Review of popular brands

There are many brands of parquet glue. Some of them are more popular due to quality and price point.

Uzin MK 92 S

This brand belongs to two-component substances. Country of origin - Germany. The adhesive has increased environmental friendliness, it is permissible to use it without protective equipment. For 1 square meter of floors, 1.2 kg of substance is required. The glue can be used on any surface, it does not cause the boards to swell.

ADECON E3

Italian brand of two-component substances. Glue consumption - up to 1.3 kg per square meter. Has increased adhesion to various surfaces, the water content in the composition does not exceed 30%. After drying, it retains elasticity, after preparation it is required to use it for half an hour. The load on the floors is possible only a couple of days after laying; if sanding is necessary, it is worth waiting 15 days. The adhesive is not recommended for use in rooms with high humidity.

ADECON K450

The adhesive is one-component and can be used immediately after purchase. Recommended for restoration, connection of modules and individual elements. The product is based on vinyl, made in Italy. Dries completely one day after the parquet flooring.

ADEGLOSS 10

The basis of the substance is polyurethane, after drying it expands slightly. The adhesive does not contain solvents. Possesses high-quality adhesion to concrete and cement. Long-term action of water does not have a negative effect.

PAVI-COL P25

Italian product with organic elements. Skin formation occurs 10 minutes after the start of use. It can be used for large planks, the load on the parquet is possible a couple of days after the flooring. Consumption - up to 1.3 kg per square meter. After drying, the glue retains its elasticity. It is recommended to work in a room with a humidity of at least 40% and at a temperature of at least 20 degrees.

PELPREN PL6

Two-component adhesive with extended working time (up to 2.5 hours) and fast drying. Floor loading is permissible already 18 hours after use. After application, no traces remain on the parquet, hardening occurs with the help of air moisture, there is no shrinkage. The product is suitable for laying underfloor heating.

WB MONO MS performance plus

Made in Italy. The composition does not contain solvents, does not emit toxic compounds during use. 1 kg of substance is enough per square meter. Silicon is present at the base, the boards are laid no later than 40 minutes after applying the glue. Full hardening occurs after 6 hours, sanding is possible 36 hours after laying. The glue has increased adhesion to concrete; protective equipment must be worn during work.

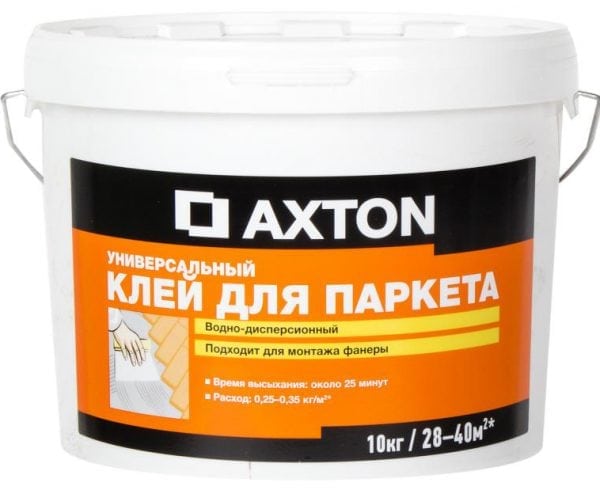

Water-dispersive adhesives

Dispersion adhesive for parquet has a whole bunch of positive qualities: it is odorless, environmentally friendly and easy to apply, which ensures its wide popularity in European countries, but not everything is so smooth. The dispersion composition contains a large amount of water, which can harm the parquet board.

The liquid evaporates and deforms the wood, so this glue can only be used with wood that has good moisture resistance, for example, it can be larch, oak or exotic oily trees. The base to which you attach the parquet board must also be made of materials that can withstand moisture, such as moisture resistant plywood.

There is a whole list of requirements for a parquet board:

- It is recommended to use water-dispersion adhesive only with multi-layer parquet board;

- Apple, pear, cherry, beech, alder, ash and maple cannot be glued with this composition, because they swell quickly when exposed to moisture.

- The thickness of the board also plays a significant role: it should be thicker than 10 mm (in more detail: "Length and thickness of parquet - standard sizes");

- The surface of the board should not be processed, varnished boards must not be fastened with this compound: the varnish will not allow the wood to dry out, which will cause its deformation.

Examples of good dispersion adhesives include:

- With the Swiss glue "BONA B-720" you can glue a parquet board made of any non-fruit wood to moisture-resistant plywood. The glue has a fairly low price: about $ 5. (300-500 rubles) per kilogram with a consumption of 1000-1400 g per square meter. This brand has one of the lowest water content in the composition, which is 22%.

