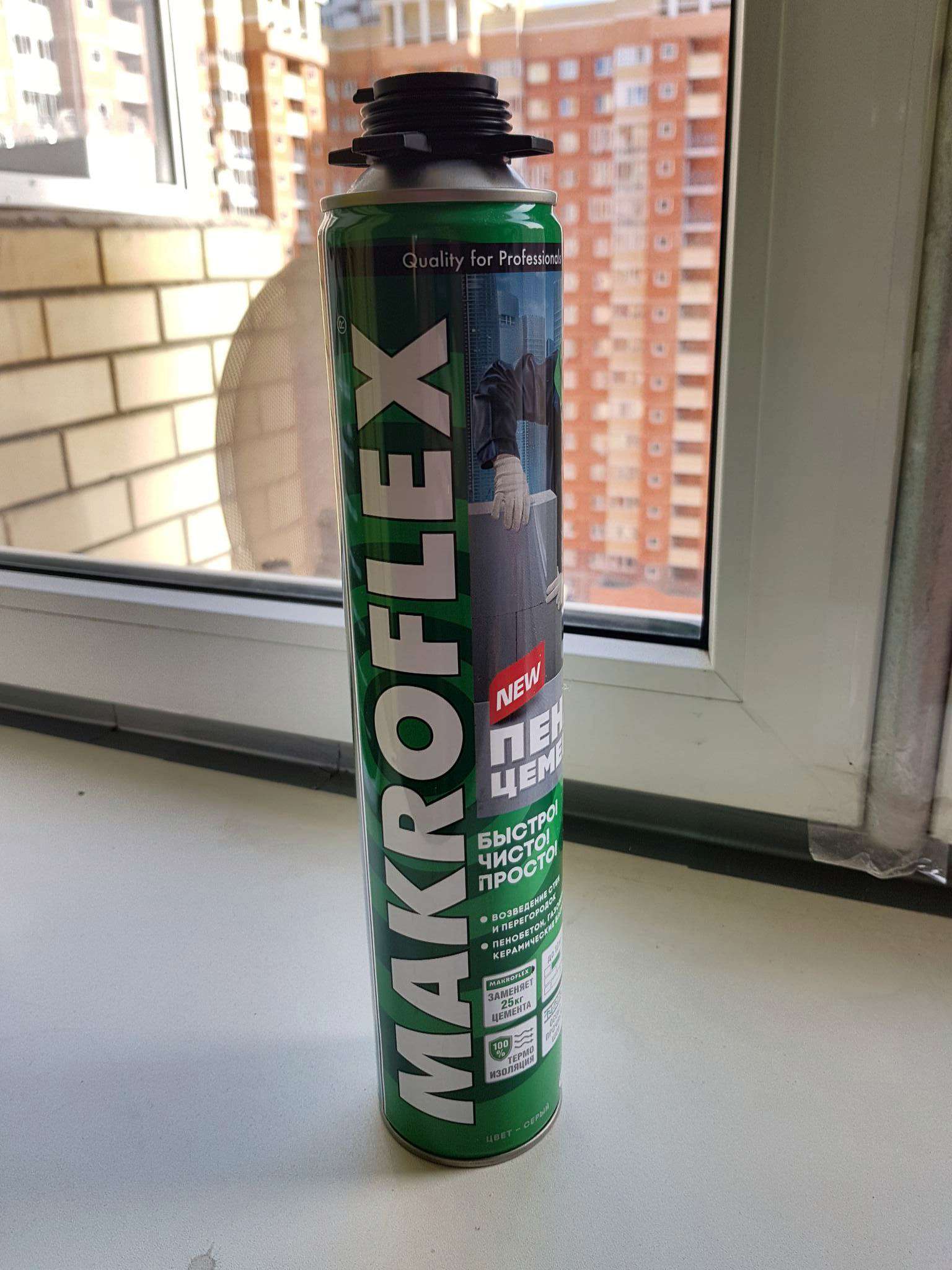

Purpose and scope of assembly foam Macroflex 750 ml

The foam canister is already ready for use, therefore, you can use it immediately after purchase. The main essence of its action is to expand and fill the entire space after application. Moreover, it can be used for any surfaces, since "Macroflex Pro" is distinguished by excellent adhesion to all materials, even if they are wet. Of course, the foam yield will depend on the general indicators of the environment - temperature, humidity, as well as the total volume of the filled space.

