Review of popular brands

There is a wide range of adhesives for roofing material on the building materials market. Before purchasing, they get acquainted with the characteristics, advantages and disadvantages of a particular variety. The most popular formulations include the products of such brands.

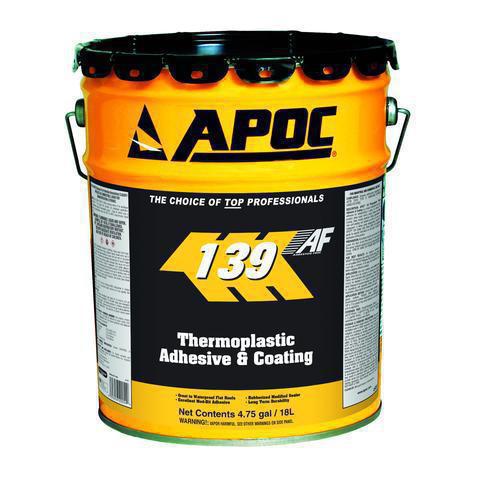

Technonikol

One of the most popular mastics is the production of the Russian company Technonikol. This type of glue does not need additional heating, therefore, the process of laying roofing material is greatly simplified. It can be glued to the following types of surfaces:

- metal;

- concrete;

- cement.

You can work with the substance at a temperature range of 5 to 35 degrees Celsius. The glue is applied to the lower part of the roofing material with a notched trowel. The layer thickness is 1 cm. It is produced in 10 kg buckets. Work with the adhesive is carried out in well-ventilated rooms. Make sure that the substance does not come into contact with unprotected areas of the body and eyes. Do not use near open flame sources.

Abizol KL DM Tytan

The glue of this brand belongs to the cold varieties. When applied, a coating is created that is resistant to water, alkalis and weak acids. Abizol KL DM Tytan mastic is used for gluing roofing material and waterproofing.

Before using glue for roofing material of this brand, prepare the surface. It must be clean and dry. With a trowel or spatula, the composition is cold applied to the lower part of the material. The number of layers depends on the characteristics of the coating. 2-3 layers are applied for waterproofing, one is enough for mounting the material. This glue cannot be used for interior work. Protect hands and eyes with overalls when working with the composition.

AquaMast

It is also a cold option for roofing installations. Homogeneous multicomponent mass consists of bitumen, solvent, processing aids and filler. Thanks to this mastic, it is possible to glue the roofing material to ceramic, metal, wood, concrete and other types of surfaces.

Bituminous

The bituminous variety contains resins and certain chemical ingredients, thanks to which roofing material can be easily glued even to a slightly damp surface. The glue forms a protective film that is not afraid of the effects of acids and alkalis.

To make the craftsman happy with the quality of work, it is recommended to apply a layer of primer before using the mastic. The need for this action disappears only if the roofing material is glued to a similar surface.

Bituminous mastic AquaMast

This multi-component mixture is specially designed for use by individuals and small organizations with little construction experience. Unlike the professional line of mastics:

- less technological;

- not intended for industrial volumes with a high speed of work performed;

- not suitable for roofs with special operating conditions.

Suitable for most types of hard substrates, including wood. It is considered the best in its price category, thanks to:

- high resistance to temperature extremes;

- small consumption of 0.8-1.8 kg per 1 sq. m;

- maintaining the uniformity of texture and properties during freezing;

- wide range of temperature use: from –10 to +40 ° С;

- short time to set the final properties - 7 days.

Important! When using AquaMast mastic at temperatures below +5 degrees, keep the mixture in a warm room for at least a day

DIY mastic for roofing material

Cold mastic is prepared from bitumen and solvent in a ratio of 3 kg to 7 kg, respectively.Preliminarily, petroleum bitumen is heated until complete dissolution, after which it is allowed to cool down to 85 °. A solvent is added to it. Gasoline, diesel fuel, kerosene will do. The mixture is thoroughly mixed. Such glue is ideal for minor roof repairs, as it has an increased consumption compared to the hot analogue.

