Technology of use

The process of using a welding pencil is quite simple and within the power of every home craftsman. The sequence of operations is as follows:

- Prepare the surface thoroughly by cleaning with a wire brush or abrasive paper to remove rust, old paint residues and other contaminants.

- Degrease with gasoline, white spirit or other solvent.

- Remove the packaging from the pencil. Move the metal cover to the other end of the rod - we will hold it by it.

- Do not forget to wear goggles (or a mask) of the welder and thick canvas (split) gloves.

- Warm up and set fire to the end of the rod with a match or a lighter.

- Bring the burning end to the place of the beginning of the welding seam and attach it to the surface of the part. Guide the rod along the seam line, staying in one place for at least 3 seconds, so that the edges to be welded have time to warm up to the melting temperature.

- Welding is carried out without hesitation, if with the right hand, then from right to left. If the tracking speed is too high, the welding gap will be filled with slag, but not enough melt will get into it for a reliable connection.

At the end of the welding work, the cinder of the rod must be placed on concrete, ground (without dry grass) and thrown into a bucket of water.

Tips & Tricks

People who constantly use glue stick share tips for buying and using:

When buying, you should sniff a pencil

If even a slight hint of chemicals is felt, the purchase should be abandoned.

The glue stick should have a homogeneous mass without lumps.

When buying glue, you need to pay attention to the lid. It should curl well or fit snugly

The tightness of the tube will extend the life of the pencil.

If in the process of work the glue stick remained open for a long time and its top layer dried out, it is not difficult to restore working qualities. You just need to close the pencil tightly and leave it for 5 hours. The hardened layer will return to its original properties.

And the last piece of advice for lovers of glue sticks - stay tuned. Chameleon pencils with disappearing color and pencils with a triangular sticker are on sale. They are much more convenient to use than their colorless round predecessors.

Share link:

Types of glue

Stationery glue comes in three main forms:

- PVA;

- pencil;

- silicate.

Silicate glue was popular during the Soviet era for lack of much choice. Now it is still found in stores, but it is not in the same demand. Now, when it became possible to compare it with other species, it became clear that the silicate substance has many disadvantages.

After drying, the applied layer of glue changes color (which makes it completely unsuitable for creative work).

The hardened glue layer is very fragile.

When using such a tool, you cannot hesitate - the composition dries very quickly in the air.

In addition, when working with this species, you need to be careful - there is a high risk of getting burned if the substance comes into contact with the eyes.

PVA glue is more familiar to consumers. It is lightweight. It is also less toxic than its predecessor

Of course, when using it, you also need to be careful, but you can not be afraid of such dire consequences.

The glue stick is the most convenient to use - the child will definitely not get dirty while creating the craft. In addition, it dries very quickly. But this type does not hold large elements as reliably as liquid substances.

Advantages and disadvantages of using a termite pencil

The main advantages of a metal welding pencil include:

- Ability to work in the most confined, hard-to-reach places.

- Energy independence - no electricity or gas sources are required.

- Small size - fits into a workwear pocket.

- The work does not require long training and special skills.

- It can work both in a workshop and in the field.

- The heat resistance of the seam is up to 180 ° C, which makes the device indispensable for the repair of household utensils and dishes.

- Cheapness.

Using a welding stick

In addition to the advantages, like any actually used method of welding, there are also disadvantages:

- The quality of the seam is lower than with electric or gas welding.

- Not suitable for large volumes of work.

- High material consumption.

The combination of advantages and disadvantages makes the method perfectly suitable for minor operational repairs.

Glue stick for paper - features of use

Reliable manufacturers do not add toxic components to the PVA pencil glue, but fragrances may be present, but they are safe and approved for use.

Due to its economical consumption, the glue is used to bond cardboard, photographic paper, and any paper products. In this case, the gluing process takes about 5 minutes.

At the same time, the composition does not grasp immediately, therefore, within a few seconds, you can re-glue the documents as required. It is easy to apply, just run the sticker over the paper and attach it to the desired place.

For childcare and home use, special brands of children's pencil glue are suitable, which, unlike the classic solid one, are distinguished by a safe composition and interesting colors.

