Cooking the main surface

First of all, the wall surface must be carefully prepared. The designated scope of work consists of a set of actions.

1. Cleaning (removal) of the old coating to a solid base (plaster, brick, concrete, etc.). The wallpaper to be removed must be carefully soaked with clean water and scraped off with a spatula. Tiles are usually chipped and paint is removed with a suitable active solvent.

2. Smoothing the surface - thoroughly filling cracks, cracks and other defects with pasty plaster, and the protruding parts are removed with a hammer or compact bump stop. After the manipulations done, a rough polishing with sandpaper is performed. Then the surface is cleaned of all contaminants, leveled with a putty and re-cleaned with a sandpaper, but already of a fine abrasive type (P140 – P170).

3. Priming the walls is a mandatory procedure necessary to strengthen the structure of the base, increase adhesion to the glue, reduce its consumption, and so on. For this purpose, it is strongly recommended to use glue, which will subsequently fix the wallpaper sheets on the surface.

4. Adequate drying of the applied primer. As a rule, this takes about four hours.

Application rules

Before starting work, you need to prepare the parts to be glued:

- Remove dust, dirt.

- Clean the surface from traces of old glue. To improve the adhesion performance, sand everything with sandpaper.

- Remove moisture and degrease.

According to the Desmokol glue operation manual, the adhesive can be used in 3 ways.

The usual way

After cleaning the area, the composition is applied in a not thick layer, after 10 minutes the surface is again coated with glue. The product is put aside for a short time. Then the parts to be joined are pressed against each other with force.

When using heating

This method provides the best connection. 10 minutes after applying the composition, the glued areas are heated to a temperature of 80 ˚. Any heating device is suitable for this, for example, a hair dryer. Hot surfaces squeeze tighter together. If the composition is of good quality, you will not have to use auxiliary weights.

Wet way

The parts to be glued are thoroughly cleaned and moistened with water. "Desmokol" is applied not in a thick layer to the surface, it is determined under a press. This method is considered the most effective.

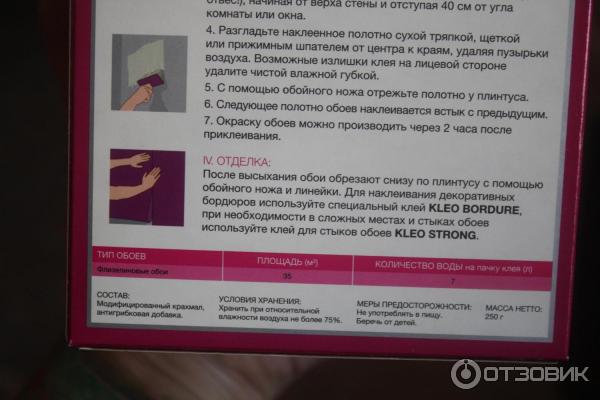

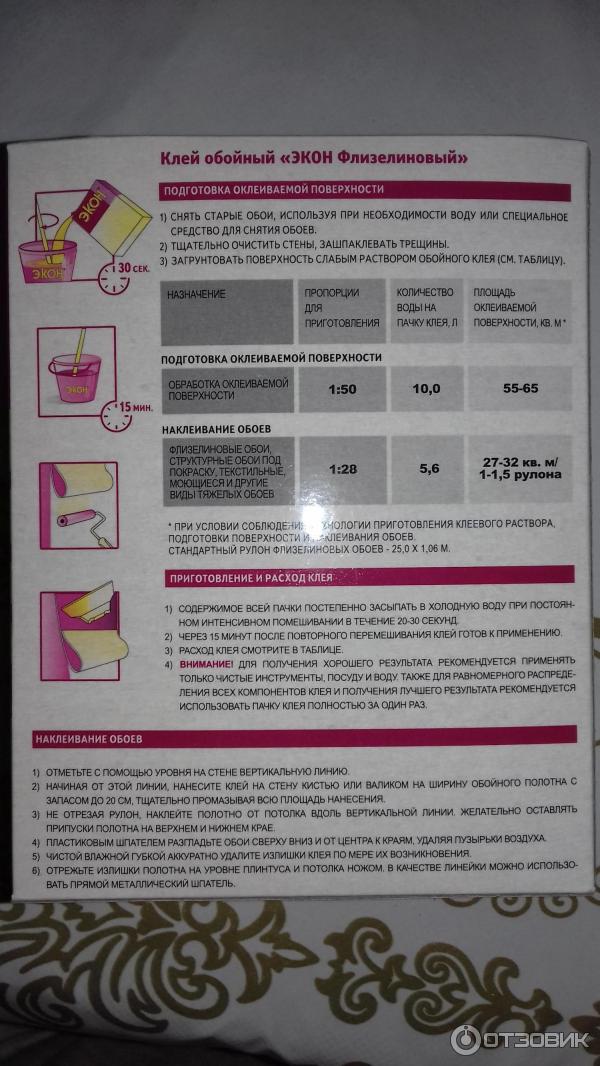

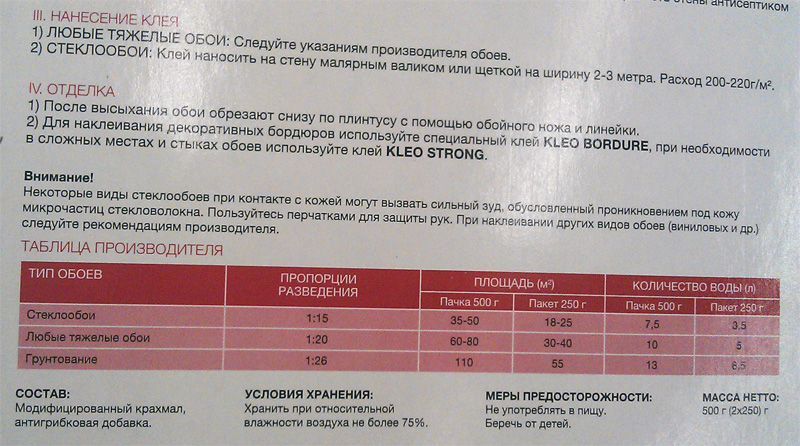

Wallpaper glue consumption

As a rule, on the packages of glue, the manufacturer indicates how much powder is required to glue 7, 15 or 30 rolls of wallpaper. But you shouldn't rely entirely on these numbers. Certain conditions significantly increase or decrease the consumption of glue, so there may be some discrepancies with what is stated in the instructions.

