Advantages and main manufacturers of CMC

In addition to the already mentioned advantages (versatility, extreme simplicity in powder dilution, reliability, protection from microbes and mold), CMC wallpaper glue has the following advantages:

- the appearance of spots and streaks on the surface of the wallpaper is excluded;

- the repulsive smell is completely absent;

- the glue is very easy to prepare and use;

- the product is successfully combined with other chemical compounds.

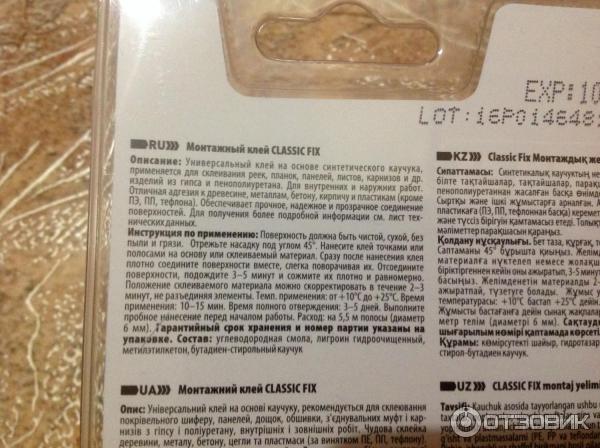

Products of this kind, both domestic and foreign, are widely represented on the building materials market. Russian KMC glue has distinctive features such as an affordable price and satisfactory performance. At the same time, it usually swells in 2 hours, which is acceptable from the point of view of the GOST standard.

The cost of foreign-made products is much higher. Along with this, the solution is prepared faster, after 15 minutes after dilution, it can already be used for wallpapering.

Undoubtedly, one of the most popular manufacturers of glue for CMC wallpaper in Russia is Vympel, LLC, operating in the Moscow region. All its products are provided with the necessary certificates.

Specifications

CMC glue, produced according to technical conditions, has the following characteristics.

It looks like a white powder from small granules, inclusions of fibers are allowed. It should not be yellowish - this color indicates poor quality or fake, which can not only adhere poorly and give the most unpredictable result, but also contain dangerous impurities.

Now on sale there are several types of CMC glue for different categories of wallpaper. There are also varieties with additional antiseptic ingredients that give it antifungal and insecticidal properties. These are additives such as

- sodium tetraborate (borax),

- potassium aluminum sulfate,

- hydroxybenzene.

Antifungal additives are especially important when gluing synthetic flooring, under which the wall is unable to "breathe". Antiseptics also prevent decay of the finished adhesive.

The technical characteristics of the KMC brand 75/400 glue, according to the information on the manufacturer's website, should be as follows.

- The main active ingredient in the dry product must be at least 50% by weight.

- Sodium chloride is 21%.

- The degree of substitution for carboxymethyl groups is 65-85.

- The degree of polymerization is at least 370.

- Water in dry matter - no more than 16%.

- Solubility - at least 96%.

- pH of 1.5% aqueous solution - from 8 to 11.

- The time for swelling to a homogeneous mass does not exceed 3 hours.

- The shelf life of a 4% solution is at least 7 days.

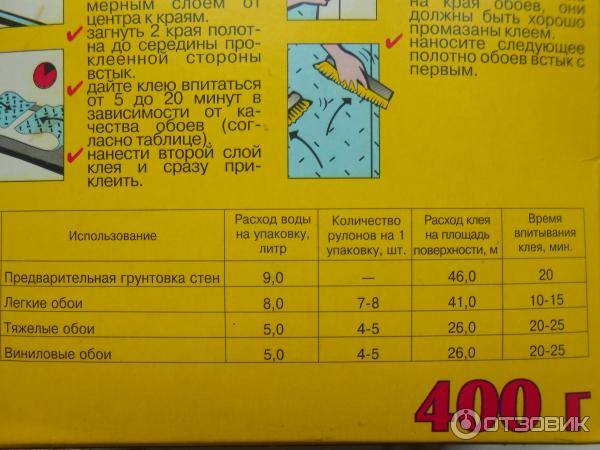

Nowadays, KMTs wallpaper glue, both domestic and foreign, is being sold. In Russia it is produced by the factories Vympel, Karbocel, Omega, Malva, Policell. As a rule, Russian glue is cheap, but it swells within a few hours. Imported counterparts are more expensive, but cook much faster - about 15 minutes. Instructions for the use of each specific type of glue are on the packaging. The general principle is that the heavier the canvas, the thicker the glue should be. The glue is gradually poured in the required proportion into a container with water at room temperature, constantly stirring it, then stirred again and left for the required time to swell.