The most common actions for which an assembly tool is used are:

- Filling voids during construction, sealing any gaps during repairs;

- Increasing the level of noise insulation;

- Sealing joints between pipes and filling around the pipe space;

- Installation with subsequent insulation of doorways, frames and window sills, wall panels;

- Installation of roofing materials, which includes not only their joint, but also insulation.

The best adhesion surfaces for Macroflex Pro foam are concrete, stone, metal and wood. However, it perfectly shows its properties with plastic, as well as with glass. The most important thing is that there is no ice on the surface, since even moisture will not be an obstacle for the sealant to demonstrate its best qualities.

In some cases, construction foam "Macroflex 750 ml" technical characteristics will be indispensable in everyday life, especially if it is planned to carry out repair work, both large and small scale. For example, when replacing old wooden frames with plastic windows, which is popular today, one cannot do without using just such a hermetic material. An excellent option would be to use "Macroflex" when sealing cracks in the walls, if any are found under the old coating.

Often, polyurethane foam is used as insulation, due to its impermeability. For example, doorways are insulated for her at the entrance to a house or apartment. Due to its expansion, the foam perfectly fills all the space provided for it, subject to the availability of the appropriate environmental parameters (temperature, humidity, etc.).

Soudal

Special mention should be made of the Soudal super-frost-resistant foam. Which successfully promotes its product to the Russian market, since such a sealant is in demand in cold conditions. Unique characteristics of "Soudal", with the help of which construction and installation work, replacement of windows and doors at temperatures up to minus 25 ° C are performed.

This material is durable, tensile and compressive resistance. The adhesive properties of the foam to basic materials (stone, metal, concrete and wood), even at extremely low temperatures, comply with European requirements. This type of sealant is fire-resistant, and in terms of other characteristics, Soudal doubles the requirements for such materials existing today.

Additional tips and tricks

The optimum temperature of the working mass inside the cylinder is 23 ° C. To achieve it, it is recommended to keep it at 22-25 ° C for about 12 hours before starting work. Use the product as follows:

- shake the balloon 20 times;

- remove the protective cover;

- attach the gun.

During these operations, keep the cylinder upside down. Carrying out the main work (applying glue), hold it upside down. The foam output speed can be adjusted in standard ways using the screw on the gun and the trigger. Shake the container regularly during work.

To prevent the foam from hardening, adhere to the following rules for using the gun:

- do not remove it while there is foam in the container;

- when the glue runs out, quickly disconnect the empty bottle, replacing it with a new one;

- after completion of work, clean the device with a special liquid (Premium Cleaner);

- Remove the hardened mass mechanically.