By watching the video you will find out more information:

Hot mastic is prepared differently. Bitumen in the amount of 8 kg is placed in a container. The reservoir must be large enough to only fill up to 60%. Pieces of bitumen are gradually heated. Then add 1.5 kg of filler.

Talc, peat chips, alabaster, limestone, chalk and other materials are used as fillers. Fillers are pre-sieved to prevent debris from entering the container. Then add 0.5 kg of used oil and mix thoroughly. The bucket is kept at 200 ° C. The resulting mixture will reliably glue any roll material, including a soft roof.

Mastics for cold and hot stickers of roofing material are not inferior in technical parameters to each other. "Hot" adhesives require additional preparation time for application. Subject to the technology of laying the flooring, a roof with a new waterproofing is guaranteed to last over 5 years without the need for repairs. The service life of such a roof with timely maintenance and continuous repair is 25 years or more.

Roofing material is a time-tested roll waterproofing material. It is widely used in construction when performing roofing works, for waterproofing foundations.

Roofing material is glued to the base using preheated or cold bitumen mastic.

The second method is most popular today because it is more economical and less laborious. In addition, it is much more convenient to carry out work using cold glue.

Adhesive for roll roofing material

This composition is a combined adhesive mass that includes several elements. In most cases, this is bitumen, a suitable solvent, some kind of filler, and also a variety of additives.

The key purpose of the product is considered not only to glue the material to a variety of surfaces, but also joint sealing with him.

The trade recommends a large number of types of adhesives from popular and unknown manufacturers. Any brand has its own advantages, but the main practical task remains unchanged.

Qualities and properties

The special quality of the glue is to ensure a smooth connection without voids with air here.

Figuratively speaking, all types of glue can be divided into compositions for cold and hot use.

Already from the name it becomes clear that cold mastic is used with very little heating and further mixing with a solvent.

The hot analogue is heated to an average temperature of about 200 degrees before being applied, which takes much more time.

Such mastics are used for foundation waterproofing, floors, walls and other parts of buildings and structures.

Which brands are much better known?

These include glue for rolled roofing material "Technonikol", Lepik na zimno, ASKOWIL and others.

Bituminous mastic

In its own composition, bitumen-based mastic has a number of resins and some elements of chemistry, which qualitatively improve the adhesion of the material to a wide variety of surfaces. With her help roll roofing material can even be glued to a wet surface without compromising the quality of the connection itself. During operation, a layer resistant to aggressive compounds and water emerges, which is not afraid of alkalis or acids.

If you plan to work with an old roll roofing material, you need to thoroughly clean its surface, cut and glue all the inherent bulges, thus eliminating them.

Bitumen based mastic workflow

- at the beginning of events, the surface will be better primed. The same applies to concrete surfaces.

- The adhesive mass is uniformly applied throughout the material.

- It is required to perform an overlap of at least 10 centimeters.

- No primer required if you plan to glue roll roofing material for rolled roofing material.

Bitumen-rubber mastic

This tool is used at least as often as primitive bitumen mastic. It is made in the consistency of a paste, which has good adhesion to wood, gypsum, concrete surface. The rich pasty mixture does not flow when applied even to vertical surfaces.

Mastic for roll roofing material is considered not dangerous for the surrounding nature and for human health. It does not have organic solvents in its own composition, so it can be safely used on the balcony, terrace, garage, etc.

Working process with bitumen-rubber mastic

- Before using the product, the surface for work must be thoroughly cleaned: grease stains, dirt and dust are removed from it.

- All inherent sharp edges must be rounded.

- First, the surface is covered with a special primer, which dries for two to three hours.

- Then, with a special metal spatula, mastic is applied to it twice.

- After applying an initial layer of 1 mm, it should dry within 24 hours, only after that you can spread the mastic again.

It must be borne in mind that if the events are carried out at a low temperature, then the mastic dries a little longer.

Pros of using glue

The most reliable method of roofing felt waterproofing is deservedly considered to be the use of bitumen glue for rolled roofing material.