Technical characteristics of CMC glue for wallpaper

As for the name itself, CMC wallpaper glue is made on the basis of a special substance called carboxymethyl cellulose. For ease of pronunciation and notation, the manufacturers decided to shorten the name by creating an abbreviation based on the initial letters of each of the three parts of the compound word CarboxyMethylCellulose.It turned out what we have today, and what we have long been accustomed to - CMC. In appearance, it is a white powdery material, consisting of small granules.

CMC are small white granules

As for the main characteristics that must be considered when choosing, then you should pay attention to what color the powder has. It should never be yellow.

Such products, as a rule, are supplied to the market by unscrupulous or even artisanal manufacturers. Such a product not only does not meet the gluing standards, but can also spoil the appearance of the wallpaper, for example, when it comes to paper canvases. Due to the yellow color of the glue, yellow spots may appear on them, which can no longer be corrected, and you will have to re-glue the entire room.The adhesive composition made according to GOST standards should only have white color. Such products are of the highest quality; when mixed, they form a uniform homogeneous mass without lumps and sediment.

If we consider the classification of this composition in relation to which canvases it is intended for gluing, then three main varieties can be distinguished here:

- For light wallpapers.

- For medium.

- For heavier ones.

The viscosity of the solution and, as a consequence, the ability to reliably stick heavier webs, is determined by the content of the main raw material - carboxymethyl cellulose. The more it is, the correspondingly higher is the viscosity of the composition. And all the more heavy canvases (for example, vinyl, or even linkrust wallpaper) you can reliably stick to the working surface of the walls.

Algorithm for spreading and gluing wallpaper

In recent years, CMC wallpaper glue with additional antiseptic properties has become quite popular. This is made possible by the use of special additives. Thus, this coating quite successfully prevents the formation and spread of mold and mildew.

Technical details

So, let's list in more detail the main technical characteristics of this glue:

- The dry matter content is not less than 57%.

- The proportion of the active substance to the total volume of dry matter is not less than 69%.

- The share of sodium chloride in the total dry matter is 21%.

- The moisture content of the product is 12%.

- The time of complete swelling until a homogeneous mass is obtained does not exceed 2 hours.

- The suitability of a 4% solution is at least 7 days.

Moreover. Sometimes it can be added to other solutions, for example, for gluing tiles, cement-based and chalk-based putties, which increases their strength and adhesive characteristics.

CMC can be used to glue different types of wallpaper, as well as other materials

All these characteristics show why this particular product has been so popular for a long time in the market of goods for repair and construction. In addition, an important factor is the low price of CMC, which makes it quite affordable for all categories of buyers. Manufacturers manage to keep the cost competitive in order to ensure consistently high sales. By the way, let's talk about manufacturers now.

Who produces

Many people who intend to start repairing and glue new wallpapers have already made their choice in favor of CMC wallpaper glue, on the basis of which they will prepare an adhesive composition. On the other hand, buyers are often interested in what manufacturers are on the market. We can say that the manufacturer of KMTs glue is not alone, since in specialized stores, as well as on Internet sites, products from several factories are presented at once, among which there are both imported and domestic ones.

On the other hand, it should be noted that the domestic glue takes a long time to prepare. It takes about 120 minutes to swell. Of course, this fully complies with GOST standards.Nevertheless, imported counterparts are prepared much faster: from the moment of dilution to the state completely ready for gluing the wallpaper, it takes no more than a quarter of an hour.

Everything is worth paying for, and wallpaper adhesives are no exception. So, more advanced characteristics require somewhat more serious costs, which also affects the total cost of the entire repair. However, if you need to save some extra time, then there is no point in saving. If we talk about manufacturers, the most famous of the Russian factories is Vympel, which is located in the Moscow region.

Varieties of glue

Before you buy CMC glue in the store

… Pay attention to the color of the dry matter. If all GOST standards were observed during the manufacture of the adhesive, the powder will be white

In this case, you do not have to worry that during the preparation of the solution, an inhomogeneous mixture with lumps or sediment is formed.

