Roof repair without heating

Not so long ago, it became popular to purchase material with a self-adhesive base. This variety has its own positive and negative characteristics.

The pluses include:

- Stronger and more durable than other similar materials.

- Has a long service life.

- It is very convenient in installation, does not require the involvement of specialists for installation.

- It is possible to use the material on wooden surfaces.

The disadvantages include:

- Increased flammability.

- The need to make several layers between each other.

- Increased fragility.

Step-by-step installation instructions without heating are as follows:

- They clean the surface from dirt and debris, if necessary, dismantle the old coating.

- Divide the roll of roofing material into sections of the required length and let them rest for a while.

- Peel off the protective film from the base and apply it to the structure, smoothing it to get rid of the accumulated air with the surface and roofing material.

- The next pieces are shifted 15 cm to protect the seams from destructive penetration of moisture drops.

In order for the work to be done efficiently, they strictly follow the instructions and recommendations of the manufacturer.

iv class = 'code-block code-block-12' style = 'margin: 8px 0; clear: both; '>

Share link:

Overview of adhesives for finishing stoves and fireplaces with ceramics

"Terracotta" is a heat-resistant reinforced glue in the form of a dry mixture of gray color, made on the basis of chamotte kaolin dust with the addition of a heat-resistant binder and functional chemical components. Possesses a high degree of adhesion (not less than 0.8 MPa) and plasticity, heat resistance of 400 degrees, the time of tile correction is not less than 15 minutes. The glue is intended for facing bases made of aerated concrete, ceramic and fireclay bricks with heat-resistant tiles with a mixture layer of up to 8 mm.

Ivsil Termix is a heat-resistant adhesive for finishing stoves and fireplaces based on aluminate cement with profile chemical additives, produced as a dry mix. Adhesion of the adhesive composition not less than 0.9 MPa, operating temperature up to 250 degrees

Glue IVSIL TERMIX heat-resistant for stoves and fireplaces

"Leader" - universal moisture and heat-resistant adhesive mastic "Leader" gray, ready to use, environmentally friendly, heat resistance at 1300 degrees, ideal for finishing stoves and fireplaces, including baths and saunas, tile adjustment time 1-2 hours, consumption 1 kg / m2.

Self-preparation mortar for refractory finishing

If the stove or fireplace does not pretend to be highly aesthetically pleasing, then a heat-resistant stove adhesive for laying tiles can be prepared by hand. For this, a well-mixed dry mixture of cement and sand is prepared in a ratio of 1: 3, to which 1 glass of salt is added. Then 1 part of clay is added to the dry components in the form of clay pulp (clay diluted with water), and the mixture is mixed with a trowel or shovel.

Upon reaching the consistency of thick sour cream, the solution is ready for use. It is good to put heat-resistant ceramic tiles of a standard size 20x25 cm on such a composition.

Choosing reliable glue liquid nails - an overview of proven options

When choosing the most suitable brand of adhesive, consider the following:

- What materials need to be glued;

- What kind of load will the glue line experience;

- In what conditions will the glued product be used (inside or outside the room).

Today, the most popular among professionals is liquid nails from such manufacturers as: Moment (Henkel), Titebond, Makrofix, TYTAN, Krass, Kim Tec, Liquid Nails, Kraftool, Titebond, Quadro.

The following brands enjoy a very good reputation:

Glue Moment Installation MV 50 liquid nails - universal moisture-resistant express glue based on water dispersion (polyacrylate).

Perfect for joining different surfaces (wood, styrofoam, metal, plastic, ceramics, chipboard, MDF, cork coverings, polystyrene, gypsum, etc.) when carrying out installation work inside and outside the room.

Ideal for gluing plastic and wood skirting boards and other decorative elements, various profiles and panels indoors.

Glue liquid nails Titan Professional 901 - heavy-duty construction and assembly adhesive based on hydrocarbon solvents.

Provides fast and durable bonding of various types of surfaces (wood, metal, ceramics, concrete, plastic, stone, etc.). Resistant to temperature extremes, high humidity.

Suitable for outdoor use (frost resistant). Titanium Professional 901 is suitable for bonding heavy decorative elements and building materials.

