Helpful hints

Fiberglass is a common material that is used in various fields. It is glued to different substrates using special adhesive mixtures, the characteristics and composition of which are discussed above.

If you decide to independently apply fiberglass to the walls or ceiling, then you should take into account some useful recommendations from professionals in order to avoid mistakes.

Despite its many advantages, cobweb glue also has its weaknesses. For example, if a crack appears in the place next to which the seam is located, then it will still crawl out. Most often, such defects are formed when the fiberglass is glued to the gypsum board

For this reason, experts do not recommend gluing such canvases along the seams of drywall sheets - 2-3 cm should be retreated.

When gluing, you need to pay attention to the position of the front of the canvas. Most often it is inside the roll.

At first glance, it may seem that both sides of this material are identical, so it is recommended that you carefully study the label of the purchased product.

Walls and ceilings are usually primed before finishing. The primer mixture will strengthen the base, as well as reduce the consumption of paintwork.

- Always observe safety precautions during work. Before you start applying the fiberglass, you need to wear gloves, a respirator and a hat. It should also be borne in mind that sharp particles of the finishing material can get on the skin, mucous membrane or in the respiratory tract - this can cause serious irritation.

- The fiberglass must be applied on neat and even surfaces. For example, if there are height differences or any irregularities on a drywall sheet, then first you need to seal them and only then glue the finish.

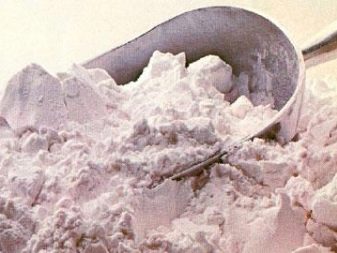

- If dry glue is purchased, then it is necessary to prepare it for application, relying on the instructions. Most often it is found on the packaging. Add glue powder to the required amount of warm water, and then mix everything. The finished composition should stand for 10-15 minutes to swell. After that, the glue should be re-mixed.

- To paint glass fiber, you need to use a high-quality paint and varnish coating exclusively on a water basis, while the paint can be not only ordinary, but also facade.

- It is recommended to use a wide spatula to putty the glass fiber - it will be much more convenient to work with this tool.

- If necessary, fiberglass can be laid on the slopes in the room.

- According to experts, for fixing the fiberglass, as a rule, large amounts of glue are required, so it is better to buy it with a margin.

- It should be noted that it is not very convenient to work with too large sheets of fiberglass, especially when it comes to finishing the ceiling.

- If it is required that the paint on the glass fiber has a relief and rough texture, then it is worth covering the base with a leveling layer of putty.

- You need to buy both fiberglass and glue only in trusted stores so as not to run into low-quality products.

For information on how to glue a cobweb (fiberglass) on a curly plasterboard ceiling, see the next video.

Adhesive selection

For fiberglass it is necessary to choose a suitable adhesive. Below are the requirements that apply to such adhesive mixtures, and companies that produce such products.

Types of mixtures

Two types of adhesive mixtures are used to apply fiberglass:

- dry;

- ready.

Finished products do not need to be prepared in advance - they are initially ready for use

However, when choosing such an adhesive solution, you need to pay attention to its shelf life.As a rule, it is indicated on the container in which the glue is located.

It is worth considering that an expired product can cause a lot of inconvenience during the pasting process, for example, it starts to bubble and flake off.

If the bucket is already open, then it is recommended to use the glue as soon as possible. You always need to measure the amount of adhesive with the planned production of the product. For this, knowledge of the consumption rate of the adhesive mixture, which is indicated on the package, is useful.

Dry mixes are good because they can be prepared in the volumes that are needed at the moment. Such formulations should be prepared for work, strictly following the instructions. The recipes for the preparation of these glue mixtures are of the same type, however, there are options with some nuances that must be followed.

Many consumers are wondering whether it is possible to install fiberglass on the popular PVA glue. According to experts, this composition can be used when working with such finishing materials.

Composition requirements

A high-quality adhesive solution for fiberglass should contain a number of special components.

