AKFIX 705 (glue + activator)

Product description

Akfix 705 Express Glue Kit The kit consists of a viscous cyanoacrylate gel and an activator aerosol. Two-component cyanoacrylate-based adhesive is used for fast and reliable bonding of solid wood or plywood parts and elements, as well as synthetic materials (MDF, chipboard, PVC, rubber, etc.). Akfix 705 glue has excellent technical characteristics when gluing various types of materials, is characterized by very fast and durable gluing, resistance to temperature changes and moisture.

Application area

It is used for gluing any wood materials. Suitable for MDF, chipboard, wood, plywood, rubber, most plastics, leather, etc. It is used in the manufacture and repair of furniture. Especially suitable for fast bonding. Designed for fast (in seconds) and reliable connection of solid wood or plywood parts and elements, as well as synthetic materials (MDF, chipboard, PVC, rubber, etc.). The two-component cyanoacrylate adhesive is widely used in the automotive industry, electrical engineering, household appliances, bonding various plastics, metal, signage and displays, thermal enclosures in the advertising industry, etc. Bonding ABS, aluminum, stainless steel, fiberglass, FRP, FRT, wood, cold rolled steel, hydrocarbon steel, nylon, polyurethane and other materials. Quickly bonds a wide variety of surfaces, including aluminum, steel (both galvanized and uncoated). Ideal for bonding small to medium sized components. Perfect for gluing glass, transparent plastics used in illuminated advertising, for gluing boxes, shelves, remotes, etc. Also suitable for bonding stone and wood products.

Physical properties

- The curing speed does not exceed 8-10 seconds.

- Adhesive for instant bonding of all types of plastic, metal, rubber, leather, MDF, chipboard, wood and many other materials.

- Does not run off vertical or upside-down surfaces.

- Suitable for bonding elastic materials or joining materials with different coefficients of expansion.

- Has increased peel strength compared to other adhesives.

- Provides exceptional bond strength.

- Suitable for bonding pre-assembled parts.

- Ideal for adjacent plastic parts.

- Suitable for bonding natural and synthetic rubber.

- It has strong vibration resistance and butt joint resistance.

- Does not contain solvents.

Directions for use

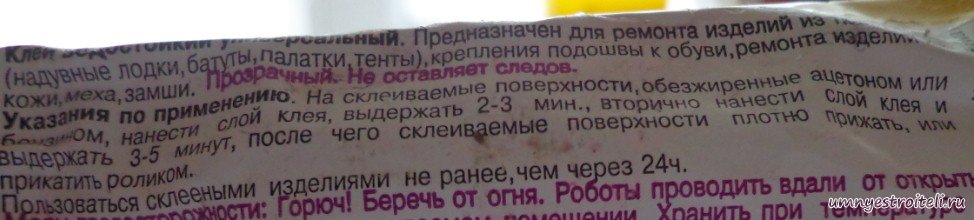

- Surfaces must be clean, dry and free from grease;

- The glue is applied to only one of the surfaces;