Krass Extra Durable - specialized liquid nails for quick installation of plastic and tiles.

It is considered one of the best options for mounting heavy and light elements made of plastic (polystyrene, PVC), chipboard, MDF, ceramics, plaster, plywood, stone, metal.

Suitable for use in damp rooms, has excellent adhesion.

Comparison table of popular brands:

| Glue brand |

Volume |

Advantages |

Price |

| Moment Installation MV 50 |

125 grams.; 250 grams.; 400 grams. |

quick-setting, solvent-free, white. |

about 300 rubles for 400 grams. |

| Titanium Professional 901 |

380 grams. |

strong initial adhesion, forms an elastic seam, suitable for gluing heavy products. |

about 100 rubles. |

| Krass Heavy-duty assembly |

300 grams. |

convenient to apply on vertical surfaces, elastic, non-shrinking, odorless. |

about 200 rubles. |

Instructions - how to properly glue with liquid nails using the example of PVC panels

Most often, liquid nails are used to attach PVC panels to walls and ceilings.

This method of installation eliminates drilling; moreover, there are no traces of fasteners on the front surface of the panels.

How to glue PVC panels on liquid nails KRASS "Extra strong installation"?

For this you need:

- Prepare the surfaces to be glued beforehand - they must be clean, dry and free from grease.

- Remove the protective cap from the tube, cut the plastic tip closer to the thread.

- Insert the glue tube into the assembly gun.

- Apply glue to the material to be glued in thin strips of the same thickness with an interval of several centimeters (depending on the weight of the product) or pointwise.

- Lean the PVC panel against the wall / ceiling, press down and fix for a few seconds. To correct the position of the panel, do not peel off the material, but carefully move it. It is recommended to additionally fix heavy elements with supporting structures until the glue is completely dry (24-72 hours).

- Immediately after completion of work, the tools should be cleaned of glue with warm water.

VIDEO REVIEW

Frequently asked questions

How to use a glue gun for liquid nails?

This is not difficult. It is only necessary to insert the tube into the gun body, having previously pushed the rod outward, and cut off the tip of the tube.

When the trigger is pulled, the rod is set in motion, creating pressure on the piston inside the tube. The glue is squeezed out through the hole. The intensity of pressing regulates the supply of glue.

What is the consumption of glue liquid nails per 1m2?

Average consumption is about 200 grams of glue per square meter of decorative panels. When gluing narrow profiles and panels, the average consumption is 20-40 grams per meter.

How long does liquid nail glue dry?

The time for complete curing of the glue is usually 24-48 hours (depending on the thickness of the applied glue), the setting time is usually 20-40 minutes.

Features of marking

Regulatory documents (GOST R 56387-2015, EN 12004: 2007) record a number of standard markings that allow determining the main characteristics of the product.In particular:

- C - mixtures based on cement binder.

- D - dispersion tile adhesive.

- R - reactive type adhesive.