- plasticizer - it is this ingredient that makes the adhesive base elastic even after it has completely dried, so cracks and other damage do not appear on it;

- polyvinyl acetate is a special polymer that is known to most consumers as PVA, is a versatile adhesive that does not have toxic constituents and is suitable for many different substrates;

- fungicidal additives - these components prevent the destruction of materials applied during the repair process by bacteria;

- modified starch;

- bactericidal components.

Sometimes a special glue is included with the fiberglass. Such products can be used for finishing a wide variety of areas: a bathroom, kitchen, loggia or balcony, as well as other equally important places.

Characteristic

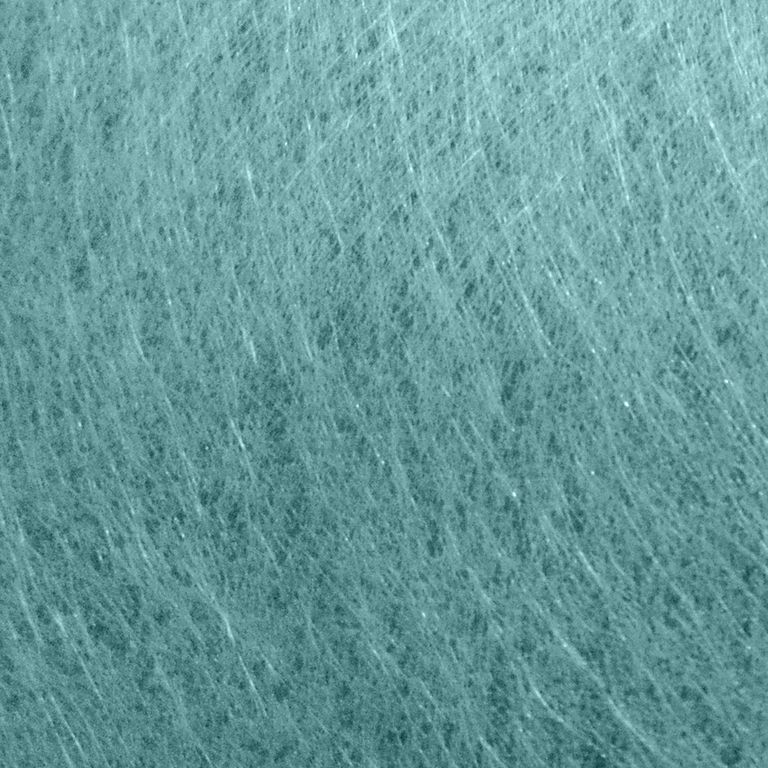

The fiberglass material is a kind of cobweb, fiberglass threads that are linked in an indefinite order. This structure allows you to create an ideal surface that will combine both visual characteristics and internal, that is, characteristics of strength and density.

There is a special glue for fiberglass. The composition of such an adhesive usually includes: modified starch, vinyl acetate polymer, a plasticizer that increases the elasticity of the web, as well as other bactericidal additives. The glue is made in special packages - in plastic boxes, which are secured with a tight lid.

Adhesive for fiberglass

Advantages of Oscar glue

There are a number of positive characteristics that Oscar's glue for fiberglass has:

- no harm to the human body;

- profitability - only 0.5 kg of dry powder is needed for 10 liters of water;

- ease and speed of preparation of the solution: the existing powder is poured into a container with cold water and after 8-10 minutes is ready for use;

- savings in the consumption of funds: only 0.25 kg of a ready-made mixture of glue is enough for 1 square meter of coverage;

- a rather long storage time of the prepared mixture: it can be stored up to 2 months, but only in closed packaging;

- you can easily move the glue in a closed container.

Before starting the process of gluing the material to the finished surface, it is necessary to carry out the main stages of the preparatory work. Is it possible to glue fiberglass without preparation? Of course not, otherwise he won't stick. The surface should be cleaned of any dirt and dust, and cracks that are visible to the naked eye should be treated initially. Working with glue makes the task much easier than gluing wallpaper to the wall, because the glue is applied only to the surface itself, as shown in the video.