Do not purchase yellowish glue. Often, the composition acquires such a color if the manufacturer saves on manufacturing technology, does not adhere to standards and specifications. It is strongly discouraged to use such glue, as it can lead to unpleasant consequences. For example, yellow stains may appear, which cannot be eliminated, over the pasted wallpaper and repairs will have to be redone.

If we evaluate the CMC by its ability to glue wallpaper to the surface, three main types can be distinguished: for light, heavy and medium wallpapers. The main active ingredient, sodium carboxymethyl cellulose, gives the solution its thickness and stickiness. The more it is in the composition, the thicker and more sticky mixture, which will hold heavy vinyl wallpaper on the wall, can be prepared.

Advantages of CMC glue

- It is a versatile adhesive. It will not be difficult to dilute the dry substance to a ready-made solution, and additional antiseptic additives will save your repair from the formation of mold.

- The ready-made solution is easy to use for wallpaper installation.

- The glue does not have harsh, unpleasant odors.

- Due to its composition, the likelihood that stains or streaks appear on freshly pasted wallpaper is reduced to zero.

Today, many manufacturers present their products on the market for adhesives. Both domestic and foreign. The advantages of Russian-made CMC glue, undoubtedly, include low cost. On the other hand, the time that the mixture is ready for a ready-to-use solution is about two hours, which does not contradict GOST standards.

As for wallpaper glue from foreign manufacturers, the disadvantages include the high cost compared to Russian counterparts, but you will overpay for the time, since less than a quarter of an hour after diluting the dry matter, you can already start gluing wallpaper.

KMTS glue types

Different types have their own characteristics of application.

- КМЦ-1 "Chips" - used for gluing light washable wallpaper with a paper base.

- КМЦ-1 - suitable for light paper wallpapers.

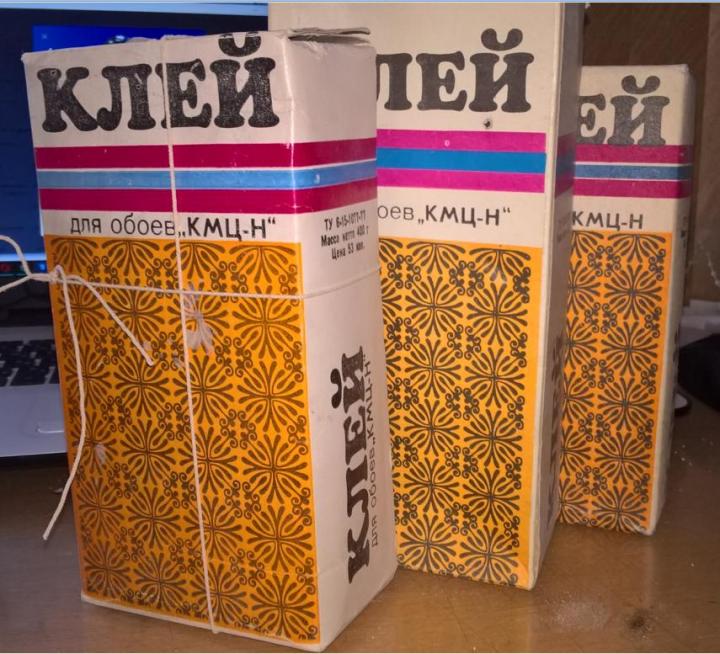

- KMTs-N - for gluing light wallpaper with a textile or paper base, it is considered more economical.

- CMC "Extra Fast" - suitable for gluing wallpaper to concrete and plastered surfaces. Can be used as a primer to prepare walls for pasting.

- КМЦ-Н "Super-Max" - suitable for all paper wallpapers on concrete and plastered walls.

- КМЦ-Н "Mini-Max" - glue for light washable and regular paper wallpapers.

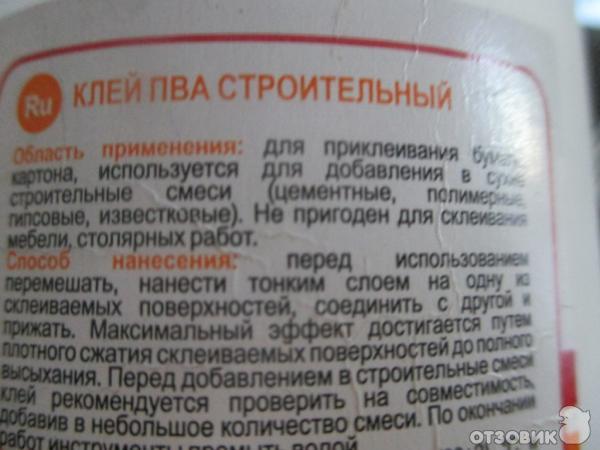

There is also a CMC with the addition of PVA.