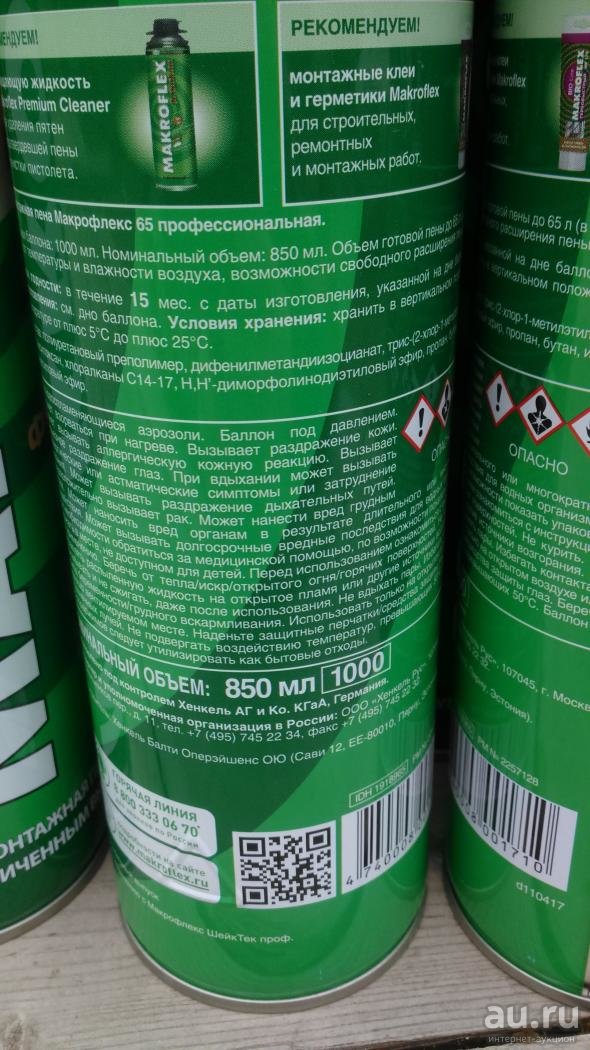

It is recommended to store glue cylinders for no more than 15 months, observing a storage temperature of 5-25 ° C. In this case, put them strictly vertically, the valve should look up. When transporting the product, wrap it in a cloth. Carry in the trunk. Observe safety precautions when working. Do not smoke, do not light a fire nearby. A supply of fresh air must be provided in the room. Protect the skin of the hands with gloves, eyes with goggles. Do not inhale vapors.

Share link:

Advice

Recommendations of specialists for the use of Macroflex polyurethane foam:

- Before use, the foam should be kept at room temperature for about 12 hours, this is necessary for the mixture to completely warm.

- Installation work with Macroflex products can be carried out only after one hundred percent shaking of the can, so that the ready-made foam solution will have a uniform consistency when it comes out. During application, the spray can must be kept upside down, regardless of how the foam is applied to the coatings (manual method or with a pistol).

- Before applying the mounting solution to surfaces or coatings, they must be cleaned of dust and various contaminants. Metal coatings contaminated with old sealant can be easily cleaned with white spirit. Also, for better adhesion, it is recommended to wet the surfaces with water using a special spray.

- If there is a need for a break in construction work (more than 15 minutes), the channel and pipe must be cleaned of the foamed mixture before resuming the use of the mixture.

- Foam spots that have not yet hardened can be easily cleaned with specialized cleaners. The frozen mixture lends itself only to mechanical stress (cutting from surfaces).

- It is recommended to use Macroflex in filling gaps and seams with sizes from 0.5 cm to 8 cm. The mixture may not penetrate into narrow gaps to the required depth, as a result of which voids may form. Wide joints and crevices will not be able to withstand the heavy mass of mortar.

Safety precautions for installation work with Makroflex foam:

- Do not allow the finished mixture to get on the skin and organs of vision, severe irritation may occur. If this happens, immediately rinse the composition from the skin or rinse the eyes with warm water.

- Never remove a cartridge from the gun that is not fully used. Only an empty bottle can be replaced.

- Construction work with polyurethane foam is carried out only in rooms with good ventilation. When the mixture is sprayed, harmful substances are released that affect the respiratory system. It is recommended to use protective equipment.

- Do not apply foam on hot surfaces and old electrical wiring. Foam contact with hot coatings can cause an explosion. Unreliable wiring can contribute to the sudden appearance of a spark, which will lead to dire consequences. Also, do not smoke near the sealing solutions.

For the pros and cons of Makroflex polyurethane foam, see the following video.

