Advantages and disadvantages of casein glue

Finishers value casein glue for its benefits.

These include:

- Ideal for gluing wood products.

- Environmental friendliness of the product, thanks to which you can work with it without protective equipment.

- Duration of storage in dry form, subject to the rules.

- The finished seam is resistant to prolonged exposure to moisture, temperature extremes.

Disadvantages:

- After bringing the powder to a ready state, its shelf life is no more than 5 hours. It is necessary to prepare the exact amount of the mixture so that the hardened mass is not disposed of later.

- Due to its natural ingredients, casein glue is susceptible to mold.

- Over time, the finished joint may darken and spoil the appearance of the product.

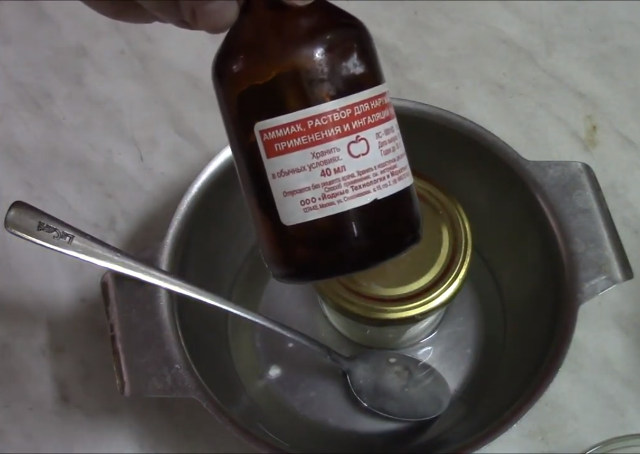

To protect the sticky mass from the appearance of fungus, mold, you can add a small amount of ammonia to it.

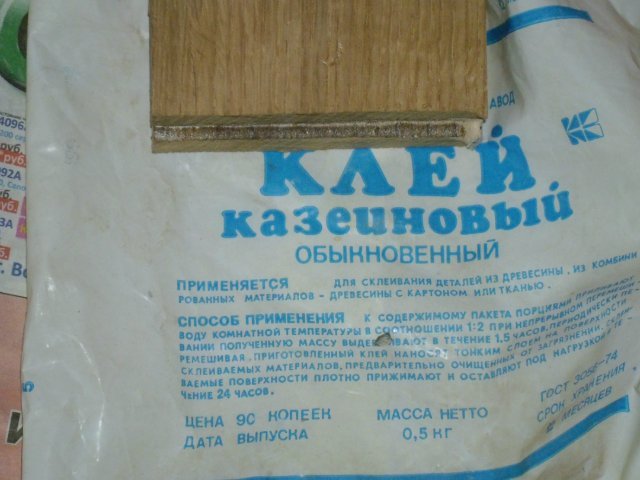

Industrial production

Casein glue is made according to GOST. This applies to the production of adhesive masses by large enterprises. For the manufacture of used waste remaining after processing milk. They are supplemented with rennet enzymes, which are diluted with different amino acids. The most common choice is lactic acid.

Auxiliary materials: slaked lime - fluff, sodium fluoride, copper sulfate, kerosene, caustic soda and soda ash. Users add fillers according to the recipe - bone meal, Portland cement (M 400-600), liquid glass, chalk.

Two types of glue: ordinary and extra

There are two main types of adhesives based on natural ingredients - "Extra" and "Ordinary" (OB).

The first option has improved technical characteristics, it is more expensive, it is used for repairing wooden products, joining different materials. The second one is at woodworking enterprises.

Casein products "Extra" are chosen by professionals. They provide a high strength bond that can withstand environmental and physical stress. In hardware stores, you can easily find these two types based on milk protein - "Ordinary", "Extra".

DIY glue preparation

There are a number of ways you can make good casein glue at home. In the future, they can glue any of the materials listed above. What is the tool made of on its own? Here is the simplest "cold" way based on cottage cheese:

- take 40 g of store cottage cheese;

- grind the cottage cheese through a sieve to get a fine powder;

- add 10 ml of ammonia to the mass;

- mix the mixture well, the product is ready.