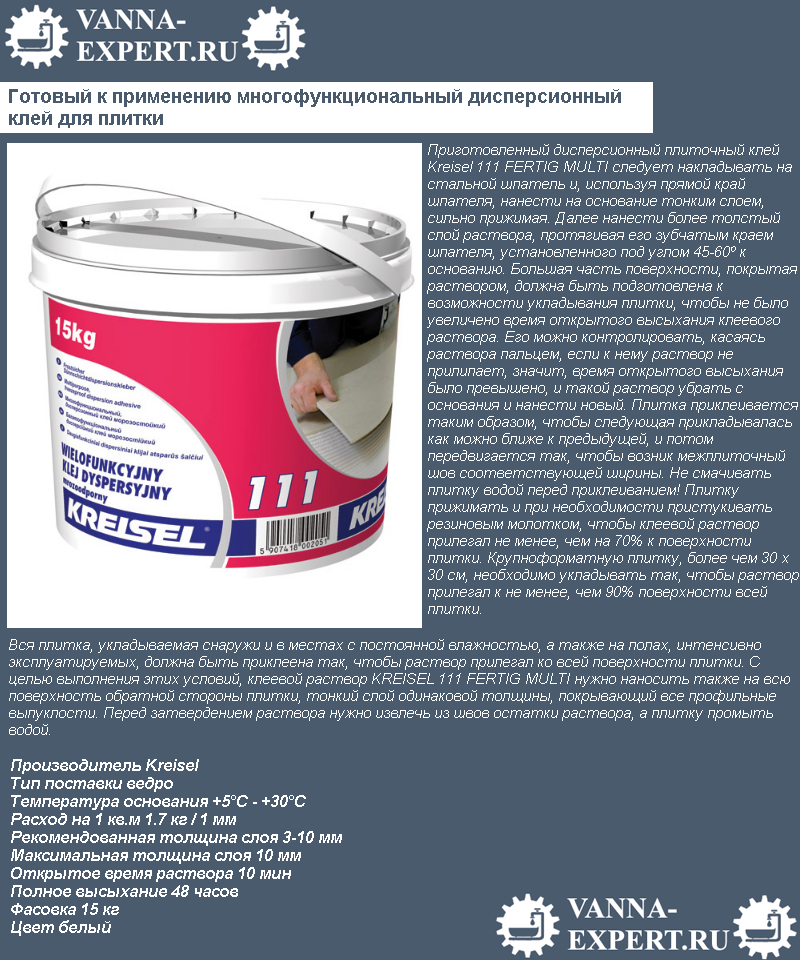

In practice, almost all letters are supplemented with numbers 1 and 2, which means "basic" and "enhanced". That is, D1 is the standard dispersion adhesive for indoor and outdoor use, and D2 is its improved version. The same is true for polymer formulations.

Let's take a look at marking using cement adhesives as an example. The EN 12004: 2007 standard approved a number of clarifying designations (classes):

- С0 - products for the installation of tile materials with a water absorption level of up to 5% by weight. Scope - indoors.

- C1 - adhesive for ceramic tiles and porcelain stoneware used for indoor and outdoor use.

- C2 is an adhesive composition, which is subject to increased requirements for a number of quality characteristics.

- F - mixtures with a short pot life (fast hardening).

- T - solution of increased thixotropy. That is, due to the introduction of special additives into the composition, it perfectly holds the tile on vertical and inclined surfaces, preventing it from slipping during gluing.

- E - mixtures with prolonged pot life (open layer).

- S1 - adhesives from a series of elastic, which, after hardening, give a deflection of up to 2.5 mm.

- S2 is a highly elastic compound designed for highly deformable substrates. Deflection limit - up to 5 mm.

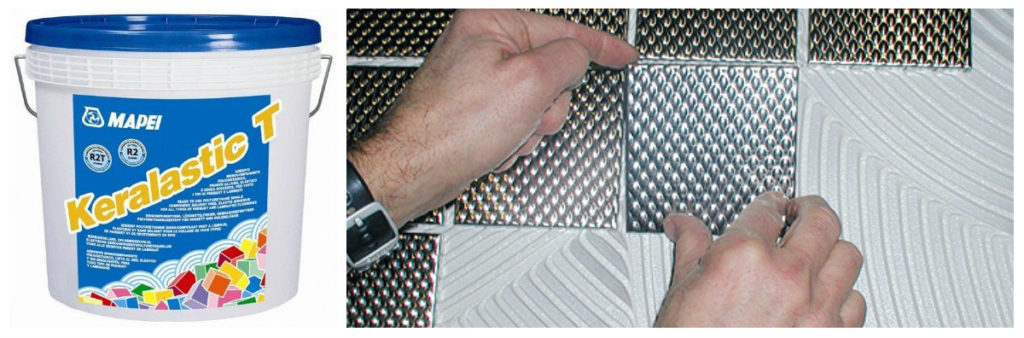

Thus, even the most complex marking is deciphered quite simply. For example, the name "Kerabond C2ES2" means that this is a reinforced cementitious adhesive with a prolonged open layer life and a high degree of deformability.

In addition to the special marking, the standard one is also used. On the packages you can find such pictograms as the thickness of the mixture, consumption, time before walking, operating temperature and others. They, as a rule, are as simple and understandable as possible, even without explanation.