It is important to take into account the type of wallpaper: the greater the weight and the denser the structure of the canvases, the thicker the glue mass should be. In this situation, it is possible to slightly reduce the consumption of the composition due to the correct preparation of the wall surface.

You can reduce consumption by about a third as follows:

- use a two-layer priming treatment instead of a single one;

- use all materials (glue, wallpaper, primer, etc.) from one manufacturer.

If the surface of the wall needs a preliminary primer, the adhesive mixture (in dry form) should be diluted with water in a ratio of 1:40. Such a composition is obtained by dissolving a standard three-hundred-gram pack in twelve liters of water. The amount of glue obtained is quite enough for a full-fledged primer of 100 square meters of concrete-brick surfaces.

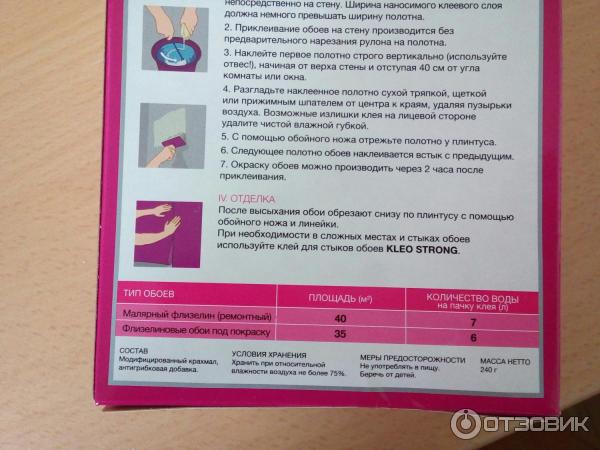

A thick adhesive mass is required for gluing textile, vinyl wallpaper or textured webs.The dry mixture (300 g) is diluted in six liters of water (1:20). The prepared amount of the mixture is enough for high-quality processing of 40 square meters.

Light thin wallpaper is glued to a less saturated composition. A standard packet of dry powder (300 g) can be diluted in nine liters of water (proportion 1:30). The resulting volume, when applied correctly, is sufficient for 50.3 square meters of surface. ">