You can go the hard way and make glue from milk. To do this, a liter of milk is heated without boiling, 9 teaspoons of vinegar essence is introduced into it. The mass is heated until lumps of cottage cheese appear. Strain it through cheesecloth, put it in a pan, add 3 tablespoons of soda, a few drops of water. Heat until the mass begins to bubble, then mix thoroughly and allow to cool. The glue is ready.

How to dilute glue from ready-made casein powder? Dilute casein powder according to the instructions in the instructions. Usually the proportions of water and glue are equal. The mixture is infused for 40 minutes, after which it is ready for use.

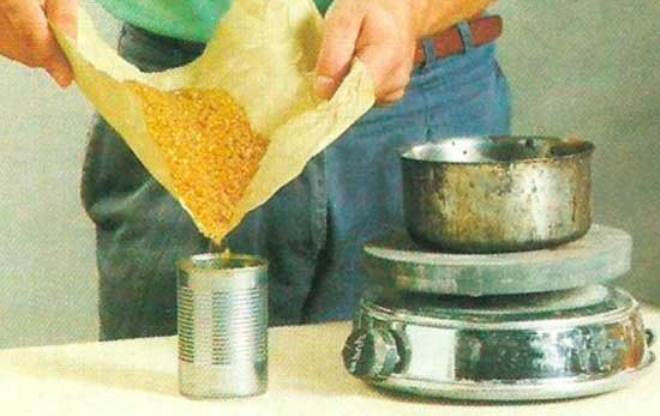

On the basis of casein powder (not glue, namely casein), you can make a glue that will be close in quality to an industrial one:

- Combine 20 g of the substance with 100 ml of water;

- let stand for 30 minutes;

- introduce 6 g of borax;

- Heat the mass for 30 minutes in a water bath (at 50 degrees).

Another way to make glue: insist 20 g of casein and 100 ml of water for an hour, add 20 ml of ammonia (25%), 10 ml of sodium hydroxide (50%).If the glue is too thick, it is permissible to dilute it with water.

The next method involves mixing 20 g of casein powder, 4 g of rosin, 40 ml of water, 1 g of slaked lime. After 120 minutes, make a hot solution of borax (2 g) and water (12 tablespoons), add to the original mass, mix everything. Another 20 ml of water, 2 ml of ammonia are added. The glue is ready.

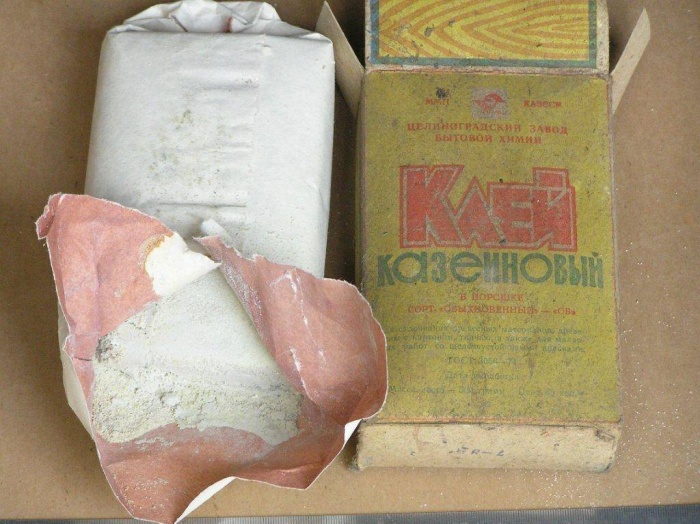

Powder casein glue

In practice, there are many proven, reliable recipes. Available for paper and cardboard, for wood and furniture, for glass and porcelain, waterproof for paint. It all depends on the starting components in addition to powder and water, which will give the required characteristics.