Foam types

The manufacturing company has developed technology- and operation-competent solutions for all users. We offer to buy at a good wholesale price:

- Makroflex Premium - premium polyurethane foam with increased yield;

- a wide range of professional and standard products for different purposes;

- several types of special grades for use in specific situations.

| Makroflex Premium | Type of | Characteristics, application |

| Premium | Professional foam gun with increased output. Application temperature + 5 ... + 30.It is used for insulating windows, doors, filling hollow spaces, sealing holes, making partitions with high sound insulation, filling air spaces around pipes, insulating roofs. | |

| Premium Pro Winter | Apply at t -15 ... + 25. Leave at room temperature for about 12 hours before use. | |

| Premium Mega | Especially high yield - 45% more than standard cylinders. Works at a temperature of +5 ... + 30 | |

| Premium Mega Winter Pro | Winter, works in the temperature range -15 ... + 25 | |

| Premium Window Pro (All Season) |

Recommended for applications requiring the highest quality |

|

| Macroflex pro and standard | LOWEX PRO |

|

| PRO | It has a good cellular structure and high mechanical strength. Suitable for insulating tile roofs, wall panels, window and door frames, etc. High adhesion, sound and heat insulation | |

| MAKROFLEX 65 PRO | Increased foam yield, for working on all surfaces at temperatures + 5 ... + 30 | |

| All-season | Does not lose properties when working in hot or cold conditions (up to -10) | |

| 65 PRO all season | Similar characteristics with increased output | |

| Standard | The balloon is equipped with an applicator tube. t + 5 ... + 30. Cost effective solution for filling voids on different surfaces. Good adhesion and mechanical strength. | |

| Macroflex 65 standard | With increased output | |

| Makroflex Winter | Standard, with applicator | |

| ALLSEASON | All-season, works in the temperature range -10 ... +25 | |

| Special | Macroflex 2x2 | Works with gun and applicator tube |

| FR77 | Fire resistant: does not light up within 240 minutes (the specific time depends on the type of line joints) | |

