Composition and quality

The kit includes two types of resins (epoxy, polyamide). The volume of containers depends on the manufacturer. The standard mixing ratio is 1: 2.

Epoxy resin is a transparent mass with a yellowish tinge, soft consistency. The substance provides high adhesion to metals, resistance to chemical elements, water and heat resistance.

It is not worth using one epoxy resin, as it does not give a strong bond. The seam will turn out to be fragile, it will not be able to withstand vibration processes.

To give the resin elasticity, a special hardener is added. The hardener is polyamide resin. It is characterized by increased elasticity, abrasion resistance, waterproofing characteristics.

When resins are combined, an adhesive with unique properties is obtained:

- high strength connection with almost all surfaces;

- resistance to chemicals;

- creation of complete tightness of the seam;

- moisture and temperature resistance;

- the seam can withstand loads and vibrations.

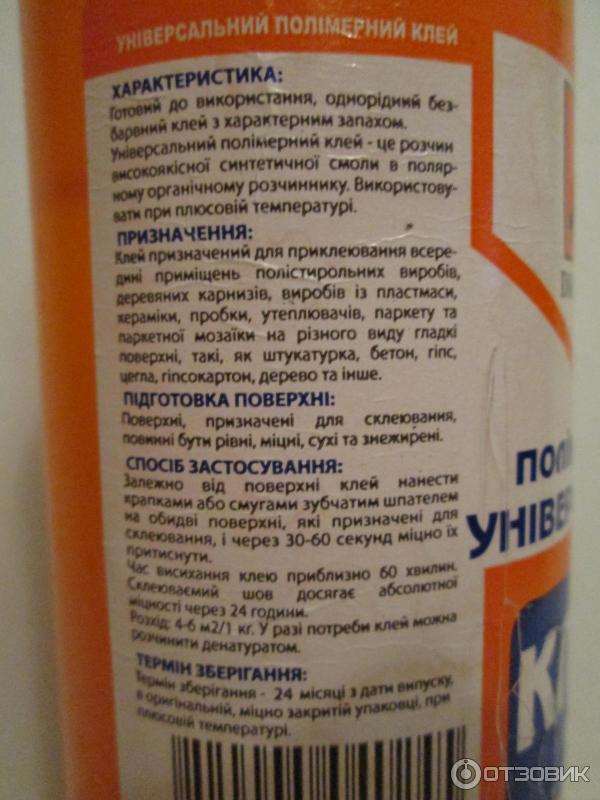

Appointment

Every person who is going to use this mastic must understand its purpose. Experts recommend using KN-3 for gluing the following materials:

- Tile. When renovating a kitchen or bathroom, walls and floor coverings are often laid with ceramic tiles. There are various means for fixing this material, but it is better to use KN-3. This tool fixes tiles on surfaces better than others.

- Linoleum. This is another common material that is often used for flooring. To securely fix the linoleum on the floor, its edges are processed with a small amount of rubber glue.

- Styrofoam. Sometimes people decide to insulate the house and paste over its walls with special sheets made of foam. Experts advise fixing them with screws. However, for additional fixation, the edges of the sheets are processed with KN-3 glue.

- Parquet board. This material is often used to improve and level the floor surface. Parquet boards are often laid without the use of additional fixing means. However, it is better to process the joints with an adhesive solution so that they are more securely fixed with each other.

Advantages and disadvantages

KN-3, like other adhesives, has a number of advantages and disadvantages, which must be familiarized with before using the adhesive. The main advantages of the rubber mixture include:

- Waterproof. The main advantage of the rubber composition is that it is completely impermeable. Thanks to this, the product does not lose its properties even in direct contact with water. This allows it to be used outdoors.

- Fast solidification. KH-3 is known for its high drying speed. Within 2-3 days, the applied adhesive layer completely hardens.

- Versatility. KN-3 is considered a versatile tool, since it can be used to glue most materials to various surfaces.

- Resistant to temperature changes. Such a rubber mixture is resistant to sudden temperature changes and retains its properties even at low and high temperatures.

The tool has much fewer disadvantages than advantages. The main disadvantage is the high cost. Also, the disadvantages include the fact that the composition does not adhere well on surfaces with roughness.