They are based on glucose, so even if it gets into the mouth, the composition will not cause poisoning.

VIDEO ON TOPIC

What glue stick to buy Erich Krause or Kores

Erich Krause paper pencils adhesives are deservedly considered one of the best on the market. They allow you to use them both for creativity and for working with documentation.

Some models of Erich Krause pencils have a color when applied, which disappears after drying. It is fun for children, and for adults it helps to control the distribution of the composition over the surface.

Kores adhesives pencils are a convenient option for working with textiles, cardboard, paper. It is an environmentally friendly product without solvents. Ideal for creativity, creating photo albums, working with office documents.

Consider the characteristics and properties of the most famous pencil glue options of these brands.

1.Erich krause joy - composition for working with paper, photographs, cardboard. After application, it leaves a color imprint, which allows you to more accurately glue the part. Does not damage paper, does not stain and dries very quickly. Convenient packaging ensures comfortable use - the glue can be easily twisted out of the plastic tube. The composition is not recommended for use by children under 3 years of age.

The cost is about 40 rubles.

2.Erich krause crystal is a transparent glue designed for fixing thin cardboard, photographs, paper. Does not have an unpleasant odor, it is applied evenly. Washed off with water. Ideal for office work, suitable for craft projects in schools.

The cost is about 40 rubles.

3.Kores 20g - this glue stick is suitable for gluing not only paper and photos, but also textiles. The rod has a soft structure, it glides easily on the surface thanks to the glycerin included in the composition. Glue stick is used sparingly. Colorless, it is easy to wash it off and wash it off with water. It does not have an unpleasant odor, can be easily twisted out of the tube, and sets within 30 seconds after use. Safe, approved for use in childcare facilities.

The cost is about 110 rubles.

The author of the article is Kristina Sekushina

Using office glue in everyday life

People have found many more ways to use stationery glue. Technical characteristics allow it to be widely used in everyday life. Let's consider further how you can still use silicate glue or PVA glue.

Silicate glue or liquid glass is a substance that is used in construction. The main purpose of use is waterproofing.

Variants of using silicate glue.

- Add to paint for facades. Gives firmness.

- Treatment of walls and floors in the bathroom for sealing.

- It is used for waterproofing foundations.

- They are added to cements and concretes to obtain new grades of mortars.

- Used to make a special putty, which is used to cover water pipes.

- Impregnated fabrics will become durable protective materials.

- Gardeners treat pruning areas of trees and shrubs to protect them from harmful bacteria.

- They cover surfaces that need to be protected from ultraviolet radiation.

- Used for washing dirty dishes and pans.

Recipe for removing carbon deposits from pans using silicate glue.

Our grandmothers and great-grandmothers used this method. You need to take a metal bowl or a large saucepan. Pour one tube of silicate glue into it. Place all pans and lids there. Put this container on fire and boil. In a miraculous way, all the carbon deposits come off the dishes. After that, all dishes must be thoroughly rinsed under running water. There is a similar recipe with the addition of laundry soap and soda ash.

PVA glue is also well known to builders and furniture makers.

Variants of using PVA glue.

- Used when assembling furniture.

- Attaches the carpet to the floor well.

- Reliable when fixing linoleum.

- Used for gluing facing tiles.

- It will be useful when gluing wallpaper.

- Add to the primer and putty, to the water-based paint.

PVA glue has gained popularity due to its non-toxicity, fire safety, high adhesive ability and ease of use. They can glue paper, leather, glass, fabric, plastic, metal.

Making glue

Our ancestors used brew made from natural materials and animal waste until the 20th century.

When science began to develop rapidly, people expanded their knowledge of the quality and properties of materials and substances, artificial components began to appear for creating glue. The first to receive a patent for the invented glue was the chemist Leo Bakeland. This happened in 1901. And in 1909, according to his patents, they began to mass produce phenol-formaldehyde adhesives with electrical conductivity. Stationery glue appeared in the late thirties - early 40s of the last century.

Nowadays, high-tech equipment is used for the production of glue. The process is becoming more and more automated. In a modern factory, the complete process can be carried out, from the production of a bottle to the application of a label on it.