An important advantage of mastic over other methods of fixation is that air pockets do not appear when joining the joints of the material.

Thanks to the mastic, a waterproofing solid sheet comes out, which in the process of durable operation keeps its own integrity.

As for the price of the product, there are significant differences between cool and hot mastic. In bituminous roofing glue, in other words, in the cold category, it is much higher, which is clear: it does not need laborious and lengthy preparation and is almost ready for use.

How to glue roofing material?

To use any type of glue, it is necessary to prepare the surface: clean it of dust, dirt, crumbs, putty pits, irregularities on the surface. For a good result, it is advisable to apply a primer. Allow to dry.

Bitumen glue for roofing material is applied to the prepared surface, roofing material is laid on top, smoothing from the center to the edges so that there are no bubbles. If there are bubbles, you need to pierce them, release the air and press this place tightly. After solidification, release.

Hot glue is more difficult to work with. It must be used before hardening.

To create a tight connection between the laying sheets, you need to make an overlap, not end-to-end connection, leading one sheet onto another by about 10 cm. The seam should also be coated with glue. In this case, a reliable leak-tight connection can be obtained.

In all cases, when working with glue, regardless of manufacturers and types, it is necessary to follow the general rules:

do not work near open flames;

perform work with the use of respiratory protection;

when using hot glue, wear protective clothing against burns.

For a more reliable fit of roofing material, you can use a hand roller. This will create a stronger fit and eliminate the possibility of air getting inside.

Features of the roofing cake

The reliability of a soft roof is only guaranteed with a correctly laid roofing cake. It is imperative to plan and do on the roof:

- ventilation;

- vapor barrier layer;

- high-quality drainage of excess water;

- several layers of roofing felt.

Usually, for the reliability of a soft roof, roofing material is laid in 3 layers

Roofing material is a material that requires installation in several layers. Unless it is a weld-on sheet of the TechnoNIKOL company (or the like). Such a complex method of laying the material has its own characteristics:

- lower layers - thin, light and cheap lining roofing material with fine-grained dressing;

- the top layer - with coarse-grained dressing (mineral chips and others);

- if laying is planned over the entire roof plane, then the amount of bituminous mastic increases;

- in places where roofing material is glued, it is recommended to remove the grit to ensure a high-quality connection of the canvases.

Roofing material glue - we prepare the mastic ourselves

Bituminous mastic consists of bitumen and fillers. It happens cold and hot, the quality does not differ, but the price of the first variety is significantly higher. We will analyze how to prepare glue for both types of roofing material.

"Cold" mastic

You will need bitumen (BN-90/10), a solvent (kerosene, diesel fuel, gasoline). The first component must be melted over an open fire, then cooled to 85 degrees Celsius and mixed with a solvent. The proportions are approximately as follows: 3 kg of bitumen per 7 kg of solvent. One should be especially anxious about the heating of BN-90/10; intensive heating should not be allowed. It is necessary to wait until the composition begins to boil gently over low heat, it comes out water. After the boiling stops, the process is over, you can proceed to further work. The whole mixture at 20 degrees Celsius retains a liquid state suitable for work, which is why it is called "cold".

When heating bitumen, its smoke and surface can be used as indicators of the correct course of the process. Gray smoke and light hiss are okay, yellow smoke and bubbles are bad. After such a process, it is advisable not to use bitumen, there has already been partially coked. Although if you notice this in time and manage to reduce the temperature, then the bitumen can be saved. It is especially undesirable to use the mixture after ignition, but this is already a completely neglected case, do not leave boiling bitumen unattended.

"Hot" mastic

This option takes a little longer to prepare, and it is advisable that you use a container with thick walls, and not a metal bucket. Some people buy a special boiler, which is also equipped with a lid.