- Spray an aerosol on one surface and apply glue on the other

- Press tightly together

- Use at temperatures from +5 to + 40 ° C

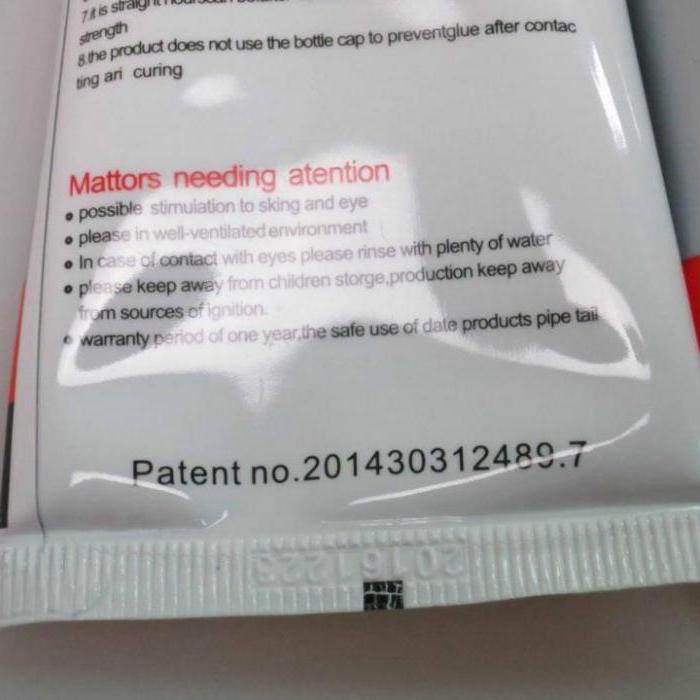

Security measures

Use only with exhaust ventilation. Avoid getting the glue in your eyes or inhaling its vapors. Do not swallow. May cause skin irritation.First aid:if dizziness or other unpleasant effects appear, you need to go out into the fresh air, consult a doctor if unpleasant sensations persist. Wash the skin contact areas with water and soap. If glue gets in your eyes, rinse them with water for 15 minutes. Keep the glue out of the reach of children! Use only for its intended purpose.

Return to catalog

Home / Related products / Porilex glue

Glue Porileks- specially designed for the installation of thermal insulation materials from foamed materials, products from polyurethane foam and foam rubber.

Instructions for use and basic rules of work

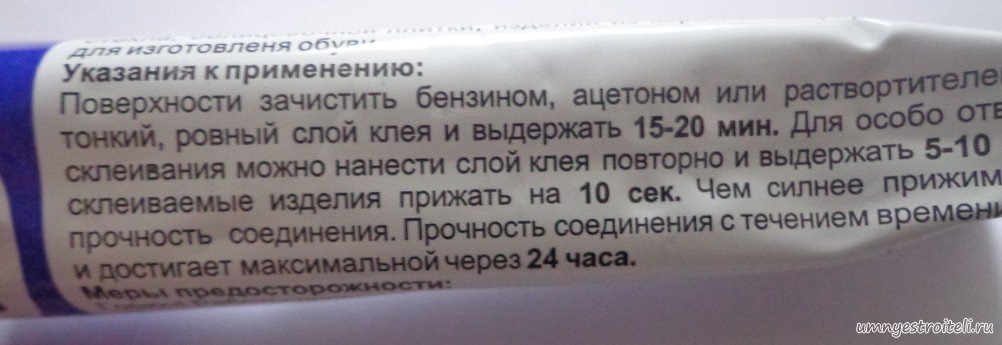

Working with B7000 glue is in many ways similar to working with other formulations, below is a step-by-step plan of action:

- The temperature regime required for operation is from 18 to 32 ° C.

- The surfaces to be glued must first be cleaned of dust, remnants of old glue and other contamination, and then degreased with acetone or medical alcohol.

- The glue is applied to a dry surface in a thin layer directly from the tube, for this it has a thin metal tip.

- If the compound gets on other parts, it can be easily wiped off until it is completely cured. Excess glue from the cracks is removed with any thin and sharp object (needle or toothpick, for example). Even if it is completely hardened, the work can be redone: heat it up to at least 80 degrees, and it will lose its properties.

- It can take up to 15 minutes to set the parts, and it will take a day to completely dry.

Video instruction:

How to make dichloroethane glue with your own hands

Adhesive solution with dichloroethane can be prepared independently at home. It is not difficult to make a working mixture; you will need to dissolve a small amount of material in a volatile substance, for which a solution is required to glue. Step-by-step instructions for preparing the mixture include the following steps:

- For the solution, take a glass container with a hermetically sealed lid. A tight seal is required due to the rapid evaporation property of dichloroethane.

- Chips or small particles of plastic are added to the container. The filler must be completely in the liquid.

- The lid of the container is tightly twisted and the mixture is removed to a place limited from exposure to ultraviolet rays. You also need to take care that children do not have access to the solution.

- After waiting for the complete dissolution of the plastic filler, you can use the prepared solution for its intended purpose.

When deciding on the proportions of dichloroethane and filler, you need to take into account the desired consistency of the finished solution. The more plastic you add, the thicker the working mixture becomes. In case the glue becomes too thick, you can always dilute it with a liquid substance. Some experts use pure dichloroethane in their work or add a small amount of plexiglass crumbs to it, adhering to a 1:10 ratio.

Having prepared the working mixture, you need to check the adhesion ability on the scraps of the material in order to visually see what the reaction will be when the solution is applied. Then you can proceed to the main work, if during testing the mixture did not damage the material and formed a strong seam resistant to tearing.

Description of the substance

Chinese new generation B-7000 glue based on epoxy resin and with a gel consistency is used to repair damaged and replace new touch screens, as well as display modules on mobile communication devices. The clear adhesive acts like double-sided tape, but it holds more firmly and can be easily removed when re-assembled.