Features of Wellton glue

Glue for fiberglass cloth Gossamer was created specifically for working with fiberglass cloths.He is able to firmly fix the canvas on any substrate, even if it is not perfectly smooth. The improved features of this glue give such characteristics as:

- high solubility of the agent;

- obtaining a uniform and homogeneous mixture;

- effective adhesive ability;

- cost savings;

- safety and preliminary protection of the development of bacteria or fungi during operation.

Manufacturers overview

There are various brands of means for gluing fiberglass on the market. Usually within the range of one manufacturer there are 1-2 products suitable for gluing heavy webs.

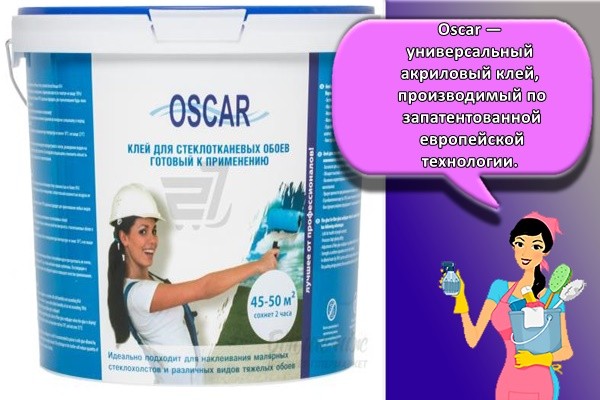

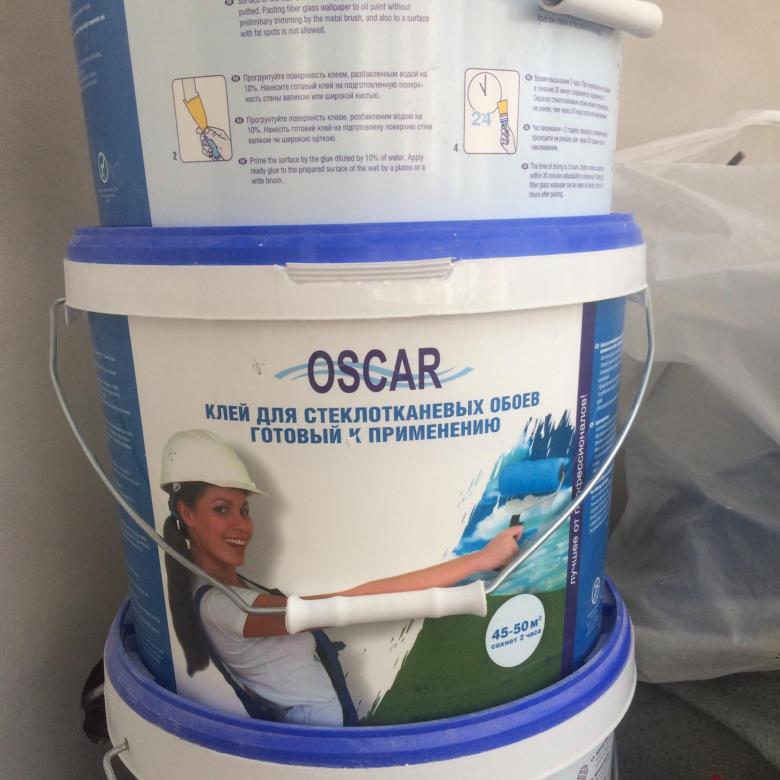

Oscar

Oscar is one of the most popular adhesives that reliably adheres to the heaviest materials. It is divorced without lumps, when the wallpaper is applied, it remains mobile, so the position of the canvases can be corrected in time. After drying, there will be no yellowness or stains on the walls. The adhesive contains fungicidal additives, prevents the appearance of fungus, and is suitable for use in the bathroom.

Note! One package is enough for 25 square meters of glass walling or 66 square meters for priming

Kleo

Cleo Ultra 50 Glass fiber is another well-known adhesive designed specifically to hold such a strong, heavy material on walls. It is frost resistant, contains modified types of starch, several improvers and antifungal additives. The tool is considered hypoallergenic, does not react with paints that will cover the glass wallpaper.