Varieties and their technical characteristics

PVA glue is widespread in everyday life and construction. A schoolboy, a professional carpenter, and a housewife use polyvinyl acetate. Depending on the type of activity, polyvinyl acetate is divided into types:

Stationery (PVA - K). Popular in kindergartens and schools. The consistency is thick, white mass, with the formation of a surface film. Non-toxic, not resistant to frost and high humidity. It is used in working with paper and all its varieties.

Wallpaper (household). It is used for gluing paper, vinyl, non-woven and textile wallpapers. Creates a reliable adhesion to concrete, plasterboard or combined surfaces. The glue is resistant to frost down to -40 degrees.

PVA-MB (universal). Bonds various types of materials. It is used in water-based building and finishing mixtures. Withstands temperatures up to -20 degrees.

PVA-M is a cheap modification of the universal glue. Only holds paper and wood together. Not recommended for use on glass and porcelain surfaces.

Polyvinyl acetate dispersion - adhesive emulsion, improved for adhesion to surfaces.It is divided into two types: plasticized and without plasticizers. It is found in household chemicals, packaging products, water-dispersion paints and mortars.

Dispersion glue is used in textile, footwear and other industries. Also used in the manufacture of tobacco products - for cigarette filters. Possesses frost and moisture resistance. Has a creamy yellow tint and a viscous consistency.

Class d waterproof adhesive. It is used in the construction and repair of wooden products, furniture manufacturing. The range of moisture resistance is from d1 to d4.

The most optimal for gluing on wood, fiberboard, chipboard and cork is PVA d3 glue. It stands for polyvinyl acetate dispersion emulsion of 3 degrees of moisture resistance. The consistency is transparent, thick and viscous. It can be used in rooms with a high degree of air humidity.

6 best adhesives for metal

Any ratings of adhesives are controversial and subject to change, because the chemical industry does not stand still. Now such TOP-6 means for gluing metals, alloys is relevant:

- Weicon VA 110 is the best adhesive in this ranking. It is waterproof, temperature resistant and safe (NSF). The treated surfaces are in contact with food without harm to health. Grabs in 20-50 seconds. It hardens in a day.

- Strong steel stick renewal composite. Knead the mass with your fingers and apply. After 20 minutes, the material cures and becomes extremely hard. Suitable even for patching metal pipes. Resistant to the most aggressive substances: acids, alkalis, ethers. The strength of the glue is due to the content of epoxy resins.

- Weicon RK-1500. Surfaces can be fastened in several ways: overlap, butt. It is a super strong, extremely temperature resistant composition. He is not afraid of heating up to +130 ° C. Withstands even +180 ° C, but not for long.

- Epoxy EpoximaxX. Liquid formulation that can be applied with a brush. Keeps temperature up to +120 ° C. Suitable not only for metals.

- Cold welding Poxipol. It becomes firm after 10 minutes. After an hour, the connected parts can be drilled, cut, processed. The bonding site takes 24 hours to dry completely. The seam is noticeable.

- Super Glue Gel. Produced by BISON. A durable, eco-friendly product with a gel-like consistency. Does not spread.

Composition and properties

There are two types of glue sticks. They are made on the basis of PVA and PVP. These bases are humectants. The working qualities and application of the formulations differ from each other.

PVA-based

The base of the PVA glue stick is polyvinyl acetate. The active ingredient is glycerol. It is a synthetic component, which is a viscous transparent liquid. Glycerol is viscous. It doesn't smell. The moisturizing properties of glycerol are lower than that of glycerin. Various components are added to PVA glue to improve its quality:

- tricresyl phosphate,

- EDOS,

- acetone,

- esters.

These substances improve the adhesion of the adhesive. PVA glue dries faster. The shelf life of PVA pencil glue is 1.5-2 years. After that, the rod dries up, turning into a dense plastic cylinder. In doing so, it separates from the tube. But the fixation time on the surface is also shorter. It takes only 2 minutes for the glue mass of a PVA pencil to dry completely.

PVA glue stick allows exposure to high temperatures. But the lower threshold is limited to 15 degrees Celsius. At lower temperatures, the adhesive hardens quickly. It becomes difficult or impossible to smear it. PVA glue does not dissolve in water. He is not afraid of oil attacks. Atmospheric phenomena are not reflected on it in any way. The only thing he doesn't like is temperature changes.