This glue is suitable for wallpaper on paper and textile backing and paper, it is able to adhere well to concrete, wood, plastered and other non-metallic surfaces, except for painted ones - it does not adhere well to them, and it is better to choose a glue based on methylcellulose containing PVA (polyvinyl acetate ), which increases the adhesive power.Watch a video about the different types of wallpaper glue:

Such glue is also produced with a color indicator, thanks to which it is clearly visible on which part of the wallpaper canvas it has already been applied. When dry, it becomes colorless.

- Liquid glass and its application

- How many boards in a cube

- Fiberboard or hardboard

- DIY plaster bark beetle

For many years, wallpaper has been one of the most common materials for decorating a room. And the most popular means of their installation is KMTs glue. It not only firmly and permanently attaches the canvas to the wall surface, but also differs in one important quality: it is diluted in water of almost any temperature, which is not typical for other similar compositions. It is noteworthy that in this case, lumps, clots and sediment do not form in the adhesive liquid. This is predetermined by its technical, performance and chemical characteristics.

The appearance of the glue

If the CMC is produced in accordance with the standards, it has a certain "appearance" and differs in characteristic properties. This wallpaper glue is a white powder that is made up of fine granules. It happens that the product turns yellow. In this case, the glue does not meet the technical requirements and does not have the declared properties. Usually, a yellow mass means poor quality of the finished composition, a fake or a highly expired powder.

You should not buy yellowed glue and, moreover, try to glue wallpaper on it. Made without observing technology, it is not only capable of containing harmful impurities, but can also ruin the wallpaper. As paper, thin or light canvases are glued, yellow spots appear on them, and the repair has to be redone

Also, when buying, you need to pay attention to the homogeneity of the powder: only such a product, when diluted with water, forms an even, homogeneous mass without lumps

Varieties, composition and technical characteristics of wallpaper adhesives

Chemical enterprises produce their own type of CMC for different types of wallpaper. The characteristics of each are indicated on the label or packaging. In any composition of the base substance, there must be at least 50 percent, and the proportion of sodium chloride must be 21 percent. The moisture content of the mixture is up to 12 percent. The solubility of the powder is 96 percent.

CMC differ in composition and percentage of carboxymethyl cellulose. Almost all manufacturers produce universal glue that can be used to glue all types of wallpaper. For each finishing material, its own solution is prepared, in which water is taken in more or less quantity.

For light thin wallpaper

For the thinnest paper wallpaper, it is recommended to use KMTs Burny, KMTs-N, KMTs-1 (Shaving). In shape, the glue is a powdery substance of white or pink color, without any smell. Before use, the powder is diluted in water according to the instructions for use. The adhesive solution applied to the surface dries for a long time. During the period of the repair, they make sure that there are no drafts in the room.

Middle weight

Non-woven wallpapers are considered slightly heavier than paper ones. For their gluing, KMTs-N or KMTs-N Super-Max, Mini-Max, Extra Fast are used. This product is a fine granular powder. The packaging must indicate the type of wallpaper for which the adhesive is used. Any glue is diluted with water according to the instructions.

Thick heavy wallpaper

The inil wallpaper is considered the heaviest. For pasting the surface with thick wallpaper, KMTs Super strong is used. For pasting the surface with thick wallpaper, KMTs Super strong is used. leaving the adhesive, sometimes PVA glue is added. Externally, glue for heavy wallpaper looks like a white pulp. Before use, the product is diluted with water at the dosage indicated in the instructions.

Types of "Bustilat"

The adhesive composition, which was originally developed, has undergone a number of changes.Nowadays the glue is produced in different modifications, differing in physical properties and functionality.

"Bustilat Omega"

This product is intended for gluing highly absorbent materials on walls, floors, including floor coverings with a base of felt, pile, textiles. With the help of "Bustilat Omega" you can attach fabric wallpaper, carpet. No less high quality will be the decoration of the walls with paper wallpaper, photo wallpaper. It is permissible to use a means for fastening wooden coatings, but it is better not to use it on metal, PVC, these materials have low absorbency.