To prepare simple casein glue, just follow a few simple steps. This applies to the powder from the hozmag.

Step-by-step instruction:

- Prepare a clean glass container with a wide, flat bottom.

- Combine 2 parts of water, 1 part of powder in a container.

- Stir continuously for 20 minutes.

After obtaining a homogeneous mass without lumps, it must be used in 4-5 hours.

Store casein in its packaging only in a clean, bright, dry and well-ventilated area.

Dry casein adhesives, which should have increased moisture resistance and elasticity, are best suited for working with wooden parts. If you wish, you can make an adhesive composition yourself to connect wood parts. For this, the cold gluing method is used.

The main components of the formulations

You can make almost any glue with your own hands - the difficulty can arise only in the selection of the necessary components. A few years ago, it was considered the norm to independently make a wallpaper tool, and canvases could last for decades. Such a material was prepared from flour, potato starch, since these products contain a lot of adhesives.

In the creation of adhesive for tiles, cement is definitely required - it is this substance that is able to keep the tile on the wall. Pieces of old rubber are useful for making rubber glue. The stationery contains gelatin and wood glue. There is even a special conductive glue that is used to fasten electrical circuits and mechanisms. Usually, for its manufacture, they take a ready-made "Moment", inject grated graphite, and the electrically conductive composition is ready!

Scope of glue

This tool is the main component of the production of plywood, cardboard, woodworking. Thanks to the properties of this glue, the internal structure of the wood is significantly improved.

Casein glue is becoming more and more relevant:

- It is widely used in furniture production. Together with auxiliary components - copper sulfate, soda, lime, kerosene, rosin and others - it is used in working with various types of wood, as well as when gluing wood, leather, plastic or cardboard. The natural origin of the substance makes it possible with the help of it to produce furniture and other items with the “Environmentally friendly” brand.

- It is used in everyday life and in the construction industry. It is a component of putty, putty and alkali-resistant paints.

- Due to its properties, casein is excellent as a raw material for the chemical industry. It is favorably distinguished by resistance to high temperature and high humidity. This makes it possible to use it for the manufacture of ceramics, plastic products, various types of paints and concrete. Casein dyes create beautiful, porous and high-quality surfaces of matte or silky textures, which, together with the properties of durability and quick drying, allow them to be used for painting the facades of buildings. This is another advantage of casein glue.

- Casein is also very well known in other industries such as printing, painting, toy manufacturing, and as a dye and binder in automobiles and shipbuilding.

- Casein is a nutritious and healthy product and is one of the main proteins of animal origin. This makes it possible to widely use this substance in the food industry. Casein has become a constituent additive in infant formula for newborns and in specialized nutritional supplements for adults and athletes.

- Casein glue mixed with modified starch is used commercially. With its help, labels are glued to glass products and dishes.

The scope of application of casein glue is quite extensive. It is used in the production of multilayer building materials from wood, cardboard or woodworking industry waste. It is used to attach parts to create scale models or wooden toys. It is suitable for repairing shoes, ceramics and porcelain. Such glue even participates in the technological process of producing some concrete models.

Finally, the main question that worries everyone. The price of casein glue fluctuates around 300 rubles per kilogram of dry mix. Considering the cost of modern building materials, it is quite inexpensive. Moreover, it is worth making allowances for the very low consumption of the substance. It is sold in the form of a dry mixture, which must be diluted with water as needed.

Characteristic

PVA

The manufacture of PVA glue begins with the selection of the following components:

- Gelatin - 5 g;

- flour - 100 g;

- water - 1 l;

- glycerin - 4 g;

- alcohol - 20 ml.

Previously, a day before the manufacture of PVA, gelatin is poured with water. Swollen gelatin, flour and distilled water are mixed, boiled in a steam bath and until a dense, uniform texture is formed. Then add glycerin and ethyl alcohol to the mixture, stir and bring again to a thick, uniform texture. Allow the resulting adhesive mixture to cool and use it as directed.