Output. PVA glue stick has a wider range of applications.

PVP

The base of the PVP glue stick is glycerin. It is a natural substance that effectively protects the glue from drying out.Glycerin absorbs moisture from the environment. He is able to hold it for a long time.

The drying speed of the finished work increases up to 5 minutes. Unlike PVA, PVP pencil connects not only parts of cardboard and paper. It glues photographic paper and fabric. The glue is more resistant to low temperatures than PVA. He is less afraid of her drops. The paper after gluing PVP is not deformed. The adhesive does not change the color of the materials to be glued.

The composition of PVP glue is more complex. It varies from manufacturer to manufacturer. We can only talk about a small list of components that can be included in it in addition to glycerin:

- Water. It serves as a natural solvent. Evaporating, allows the composition to harden.

- Acrylic polymer is the main adhesive component, due to which the substance, when dried, polymerizes.

- Sodium stearate is a substance that makes the glue mass more plastic and facilitates friction.

- Polyethylene glycol - This substance is added to the adhesive to maintain flexibility.

- Polyoxyethylene monooctylphenyl ether is a chemical compound that acts as an emulsifier, providing an emulsion when mixing dissimilar components.

- N-vinylpyrrolidone polymer is a polymerization-enhancing ingredient.

- Aminomethylpropanol is a buffer that neutralizes acids and contributes to the safe application of the adhesive.

- Sodium hydroxide is an alkali. It is added to maintain the neutral pH balance of the adhesive.

The glue stick may contain hydrogen peroxide and caprolactam, which impart plasticity to the mass. If the glue stretches, forming threads, then this is the action of caprolactam.

How to cook properly at home

When brewing a paste for crafts or repairs, you must have a sufficient amount of starch available

It is important to keep the proportions when using starch, flour and water to get the mixture the right consistency - not too thin or thick. There are several recipes for making paste, which are recommended to be used to choose from.

First recipe

To make a starch-based glue with the addition of flour, you must:

- 5-6 tablespoons of starch or flour (you can take these ingredients in half) and pour 200 g of cold water into the dry mixture, stir well;

- pour a glass of water into an empty saucepan, put on fire and bring to a boil;

- add a solution of the resulting gruel to boiling water;

- stirring, boil for several minutes until the mixture thickens;

- then set aside to cool.

Second recipe

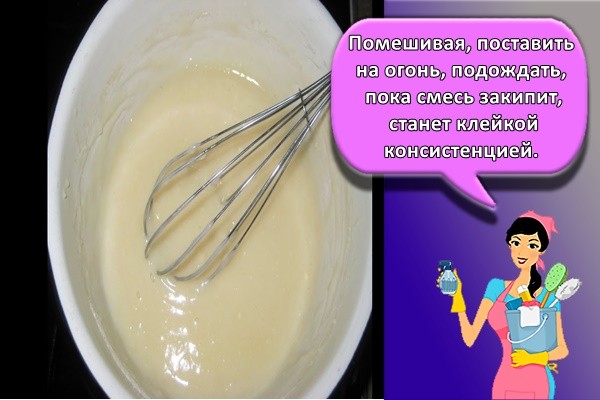

You can quickly prepare such a starch paste at home by pouring the right amount of starch and flour with cold water. While stirring, put on fire, wait until the mixture boils, becomes a sticky consistency. After cooling down, for greater strength it is worth adding a little PVA.

Attention! After preparing the adhesive composition, it should be filtered to get rid of lumps and get the perfect paste quality. This can be done either through a sieve or gauze, or through an old nylon stocking.

Manufacturers

Consider the most famous firms that produce stationery glue.

- Attache. This company does not skimp on the types of produced glue - the assortment includes silicate, PVA, and a pencil. At the same time, the manufacturer himself recommends using silicate glue for gluing paper and cardboard, for decorative work. PVA glue, according to his statement, is also suitable for application to wood. The pencil-shaped tool can handle photographic paper too.