Review of popular brands ↑

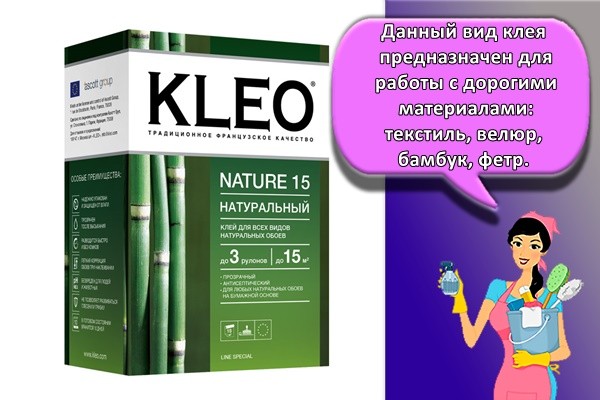

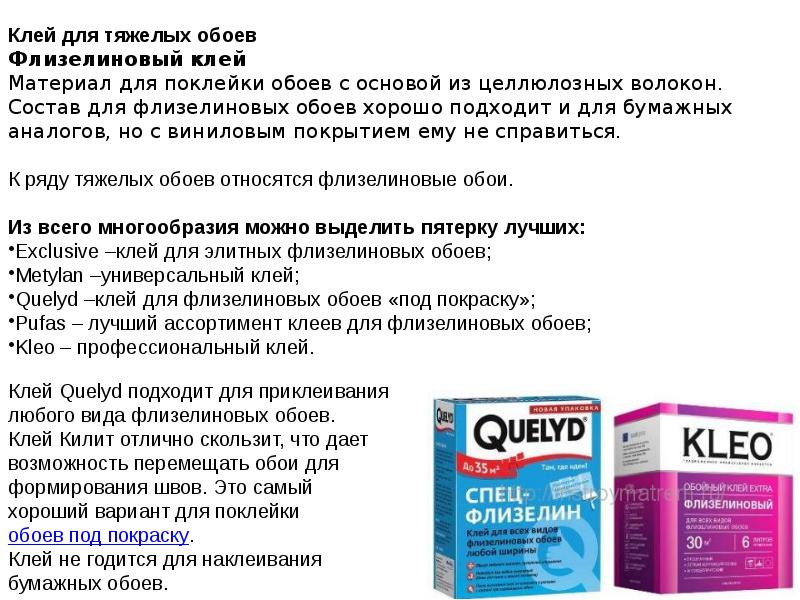

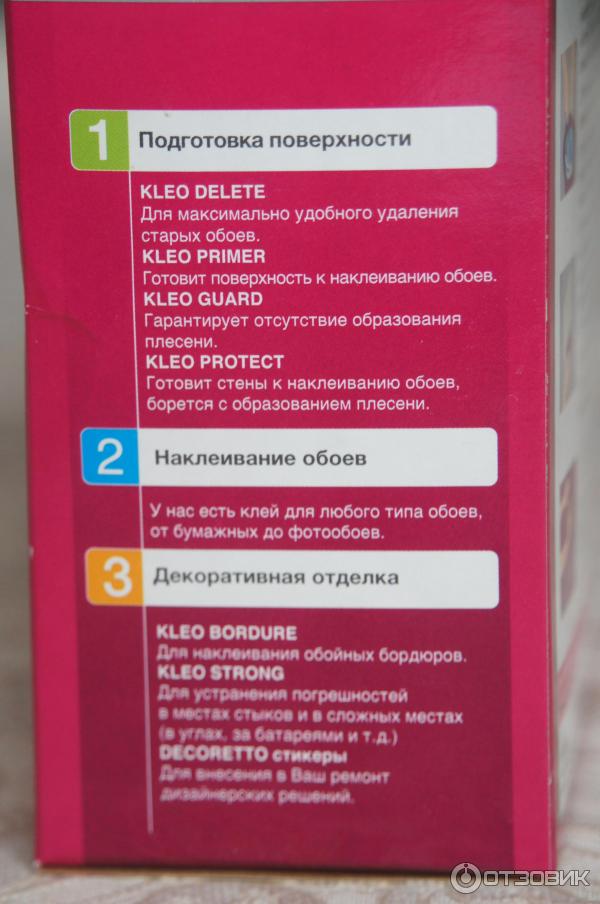

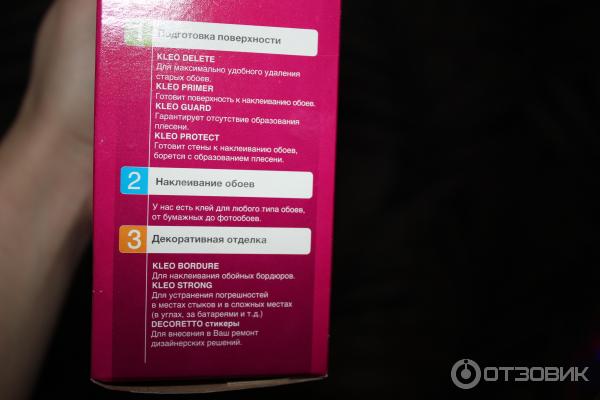

Non-woven is the most popular of all types of wall covering. There are several reasons for this: reasonable prices, easy pasting and a variety of designs. Whatever the decorative layer (vinyl, paper, with fibers of natural or synthetic fabrics), the base is always the same, so we will try to choose the best glue for non-woven wallpaper. According to consumer reviews, the top quality brands include Cleo, Methylan, Kelid, Pufas and Moment.