The powder is diluted with cold water without lumps, it is ready for use in 5 minutes. Usually the packaging is enough for 35 square meters.

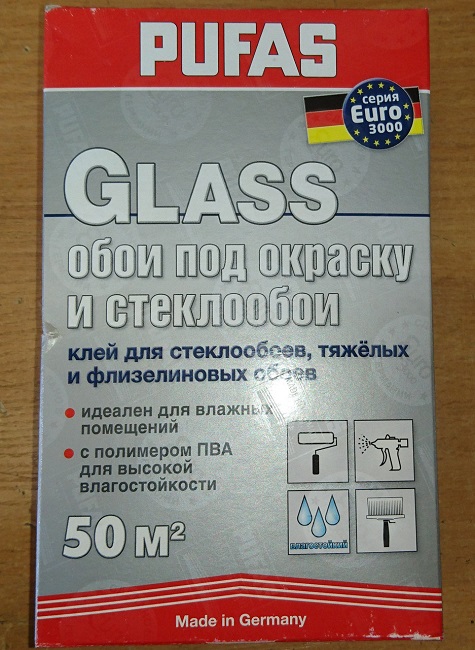

Quelyd

Quelyd (Kelid) looks like coconut, it is a dry glue powder for wallpaper, a pack of which is enough for 35 square meters of walls or ceilings. Kelid Glass wallpaper allows you to keep the finish breathable, does not violate the vapor permeability of the walls, while protecting them from mold. The product is of high quality, does not leave stains, and reliably adheres to all types of materials.

Metylan

Methylane Fiberglass Premium has all the advantages of the previous adhesives, but at the same time it contains an indicator - a pigment that allows you to distinguish a wall with an applied composition from a dry one. This makes it easier to work with fiberglass. After the glue dries, no stains remain on the walls. The glue can also be used in the bathroom and in the kitchen, in freezing rooms.

The Methylane brand produces ready-made glue - Ovalit for fiberglass, heavy and exclusive types of coating. It does not need to be diluted, the product is completely ready for use, moisture resistant and very reliable.

If it is decided to decorate the walls with fiberglass, you should not save on the adhesive composition. Only a high-quality product is able to hold such dense canvases, and they will serve for a long time.

Material characteristic

This glue for glass wallpaper is produced in dry or ready-made form. If we talk about the second option, then the product is contained in 10 kg buckets. It has a narrow scope of use and is used specifically for gluing heavy fiberglass wallpaper. And for this Oscar has all the characteristics.

The composition is characterized by high adhesion, it is in contact with any surface, and also combines the properties of ordinary wallpaper glue. As a result, it provides protection against fungi, corrects the canvases.

Container with ready-made composition

Container with ready-made composition

Initially, Oscar glue was used for pasting walls with decorative canvases, as well as wallpaper, which serve to reinforce the surface. But the operation of the composition does not end there, since it is allowed to use it for priming the walls when there is strong looseness.

The next characteristic of the composition can be called its method of application to the surface to be treated. Here it is not necessary to apply the solution to the wallpaper and to the wall, only the working surface is enough.Thanks to this, the wallpaper can be glued much faster.

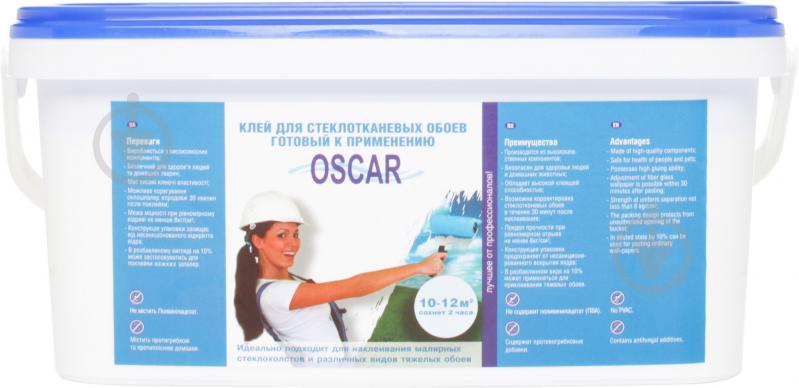

The presented composition for heavy wallpaper boasts the following advantages:

- Environmental safety, since in the process of operation the canvases do not emit harmful substances. Thanks to this, the composition of the wallpaper does not harm human and animal health. (The glue is certainly environmentally friendly, but not so much that you can eat it, because in this case it can harm your health.) After the canvases have dried, they do not become yellow, but become transparent.