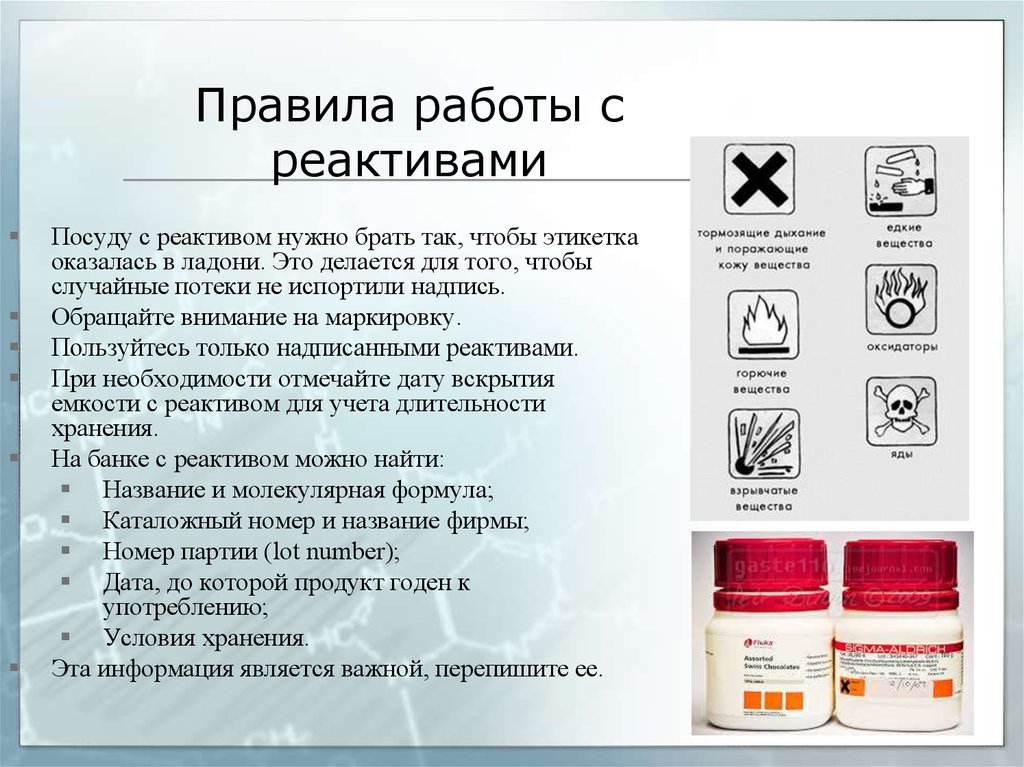

Precautions and safety

Manufacturers warn about the need to carefully use KN-2 and KN-3 adhesives. It is an explosive and toxic substance.

However, when used correctly, rubber mastics will not harm human health.

It is forbidden:

- Heat a jar of mastic or keep it near an open flame.

- Use the glue after the expiration date.

- Use for repairing kitchen and dining utensils.

The most toxic ingredients in adhesive are solvents. Due to the fact that within 3 hours after application to the surface, up to 80% of toxic fumes evaporate, it is absolutely safe to be in rooms in which rubber mastics were used for repair and construction work.

Alternative

For those who, for any reason, cannot use rubber mixtures, bitumen glue, rubber mastic, may be suitable. KN-2 and KN-3 in certain cases can be replaced with bitumen-rubber adhesives.

Instructions for use of VK 9 glue

According to the instructions for using VK 9, the following points must be completed:

- The surfaces to be glued are cleaned of dirt, to give better adhesion, it is also recommended to clean it with sandpaper.

- Steel, metal surfaces are treated with petroleum solvents to prevent rust formation.

- Degreasing with alcohol, solvents.

- The resins are mixed in the appropriate proportion, to speed up drying, more polyamide resin is added.

- The glue is applied to two glued surfaces with a spatula or spray, depending on the type of surface.

- The elements are connected and fixed, placed under a press, yew for 24 hours.

To speed up the polymerization process, the product is heated up to 60 degrees.