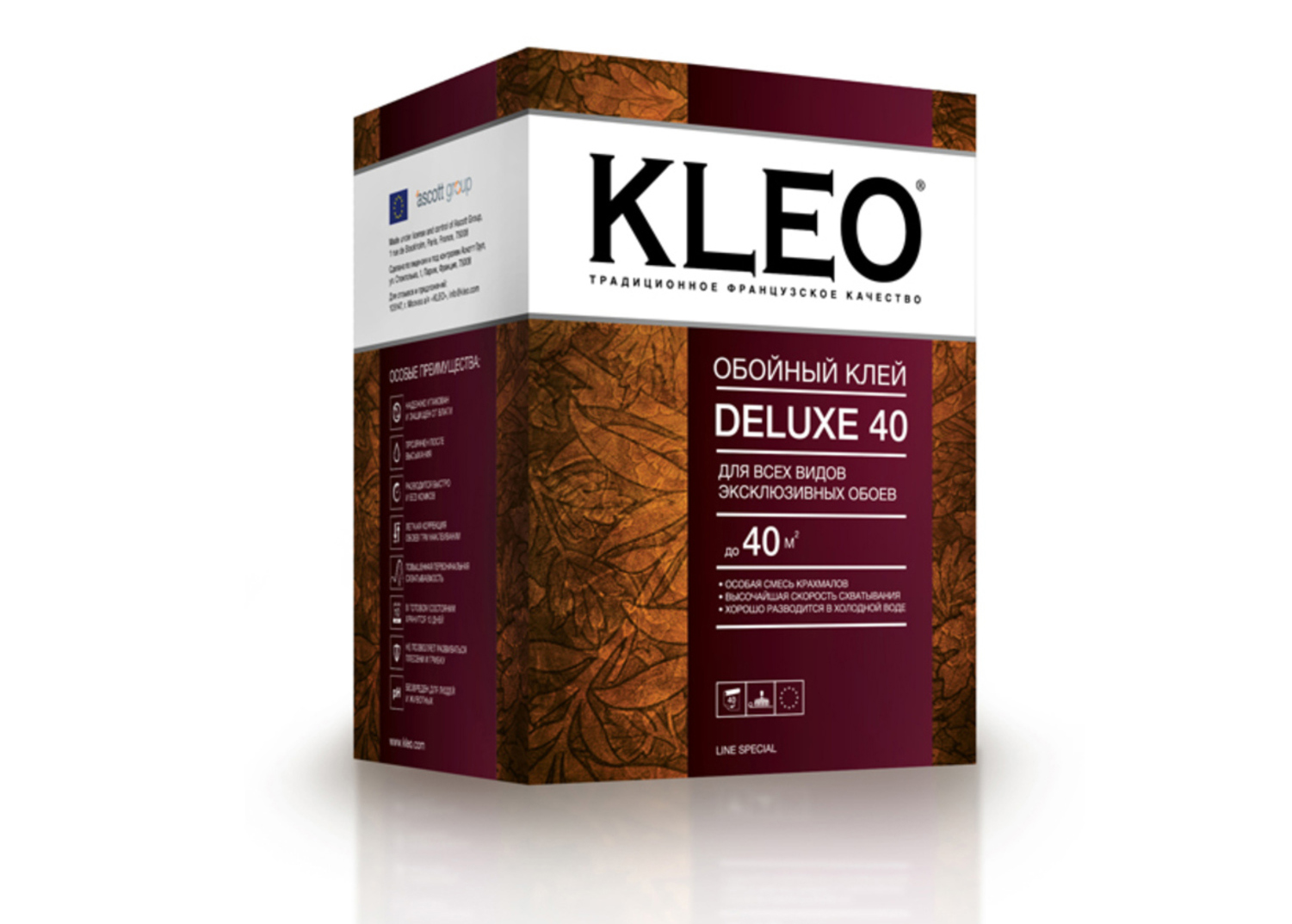

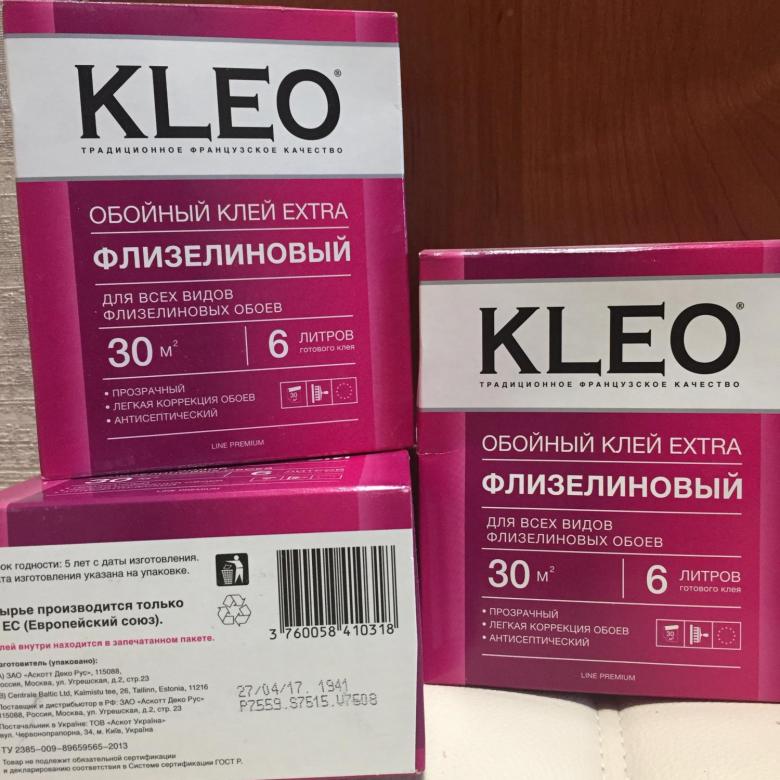

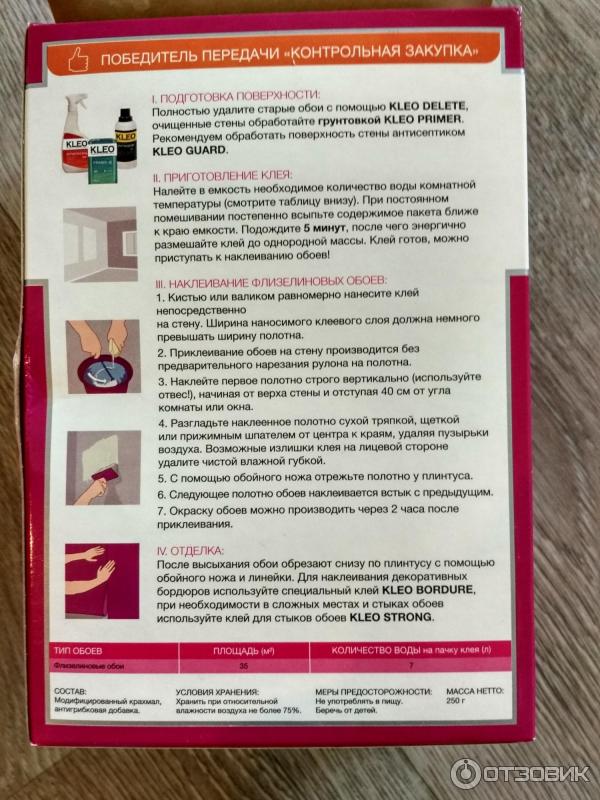

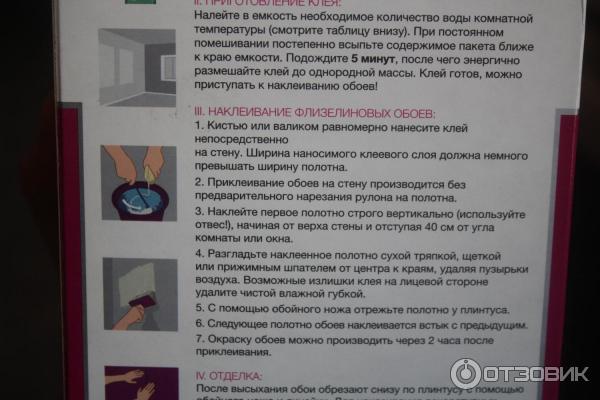

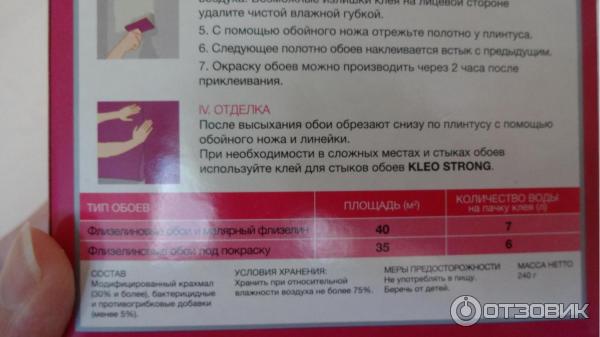

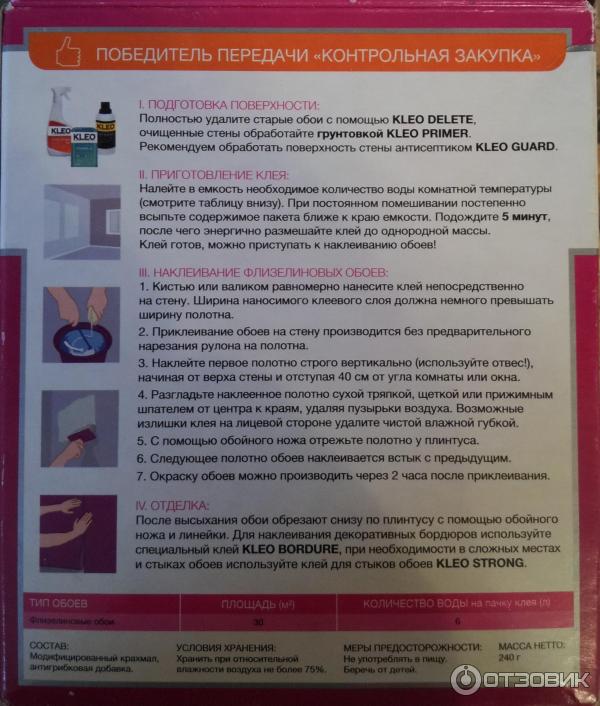

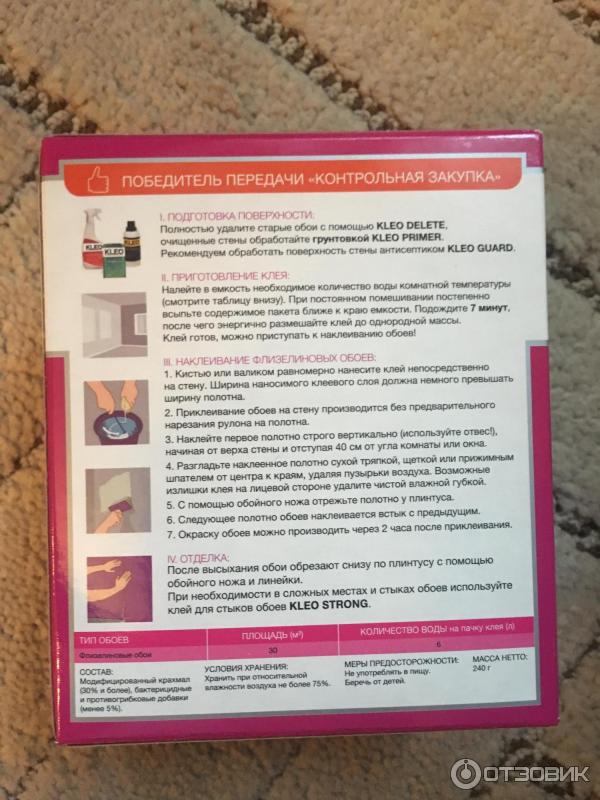

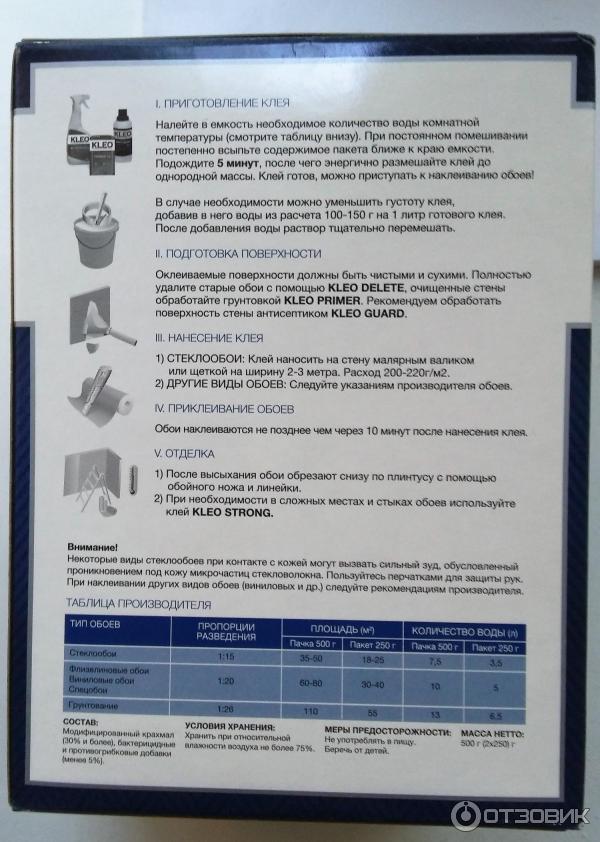

KLEO Extra (France) is suitable for all types of finishing with a non-woven base. It is sold in cardboard boxes (250 g), quickly divorces and is ready for use within 5 minutes after preparation. After drying, it remains transparent, so residues that accidentally fall on the surface are invisible. Contains antiseptics, therefore, the likelihood of fungus or mold is very small. There are several types - for heavy, textured and regular wallpapers.

KLEO EXTRA Special - dry packaging

Unlike cheap counterparts, Cleo glue for non-woven wallpaper can be stored for a long time - up to 10 days. If after pasting you want to apply paint, then you will have to wait only 2 hours before starting work. This means that the mortar is completely dry, and the veneer can easily withstand a layer of decorative paint. The main substance of the powder is dry modified starch, an additional one is a fungicidal additive.

An alternative option is Methylane glue for non-woven wallpaper of German production. If you want a quick and effective result, we recommend the special product Methylane Express Premium. It is not suitable for heavy structured rolls, but it adheres perfectly to single-layer products with a smooth surface. Provides strong adhesion to concrete, brick, plastered surfaces, is compatible with lime and cement (provided they do not crumble).

Dry powder packaging Methylane Express Premium

It takes 3 minutes to prepare the working solution. For a short time after pasting, it allows you to adjust the position of the strips, ensuring easy gliding. Does not emit an unpleasant smell or harmful substances, it is suitable for decorating children's rooms.