B-7000 glue creates an elastic film that has anti-vibration characteristics due to its soft consistency. The layer of material is waterproof, therefore it can serve as a kind of waterproofing. In addition to being used in the repair of mobile devices, it is used for gluing handicraft parts, ceramics, glass, metal, wood, natural and artificial leather. Compounds of fabric, stone, PVC materials, nylon, porous surfaces are strong and durable. The glued surfaces of plastic, rubber, paper, bamboo serve reliably.

Rules for working with glue

The open time is about six minutes for a B-7000 bond. The adhesive sealant for gluing touchscreens completely cures after 1-2 days (24-48 hours). It is recommended to store it in an ambient temperature of 10 to 28 ºС. For the correct fixation of surfaces, consideration should be given to such points as:

- before using the substance, read the instructions;

- check the action in a small area;

- during use, the product should have a temperature up to 18-35 ºС;

- the surface of the part is degreased before gluing and evenly covered with glue;

- the substance is squeezed out as it is consumed from the hole;

- contact with skin and eyes causes irritation;

- because of the pungent odor, it is recommended to work with it in a well-ventilated area;

- if the mucous membranes get on, then they are washed with plenty of water;

- it is better to store the substance in places where small children do not have access;

- it is not recommended to use glue after the expiration date.

Analogs

There are many analogues of E8000 glue:

- B7000. It is one of the most popular formulations used as a touch screen sealant. In this case, the tool is considered multipurpose. It can be used to fix glass elements, plastic, wood, metal. Key characteristics include high bond strength. The finished seam can be more reliable than the fixing parts.

- T7000. This tool is also used to fix touch screens and cellular modules. A distinctive feature is the black color. Therefore, it is permissible to use glue for repairing dark cases. The product is resistant to moisture and mechanical factors.

- T8000. This composition is actively used for domestic purposes. However, the main purpose is considered to be the fixation of touchscreens. According to the principle of action, the composition resembles double-sided tape, but provides a stronger connection. When repaired again, the substance can be easily removed by heating and rolling. It takes 3-5 minutes to dry the composition. The final drying time is 1-2 days.

- B8000. The composition is also intended for sealing and fixing touchscreens. The tool is intended for repairing iPhone parts, since it certainly does not corrode surfaces. If you want to remove the glue, it is heated with a hair dryer. The product has a completely transparent consistency. Polymerization takes 2-3 days.

E8000 glue is highly effective and helps to fix the details of mobile devices and other gadgets. To achieve success in the use of a substance, it is worth using it correctly. To do this, it is recommended to thoroughly clean and dry the surface, and then apply a thin layer of glue.

p> Share link:

Instructions for use

How to use glue correctly for the main purpose of its application - installing a new touchscreen? Work should be done in a room with a temperature of 18 - 30 degrees, ventilation should be sufficient. First, you need to buy a screen of the right size, which will ideally fit the corresponding smartphone model.

The order of work is as follows:

- wash your hands, thoroughly clean and degrease the surface of the phone and a new touchscreen - not even the slightest particle of dust should remain (use a special napkin or regular alcohol for degreasing);

- apply B-7000 in a thin layer, wait 1 minute;

- attach the part to its proper place;

- immediately remove excess material with a napkin or collect in a lump with your finger, remove small nodules with a toothpick;

- press the screen firmly, hold for 3 - 5 minutes;

- do not operate the phone for another 24 - 48 hours.

If you need to remove the screen when the glue has completely set, you can heat the product to a temperature of 80 degrees using a UV lamp. This will allow the part to be easily removed for repair or replacement.

Additional tips and tricks

Ensuring a high-quality result and a reliable connection of surfaces allows compliance with a number of additional recommendations of specialists.

Common tips include:

- Avoid getting moisture on the glue line, as liquid significantly impairs the strength of the joint. Contact with water can lead to displacement of the glued surfaces and seam rupture.

- When gluing with a solution containing dichloroethane, it is possible to adjust the position of the surfaces for a long time. At the same time, you should not delay this process, since there is a risk of squeezing out a large amount of glue from the seam, which will negatively affect the quality of the connection.

- The composition must be applied with maximum care. Otherwise, the substance can corrode the material and spoil the appearance of the workpiece.

- When squeezing the surfaces after applying the adhesive, you need to make sure that the seam is completely closed. The junction of the materials is fixed in a static position for several hours to dry the substance.

- Due to the increased volatility of dichloroethane, chemical dishes are the optimal place for the preservation of the substance. The container must always be sealed tightly to prevent evaporation. Also, leaving the dichloroethane container open can easily spill liquid.