Brand advantages and disadvantages

High technical characteristics of the composition allow you to choose a brand among other manufacturers of building materials. The popularity of the glue is related to its properties. After all, glue paste has:

- excellent adhesive properties;

- frost resistance;

- heat resistance, withstanding temperatures up to +400 degrees;

- aseptic action against pathogenic fungi and bacteria;

- ease of application, without requiring special skills in working with glue;

- a wide range of applications.

The disadvantages include the fact that the KS plastic does not adhere well. At high humidity in the room, the bonding time will increase. This should be taken into account when facing walls, floors and ceilings in the bathroom, in the kitchen.

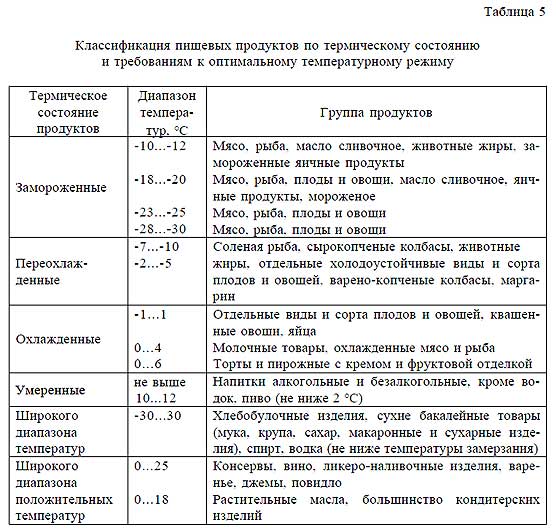

Composition, properties and technical characteristics of various varieties

There are five manufacturers that produce high-quality glue. Before purchasing an adhesive mixture for wall cladding, it is recommended that you familiarize yourself with the characteristics of various brands of tile adhesive mixtures.

Keramik

Many people who are often engaged in wall cladding recommend using a special glue "Ceramic". It has good physical and mechanical properties, which are many times superior to the base adhesive. "Ceramic" is considered a plastic and moisture-resistant agent, which allows it to be used in rooms with high humidity levels.

This glue is considered the ideal mixture for laying porcelain stoneware and ceramic materials. It stands out for its resistance to temperature changes and has a considerable moisture absorption coefficient. Also, the advantages of "Ceramics" include the following:

- strength, thanks to which the composition can be applied to bends;

- setting speed, which is twenty hours;

- resistance to frost and high temperature indicators.

Keramik Pro

The most popular tile adhesive is considered to be the reinforced composition "Ceramic Pro", which is often used for wall cladding. Such a solution is considered highly elastic and durable. Most often it is used for laying large-sized ceramic tiles or decorative stone of medium size. "Ceramic Pro" is universal, as it can be used indoors and outdoors.

Before using "Ceramic Pro", you need to understand its main characteristics:

- Increased flexural strength, which is about 2-3 MPa.

- Resistant to sudden temperature changes. "Ceramic Pro" does not lose its properties at temperatures from -60 to +90 degrees.

- Fast solidification of the applied mixture. The glue dries up within 10-12 hours.

- Low consumption of the composition. To process a square meter of surface, you will need one and a half kilograms of solution.

Praktik

Some builders prefer to use not "Ceramics", but "Practice". This composition is recommended to be used to mount tiles made of silicate stones or concrete mixtures on the surface of the walls. "Praktik" is made from fractional sand or synthetic components. These substances make the product many times stronger and more durable than other tile adhesives. "Praktik" possesses frost resistance, which allows it to be applied on surfaces inside and outside the premises.

There are several characteristics that are recommended to be familiar with before using the mixture:

- Strength that is maintained even in places of compression. This figure is 4-5 MPa.

- Tolerance to various temperatures. The solution is capable of transferring values from minus fifty to plus eighty.

- High speed of hardening. The applied composition hardens within thirty hours.

Isofix

"Isofix" is considered a universal adhesive, which can be used to glue not only ceramic tiles. Also, such a tool is suitable for gluing polystyrene and glass wool. Some experts recommend using Isofix as a reinforcing agent when decorating building facades.