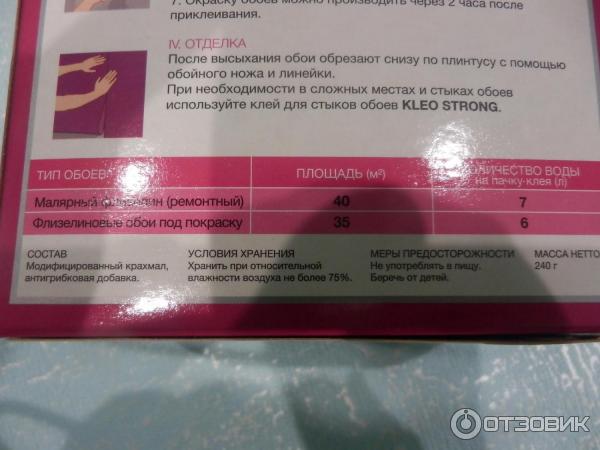

QUELYD Spec-Flizelin (France) is suitable for wallpaper with any decorative layer (including heavy textured vinyl and for painting) and non-woven base. Cooking time - 10 minutes. It is applied directly to the prepared wall with a wide paint brush, after which the cut pieces of trim are immediately applied. Allows you to customize the joints, adjust the length. The dried solution does not come into contact with the paint, which can be applied within a day.

QUELYD Spec-Non-woven paper wrapped

One of the advantages is easy dismantling without leaving marks. To remove old strips, soaking is not required, usually light efforts and manipulation with a spatula are sufficient. Dry powder contains antifungal additives that prevent mold and mildew. Kelid is absolutely safe.

Moment non-woven fabric is a product of the famous German company Henkel. It is sold in custom cardboard packs of 270 g and 500 g. Created on the basis of modified starch and methylcellulose, it belongs to the category of instant (preparation time - 15 minutes). Suitable for smooth and textured wallpapers, has a high adhesive power. Ready-made can be stored for up to 7 days.

Moment non-woven in a package of 500 g

Differs in high moisture resistance, that is, it can be used not only in living rooms and bedrooms, but also in the kitchen. The composition contains fungicides, therefore, the finish is protected from the appearance of fungi and mold. When purchasing a Moment, do not forget to check the expiration date indicated on the package. In prepackaged and packaged form, dry powder can be stored for 2 years.

Pufas Euro 3000 Vlies are German products. It has a universal focus, that is, it is suitable not only for non-woven fabric, but also for paper simplex, heavy vinyl, textile lining, silk-screen printing and structured products. It can be applied to concrete, brick, plaster and even drywall. Reaches readiness in 30 minutes after cooking.

Ecological line Pufas

The composition contains starch esters, dispersion additives. Before gluing, it is recommended to impregnate the walls with PUFAS Primer, which increases adhesion and guarantees a good result. Differs in an increased shelf life - 4 years.

Tips for mixing glue

It was said above that it is always necessary to adhere to the instructions, especially in the matter of proportions. Practice shows that the amount of this water must be reduced by 10%. The reason is that manufacturers overestimate their own criteria. Because of this, they claim that the glue is stronger than it actually is. With a thicker consistency, the strength of the adhesive composition increases, the main thing is not to be zealous. After the glue is mixed, it must be given some time to infuse. For priming the walls with glue, it is enough to bring the composition to the state of kefir. All aspects of glue dilution are now known.

How To Work With Cyanoacrylate Superglue - Procedure

Any gluing of objects with superglue can be done at home, for this you do not need to have special skills

The instructions for working with it are simple, it is important to perform all actions quickly - there is almost no time left to adjust the position of the parts. Only on soft, hygroscopic materials is superglue bonding slower, and it will be possible to correct their position within 30-120 seconds

Before bonding, large gaps and cracks must be filled with concrete dust, dry plaster or soda, and then drop superglue there - the defects will immediately be filled with a dense white acrylic-like mass. The surface should be washed, all dirt and grease should be removed. Acetone or alcohol can be used as a cleaner and grease remover. Further, the procedure for working with superglue is as follows:

- pierce the metal protection on the tube with the upper part of the cap;

- on an absolutely dry base, apply a little superglue, firmly press the second part;

- start gluing from the center to the edges, otherwise air may get inside the seam;

- press the parts for 10-30 seconds;

- leave the product to dry.

At the end of the work, you need to wipe the nozzle of the tube from the superglue, screw it tightly. Opening if the lid is stuck, the bottle will be problematic, so it must be cleaned thoroughly.

How to mix tile adhesive correctly?

Only at first glance it seems that diluting the glue is as easy as shelling pears.

There are many nuances, non-observance of which can not only make the glue unusable, but also completely ruin the cladding.

Rules and principles for the dilution of dry glue

Experienced builders recommend following these rules:

- the mixing container must be clean, you need to scrape off the remnants of the previous glue or solution from the walls, otherwise they will violate the composition;

- the water must be clean, match the temperature of the dry mixture and the environment (it will need to be heated or cooled);

- the mixture must be poured into a liquid, and not vice versa, otherwise it will be more difficult to get rid of lumps;

- it is better not to use industrial water due to the presence of impurities that can react with glue;

- if the cement slurry in the container has begun to set, dilution with water will not help, it is better to prepare a new mixture;

- the permissible volume of water must not be exceeded, otherwise the solution will turn out to be liquid and will not hold the tiles.

Advice! If in doubt about the consistency of the glue, leave the mixture for 5-10 minutes. If the texture remains unsatisfactory, you can add a little water or dry powder.

How to knead tile adhesive: choose a tool

If you have to cook 10 liters or less of glue, it will be convenient to mix the components using a long rectangular trowel.

This steel shovel with a curved handle can be hand-worked to lift dry particles from the bottom so that there are no lumps.

Making large volumes of glue by hand is problematic. You will need a drill with a blade-like attachment - only it should be designed to mix the solution, not paint. Experienced craftsmen use a construction mixer with a whisk for this purpose.

The rotation speed of the nozzle should not exceed 300 rpm.

In this case, the blade must be completely immersed in the solution, otherwise bubbles will appear in the texture, deteriorating the quality of the glue.

Step-by-step dilution of glue

Work order:

- Pour water of the required temperature into a clean prepared container. Add the dry mixture to the liquid according to the instructions. For a start, it is better to take ⅔ of water, and if the mixture is thick, dilute it with the rest of the liquid to an optimal consistency.

- Measure out the required amount of dry mix planned for the first batch.

- Add the first portion of dry glue while stirring the solution. Introduce the entire prepared mass in small doses, achieving a homogeneous consistency by stirring.