- Finnish glue of the Kiilto Standard brand contains much more water (36%), so you can only glue it with oak or hardwood parquet. The price for this glue is slightly higher than for the previous copy, but its consumption is also lower: 600-1200 g per square meter.

- If you are laying the parquet on top of the "warm" floor system, then the water-based glue "Tarbicol KP-5" is suitable for you. They can be glued to boards with a thickness of 10 to 15 mm. Due to the high water content, the glue has a low cost and consumption, approximately equal to the Finnish glue.

Parquet laying: the plywood-free method

Plywood is not always used as a substrate. Often the boards are fixed directly to the concrete, leveled and prepared (dry, clean, perfectly flat, free from defects).

How parquet is attached to concrete:

- The concrete surface is primed.

- The planks of the first two rows are laid out as they plan to mount, then the base is treated with glue with a notched trowel, the first board is fixed at a distance of 6-12 millimeters from the wall. Then the next board is fixed using a tamping block, pressed tightly to the floor.

- After laying the first row, the last die is trimmed, go to the next row.

- When performing installation, you need to constantly use a level and make sure that there are no gaps between the rows and boards.

- When the installation is complete, all seams are treated with an acrylic-based sealant and the floor is allowed to dry (2-5 days, depending on the glue), then the finishing is done.

How to use correctly

Before laying parquet, it is necessary to check the temperature and humidity of the concrete screed, especially in the corners. Complete hardening of concrete occurs after a couple of weeks. The glue is prepared according to the instructions, and then the installation begins:

- A primer is applied to the concrete, waiting for complete drying.

- Previously, it is possible to lay out the parquet as it will be glued.

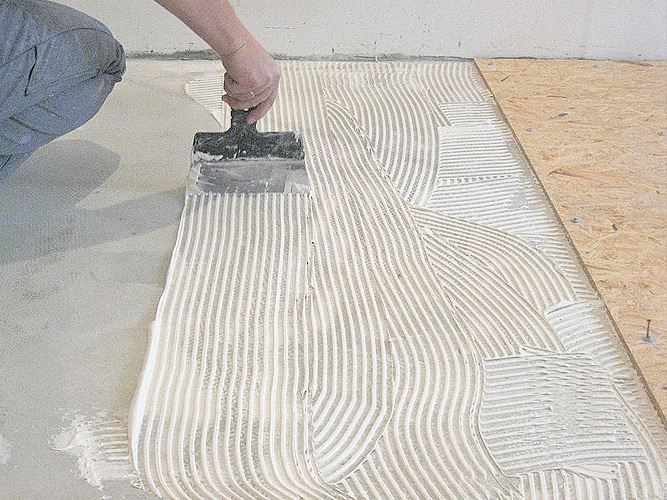

- Glue slightly larger than the size of the board is applied to the base using a comb trowel.

- Lay the parquet, lightly press down. Excess glue is removed immediately.

If the boards are small, then several pieces can be stacked at once.

Laying solid boards on glue - a step-by-step process

- Before starting work, you need to unpack the solid board and leave it indoors for at least three days. This will allow the material to adapt to the climate of the room in which it has to "work", namely, temperature and humidity.

- Then you can start preparing the base. For this, the floors are leveled using a cement-sand screed. In order for it to gain strength, it will take about a week.

- The next stage is laying plywood or chipboard sheets on the floor. The material must be dense and moisture resistant. The optimum plywood thickness is at least 15 mm, sheet size is 600-1000 mm. Fix the sheets to the floor with self-tapping screws.Additional fixation will be provided by smearing the base with glue, and the joints of the sheets with an elastic sealant.

- The laying of the flooring starts from the wall. The markings are performed on plywood with an indent from the wall of 5-10 mm. For convenience, you can drive in wedges. It is recommended to lay out two rows of boards without glue, sign the elements so as not to confuse the stacking order, and disassemble them.

- Polyurethane glue for a solid board is applied with a spatula, then the boards are laid, joining in the lock. First, lay out the first row, then the second with a neat fit to each other. Additionally, the boards can be nailed down with small nails. Experts do not recommend applying glue to the back side of the boards, as the material can stick poorly due to the resulting voids.

- Next, you can lay the rest of the rows. After that, it is necessary to stand for several days for the coating to adhere completely.

- If the flooring does not have a protective layer, oil or varnish is required. To do this, sanding is performed, then polishing and dust collection, after which a protective coating is applied.

- The final stage is the installation of skirting boards.

Laying solid boards with glue

Is it worth laying a solid board without glue

Laying is possible without glue, this method is called "floating", that is, the boards are not fixed on the base, but are fastened only to each other.