Appointment

The purpose of the tile adhesive is determined by the way it is used, as well as its location in the house.

For outdoor decoration

The glue is used for cladding street buildings and structures. It is also used for laying tile tracks in suburban areas. Since the place where it will be used is the street, the conditions for its operation will be more stringent.

The outdoor environment is characterized by temperature extremes, high humidity, and windiness. In addition, the tiles are exposed to direct UV rays. Therefore, a composition is required that is capable of providing maximum adhesion to the surface, and in addition, resistance to mechanical damage.

The adhesives for outdoor use may also differ depending on where the tiles are to be laid:

- Porch models must be water-repellent. This is due to the fact that it is there that a large amount of moisture from the feet always remains when entering the house.

- For the basement floor, it is necessary to purchase glue with increased fixation, a waterproof composition is especially well suited. This is due to the high humidity in this room.

- For paving slabs, cement mortar is required. However, for additional fixation, a specially designed outdoor adhesive is often used. It will make the tracks more durable.

- For balconies, loggias, gazebos and verandas, even if it is of a closed type and the balcony is glazed, it is necessary to use an exterior finish compound. It allows you to protect the coating from destruction. In addition, this model is frost and moisture resistant.

For interior decoration

The glue differs from analogs for outdoor decoration. So, in all rooms and premises, except for the bathroom, you can use almost any tile adhesive. The bathroom is an exception, since there is always high humidity and there is a possibility of water penetration into the joints between the tiles.Therefore, a special tile adhesive is purchased for it, which protects the floors from moisture.

Some now prefer to use universal compounds in the bathroom. This is due to the fact that it is possible to process the joints between tile elements using a special waterproof grout. In such a case, the adhesive may not have the required characteristics.

Tiled models are divided by purpose and depending on the scope of its application: for walls and for floors.

For floor laying, tiles acquire a composition with high elasticity, which is provided by plasticizers. For walls, such a coating is completely unsuitable, since it will not be able to immediately reliably fix the tiles on a vertical surface. The coating will float on the wall and deform.

Wall adhesives have fast and high adhesion. That is, they are able to withstand high tensile loads. This means that the tiles, even very heavy ones, will reliably fix on the surface in a short period of time.

Bathroom wall adhesive

For mounting ceramic tiles on vertical and horizontal surfaces, ready-made adhesive solutions are usually used, which have the following qualities:

- high astringent properties;

- good adhesive qualities;

- increased adhesion to various surfaces;

- optimal curing time (this gap should be such that it is enough for the correct placement and leveling of the decorative material).

The use of tiles in the bathroom has its own characteristics that must be considered when choosing an adhesive.

| Characteristic |

Description |

| Temperature resistance |

During bathing procedures, the air in the bathroom often heats up to a high temperature, after which it cools down. Accordingly, the adhesive on which the tiles are glued must withstand these vibrations and have a minimum coefficient of thermal expansion. |

| Moisture resistance |

The content of water vapor in the air in the bathroom is also higher than in other areas of an apartment or house. The hardened mortar holding the tiles must retain their operational properties even in direct contact with water (when liquid leaks through the seams). |

| High strength |

The adhesive composition (especially for floor tiles) must withstand significant operational loads. Firstly, heavy household appliances and plumbing fixtures are often installed on the tiles in the bathroom, and secondly, this room is one of the most visited in the home. |

| Environmental friendliness |

The adhesive will be used indoors (sometimes with poor ventilation). Therefore, the material should be as safe as possible for humans and have zero emission of chemical compounds harmful to health. |

These are the most important characteristics

But when choosing which is the best glue for tiles in the bathroom, I advise you to take into account other points:

- what material is the surface made of, which will be tiled;

- what size the tile will be used for work;

- whether the underfloor heating system will be used (water or electric).

The specific type of tile depends on many additional factors.

Well, now in more detail about the currently existing varieties of adhesives for tiles.

What kind of glue is needed for the walls? Here, each buyer can choose the required composition for a long time, since their quantities are really huge. Based on consumer reviews and an expert, only the highest quality adhesives can be identified.