- The composition of wallpaper glue contains chemical components that prevent fungi and mold from appearing on the wall in conditions of high humidity.

- Frost resistance of the composition. You can store glue for heavy wallpaper at temperatures of -40 degrees for 3 days. In addition, it is able to maintain its properties for up to 5 freezing cycles.

- Oscar is very beneficial to use. You need to take 100 g of dry mix to get 3 liters of ready-made glue.

- Economical consumption composition for fiberglass wallpaper. For 1 m2, you will only have 300 g of the finished composition.

- Ease of preparation. To get a ready-made solution, you need to add water to the mixture, wait 10 minutes until it swells.

- The resulting adhesive solution can be stored in a closed bucket for about 2 months.

- Storage of Oscar dry glue in sealed packaging can last up to 4 years.

Another important characteristic of the product is its ability to be applied to a large number of building substrates. You can buy Oscar glue for gluing canvases on drywall, concrete, gypsum, cement, wood or brick

To obtain an optimally smooth surface, it is best to apply a layer of gypsum plaster to the surface before applying the adhesive.

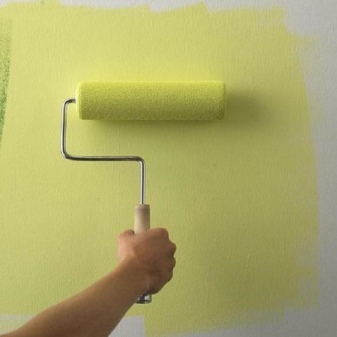

To apply the adhesive, use a roller or spatula and weigh the surface. After that, you can apply wallpaper and smooth it with a spatula. After gluing, the glass cloth wallpaper must be treated with an adhesive again.

This is interesting: Materials for the roof: we tell the main thing

What is painting glass canvas

The latest trend in modern finishing work is the gluing of fiberglass before the final stage of decorative wall decoration. The material gained popularity due to its useful qualities, but not everyone came to a consensus on how to use it and how to cover it after gluing, paint the fiberglass immediately after gluing or pre-apply a protective layer on it.

The need to use fiberglass when working with drywall turned out to be dictated by the occurrence of cracks in this building material, which mainly appeared at the joints, along the seams. Earlier, a serpentine mesh was used, but it turned out that it does not provide sufficient guarantees of strength and does not always prevent the formation of cracks, especially if they appear under the influence of building shrinkage or sudden temperature changes. The trend towards the use of fiberglass appeared in order to avoid such a nuisance.

By itself, the building material breaks easily enough, because it is made of thin strands of fiberglass, bonded together with an organic compound. However, on the wall, such a canvas acquires non-analogous reinforcing properties and helps to ensure the integrity of the coating of the finished walls for a long time.

Advantages, disadvantages of a cobweb

Fiberglass is not devoid of strengths and weaknesses in the same way as other counterpart materials. By tradition, they first talk about the benefits, so let's go straight to their impressive list. Gossamer:

- considered environmentally friendly, absolutely safe, since there are no harmful or suspicious components in its composition;

- sometimes it makes it possible to do only with a starting putty, without the participation of the finishing type of this coating;

- it is not noticed in the accumulation of static electricity, therefore the dust ignores it;

- not afraid of high temperatures, their drops, high humidity;

- durable, she is not afraid of mechanical stress, fire, corrosion;

- makes it possible to carry out work indoors and outdoors;

- vapor permeable, which means that mold does not threaten surfaces;

- and the adhesive does not provoke allergies for it;

- does not have strong unpleasant odors;

- does not require serious maintenance.

The material can be safely glued to any surface - on wood, concrete, brick, plasterboard, on ceilings or walls.