The wood constantly shrinks and expands as a result of changes in temperature and humidity, and laying without glue does not impede the movement of the floor, as it becomes one whole. That is why this method of laying has an important plus - there will never be gaps in the floor between the boards.

Helpful hints:

- Installation without glue is possible on any substrate, be it plywood, concrete or tiles.

- This technique is suitable for creating warm floors.

- You can choose any solid board as the material for the flooring.

- This option is not recommended in rooms with heavy furniture, which, when rearranged, can pull out or damage the lock.

Adhesive primers

Primers correct the process of glue absorption by the base, bind dust, and somewhat harden the surface. Without them, one cannot hope for a strong connection of the parquet with the base. Universal advice - buy the primer at the same time as the glue, their compositions should be as identical as possible. Polyurethane adhesives require polyurethane primers, dispersion dispersions, etc.

Dispersion primer for parquet under Berger Primer D glue

In addition to these important functions, primers on concrete substrates protect the coating from capillary moisture buildup. High humidity negatively affects the adhesion performance of all adhesives. It is possible to apply primers to concrete substrates only after checking their moisture content. For readings ≤ 5%, only epoxy primers should be used; for humidity ≤ 1.5%, polyurethane primers are acceptable. If the moisture content of the concrete screed is> 5%, then the room must be dried before priming.

Primer application

What to choose in the adhesives market

In general, in areas with low stress and humidity (such as a bedroom or living room), it is recommended to use dispersion based adhesives.

At the same time, a composition of solvents will be required in the kitchen or in the corridor. For the bathroom, hallway and balcony, a two-component composition is best suited.

When choosing an adhesive, it is best to focus on proven brands: Bostik, Ibola, Kiita, Sika, Stauf, Artelit, Hermetic and Monosil.

Types of parquet adhesives (for parquet)

Today in stores you can find a wide range of parquet adhesives. All of them differ in composition, type for wood, as well as the size and thickness of the boards used. The choice of the right adhesive for parquet is especially important, since it is this material that is responsible for the strength and durability of the floor.In this article, we will look at the types of parquet adhesives, the differences between them, and also give recommendations on how to choose the right type of parquet adhesive for your home.

Polyurethane parquet adhesive

It is one of the most popular parquet flooring products. Polyurethane adhesives are characterized by high adhesion strength and durability. Note also the fact that they can be used in the case of laminated parquet, as well as when using floor heating.

All polyurethane adhesives can be divided into two types:

- One-component parquet glue - used mainly in the presence of warm floors and in rooms with high humidity. Under these conditions, the tree swells and changes its structure, therefore it requires flexible glue. The main advantage of one-part adhesives is the relatively long drying time, so you don't have to rush to make any fixes. However, this type of glue cannot be used on boards that may be damaged due to the aforementioned conditions;

- Two-component parquet adhesive - you can use these on almost any wood floor. Note that two-part adhesives are usually used in conjunction with a hardener, which means they dry very quickly. Therefore, if you accidentally stain the board with glue, remove it immediately. Otherwise it can be very difficult and sometimes impossible to do. Two-component adhesives work best when gluing varnished parquet flooring.

Parquet polyurethane epoxy adhesive

It is a two-component product that, thanks to its additional composition, has a special adhesion. However, it can only be used at temperatures from +10 to a maximum of +30 degrees Celsius.

Polyurethane parquet adhesive with silane or polymer

This product can be qualified as a product that combines the properties of a one-component and two-component polyurethane adhesive. You don't have to mix them with hardener, so they dry for a long time, which allows you to work with parquet in a more relaxed mode. In addition, such adhesives are easy to remove from the board if necessary, and they are also considered environmentally friendly. All this makes these types of parquet adhesives ideal for all types of wood.

Solvent Parquet Adhesive

At one time it was the most popular type of parquet glue. The main advantage of solvent adhesives is their great resistance to changing conditions - they are not afraid of either high or low temperature or humidity, therefore they are often used for gluing wood that is sensitive to water.

Why did they cease to be popular? What are their disadvantages? First of all, it is a very low flexibility, low strength of such adhesives. And, of course, the presence of a large number of substances that are harmful to the environment and people.

Parquet diffusion adhesive

This is a new generation of parquet adhesives, which is sold in the form of one or two-component composition. Such adhesives are well suited for gluing so-called "strips".

The advantage of diffusion glue is its low price. Note, however, that it can only be used for “stable” and exotic types of wood (teak, beech, etc.), because in the case of a material with a high tendency to swell, it will be harmful to parquet.