- In work, it is better to use small bottles with a substance with a volume of 20-50 ml. Such containers are more stable, and if handled carelessly, a minimum amount of substance will spill.

Following these tips will help you use the solution with high efficiency. Also, recommendations help to avoid dangerous situations.

p> Share link:

How to remove glue from skin?

People who regularly work with glue are often faced with the need to clean their skin. There are two effective remedies that will quickly remove the substance from the surface of the skin.

"Dimexid"

Often, when dissolving superglue, they use "Dimexidum", which is sold in any pharmacy. Before cleaning, the product is diluted with water in a ratio of one to three. To get rid of dried glue spots, moisten them with a solution and wipe them off after 2-3 minutes.

Acetone with soap to remove

Acetone is considered the most common skin glue remover. A small piece of cloth is moistened with acetone, after which the dried layer of glue is wiped off with it. Then the treated skin area is thoroughly washed with hot water and soap.

Varieties and properties of adhesives

On the construction market, you can find several types of glue with dichloroethane. Each variety has individual adhesive properties. Before starting work, you should study the features of each option and choose the appropriate one, taking into account the tasks and your own requirements.

Liquid

The liquid adhesive is water-based and solvent-based. When set, the solvent evaporates, and the substance becomes solid and provides a secure connection between the parts. This variety is suitable for interior decoration with porous materials, including fabrics, wood and plastic. At the same time, the liquid solution does not glue sealed materials, since upon contact with them it does not even begin to harden.

Contact

Contact formulations can be with or without a hardener. The principle of using the solution is simple - contact adhesive with a viscous consistency is applied to both surfaces to be joined, where it should dry slightly, after which the surfaces are applied to each other and held under pressure.

A common contact composition is Rexant products. The epoxy mixture with a hardener has a universal purpose and, among other things, is suitable for working with plastic surfaces. Like the rest of the contact category, Rexant takes a day to cure completely.

Hot glue

Hot melt glue, also called reactive glue, needs to be warmed up before use. As a result of heating, the solution turns into a liquid state and solidifies upon further cooling. The need to use hot melt glue arises when fixing large elements. A popular version of the rocket train is "Moment".

Reactionary

Reactive versions of a solution with dichloroethane can be one- or two-component

This option is suitable for instant setting of materials, therefore it is important to carefully monitor the correct connection during use. The one-component composition is available in a ready-to-use state, and the two-component mixture will need to be pre-diluted with water

Acetone with soap to remove

If the above drugs are not at hand, and the glue has pretty much adhered to the skin in sufficient quantities, then some people use acetone to eliminate stains, after which you need to wash your hands for a long time and thoroughly with soap. Instead of acetone, solvents No. 646, 647, sold in hardware stores, are used. The nail polish remover also works in a similar way.

After applying a certain amount of acetone with cotton wool on the glue layer, you need to wait about 30 seconds, then take a sponge and erase the adhering layer, having previously soaped the place. Gradually, the glue will go away, and the processing ends after washing in running water. If there is no means at hand, then you can wash off the glue in warm water with a detergent composition, dipping your hands into the solution for half an hour. The glue contains cyanoacrylate, which dissolves in warm soapy water.

In conclusion, it should be noted that the use of B-7000 glue is effective for gluing touchscreens and mobile technology modules. Using this glue, repairers will receive an undeniable advantage in the form of ease of work, a strong connection that will remain unchanged for a long time.

Types and instructions for use

For gluing screens, different types of adhesives are used, the features of which should be familiarized with before using them.

B-7000

This is a Chinese hermetic adhesive made from epoxy resin. It is considered by many to be a versatile product as it can be used to bond glass, wood, iron and plastic. The composition is sold in small tubes, the volume of which can be 50-150 milliliters.

E-7000 and T-7000

E-7000 glue is most often used when working with jewelry, but some people use it for gluing glasses. This adhesive is sold in 50 ml tubes. An epoxy-based product is made, which makes it more reliable.

Some people use T-7000 as a replacement for B-7000. However, experts do not recommend using it when gluing telephone glasses, since the mixture is painted in a dark color.

T-8000, E-8000 and B-8000

T-8000 is often used in everyday life when working with glass and plastic products. The main advantage of this glue is considered its reliability and ease of removal from the surface.