There are also disadvantages, these include:

- The ability to "attack" low-quality, inexpensive material with a short service life. Such products will disappoint because of the inconvenience of working with them, inelasticity, fragility.

- Impossibility of using first grade fiberglass in premises. It contains phenols, formaldehyde resins, which are undesirable components.

- Inefficiency of the material if there is a need to hide serious defects - large cracks, chips, potholes. They will have to be repaired in advance.

- The need for protection (gloves, goggles, masks, better - a respirator) when working due to small glass particles.

- Difficult dismantling of the cover.

- Large consumption of glue.

One cannot but agree that the disadvantages are still relative, since most of them refer to low-quality products. Therefore, in the "battle" of advantages with disadvantages, the first ones emerge as winners.

Features of the "cobweb" sticker

There are several nuances that allow both to properly glue the fiberglass, and to do it with a minimum consumption of materials. First of all, before performing work, you should definitely make sure that certain conditions are met - temperatures within 15-25 ° C and humidity not higher than 60%. During the gluing process, the fiberglass should not be exposed to a draft or direct sunlight. Approximately the same requirements are indicated in the instructions for Bostik glass fiber glue, which is one of the best options for performing work.

The process of sticking the "cobweb" begins with the preparation of the surface, which must be free of dust and completely putty, except for the smallest cracks. At the same stage, it is chosen which glue for the fiberglass will be used. First of all, one should abandon the usual solutions and mixtures with which wallpaper is glued - substances based on starch do not hold such a canvas well. A more suitable option may be to use Bostick glue for fiberglass, which contains PVA with a strength several times higher than that of a starch base.

It is not recommended to choose plaster as a base - due to its high density, it cannot be saturated with glue and it will not be enough to hold the canvas firmly. Liquid putty is also not suitable, and after trying to stick a "cobweb" on it, bubbles may appear in places that are not sufficiently saturated with adhesive. All this can be avoided only by using glass fiber glue - ready-made or in the form of a mixture.

It is advisable to use your own adhesives for each type of "cobweb":

- Oscar fiberglass glue will be the best option for gluing material of the same brand with a density of 40 g / sq. m;

- a similar adhesive is best suited for Wellton fiberglass;

- at the same time, Cleo's glue for fiberglass, which is also used for non-woven wallpaper, is compatible with any brand of canvas.

It is possible to achieve the optimal consumption of the mixture, counting that 10 grams is enough for 1 sq. m of fiberglass. And one 300-gram pack is enough for a 25-meter roll. The time for preparing the solution, if it is purchased not ready-made, but dry, does not exceed 10-15 minutes. And the setting takes place within 12–48 hours, depending on the brand of glue and fiberglass - you can specify the specific value on the package with the mixture.

The technique of how to glue the fiberglass consists of several stages:

Surface putty.

Treating walls or ceilings with a deep impregnation primer.

Application of pre-prepared glue

Using this method, how to glue the fiberglass to the ceiling or walls, it is important not to miss a single non-impregnated area. At the same time, no excess adhesive should be left, which can be removed with a spatula.

Bonding the first sheet, starting from the corner, and smoothing the edges of the material to improve the reinforcing qualities.

Applying the next portion of glue with an approach to the already glued part (the canvases are glued with an overlap).

Laying the next piece of fiberglass.

Cutting canvases with a clerical knife clearly at the junction and removing the cut parts.

Repeating the same actions until the end of the surface.

Regardless of whether the walls or ceilings will be covered with wallpaper or painted, after the fiberglass has completely dried, they are treated with a finishing putty. And the already putty surface is cleaned with an abrasive mesh (N150 or N120). It is not recommended to skip this stage, since it will be possible to glue the fiberglass for painting without additional leveling only with a large overspending of paint.

Analogs

On the construction market, you can find several types of adhesive solutions that have similar characteristics to the products of the Oscar brand. The most popular and proven substitutes include the following options:

- Quelyd glue is a multipurpose strong action solution. This option is used with all types of glass cloth wallpaper and glass canvas painting. During the drying process, the solution does not darken and does not form mold due to the content of antiseptic additives. Quelyd provides a smooth web slide for added convenience when adjusting material placement. The composition is sold in cardboard packages with a capacity of 500 g.