Among the main characteristics of "Isofix" are the following:

- High adhesion to most substrates. The value of this indicator is 1-2 MPa.

- Resistance to low temperatures. "Isofix" is able to withstand temperatures below 30-40 degrees of frost.

- Solidification rate. The glue hardens in an hour and a half after application.

Mosaik

This is a high-quality moisture-resistant compound that is ideal for finishing a pool, bathroom, sauna and other rooms with high levels of humidity. The properties of "Mosaic" make it possible to use it for laying slabs not only on walls, but also on floors that are equipped with an additional heating system.

Mosaic has the following characteristics:

- High coefficient of moisture absorption. It is about five percent.

- Fast drying of the solution. The mixture has time to dry within 4-5 hours.

Glue 88-CA

Attention! Rubber glue 88-CA is not toxic, but it belongs to fire and explosive substances! It is forbidden to carry out work near open flames, near electric heaters, in the area of high temperatures and in places where sparking is possible (for example, next to welding)!

Advantages of 88-CA glue:

- high elasticity of the glue line;

- a wide range of glued materials;

- long-term stickiness, the adhesive layer retains residual stickiness for a long time, which is especially convenient when working with large areas of glued surfaces;

- non-toxic, does not emit harmful or hazardous substances into the atmosphere when dried and under the influence of high temperatures;

- the adhesive mixture does not contain toluene and other narcotic solvents;

- the adhesive bond remains functional in air, in fresh and sea water at temperatures from -50 to + 60 ° C;

- the adhesive mixture is produced completely ready for use.

Directions for using 88-CA glue:

- Stir the glue 88-CA thoroughly before use.

- Thoroughly clean the surface of the product from dirt, degrease with gasoline or acetone and dry.

- Grease the surfaces to be glued with a thin layer of 88-CA glue, air dry for 10-15 minutes, apply a second layer - dry for 3 minutes.

- Roll the lubricated surfaces with a roller or press them together under light load for 2-3 hours.

- Operate the product after 24-48 hours.

The adhesive film (formed after the volatilization of the solvents) retains some elasticity.

Mode of application

- Rough the surfaces to be glued with a sandpaper, wipe with a solvent, dry for 10-15 minutes, coat with glue, dry for 8-12 minutes, smear a second time and dry for 2-3 minutes.

- Glue the surfaces, press firmly and allow to cure for 24 hours.

- Stir the glue thoroughly before use.

- The temperature of the glue before use should not be lower than + 18 ° C.

Short description

Application area

The composition is intended for industrial use in order to create a protective and decorative coating for the protection of metal, reinforced concrete, concrete structures, building facades, facing building materials used in mildly and moderately aggressive environments.

Certificates

- Certificate TsNIIPSK them. MELNIKOVA No. 44-1390 dated 05/17/2007. - 20 years (180 cycles) of operation according to method 6 of GOST 9.401

- Conclusion of the NIIZhB dated 01.06.2006. - high quality paintwork on a concrete substrate

Description of the material and coating based on it

- One-component

- High anti-corrosion properties

- Weather resistance

- Heat resistance

- High resistance to UV and color fading

- Operating temperature from minus 60 to plus 300 ° С

- Electrical insulating properties of the coating

- High manufacturability and ease of application

- Maintainability after installation

- Color according to the RAL CLASSIC catalog, as well as according to other catalogs and individual samples

Main characteristics

- Covering - matte

- Mass fraction of non-volatile substances - 55%

- Coating thickness (dry layer) - 100-200 microns

- Consumption¹ per 100 microns (on a dry layer) - 350 g / m²

- The minimum holding time of the coating before applying the next layer when spraying is not less than:

| Application temperature, оС | — 20 | 20 | |

| Exposure time, min. | 90 | 60 | 30 |

- The holding time of the coating based on the OS-12-03 composition to a set of optimal properties (at 20 ° C) - 72 hours

- Application temperature from minus 30 to plus 35 ° С

- Coating based on composition OS-12-03 - natural drying (cured at ambient temperature)

1 Consumption without taking into account technological losses, depending on the method of application, the degree of spray, the equipment used, the qualifications of the workers, the characteristics of the surface.