This is important because no debris should be allowed to enter. Prepare also a metal can and a long piece of wood, build a kind of scoop out of this, they will have to collect the "foam"

It is necessary to fill the container with pieces of bitumen by 60% and start heating it over low heat, and when they melt and stop foaming, you can add a filler (asbestos, chalk, peat chips, limestone, talc and others). All this requires good mixing. Do not forget to sift the additives before adding, so as not to accidentally throw in large debris, which will significantly reduce the quality of the mastic. Continue to warm all this, removing with a scoop all the excess that floats up. After that, you can add the prepared butter and mix thoroughly. Now the mastic needs to be used while it has not cooled down, which is why you should have everything ready, because we have already thought of how to fix the roofing material.

Roofing material glue

The main purpose of the tool is not only to glue the material to all kinds of surfaces, but also to seal the joints with it.

The trade offers many types of glue from different manufacturers. Each brand has its own advantages, but the main functional task remains unchanged.

Qualities and properties

The special quality of the adhesive is to ensure a smooth connection without air pockets in these places.  Conventionally, all types of glue can be divided into compositions for cold and hot use.

Conventionally, all types of glue can be divided into compositions for cold and hot use.

Already from the name it becomes clear that cold mastic is used with very little heating and subsequent mixing with a solvent.

A hot analogue is warmed up to an average temperature of about 200 degrees before use, which takes much more time.

Such mastics are used for waterproofing foundations, floors, walls and other parts of structures and buildings.

What are the best known brands?

These include glue for roofing material "Technonikol", Lepik na zimno, ASKOWIL and others.

Bituminous mastic

In its composition, bituminous mastic contains a number of resins and some chemical elements that qualitatively improve the adhesion of the material to various surfaces. With its help, roofing material can be glued even to a damp surface without risking the quality of the connection itself. In the process of work, a layer resistant to aggressive compounds and water is obtained, which is not afraid of alkalis or acids.

If it is supposed to work with an old roofing material, it is required to clean its surface well, cut and glue all existing bulges, thereby eliminating them.

Before starting the events, it is advisable to prime the surface. The same applies to concrete surfaces.

The adhesive mass is evenly applied over the entire area of the material.

It is required to observe an overlap of at least 10 centimeters.

A primer is not required if it is supposed to glue the roofing material onto the roofing material.

Bitumen-rubber mastic

This tool is used at least as often as a simple bitumen mastic. It is made in the consistency of a paste, which has excellent adhesion to wood, drywall, concrete surface. The thick, pasty mixture does not run off when applied, even on a vertical surface.

Mastic for roofing material is safe for the environment and for human health. It does not have organic solvents in its composition, so it can be safely used on a balcony, terrace, garage, etc.

Before using the product, the working surface must be thoroughly cleaned: grease stains, dust and dirt are removed from it.

All existing sharp edges must be rounded.

First, the surface is covered with a special primer, which dries up within two to three hours.

Further, with a special metal spatula, mastic is applied to it twice.

After applying an initial layer of 1 mm, it should dry within 24 hours, only after that you can spread the mastic again.

It must be borne in mind that if the events are carried out at negative temperatures, then the mastic dries a little longer.

Advantages of using glue

The most reliable method of roofing felt waterproofing is rightfully considered to be the use of bituminous glue for roofing material.

The main advantage of mastic over other methods of fixation is that no air pockets are formed when the joints of the material are joined.

Thanks to the mastic, a waterproofing monolithic canvas is obtained, which retains its integrity during long-term operation.

As for the cost of the product, here cold and hot mastic have significant differences. In bituminous roofing glue of the so-called cold category, it is much higher, which is understandable: it does not need labor-intensive and lengthy preparation and is actually ready for use.

Mounting

Even an inexperienced craftsman can do the installation with his own hands, for this you do not need special skills or tools

It is important to follow the manufacturer's instructions and strictly follow the installation technology:

- First of all, they inspect the condition of the roof. If the coating is severely damaged, swollen, then it should be dismantled. If it is in satisfactory condition, it can be laid directly on the old subfloor.

- The base of the roof must be thoroughly cleaned of debris and dirt. If it is made of concrete, then it is treated with bituminous mastic. The lathing of wood is treated with an antiseptic composition.