Eunice Plus

This composition is characterized by high moisture resistance, due to which it is chosen for cladding floors in the bathroom. Also, the glue can be used when arranging the "Warm floor" system. The solution is characterized by high adhesion, strength, reliability and plasticity. The cost of the product is 250 rubles per bag.

Glue (FLEX)

This composition is actively used for laying floor tiles in rooms with high humidity. It has high plasticity, therefore, it is advisable to use glue on surfaces that are subject to periodic deformation associated with moisture and expansion. This also applies to the bathroom. Such a mixture costs 350 rubles per bag.

Glue - 10 (strength)

I also use it very often when tiling floor coverings in a bathroom. This composition is characterized by high fixing power, it is water-resistant and very convenient to use. When laying tiles with glue-10 strength, you will be able to enjoy your floor for a long time, no cracks or other defects will arise. The cost of the product is 400 rubles per bag.

Siltek T-80

The main characteristics of this composition include:

- mineral;

- easy to use;

- highly plastic;

- frost-resistant;

- environmentally friendly.

It contains components such as cement, fractionated fillers, modifying additives. The glue costs 150 rubles. And here you can learn about the Prospector Standard glue.

additional characteristics

The operating conditions of the decoration or work can be strikingly different, and it is unacceptable to neglect this fact when performing the decoration. From this point of view, the following types of adhesive mixtures are distinguished:

Quick dry

Due to additives that accelerate the evaporation of moisture, the glue sets and dries very quickly. Full use of the premises is allowed within 3-4 hours after the completion of the work. Such a convenient quality puts forward increased requirements for the qualifications of the master, since the work will have to be extremely fast, and it will be impossible to correct anything.

Naturally, quick-drying glue is not suitable for tiling complex and curved substrates. A definite plus is its frost and moisture resistance, due to which it is allowed to be used for external cladding. This type of mixture is produced only in dry form, since the finished composition would have a very short shelf life. Famous brands offering quick-drying adhesives include Ivsil Express and Knauf Schnellkleber.

Heat resistant

Finishing surfaces that will have to warm up strongly during operation is a very important event. With a rapid increase in temperature, the layer of adhesive solution should not dry out and crack, retaining some plasticity. Heat-resistant tile adhesives can withstand temperatures up to 100 ° C without damage to repairs, so they must be used when facing fireplaces, stoves and rooms with an equipped floor heating system. Stove-makers speak positively about such brands as Ceresit CM 17, Weber vetonit RF, Ferozit-108.

Frost resistant

Progress in the mortar market allows facing work even at subzero temperatures. After dissolution, dry mixtures set fairly quickly, so you need to work with them quickly and knead for no more than 1.5-2 hours of work. Kreisel MULTI 102 glue deserved positive feedback from tilers.

Acid resistant

For repairs in ordinary living quarters, this type of material is irrelevant, but it is widely used in industrial or research facilities. The risk of acidic substances coming to the surface exists in laboratories, dairies and breweries. Adhesives such as Glue 88-NP or Boton TK 150 can be used on surfaces with high humidity, they quickly harden and do not have harmful impurities.

Water resistant

Recommended for use for facades, outdoor terraces, porches, bathrooms, swimming pools and fountains. The hydrophobic characteristics and the ability for enhanced fixation are imparted by certain modifying additives, which negatively affects the cost.Popular brands among the products of this category are Pobedit Pool TM-16 and Ceresit CM 17.

Universal

This category includes adhesives suitable for most standard conditions and substrates. Universal varieties are not suitable for outdoor work, rooms with high humidity or temperature, for fixing porcelain stoneware or tiles over a floor heating system.

What to consider when choosing an adhesive

The stores offer a wide range of bathroom tiles of different shapes and qualities, which requires a more careful choice of glue. This will allow you to perform the work efficiently and reliably. You need to take into account many points: type of tile, base, climatic conditions, etc.

Application area

The type of room in which the tiles will be used is the main selection criterion. For the kitchen, you can buy universal mixtures designed for interior decoration, for the bathroom - a waterproof solution. Versatile mixes are good for cladding. Grouting requires materials that are resistant to moisture.