"Bustilat Lux"

The glue is suitable for attaching various polymers, PVC films, linoleum, tiles. It reliably attaches the specified materials to surfaces of concrete, wood, to plastered walls.

"Bustilat-M"

The tool is the most famous type of "Bustilat", suitable for most materials of walls, floors, ceilings, partitions and ceilings. The adhesion of the finish to concrete, wood, brickwork, plaster and putty, drywall will be best. Dense "Bustilat-M" can be used for laying tiles, linoleum, wallpaper stickers. After dilution with water, the product turns into a high-quality primer.

"Bustilat-N"

This glue has the highest adhesion among the "brothers". It can attach a variety of materials even to smooth substrates, including those painted with oil paint. Due to its high moisture resistance, the glue is widely used as a liquid waterproofing. They can also attach complex finishes:

- glass wallpaper;

- heavy vinyl wallpaper;

- linoleum without a base;

- synthetic carpets.

Due to its high elasticity, the product is suitable even for deformable substrates; over time, it will not collapse, since it does not shrink.

"Bustilat-D Super"

This is another reinforced compound designed for gluing smooth polymeric materials. The product is suitable for dense and heavy roll wallpaper, baseless vinyl linoleum. Special additives have been introduced into the glue to prevent the appearance of mold and mildew.

Solution composition

The ingredients in the cement based adhesive are very simple. The base is sand and cement, as well as water, which is added during its preparation. Additional additives are plasticizers. All this is appropriately mixed in certain proportions. You can prepare such a mixture from sand and cement yourself, but there is a risk of making a mistake in the proportions, which will lead to the unreliability of the mixture.

To prepare a tile mortar of cement and glue, you must carefully follow the instructions on the package. It usually looks like this:

- a container is taken, for example, a bucket or a basin, a certain amount of water is poured into it;

- according to the instructions, the required amount of powder is poured into the water;

- the resulting solution is mixed using a drill with a special nozzle until a homogeneous mass is obtained.

If, after cooking, the composition turned out to be too liquid, it must be given time to infuse a little. This usually takes no more than 10 minutes. After that, the PVA 2000 Cement glue is ready for use (see photo). It is worth noting that you do not need to try to prepare the entire mixture at once, if this is not necessary, because it will harden quickly enough and become unusable for further use. It is better to prepare the solution in parts and immediately apply it in work.

Clay Cement

Glue VK-9

Glue VK-9 PI 1.2A.526-99 TU 1-595-14-842-2004, GOST B 84-2081-83

Designed for bonding steels, aluminum and titanium alloys, between themselves and with non-metallic materials. For radio-technical products and glue-thread connections. It looks like a viscous-fluid gray mass. Highly elastic and high strength film adhesives.

The use of high-strength adhesives ensures the creation of structures with a high resource and operational reliability.Adhesive joints have high long-term strength, vibration resistance, resistance to fatigue crack propagation, climatic factors and aggressive environments. The strength of adhesive joints in a shear test is from 25 to 40 MPa, with peeling from 3 to 12 kN / m. Tensile elongation from 40 to 200%. Such a variety of properties for structural adhesives allows the product designer to select adhesives for glued structures depending on the requirements for the adhesive bond.

The main adhesives for the manufacture of power structures of modern aircraft are the VK-25, VK-36, VK-41, VK-46, VK-50, VK-51, VK-51A adhesives and their modifications. VK-25 glue (liquid) is used for the manufacture of honeycomb filler from AMg2-N aluminum foil and polymer paper. Film adhesives VK-25, VK-51A and VK-50 are intended for the manufacture of laminated load-bearing structures from metals and PCMs operating under conditions of increased fatigue and acoustic loads. Film adhesives VK-41, VK-36, VK-51 and their modifications are intended for gluing metals and non-metallic materials in the manufacture of honeycomb structures.

Paste adhesives VK-9, VK-27, VK-57 and VK-67 are used for the manufacture of adhesive and glue-mechanical (glued, glue-threaded, etc.) joints, including during the slipway assembly of the airframe. They are cured at room temperature, have a range of operating temperatures: - from -60 to + 125 ° С for a long time, at 200 ° С - 500 h; at 250 ° С - 5 h (adhesives VK-9, VK-57, VK-67); - from -60 to + 80 ° С for a long time and at 250 ° С for a short time (VK-27 glue).