People who prefer to use viscous adhesives should pay attention to E-8000. The composition is suitable not only for gluing glass, but also for gluing ceramics and fiberglass

B-8000 is often used to seal mobile screens. It contains no toxic components and therefore does not corrode the surface.

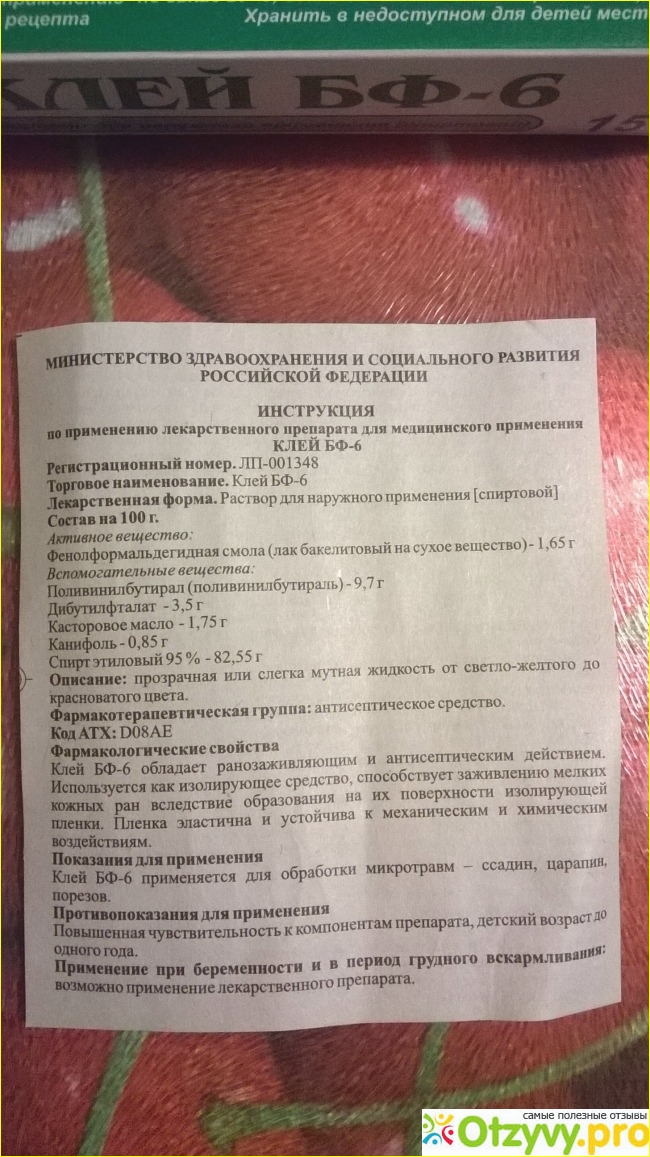

E-6000 and B-6000

For gluing glasses, the composition E-6000 is often used. It is also capable of gluing products from plastic, stone, wood and fabrics

Such glue sets in a few seconds, and therefore must be used very carefully.

When working with jewelry and smartphone displays, you can use the B-6000. It contains silicone, which makes the mixture more viscous and reliable.

B-5000

Previously, this glue solution was popular with people who were engaged in gluing the glasses of smartphones.Today the B-5000 is not produced, as it has been replaced by better quality equipment.

The main features of the substance

Fast curing epoxy adhesives cure quickly after adding a hardener to the base composition. The hardened mass has the following qualities:

- frost resistance (the mass can easily withstand temperatures up to -20⁰С);

- heat resistance (temperature limit at which the glue keeps gluing: up to + 250⁰С);

- good ductility and elasticity, which provides a high level of bond strength;

- resistance to aggressive media (acids, alkalis, oils, petroleum products, household chemicals);

- low shrinkage;

- water-repellent properties and high waterproofing performance;

- excellent interaction with almost all materials.

But you should be aware of some of the disadvantages of such glue. For example, not all surfaces lend themselves to gluing - epoxy cannot connect Teflon, silicone and polyethylene. Take into account the accelerated polymerization time, so if there are blemishes during gluing, it will be very difficult to remove them later.

Adhesive does not work with all materials

Adhesive does not work with all materials

Where is used

Due to its high technical qualities, versatility, epoxy glue is actively used in various branches of modern industry. Namely:

- in construction, to connect reinforced concrete structures, panels, cracks and potholes in concrete are filled with glue, with its help, tiles are laid;

- shipbuilding uses an adhesive substance for the installation and assembly of ship parts made of fiberglass, plastic and metal, the substance is also used to improve the waterproofing qualities of materials;

- aviation (design), used for gluing various parts, manufacturing and installing batteries, additional fixation for thermal protection;

- mechanical engineering uses epoxy glue for mounting accessories, fastening brake pads and various parts when assembling machines, for carrying out various repairs.