DIY glue making

Joiner

Carpenter's glue is ideal for permanently gluing materials, mainly from wood, for example, cardboard, plywood. To make the glue, you will need a tile, which you need to grind and soak the crushed small pieces in cold water so that it completely covers them. The resulting mixture must be kept until a soft jelly mass is formed. As a rule, it takes 10-12 hours for the transformation. Then the mixture in the container must be put on a steam bath and continuously stirring to bring to a uniform liquid texture. Allow the resulting mixture to cool, then use it as directed. If a light glue is required, a little hot water is added to it. For strong adhesion of leather products in 500 ml of the composition, add 1 teaspoon of glycerin. This is such a difficult technology for making glue.

Tiled

It is best to glue front, decorative tiles with tile adhesive. It is made from water, sand, cement and PVA. Since sand, in fact, acts as a putty, it is recommended to take sand with a boundary diameter of 2 mm. The proportion of cement and sand is 1: 3. For example, 1 bucket of cement requires 3 buckets of sand. To prepare the mixture, cement and sand are thoroughly mixed, and then a solution of water with PVA is added. For 1 bucket of tile glue, you will need 500 g of PVA. The volume of PVA can increase when tiles are glued in places of high humidity. The resulting mixture is mixed until a uniform, thick texture is obtained and is suitable for use. The glue should be used immediately, without waiting for it to harden. The hardened mortar should not be diluted with water and applied during the gluing process.

Casein

There are many similarities between carpentry and casein adhesives, but the latter is more resistant to moisture. In the manufacture of casein glue, casein powder, water, and borax are used. Water is added to casein powder, and then infused for about 3 hours.Hot water is also added to borax in a ratio of 1: 7. The resulting solution is mixed with casein, boiled in a steam bath and stirred continuously. After 40 minutes. after removing from the steam bath, the glue is usable.

You can make casein powder yourself. Why sour low-fat milk is expressed through thick gauze. Casein with gauze is washed in water, boiled, wrung out and dried until firm.

To make a mixture of homemade casein, you need borax, water and casein powder in a ratio of 1: 4: 10. When combining ingredients, water should be added gradually. It is advisable to use the finished composition immediately, since after about 3 hours it hardens and loses its stickiness.

Water resistant

Quite often in the household, glue is needed that is not afraid of damp and is waterproof, for example, for a rubber boat. We offer several methods for making adhesives:

- Low-fat cottage cheese and slaked lime are mixed until a thick, uniform mass is obtained. Then the glue is ready for use. It is applied to surfaces that should be clamped and dried well;

- 100 g of high-quality wood glue is cooked over low heat until a liquid texture is obtained. Then 35 g of drying oil is added and the mixture is well stirred. Please note that it can only be used preheated.

Making glue at home is a simple and affordable process! Of course, homemade glue is not used to glue the frame or repair punctures in the wheels of a car, but it is not replaceable in everyday life.

Powder casein glue

In practice, there are many proven, reliable recipes. Available for paper and cardboard, for wood and furniture, for glass and porcelain, waterproof for paint. It all depends on the starting components in addition to powder and water, which will give the required characteristics.

To prepare simple casein glue, just follow a few simple steps. This applies to the powder from the hozmag.

- Prepare a clean glass container with a wide, flat bottom.

- Combine 2 parts of water, 1 part of powder in a container.

- Stir continuously for 20 minutes.

After obtaining a homogeneous mass without lumps, it must be used in 4-5 hours.

Store casein packaged only in a clean, bright, dry and well-ventilated area.

Dry casein adhesives, which should have increased moisture resistance and elasticity, are best suited for working with wooden parts. If you wish, you can make an adhesive composition yourself to connect wood parts. For this, a cold gluing method is used.

Hello, dear blog reader, casein glue is used to connect materials of various structures and properties. It is ideal for gluing wood, paper leaves, cardboard, earthenware and porcelain. For more complex joints, it is better not to use such glue.