- Composition:

- Glue VK-9 (PI 1.2A.526-99) is a two-component cold-curing epoxy composition. Consisting of epoxy and polyamide resins modified with organosilicon compounds and mineral fillers (asbestos, boron nitride, titanium dioxide, etc.).

- Application:

- Glue VK-9 (PI 1.2A.526-99) is intended for adhesive, glue-welded and glue-thread joints made of steel, aluminum, magnesium and titanium alloys, non-metallic materials in structures operating from minus 60C to plus 125C for a long time, at plus 200C - 500 hours and at plus 250C - 5 hours.

- Package:

- Glue VK-9 (PI 1.2A.526-99) is supplied in metal or plastic containers in sets of 1 and 5 kg or packaging at the request of the customer.

- Transportation:

- Glue VK-9 (PI 1.2A.526-99) is transported by road or rail in accordance with the rules for the carriage of goods.

- Storage:

- The guaranteed shelf life of the components of VK-9 Glue (PI 1.2A.526-99) at room temperature is 12 months.

Indicator name

Norm according to instructions

Appearance

Homogeneous viscous mass from gray to white (depending on the filler) without foreign inclusions.

Viability at + (15-20) С, h

2,5

Shear strength of adhesive joints of alloy D16AT anodized, kgf / cm2, not less at: -20С-80С-125С

1405545

Varieties

CMC belongs to the universal adhesives. It can easily glue wallpaper to any type and density of substrate.

The good thing is, the glue can be used on vinyl, paper, acrylic, fabric.

In addition to the universal CMC, you can also find such types of glue as:

For light canvases - KMTs Lux, KMTs-N Mini-Max.

An economical option is KMTs-N.

For plastered and concrete substrates - Extra Fast, Super Max.

There is also a CMC with the addition of PVA glue. It is great for paper wallpapers that can be fixed to wood, concrete, plastered and other substrates. On painted surfaces, such a composition does not last long.

Each type of glue has unique additives that give the glue special properties. You can find out more about this directly on the packaging of a separate CMC.

Reference! When choosing an adhesive, it should be borne in mind that the thicker the canvas, the thicker the prepared solution should be.

Some CMC adhesives contain an indicator. On contact with water, the glue changes color, and after drying it becomes transparent. This property allows you to control the application.

Technical details

What technical characteristics does this glue have?

- It contains at least 57% of the substance in dry form.

- 21% in sodium chloride powder.

- 69% is the active substance, taking into account the volume of the substance in dry form.

- Permissible humidity 12%.

- In new formulations, the powder will swell within 2 hours.

- 4% usable per week. This means that it is best to wallpaper the walls when the mixture is fresh. The composition contains additives that will prevent rot in the paste and has insecticidal properties. The composition is completely safe (there is GOST) for human health.

If you want to putty, you can add this powder to the chalk and cement. This composition is also good for pasting a kitchen or bathroom, a toilet room with tiles.

Considering GOST, it becomes clear why this wide range of products is so popular on the domestic market. It is widely used by construction organizations, private traders buy it for minor repairs. The cost of the glue is low, which only adds to its popularity with regular and potential buyers. Manufacturers are interested in a fast and large turnover of products, therefore they keep a low cost of goods, which is what buyers are happy about.

GOST shows that the technical characteristics of the product are normal and there will be no problems during use. This wallpaper glue has an excellent composition with the right antiseptic additives. You will not be poisoned by toxic fumes, do not accidentally stick your finger to the wall, everything is normal.

Here is such a composition, one of the classic, used for a long time.

Where else is CMC glue used?

In addition to carrying out repair work in a home, such a composition is suitable for finishing offices, industrial premises, as well as for production purposes:

- foundry;

- construction, production of finishing and building materials;

- chemical industry;

- mining industry.

The popularity of CMC wallpaper glue does not decrease from year to year, knowing the peculiarities of working with it, you are protected in advance from possible mistakes and shortcomings when performing repairs in an apartment.

Carboxymethylcellulose (carboxymethylcellulose) - a derivative of cellulose, which is a weak acid in the form of a light beige fine crystalline powder, odorless and tasteless. The name is often replaced by the abbreviation КМЦ. It is a simple ether of cellulose and glycolic acid.

Receiving and chemical properties

The material is synthesized from non-food natural raw materials by pouring it with a concentrated alkaline solution and treating it with chloroacetic acid. The resulting impurities of glycolate and sodium chloride are washed off.