Varieties of glue

Experts distinguish two large groups of epoxy adhesive. It:

- Liquid. Packaged in tubes. This form of release is convenient and easy to use.

- Plastic bars. Its consistency is similar to plasticine or dough. Also available in tube packaging. After squeezing out, the mass is slightly moistened with water and softened by hand.

Various modified formulations can also be found on the market. The temperature regime of polymerization of such modifications ranges from + 60–120⁰С. These adhesives are used for bonding various materials that are resistant to solvents, petrochemicals and oils.

In household, home use, several brands of epoxy glue are common. They are recognizable and familiar to almost everyone:

- universal glue Moment;

- Contact designed for sealing pipes, repairing plumbing;

- cold welding glue is used for gluing metal products.

Is epoxy glue harmful to health

When working with an epoxy-based adhesive, you should be aware that it is a health hazard. When working with her, it becomes mandatory to use personal protective equipment: gloves, a respirator mask and glasses. If the glue mass enters the stomach, a person runs the risk of serious poisoning, and contact with the skin leads to the development of allergic reactions.

Safety precautions when working with adhesives

One of the features of 88 grade glue is that under the influence of external factors and various chemicals, it does not release hazardous substances into the atmosphere. The use of the products is not harmful to human health and the environment. At the same time, when working with materials, several safety rules must be observed, including the following:

- Store products away from heat sources to prevent deterioration and fire.The best storage space is in a dark, dry room.

- Work gloves should be used when treating surfaces, as due to the quick setting, the skin of the hands can be damaged.

- Products that have expired the expiration date indicated on the packaging cannot be used for their intended purpose.

- If the solution gets on sensitive areas, you should not try to wipe it off yourself, it is better to consult a doctor.

What is a touchscreen?

In our language, the lexeme appeared from the merger of two English words touch and skreen, which means a screen that responds to touch. Such touch monitors are found in different places by the city user. You can withdraw money from an ATM using a sensitive screen, get help, make a call to a friend on a mobile phone. All this requires actions related to the sensory perception of technology. There is a response to touching a section of the screen, a signal is received to perform a certain action in accordance with the regulations of the programmed.

Today, any novice user can answer the question about the touchscreen. Some can start replacing such a sensitive device on the phone on their own, for which they use B7000 glue. Instructions for using this product are in the package. It should be studied carefully before use.

How long does the glue dry

People who are going to use adhesive solutions for displays are interested in how long they dry. There are several factors that determine the drying time:

- Temperature indicators. The rate of drying of adhesives directly depends on the temperature. To make them dry faster, it is necessary to maintain the room temperature in the room, which will not drop below 20 degrees. At low temperatures, the glue dries for a long time.

- Humidity level. Another common factor that determines the drying time is air humidity. In order for the glue to dry normally, the humidity in the room should not exceed 60-65%.

Algorithm for replacing the phone screen with glue

Before starting work, you need to familiarize yourself with the features of replacing smartphone displays. This procedure is carried out in several sequential stages:

Dismantling the smartphone. First you need to disassemble the phone and remove the battery from it. Difficulties may arise when disassembling modern phones, since they have a non-removable cover

In this case, you will have to carefully pry it off with a plastic card. Then the elements of the case with cables and boards are removed.

Removing the display module

To remove the touchscreen, you will have to carefully warm up the device with a hairdryer for 2-3 minutes. After that, a suction cup is connected to the module, which is carefully pulled towards itself in order to carefully remove the display.

Disconnecting the matrix from the sensor. When replacing touch screens, be sure to disconnect the matrix. To do this, it is heated with a hairdryer to 75-85 degrees, after which a nylon thread is wound under one of the edges. You must wind the thread very carefully so that it passes through the adhesive layer.

Cleaning the matrix. After detachment, the matrix is cleaned from the remnants of dried glue. During cleaning, use wipes soaked in an alcohol solution.

Glue application. A sealant is applied to the surface of the cleaned matrix. Moreover, it is evenly distributed over the entire surface.

Installing the module. Before placing the display module, the seat is cleaned. After cleaning, the perimeter of the case is treated with glue, on which the touchscreen is installed.

Assembling and testing a smartphone. The assembled phone must be checked.