This type of glue is widely used in the work of carpenters. Indeed, it is in their work that it is often required to connect elements without creating holes. Today, such glue is not very popular, since universal polymer mixtures have appeared on the market. But as before, the masters of the old school remain faithful to casein glue, which helped them out before and is helping them now.

Despite the large selection of adhesive mixtures on the market today, even simple inexperienced craftsmen are looking for this particular adhesive. Almost always, such glue is available in ordinary carpentry and hardware stores, as well as outlets for needlework.

Composition and properties of glue

In appearance, casein is a grayish powder with small and larger granules. What is it, what does this tool consist of? According to the chemical composition, casein is a milk protein, it contains many essential amino acids, calcium caseinate, phosphates, nitrates.Casein-based glue can have a different composition depending on the brand and subsequent use. Most often it is used for wood, and the adhesive composition includes the following additives:

- lime;

- rosin;

- kerosene;

- water;

- sodium bicarbonate, etc.

It resembles paste in consistency. All the components included in it are environmentally friendly, so the furniture, for which the product was used, is produced with the mark "ECO".

The technical characteristics and properties of the dry material are as follows:

- types of glue - "ordinary", "extra";

- appearance - a gray powder that does not have foreign inclusions, the presence of a small amount of lumps is permissible (they disintegrate when rubbed with hands);

- the smell is specific, not putrid;

- solubility in water - good, no residue;

- dynamic viscosity at room temperature - 10.8-27 P;

- preservation of fluidity after dilution: for "extra" - 5 hours, for "ordinary" - 4 hours;

- adhesion strength of wood in dry test - for "extra" - 105 kgf / sq. cm, for "ordinary" - 75 kgf / sq. cm.

DIY casein glue

In principle, you can make casein glue yourself and not look for it on sale. There are several options for making it at home:

1. This method can be attributed to the simplest methods. You will need casein powder to make the glue. It should be diluted with water in equal amounts. This mixture should be infused for 40-50 minutes, and the glue will be ready for gluing the necessary parts and elements. True, such a mixture must be used for a short time, otherwise it will dry out.

2. The second method is a little more complicated and expensive. In this case, some elements are added to such a composition to strengthen the binding properties of the resulting glue. For 20 ml of powder, take 100 ml of water and insist for about an hour, then add 25 ml of ammonia solution to the resulting mass. Be sure to also add 10 ml of sodium alkali solution, the concentration of which should be 50%.

3. The third method is to add borax during the glue making process. For 20 ml of casein, 100 ml of water is taken. The mixture is infused for half an hour, and then 6 grams of borax is added. Such a composition is kept in a steam bath, and then a temperature of 50 degrees is maintained for about an hour.

4. The fourth method requires 20 g of powder, 4 g of rosin, 1 g of slaked lime, 40 ml of water. All ingredients are mixed and left for a couple of hours. After that, a solution is prepared from 2 g of borax and 12 tablespoons of water, the resulting mass should be hot. Then add it to the main mixture, and also add 2 ml of ammonia and 20 g of water. The glue prepared in this way has the best moisture resistance characteristics.

5. The easiest way to create casein glue can be the following option: 40 g of cottage cheese should be poured with ammonia, the amount of which should be 10 ml. In principle, the glue will already be ready. This glue is ideal for home use.

6. Ash can be added to obtain a paste for gluing wood and metal.

To increase the astringent properties of casein glue, linseed oil is added to the composition.

To make casein glue yourself at home, you will need weight measuring equipment and special mixing utensils. But you can do without this, however, it will be a little more difficult. But before starting cooking, it is worth weighing the pros and cons. Indeed, in some cases, buying is both easier and cheaper.

Application area of casein glue

The simplest option for purchasing casein glue is to buy a ready-made powder, which already contains the necessary impurities. One has only to dilute with water in the right proportion and let it brew. But many craftsmen are not looking for easy ways, and they prepare the glue themselves.