CMC dissolves well in alkalis and water, insoluble in mineral oils and organic solvents. Dissolving in water, it forms transparent viscous solutions that are plastic and sometimes thixotropic.

Such solutions react well with synthetic and natural polymers, other water-soluble cellulose ethers, salts of alkaline earth and alkali metals, ammonium.

The sodium salt of carboxymethylcellulose (Na-CMC), an anionic polyelectrolyte, which is a colorless amorphous substance, has received the greatest practical application. It dissolves well in water and binds it, and such solutions show resistance to monovalent salts.

Application area

Since one of the main properties of the material is the ability to form a stable and viscous colloidal solution with long-term action, Na-CMC is widely used in various fields of industry. In particular, it is used as a thickener, plasticizer and resorbent:

- To regulate the characteristics of drilling fluids in corrosive environments in the oil and gas industries and geology;

- For flotation beneficiation of sylvinite ores in the mining and chemical industry;

- As a plasticizer of welding electrodes coating masses, an additive to concrete in construction;

- Sizing, sizing and thickening agent in the textile industry and in the manufacture of detergents;

- Thickener for putty mixtures and paints in the paint and varnish industry.

But the most popular use of this material is as an adhesive for wallpaper, linoleum and ceramic tiles.

Instructions for use

Working with VK-9 consists of 3 stages:

- preparatory;

- worker;

- final.

At the first stage, before applying the glue, it is required to prepare the surfaces. Metal, in the presence of rust, are smoothed with sandpaper. To avoid corrosion, the joints are treated with kerosene or gasoline, which are then removed with a solvent. Glass, ceramics, concrete are washed with water, if there is contamination, after drying, they are wiped with a degreaser.

The meaning of the final stage is creating a strong connection. For this, the treated areas must be pressed against each other with effort and left in this position until completely solidified.

Specifications

So we come to the point that interests many: the technical characteristics of CMC wallpaper glue. It should be noted that the name itself derives from the name of the chemical from which the glue is made. We are talking about carboxymethyl cellulose. In order to make it easier to pronounce, the name, so long and difficult for uninitiated people, was shortened to CMC, that is, to the capital letters of each of the constituent parts of this long and difficult word.

You can easily distinguish it by white granules, which look like a powder. After preparation (provided that it is correct) the adhesive will provide a good level of adhesion, so that the wallpaper will hold for a long time and reliably. Among the advantages of CMC, one can also name such as the ability to prepare a composition with water of any temperature. That is, even if, for one reason or another, you do not have hot water or the ability to heat the water, this will not be an obstacle, since you can dilute the glue solution in cold water as well. At the same time, there will be no lumps and undissolved granules: the composition has consistently high characteristics, regardless of the temperature of the water used for stirring.

This is what his granules look like.

When buying, be careful not to buy glue with yellow granules, as this may indicate that this glue was made by an underground manufacturer, which is called "in the garage." A low-quality product does not meet any GOST and technical requirements. You can only guess what properties it has. There is no need to hope that such glue will keep the wallpaper on the wall for a long time and with high quality. Do not forget that handicraft compositions can leave "marks" and stains on the surface of the wallpaper, even after complete drying.

Types for different wallpapers

Like many other brands of adhesives, CMC has a number of varieties, each of which is designed to work with a particular composition of wallpaper. This is largely based on the viscosity as well as the ratio of the main component in the composition. For heavier webs, you will need a significant level of viscosity, and vice versa.

Some manufacturers produce products with special additives. These additives affect properties such as resistance to the appearance and development of mold and mildew

This is a very important advantage, especially for rooms and premises with a high level of humidity, or for those places where it is customary to glue washable wallpaper (kitchen, dining room, hallway, as well as a closed loggia)

This becomes possible due to the fact that special additives are used in the production, which provide such a high level of resistance to moisture.Let's list the main characteristics of dry granules:

- Mass fraction of moisture in granules: 10-13%.

- Swelling time to full readiness: up to 2 hours (talking about domestic products).

- The time during which you can use a 5% solution: up to 1 week.

Suitable for gluing different types of wallpaper

By the way, CMC can be used both independently and added to other similar substances, for example, for those intended for the installation of ceramic tiles, putty compounds and some other analogs of this kind. This helps to improve the adhesion and strength of future joints.