The following criteria are relevant here:

- the size;

- material of manufacture.

Base

The quality and material of the walls and floors in the room are of great importance when choosing an adhesive.

The basis can be:

- drywall;

- cement strainer;

- cement-sand mortar.

How firmly the tiles adhere depends on the type and brand of adhesive. You need to take into account the properties of both the tile itself and the base.

Adhesive parameters

When choosing an adhesive, you should pay attention to the following characteristics:

strength (for floor tiles);

moisture resistance (important primarily for bathrooms);

elasticity (when working with wall tiles);

enhanced adhesion (for large tiles and vertical masonry);

slow setting (for unstable surfaces).

Universal formulations are suitable for dry rooms. The complexity of working with the material, consumption and costs are also taken into account.

The temperature regime affects the state of the solution and the quality of work:

- high temperature promotes rapid evaporation of moisture and an increase in glue consumption;

- low can have a negative effect on the solution and worsen the quality of work;

- it is optimal if the room is maintained at 20 ° C.

What formulations should you give preference to?

The most popular are the products of such manufacturers as: Ceresit, Index, Mapei. You can also highlight the trademarks Knauf, Osnovit, Eunis, Litokol. Most experienced builders choose the Ceresit brand because this company offers a wide range of choices that solve all problems.

Correctly selected glue is the key to the durability of the coating.

Popular types of this brand:

- CM 11 - for external and internal work;

- SM 12 - designed for indoor work;

- CM 14 is a frost-resistant and water-resistant version. These mixtures quickly "set".

- CM 17 is a universal glue that is suitable for all types of substrates.

The brand itself has proven its reliability, practicality and efficiency in practice, as the adhesives for porcelain stoneware have improved their qualities over time. Modern technologies allow us to solve any problems, based on the experience of more than a hundred years. It is better to choose tile adhesive from well-known manufacturers.

Varieties of tile glue

Almost all manufacturers of tile adhesives make their brands according to generally accepted standards and classifications, which divide the compositions according to their physical characteristics. When choosing which adhesive for tiles is better in the bathroom, in the hallway or for facing open areas, you need to refer to this classifier. According to the classification, all types of glue are divided into five main groups:

-

For interior work. This type of glue can be called one of the most inexpensive, since it does not require additional components to improve performance. Such a composition is used for finishing walls and floors of household premises. The adhesive is suitable for laying tiles on concrete or cement substrates.The lack of good holding qualities limits the size of the tile module to the standard 20x20 or 30x30 cm. For floor tiles, the modules can be even larger. The compositions are afraid of exposure to moisture and temperature changes.

-

Increased fixation. This type of adhesive already has various additives and is highly adherent to various materials such as concrete, cement or wood. When choosing which glue is best for floor tiles, many craftsmen choose exactly the compositions of this category, since they do not limit the craftsmen by the size of the module. This class of glue withstands temperature changes and deformation of the base well, is actively used for laying porcelain stoneware, stone and large tiles on the floor in public areas. However, most of these compounds are afraid of moisture exposure.

-

Universal. This type of adhesive is used for laying tiles on floors and walls. It is called universal because of the possibility of its use in interiors and for external cladding.

-

For floor installation. The composition of this glue includes a large number of plasticizers, which allow the composition to withstand high mechanical loads. It is ideal for laying large porcelain stoneware modules and tiles on the floor in public, domestic and technical areas such as warehouses, shopping centers or garages. However, these adhesives have great fluidity due to plasticizers and cannot be used to lay tiles on the wall.

-

Moisture resistant. It is the best adhesive for tiles in bathrooms and other places where there is direct contact with water. The compositions have a strong hold and are used for laying swimming pools or fountains thanks to special modifying additives. The only condition is the mandatory use of a moisture-resistant grout for joints.

When deciding which glue to choose for tiles in the bathroom, it is recommended not to save money and purchase a moisture-resistant composition. Of course, it is possible to use universal glue or mixtures with a strong hold, provided that the joints are sealed. However, in this case, at the slightest leak, the tiles will start to lag behind, so you should not save on this, especially if you use expensive types of tiles.