Casein glue is used in many areas.This material is widely used in the production of multilayer building materials. It is this glue that is used to bond the layers. These materials are produced from wood or cardboard, as well as waste from wood processing plants. When creating large-scale projects and models, as well as wooden toys, casein glue is simply irreplaceable.

It is perfect for shoe repair, restoration of porcelain and faience products. In the production of individual concrete models, this material is also added to the composition.

It should be noted that given the cost of similar building materials, the price of casein glue powder is relatively small.

And if we take into account that the consumption of this material is very small, then its cost becomes simply ridiculous.

One bag of such glue will last for a long time, and it is stored perfectly. The main condition for storing casein powder is the absence of high humidity. If you follow all storage technologies, then after opening the bag with the mixture can be stored for about six months. Therefore, everyone should decide for himself whether he needs to prepare this glue himself or buy a ready-made mixture. Or, in general, you can purchase a solution that is prepared using more modern technologies.

Best regards, Oleg Klyshko

Your thanks for my article is a click on any button below. Thanks!

PVA glue at home

The most common glue, which is popular not only for home renovations, but also in large-scale construction, is PVA glue. It is an excellent glue for wallpaper, it is successfully used in the preparation of solutions for tiling, as well as as a surface primer before final finishing. The scope of its use is so wide that it is safe to say that polyvinyl acetate is a kind of lifesaver of a zealous owner who can prepare PVA glue with his own hands.

To do this, he needs to have:

- One liter of distilled water,

- 5 g of photographic gelatin (sold in Fototovary stores),

- 4 g of pharmacy glycerin,

- 100 g wheat flour

- 20 mm ethyl alcohol (available over the counter).

Glue preparation takes place in two stages:

- preparatory, during which, gelatin is soaked in a glass of water for a day;

- main.

After the gelatin has swollen in water, you can proceed directly to the preparation of PVA glue:

- A container with distilled water is placed in a water bath. Prepared gelatin and flour mixed with a small amount of water (so that there are no lumps) are added to it.

- The whole mixture is brought to a boil (* do not boil!). It should become like thick sour cream. In order for the mixture to be homogeneous, it must be stirred constantly.

- Add glycerin and alcohol. To obtain a dense mass of homogeneous composition, the mixture must be thoroughly mixed. This can take from five to ten minutes (depending on the amount of glue to be prepared). For full readiness for use, the glue must be cooled.

Composition and properties of the adhesive

By origin, casein glue belongs to animals. The basis is milk protein, to which various components are added in order to improve certain properties, for example, water resistance. Granular powder dissolves well in water without leaving lumps.

Rosin

Rosin is known to everyone who has ever tried to solder. But in addition to being used in soldering as a degreaser, the substance is widely used in other areas, including in the manufacture of casein glue. Promotes shelf life.

Water

Water is used to dilute casein powder. As a rule, liquid and dry mixture are taken in equal proportions.

Nitrates and Phosphates

Nitrates are salts and esters of nitric acid, ammonium and some metals (nitrate) used in engineering, medicine and as mineral fertilizers in agriculture. Phosphates are salts of phosphoric acids that are found in fertilizers and are used in the production of many medicines.

Amino acids

Amino acid is an organic acid with one or more amino groups. There are over 400 different amino acids in total. Amino acids are part of sports nutrition and compound feed, used in the food industry as flavoring additives

Calcium caseinate

A protein commonly used by bodybuilders. The product is slowly absorbed, suppresses appetite, slows down the breakdown of other proteins.

Sodium bicarbonate

Sodium bicarbonate is another name for common baking soda. It is used in everyday life, cooking, medicine, food and chemical industries.

Lime

In the production of casein glue, they mainly use slaked lime - fluff. Quicklime in air loses its properties, and may also contain unwanted impurities.

Kerosene

The addition of kerosene to the powdered casein glue prevents dusting and delamination into separate components during transportation.