- Leave the solution for 10-15 minutes so that the particles are well moistened.

- Stir again, break up remaining lumps and delamination. The adhesive is ready to use.

The mixture should be quite thick and elastic. It is easy to check its quality - just scoop up the glue with a trowel and turn it over. A high-quality solution should not drain and fall off in pieces. In the process of laying the tiles, it is recommended to stir the solution periodically so that it retains its plasticity and does not dry out.

Advice! The longer the glue is mixed and whipped, the more liquid it turns out. The situation can be corrected by adding a small portion of the glue mixture.

Positive qualities of Kleo glue

Due to the unique texture and composition wallpaper on non-woven Basically, one of the main roles for obtaining a high-quality result is the use of the correct adhesive. Kleo is used by professional craftsmen for pasting and in self-repair. Due to the simplicity of dilution and application, it can be used even by those who have not experienced this process before.

The glue contains modified starch, fastening components, special additives that prevent the appearance of mold and mildew on the walls. Due to this composition, the glue has high adhesion to any surface and universal properties. Against the background of other brands that are presented in hardware stores, this glue stands out for its economy and favorable cost. So, a standard package of dry matter is quite enough for pasting 30 square meters. m. In diluted form, Kleo is a transparent mass that can be easily applied to both canvases and walls. With this glue, the wallpaper is neatly glued to the walls, and stains do not form on their surface.

Importantly, the finished coating will last a long time.

Important! If a lot of glue is diluted, and the work does not fit in one day, then it is very convenient that this adhesive composition retains its properties for 10 days.

Kleo glue is sold in cardboard boxes with detailed information about the manufacturer and composition, as well as the methods of dilution and application.Inside the package is durable polyethylene, which is packed with powdered glue. There are many varieties of glue in various volumes, among which you can choose the one suitable for certain conditions.

How to determine the quality of wallpaper glue

When buying, just read the instructions and check the expiration date. The manufacturer guarantees that the correct preparation and the recommended amount of solution will give an excellent result. A good solution should have the following characteristics:

- high degree of initial and final adhesion;

- neutral indicator of acid-base balance pH 6-7;

- mobility necessary for a possible change in position;

- moisture resistance, ability to retain shape at high humidity;

- hygiene - the absence of hazardous substances in the composition;

- environmental friendliness - the use of natural materials;

- resistance to mold or mildew (presence of fungicides, bactericides).

For example, kitchen products must be durable, moisture resistant, easy to clean, and contain fungicides.

Vinyl wallpaper for the kitchen-dining room

It is easy to check the quality of the glue during the preparation process. If the powder dissolves well in water, does not form lumps, forms a viscous translucent mass without streaks and impurities, most likely it meets all the requirements.

Do not buy powdered products with an expired shelf life, as they lose their adhesive properties - this usually becomes clear when trying to stick the first piece.

How to apply correctly

How to prepare the adhesive solution, write in the instructions on the label or package. Usually the slurry is prepared in a plastic bucket. Take water at room temperature (not hot). First, liquid is poured into the bucket. Then a measured amount of powder is poured in a thin stream, with constant stirring. Stir the glue well and leave to swell for 15-20 minutes or 2-3 hours.

Usually, a standard package of CMC weighing 500 grams is diluted in 7-8 liters of water. This solution should be enough for pasting an area equal to 50 square meters. Before gluing the wallpaper, the walls are primed with an adhesive solution based on CMC. For this purpose, take 500 grams of glue per ten liters of water. The liquid mixture is applied to the walls and left to dry for 3-4 hours. The wallpaper itself is lubricated with an adhesive mass and left to soak, depending on the thickness of the canvas, for 10-20 minutes. Before pasting the walls, the wallpaper is once again smeared with an adhesive mixture.

Main advantages

Quelyd is not a “quantity over quality” principle. The company demonstrates real French quality in its entire assortment, because it is not for nothing that Kelid adhesives are the most popular on the market.

The products have a whole list of advantages for which the company is so loved not only by ordinary amateurs, but also by professional workers.

Excellent adhesion

Due to its high-quality composition, the adhesive base of the mixture guarantees strong adhesion of any wallpaper to the wall surface. The presence of cellulose additives guarantees long-lasting adhesion, even in hard-to-reach places, without much effort.

An important fact is that if the canvas is not correctly attached to the wall (the drawing did not match, the corner has moved out and other problems), you can move the glued material to the desired place within 20-25 minutes.

Profitability

An important plus is the availability of the mixture. While the quality of the goods is excellent, the Kelid brand keeps the price at an average level, which allows you to stick wallpaper even with a small repair budget. But the low price of the product is not all, because the material itself is consumed economically, which provides a way to save on the number of packages.

Security

Environmentally friendly ingredients and ongoing product quality controls ensure that Quelyd products are completely safe. The use of the entire range is harmless to both humans and animals.

Features of the preparation of the composition and subtleties of using wallpaper glue

Before you breed the acquired composition, you have to calculate the estimated area of the surface to be glued. This will help determine the amount of composition required for the work.