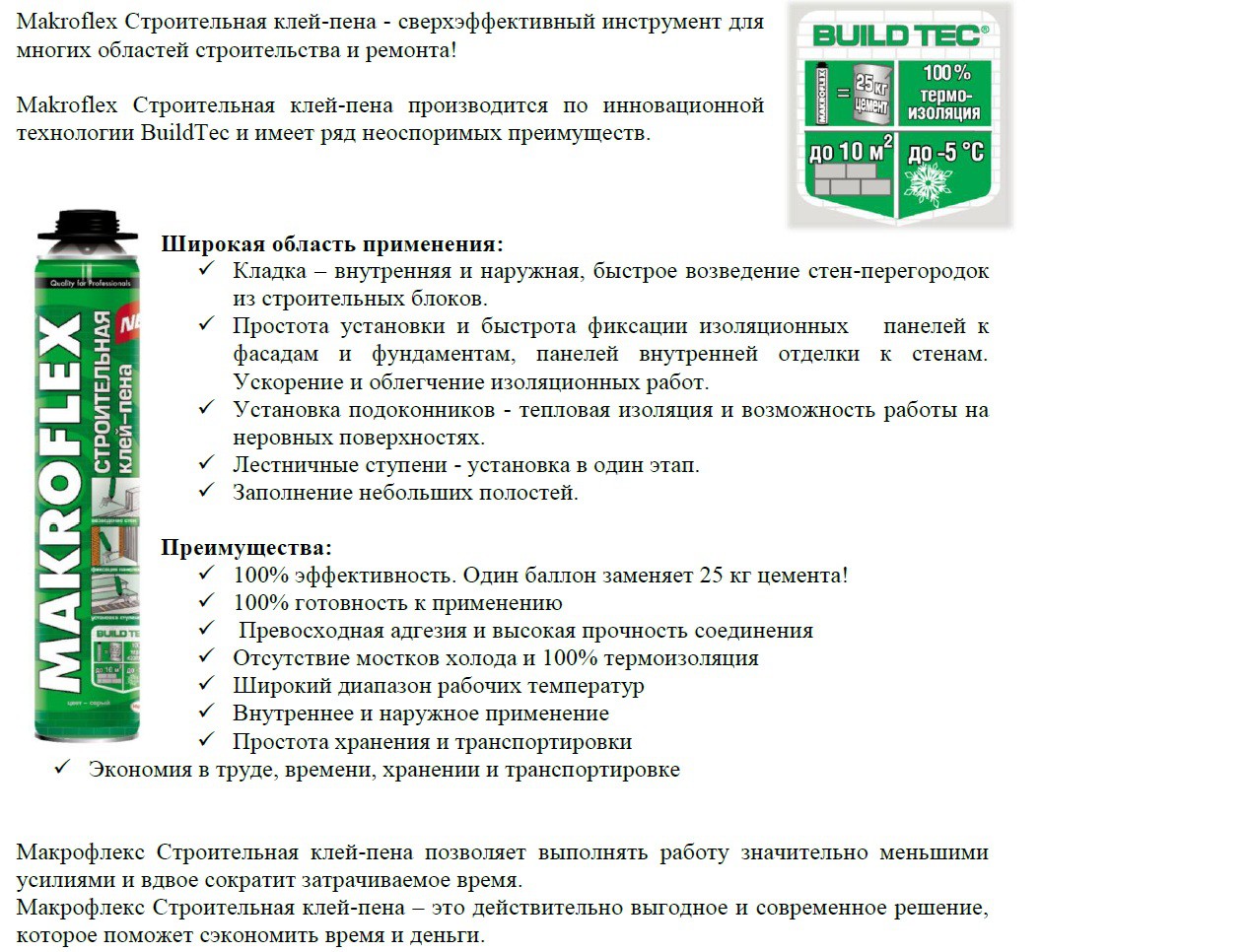

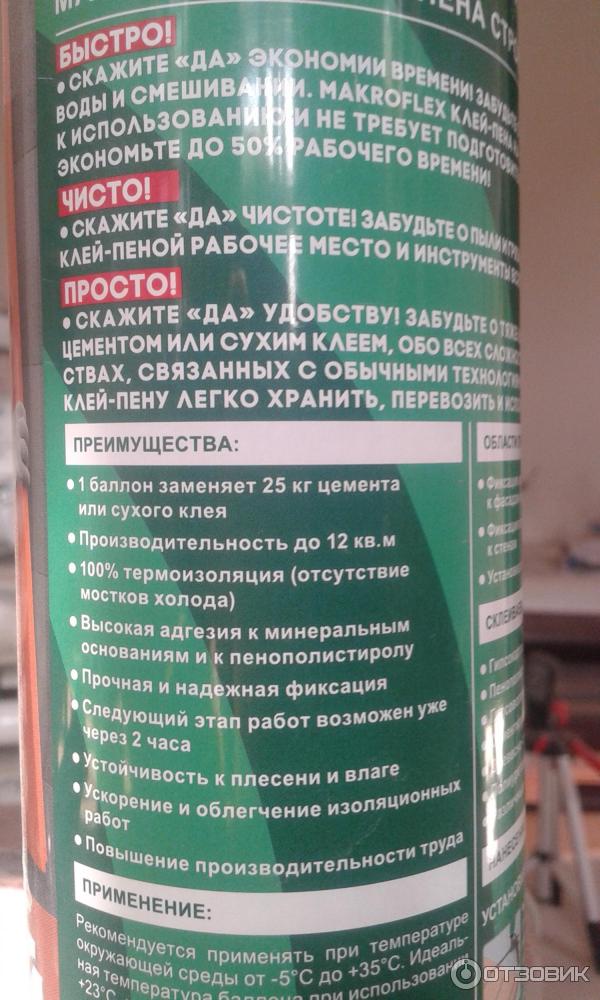

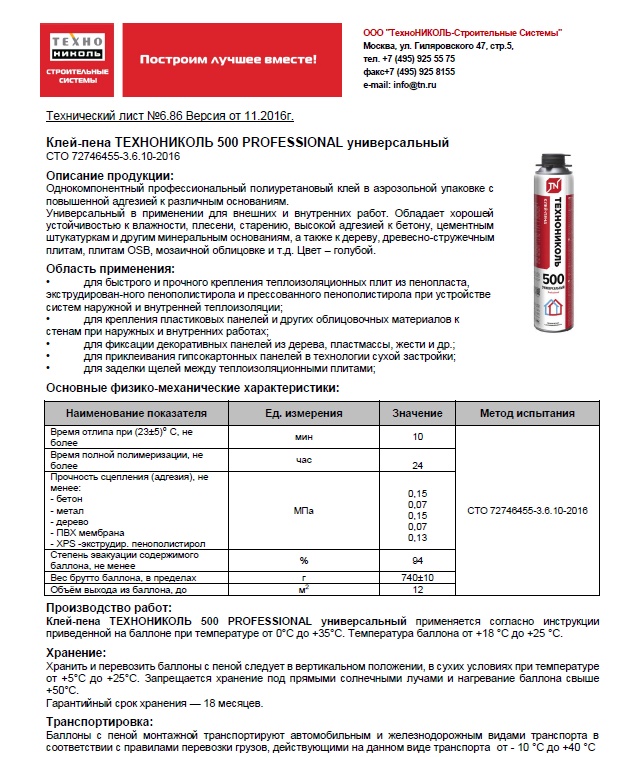

| Building cement | Serves for connecting building materials and fastening to each other. It is used when installing stairs, window sills, tying building blocks, etc. | |

| 2K 8MIN | 2-component polyurethane foam. Accelerated polymerization process | |

| SIBERIAN 65 PRO winter | Professional, with increased output, works at a temperature of -18 ... + 25 | |

| Makroflex WhiteTeq (White Technology) | UV resistant white foam. Finely porous. Possesses high noise and heat insulation. Thermoplastic, able to compensate for movement and vibration. | Shelf life is 12 months. Application:

|

Advice

In the operating instructions for the polyurethane foam, far from all the nuances of working with such a material are taken into account.

The recommendations of professional builders will bring significant benefits when working with a sealant and its choice:

- The rate of solidification of the composition is significantly affected by the level of humidity in the room. If the microclimate in the room is dry, then solidification will take longer.

- If you are filling small joints or gaps, be sure to buy low-expanding foam, which will save you the trouble of scraping off excess material and will help you fill the joints as neatly as possible.

- A construction gun in good condition can store the foam composition inside itself for no more than 3 days.

Pay attention to the appearance of the balloon. If there are traces of deformation on it, this may mean that the composition is stored under inappropriate conditions.

When choosing a gun for assembly sealant, it is better to dwell on metal models that have a collapsible design

Such options are convenient to use and at the same time are relatively inexpensive - about 500 rubles. For many, the highest priority is the material of the device, such as stainless steel. Pay also attention to the presence of a regulator that determines the degree of foam solution delivery.

If you have a large scope of work with construction foam, it is recommended to purchase a special cleaner for such material. The following components are included in the purifier: acetone, dimethyl ether and methyl ethyl ketone. All these components are enclosed in a special aerosol can, which also comes in the form of a nozzle for a gun.

- If you decide to fill the crevices with foam, then make sure that their thickness does not exceed 5 centimeters. Otherwise, you may get too high a consumption of material or an unpredictable change in composition, for example, excessive expansion.

- If the foamy composition gets on your skin or clothing, it is recommended to immediately wash off the dirt, otherwise it will be much more difficult to do as the material dries.

- Despite the fact that the assembly sealant does not allow water to pass through, but retains it inside its texture when absorbed, many experts recommend using foam only for interior decoration. Before deciding on an exterior finish, analyze the features of the climate.

For wall insulation with polyurethane foam, see the following video.