- A roll of roofing material is cut into strips, the length of which is equal to the length of the slope, straightened and allowed to lie down. Laying begins at the bottom of the ramp, placing the material along the slope of the roof.

- The lower film that protects the adhesive layer is carefully separated from the material, and then the roofing material is attached to the base of the roof. Using a rag or trowel, remove air bubbles from under the cover, patting and smoothing.

- The next strip is overlapped to the first by 10-15 centimeters to protect the connecting seam from moisture penetration. The next layer is laid apart to the previous one so that the seams between them do not coincide.

Installation of material on a self-adhesive base

Features of roofing material for the roof

Roofing felt is a dense cardboard, which is impregnated with low-melting oil bitumen to impart waterproofing properties, and then, on the inside, it is covered with a refractory bitumen composition and fine-grained dressing (most often it is talc, asbestos, sand or mineral chips).

Roofing material can be considered a universal material for any roofs

There are types of roofing felt suitable for use in cold regions. During their manufacture, polymers are added to them, which makes it possible to reduce the threshold of brittleness of the material and make it resistant to temperatures up to 50 ° C below zero.

Roofing material properties

The choice of roofing material (GOST 1092393, interstate standard) with certain characteristics depends on the purpose and place of use. Roll material differs in density, type of sprinkling and method of laying:

- material density: 0.35–0.4 kg / m2;

- type of dressing: coarse-grained, fine-grained, scaly, dusty;

- laying method: cold and welded.

Application area

The main purpose of roofing material is to cover the roof. But also this material is used as a waterproofing layer on various construction sites.

Roofing material is still the most popular roofing material

Such roofing material is called lining.

Advantages and disadvantages

Benefits of roofing material:

- low cost;

- light weight;

- ease of installation.

But the disadvantages of this material are also significant:

- low strength - therefore, the material is laid in 2-3 layers, which increases financial costs. You can also increase the strength with the help of bituminous mastic;

- flammability - you need to carefully consider the design of the roof to reduce the risk of fire.

Therefore, roofing material is most often used for the purpose of waterproofing or covering non-residential structures (garages, industrial buildings, etc.)

Some useful recommendations for arranging a roofing material covered with roofing felt

If you plan to lay roofing material on the roof yourself, you should adhere to the technology of this process, not forgetting about your own safety rules.

- Before proceeding to the installation work, you need to make sure of the quality of the roofing material, since it should not have cracks, tears, folds and other damage. In addition to the surface of the canvas, you should inspect its cut. If light or white stripes or spots are found on it, this indicates that during the production process the base was unevenly impregnated with a bitumen mixture. Such material cannot be used for roofing or waterproofing, since it does not meet the declared characteristics, which means it will become a very unreliable coating.

- Before installation work, at least a day before, rolls of roofing material must be unwound and left in this position for straightening. To speed up this process, the canvases can be moistened with water. You should not straighten the euroruberoid in advance, since it has high elasticity and is perfectly unwound during its laying on the roof slope.

A high-quality euroruberoid does not require preliminary rolling - it fits perfectly on the base right in the process of laying

- The number of layers of roofing material depends on the slope angle of the slopes. If it is less than 15 degrees, you need to purchase the material for at least three layers. In the event that the roof slopes are steeper, then it will be enough to lay two layers of canvases.Sometimes even five to six layers of roofing material are laid on flat roofs. Additional pieces of material are mounted around the chimney and ventilation pipes, as well as at the junction of the roof with the wall.

- The roofing material is cut across the roll with a boot knife along the marked perpendicular line. A longitudinal cut (if a long strip of the same width is required) can be made by sawing off a whole roll, and a hand saw for wood is used for this purpose. To simplify the process of cutting ordinary roofing material, it is often moistened with water.

- The flooring of this roofing material must be done in calm weather and, preferably, at the optimum air temperature - + 20-25 degrees.