- Solution "Optimist" - a domestic product for glass-cloth wallpaper. The main advantages are the relatively low cost, the absence of solvents in the composition, the formation of a transparent invisible film after drying. The composition is available in liquid form and is supplied in containers with a volume of 5 or 10 liters.

- Homakoll 202 is a universal composition on a water-dispersion basis for the installation of fiberglass and other types of structured wallpaper with a large mass. Using Homakoll 202, you can fix the material on plastered surfaces, walls with a porous structure and other substrates. The solution is sold in a ready-to-use liquid form in plastic buckets with a capacity of 10 liters. Consumption does not exceed 0.3 liters per square meter.

Some Recommendations

Independent work on gluing surfaces with glass fiber, at first glance, is quite simple. However, in this case, you can make several mistakes - serious and not very. Therefore, the advice of professional masters always helps to avoid trouble where it is easy to do.

- The cobweb does not always become a universal saving material. For example, if the seam of two sheets of fiberglass is close to the formed crack, then it will be visible in any case. Most often, such "surprises" appear on plasterboard surfaces. To avoid the appearance of a defect, it is advised not to glue the canvases along the seams of the gypsum board: the distance from them must be at least 20 mm.

- Before gluing, you need to carefully examine the rolls to determine the seamy side and the front side. Most often, the latter is hidden inside, but there are always exceptions to any rule. Examining the label is the second way to find the answer to this question.

- Fiberglass needs perfectly flat surfaces, so even the slightest difference in height (for example, adjacent gypsum plasterboard sheets) necessarily require preliminary leveling with a putty.

- The use of any devices for accelerated drying of materials is prohibited, since these procedures will lead to disastrous results - to deformation of the canvases, deterioration of the adhesion of materials.

- The canvas is painted with high-quality water-based paints - conventional or facade. The work is performed with a roller or brush, spray gun.

- It takes quite a lot of glue for such work, so it is better to ensure that there is a sufficient supply of it in advance.

- The optimum temperature for pasting with a cobweb is 18-25 °, direct sunlight is undesirable.

- Start work from the wall opposite the exit.

A spider web makes it possible to obtain high-quality surfaces for almost centuries, but in order to achieve a result, one must have a good idea of how to glue the fiberglass. There are good visual aids to see how the process works. For example, this video:

Main advantages

Quelyd is not a “quantity over quality” principle. The company demonstrates real French quality in its entire assortment, because it is not for nothing that Kelid adhesives are the most popular on the market.

The products have a whole list of advantages for which the company is so loved not only by ordinary amateurs, but also by professional workers.

Excellent adhesion

Due to its high-quality composition, the adhesive base of the mixture guarantees strong adhesion of any wallpaper to the wall surface. The presence of cellulose additives guarantees long-lasting adhesion, even in hard-to-reach places, without much effort.

An important fact is that if the canvas is not correctly attached to the wall (the drawing did not match, the corner has moved out and other problems), you can move the glued material to the desired place within 20-25 minutes.

Profitability

An important plus is the availability of the mixture. While the quality of the goods is excellent, the Kelid brand keeps the price at an average level, which allows you to stick wallpaper even with a small repair budget. But the low price of the product is not all, because the material itself is consumed economically, which provides a way to save on the number of packages.

Security

Environmentally friendly ingredients and ongoing product quality controls ensure that Quelyd products are completely safe. The use of the entire range is harmless to both humans and animals.

Preparation rules

The instructions for the Kleo adhesive for non-woven wallpaper recommends preliminary surface preparation. At the same time, at each stage, it is necessary to use a special tool from the same manufacturer. However, consumer reviews suggest that this is an optional condition. For high-quality gluing of wallpaper, the usual preparation of the walls is sufficient:

- removing old coatings;

- filling cracks;

- deep penetration primer application.

For these works, you can use any suitable means.