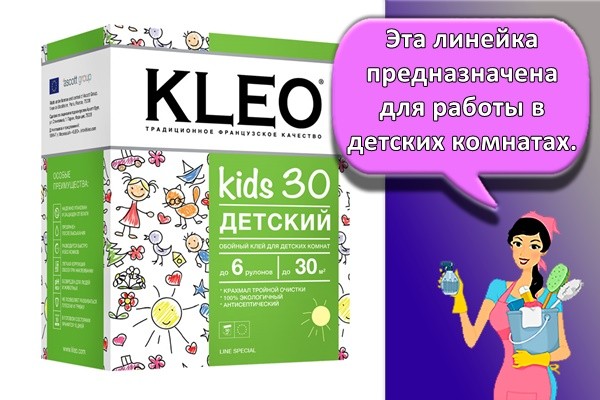

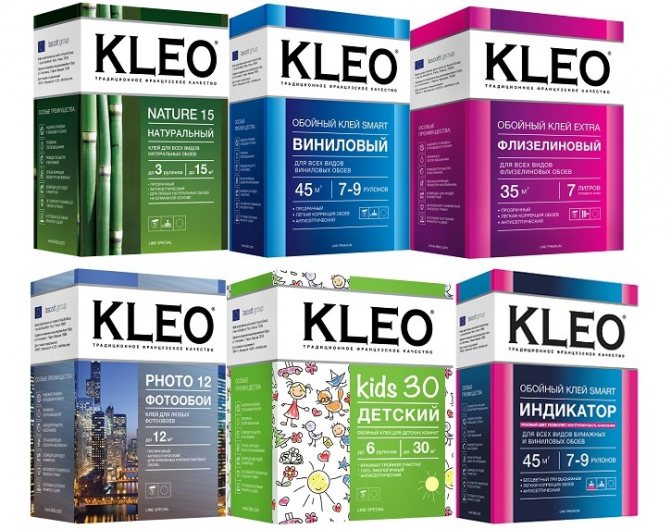

Before starting work, read the information block printed on the adhesive packaging and the instructions for Kleo - wallpaper adhesive. For example, a 250-gram package of Kleo Ultra dry glue will be enough to cover surfaces up to 25 square meters with canvases. Kleo Optima packaging is useful for pasting an area of up to 30 square meters, and when working with heavy canvases, the consumption will increase and the packaging will already be sold by 25 square meters. A pack of Kleo Kids brand glue is enough for 4-5 rolls of wallpaper, while a Smart pack can be stretched into 7-9 rolls. There are also special packages that allow you not to buy a whole shelf of funds in a construction hypermarket - Total 70 with a pack weight of 500 grams and a processing area of up to 60 square meters.

Having calculated the required amount of glue, they begin to dilute it, strictly following the instructions. By neglecting the recommendations, you risk spoiling the composition.

In order to carry out this manipulation, you will need to prepare a capacious plastic or enamel container, the volume of which is at least 5 liters.

In this vessel you have to pour the entire contents of the bag with glue, pouring into the tank before that the required amount of water indicated on the package with the product. During the pouring of glue flakes from the bag into the water, it is recommended to adhere to this technology: pour not in the center, but closer to the edges, not forgetting to stir the mixture. This will help to achieve uniform dissolution of the glue and transformation into a mushy mass without inclusions.

What is not less important

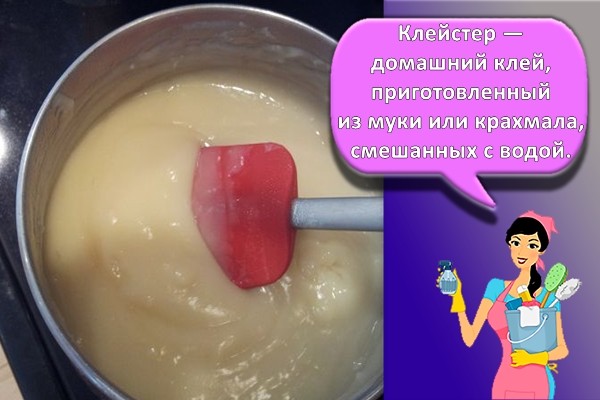

What is and why

Kleister is a homemade glue made from flour or starch mixed with water. Despite the abundance of various adhesives on sale, homemade glue is widely used in repair work and everyday life.

The most common applications are as follows:

- Wallpaper gluing. With a large amount of work, the use of paste will significantly reduce repair costs. At the same time, the quality is not inferior to store compositions.

- Pasting of windows. It will help get rid of drafts without damaging the materials.

- Priming the walls. The mixture is perfect for preparing walls for decoration.

- Seed preparation for sowing. For even distribution of seeds, they are glued to toilet paper before planting in the garden. The natural adhesive will not harm the seeds.

- Children's creativity. Hypoallergenic and non-hazardous if swallowed, the homemade formulation works well with children.

- Needlework. Craftswomen are used for scrapbooking, fabric compositions, papier-mâché.

Making glue with your own hands is not difficult at all. Most often, flour with water must be boiled and cooked for a while, but there are recipes without cooking, when the flour is diluted with a small amount of cold water, and boiling water is added to the resulting mixture.

The main advantages of homemade glue are in its cost and health safety, because it is prepared from natural ingredients. The disadvantage is the fragility of storage, therefore, it is cooked immediately before the planned work in an amount sufficient to complete the task.

For wallpaper

Flour glue is suitable for both thick vinyl wallpaper and thin, only the proportions of the components and the density of the resulting mixture are different. To brew the paste, they take the cheapest flour, since it contains more gluten due to coarser processing, which means that it will be better to keep such a composition.

What additives in the adhesive solution are used when gluing wallpaper:

- PVA. Improves characteristics, increases adhesion.

- Joiner's glue. Improves fixing properties, not suitable for light-colored wallpapers - stains may appear. They are used exclusively for dark wallpapers.

- Copper sulfate.A small amount is enough to prevent parasites.

Homemade glue is good for pasting windows with wooden frames, the cracks in which are perfectly closed with a mixture of water and flour.

Papier mache

Papier-mâché is a popular technique for making paper and glue crafts because the starting material is available and the final product is light and durable. To work in the papier-mâché technique, no special knowledge or education is needed, the result is limited only by the author's imagination. Papier-mâché is used for interior design decoration, as a hobby, in children's art, for making masks and theatrical props.

Needlework

Glue made from water and flour is widely used by needlewomen. For example, it is impregnated with it in the manufacture of artificial flowers. To work with fabric, vanillin is added to the wallpaper paste, it will add shine to the finished product.

Decor

Flour glue can also come in handy to make holiday decor elements. For example, it is better to glue New Year's snowflakes on windows with a homemade solution, since it is then easy to wipe it off the glass. With the help of paste and paper, using the papier-mâché technique, they create decorative elements such as statues, vases, and interior figures.