- Kores. The range of glue of this company is much richer. There is also a classic glue stick. Its distinctive feature is the setting time. It dries up in thirty seconds. At the same time, the substance can be easily washed off and washed off with water without additional cleaners. There are also unusual varieties of the remedy. For example, glitter silicate glue. Or a colored pencil that becomes transparent as it dries. A glue roller is also available.

- Erich Krause.All types of adhesives are also produced under this brand. Silicate, for example, is available both in regular packaging and in a convenient roll-on bottle. PVA is also produced in the form of a roller. Pencil glue is common, but there is also a "chameleon" that changes color.

The main varieties of PVA glue

Since the scope of application of PVA is determined by the type of its composition, among the varieties are distinguished:

- household (wallpaper);

- stationery (PVA-K);

- universal (PVA-MB);

- Super glue;

- building.

Household glue is used for paper and paper-based wallpaper. The properties of the composition make it possible to use it for wallpaper, which is glued to plastered walls, concrete or wooden surfaces. In consistency, the composition is a milky-white liquid, which can have a beige tint and a faint odor. The composition is non-toxic, therefore it is safely used in residential premises. With prolonged use, the glue turns yellow. The composition has a shelf life: the glue, suitable for use, is liquid and homogeneous. PVA with an expired shelf life is taken in lumps, which makes it impossible to apply it to the surface. If the glue is expired, then when the composition is squeezed out of the container, a clear liquid will flow first. The seam formed using household PVA can withstand a temperature drop of up to -40 ° Celsius.

The PVA superglue contains additives that increase its strength after polymerization. You can use the composition by repairing the surface laid with ceramic tiles. For several unsticked elements, it makes no sense to prepare a cement composition; it will replace it with PVA superglue, which can firmly fix the tile on the concrete surface. The substance, like the previous version, can withstand fluctuations up to -40 degrees, so its use is allowed in unheated rooms or on the street.

It is interesting: Autonomous gasification of the house: we look at it from all sides

Applications

Freshly prepared paste is used for gluing paper and cardboard, crafts, pasting walls and primers.

For pasting wallpaper

It is important to prepare a sufficient amount of glue in advance, remembering that you must first prime the walls with starch paste so that they are saturated, and only then apply the composition to the wallpaper. This is a very high-quality mixture of starch, which, when dried, does not leave traces, allows you to perform more accurate pasting of walls, regardless of the type of wallpaper and their color.

Papier mache

For the manufacture of products using the papier-mâché technique, a universal composition of the paste is used. For modeling, children's creativity, a mixture based on PVA glue is prepared.

Corrugated board gluing

In the production of high-quality corrugated cardboard, glue made on the basis of potato starch is used. The composition is specially developed for technological processes for gluing paper and cardboard on special equipment.

Children's creativity

Without causing allergies, without showing toxicity, such an environmentally friendly starch glue can be used for handmade paper crafts, children's art, even for the smallest children. It can be easily washed off any surface, so there will be no problem, even if the baby accidentally drops onto the parquet, carpet or smears himself, clothes, or a work table.

Bonding paper bindings

A starch paste is used when processing paper bindings, because after drying it does not leave traces. Colorless, almost transparent, hypoallergenic composition, does not form yellow streaks on the white or printed surface of paper or cardboard.

Insulation of window frames

For pasting gaps in window openings, caring housewives who keep warm in the house prepare glue based on flour or starch. Then the composition is applied to paper strips, which are glued in the area of the formed cracks.

Advantages and disadvantages

Considering the features and advantages that characterize homemade glue based on starch, flour, it is worth noting that it:

- harmless to health, it is often used by children of all ages for making handicrafts, other projects from the category of children's creativity;

- is environmentally friendly and does not contain toxic substances;

- it is used as a primer for walls - after the applied layer has dried, the surface will become even and without pores;

- easily peels off the wall if the old wallpaper is slightly moistened with warm water;

- perfectly proved itself in the formation of papier-mâché, gluing paper, corrugated cardboard.

The composition will help save on wallpaper glue, and is also quickly prepared at home. A paste made on the basis of flour or starch has practically no drawbacks, except that it must be used on the same day, and not left for future use, so that the composition does not lose its stickiness.