Adhesive mixture preparation

The most common packaging for French glue is a cardboard package containing 250 grams of dry mix. On the pack of Cleo's glue, all actions are described in great detail, including the process of preparing the mixture. So, you need to act in the following sequence:

- pour 7 liters of cold water into the container (you can at room temperature);

- open the package and pour the mixture into water near the side of the container;

- stir the water all the time with a long stick or hand;

- leave the mixture for 5 minutes;

- Stir the glue thoroughly again.

Reviews of those who have already used this brand of wallpaper glue say that the mixture is easily mixed without using a mixer or drill. But to facilitate the process, it is perfectly acceptable to use electrical appliances.

The finished glue should be slightly cloudy white - opaque. After drying, Kleo becomes completely invisible, no need to worry about it.

The package indicates that its volume should be sufficient for 35 m² of surface.

Advice! Experienced craftsmen never dilute wallpaper glue as written in the instructions.

They recommend taking into account the weight of the canvases and the roughness of the walls - the thicker the glue, the more reliably it will fix the wallpaper and fill the pores in the walls.

It is important not to overdo it - too thick a mixture is difficult to push out from under the wallpaper

According to the instructions, the finished glue can be stored for 10 days. This is a big plus for the glue, since DIY repairs are rarely done in one day.

Types of mixtures

In hardware stores, you can find ready-made solutions for glass waste or dry mixes for dilution. In addition, there is also fiberglass, already impregnated with glue, it only needs to be wetted.

Ready mixes for fiberglass

To speed up the finishing work with fiberglass, ready-made solutions are used. They can be applied directly from the packaging onto the mounting material. Usually sold in containers from 0.5 to 5 liters. When using them, the reliability of adhesion depends on the quality of the mixture.

Check the expiration date and the integrity of the packaging.

Dry powder for fiberglass

Its advantage is the possibility of breeding and using it in portions. You can independently choose the amount of powder for preparing the solution. Dry mixtures are diluted with water, manufacturers indicate the proportions on the package. Strictly adhere to the recommendations for the preparation of the composition.

Work rules, tips

Working with Oscar glue is extremely simple. In some ways, it is similar to gluing vinyl wallpaper. Algorithm for making glue from a dry mixture and further gluing fiberglass:

- Cold water is poured into the bucket. They begin to stir it, pouring the dry mixture in a thin stream. The composition is stirred for 10 minutes. The glue is ready, you can start finishing work. Make sure the consistency is uniform.

- Layouts for wallpaper are made in advance, canvases of the desired size are cut out.

- The adhesive is applied only to the surface to be treated; there is no need to put it on the wallpaper itself. This simplifies and speeds up the procedure for wall decoration, and also saves money.

- The glue is distributed with a roller or spatula strictly on a surface cleaned of dust and dirt, preferably primed. It is recommended to remove the old wallpaper.

- The layer should be about 1.5 mm thick, especially if heavy types of wallpaper are glued. Pay attention to the evenness of the layer.

- Then wallpaper is applied and leveled with a roller. Remove excess glue with a clean, dry cloth.

- If wallpaper was mounted for painting, they need to dry out for three days, and only then can they be painted.

- The optimum temperature for working with fiberglass is 18-22 degrees.

- To ensure that the glue dries evenly and does not form bubbles, it is forbidden to open windows in the room.

The consumption of Oscar glue for fiberglass is on average 200-300 g per 1 sq. M. To calculate the amount of adhesive needed, measure the dimensions of the room, then multiply the number of square meters. by 200-300. You will get the amount of required glue ready-made. For priming the walls, you will need a smaller portion - about 50-100 g for each square meter. The glue should be diluted to a liquid consistency.

When buying an Oscar, pay attention to the integrity of the packaging. Purchase goods only in hardware stores

See the expiration date of the product. The dry type of glue is cheaper than the ready-made one. One package of the latter will cost about one thousand rubles.

Oscar glass wallpaper adhesive is a guarantee of reliability and safety. The composition perfectly holds the expensive finishing material with any kind of walls, while it is absolutely harmless. Perfect when gluing heavy cloths. Using glue in the bathroom and in the kitchen will protect against mold due to excess moisture. And the unique composition ensures easy handling and long-lasting results.

It is interesting: Plans of one-story houses with an attic - we explain in detail