- Before starting installation work, the roof surface must be cleaned of small debris. In addition, the ramps should be audited for protruding areas and depressions. If such places are found, then the protrusions from the surface must be removed, and the depressions must be leveled with one of the polymer mixtures.

- Any surface on which the roofing material will be laid must be primed, and the wood (boards or plywood) must be treated with a complex compound that can protect it from rapid fire and biological damage by mold and insects.

- All joints of the canvases with each other, as well as with other elements of the roof, must be coated with waterproofing bituminous mastic.

Option for a roofing aerator with expanded clay filling

- To ventilate the under-roof space, it is recommended to install a roof aerator on roofs covered with soft tiles or roofing felt.

- Roofing material with a dusty coating can be subsequently painted and for this purpose, roofing paints on an acrylic or polyurethane base are used.

Simple device of a convenient ladder for working with rolled roofing materials on steep roof slopes

If roofing material is to be laid on a rafter system with ramps installed at a large angle, then to facilitate work at a height and ensure the required level of safety, it is recommended to make a special ladder that can be fixed on the ridge, and, if necessary, moved to one side or the other.

When performing roofing work, it is recommended to use a safety cable, and you need to move around the roof with extreme caution, not losing sight of the edge of the slope. Installation of all materials of the roofing structure must be carried out with gloves - there is a high risk of injury to the palms of the edges of the material

How can you replace roofing material

The most popular analogues of roofing material are:

-

rubemast - in composition it is identical to roofing material, but has a reinforced layer of refractory bitumen. It sticks to the surface of the base more reliably and stronger. During installation, melting is performed using organic solvents;

- glass roofing material - fiberglass is used as the basis of the material. This material is more plastic than roofing material;

-

roofing felt - building board impregnated with tar or coal products. Coarse mineral chips or sand are used as dressing;

-

glassine - building board impregnated with oil bitumen. Possesses unique water-repellent and wind-holding properties. It is used as a lining material in roofing and wall structures.

Finished roof care

Special care for the finished roofing material is not required. It is only necessary once a year (after the snow has completely melted) to check the surface for damage and the tightness of the seams. If a leak is found, repair it immediately.

Roofing material can be used to cover flat and pitched roofs

It is also recommended to carefully clean the roof from snow during the winter, but this can only be done with a wide wooden shovel, so as not to damage the outer layer of the material.

Service life of roofing material

The service life of a simple roofing material is rather short: about 5 years. If a glass fiber material is used, then the service life increases to 10-15 years. The following factors affect the duration of operation:

- quality of roll material;

- quality of fasteners;

- thoroughness of surface preparation;

- adherence to laying technology;

- literacy of the design of the entire roof structure - foundation, ventilation, vapor barrier, drainage systems;

- the presence of unnecessary mechanical stress - do not walk on the roofing material;

- timely inspections and repairs.

Damage elimination technology

You can repair a roofing material roof with your own hands. If the damage is minor, then it can be repaired quickly and easily.

Small cracks and punctures are sealed with patches:

- The damaged area is trimmed with a knife and cleaned; heated mastic is evenly applied to it with a brush or roller.

-

A piece of roofing material is cut out for the patch (10 cm larger than the damaged area) and is also lubricated with mastic. It is glued to this area and rolled with a roller. Then all the edges of the patch are smeared with mastic.

If bulges appear on the roof (or the roofing cake has been punched), the restoration is carried out in the following sequence:

- A cruciform incision is made at the site of the bulge.

-

The edges are folded back, the inner surface is cleaned of dirt, dried, covered with a primer.

- Hot mastic is used to lubricate the bent edges of the material and the inner exposed part of the base.

- The edges are laid back and carefully pressed, the place of the incision is also coated with mastic.

-

A patch is applied on top - from a self-adhesive or welded roofing material.

Loose seams must be re-glued:

- The edge of the seam is lifted and dried with a construction hairdryer.

- It is coated with hot mastic and pressed down. The seam itself is also smeared on top.

- The junction is covered with sand - in the summer this area will not overheat.