Overview of formulations and their use

Laying on a concrete or other base when laying parquet can be glued and "floating". It is the first technique that is recommended - it gives a better result. Several types of adhesives are available. Therefore, the following types of glue can be found in the store:

- two-component;

- one-component;

- water-dispersive;

- synthetic - with solvents.

Which one to choose when performing repairs? Each option is used in the practice of installing parquet, but has its own characteristics.The choice depends on the type and type of wood, on the type of base on which the boards will have to be glued.

Dispersion adhesive

It would seem that water-based glue is not suitable for parquet, because such compounds can soak the material. But special "parquet" dispersion adhesives are produced, suitable for repair. Best of all, they fix larch and oak lamellas, these types of wood are highly resistant to the influence of water, they are the most durable. Such a composition is also not bad for small-sized block parquet.

Do not use such products when working with the wood of fruit trees - apple, cherry, pear. Maple, beech, alder are also considered unstable to moisture: the wood will quickly begin to rot, deform, and collapse. You can not use such adhesive solutions with a small thickness of the boards and if there is more than 30% water in the composition of the product.

Advantages of dispersion based adhesives:

- safety for the body, the ability to apply even in the children's room, 100% environmental friendliness;

- exclusion of allergic reactions in humans;

- lack of unpleasant odor;

- simple and convenient application;

- a large assortment;

- moderate cost per kilogram (from 200-300 rubles).

Solvent adhesive

A more reliable and safer option for the material itself is a solvent-based synthetic adhesive. Experienced parquet flooring workers choose such compositions more often than others, because they are suitable for any wood species, do not cause swelling and decay. Products may contain rubber, rubber, and other substances.

A distinctive feature is the high strength of the bonding components, compatibility with most substrates (plywood, concrete, etc.). Other benefits:

- simple work, convenient application;

- the ability not to close the glue - the jar is open for up to 15 minutes;

- laid lamellas can be corrected, changed position.

The disadvantages include a long period of complete drying - up to 5 days, so it is better not to live in the room being repaired, or at least to close the room tightly. For work, a full set of protective equipment must be used: a respirator, thick clothing, gloves

Significant disadvantages are flammability, explosiveness, installation must be carried out with great care, smoking must be strictly excluded. The price of adhesives with solvents is much higher than dispersion compositions

Two-component adhesive

Reactive (two-component) adhesive is a popular choice for professionals. With the help of the means, parquet can be glued to concrete, plywood, metal, and other bases. The formulations are sold dry in buckets. To obtain the finished mass, the powder is diluted with the attached emulsion, then mixed and the time specified in the instructions is allowed.

A two-component mortar is considered the most durable for parquet among all other compounds. The adhesion strength is ensured by the presence of a hardener, while there is no water or solvents in the product. It will take from 2 to 3 days for the final hardening, but some funds set in a day. Reactive glue is used for any kind of parquet board. It does not harm even the most delicate wood, expensive art parquet, it glues solid boards well.

Adhesives also have drawbacks. Their price is very high, although this is justified by the long service life of the flooring in the future. Another disadvantage is the toxicity of the funds, until they finally solidify, they continue to emit harmful substances. It is necessary to work with adhesives only in respirators, but after complete hardening, they are not dangerous even for children. Also, do not forget about tight gloves during the installation of parquet: if glue gets on the skin, it can cause burns.

Various gluing cases

In hardware stores, you can find several types of solutions for gluing parquet, but when choosing a material, you need to take into account the overall dimensions of the planks, the type of wood and the base material.There are certain rules to help you choose the right adhesive for wood parquet:

- when using a plywood base, it is recommended to use a compound with maximum adhesion to a cement-sand screed or wood. In addition, the solution must be elastic;

- in the case of gluing strips of block parquet made of ash or oak to plywood, a water-dispersed composition is used, provided that the size of an individual element of the flooring does not exceed 42 cm in length and 7 cm in width;

- when gluing a factory parquet board, a one-component polyurethane glue is applied to plywood, which will prevent warping of the floor covering;

- for gluing any parquet, the lower surface of which is covered with a layer of varnish, use a glue that is resistant to vertical tearing. Before carrying out installation work, the material is tested for pull-off. Peeling of varnish from the surface of the product is not allowed;

- the sticker of a parquet board made of exotic wood (cherry, maple, pear, beech) is carried out on an adhesive mixture that is resistant to changes in temperature and humidity conditions. It is best to carry out installation on a silane mixture of the Bona brand or another, since there is no water in this composition;

- a large-sized parquet board, which is fastened by means of grooves and locks, is fixed on a two-component reactive glue or on any other mixture that does not contain water. Massive parquet boards with a width of up to 12 cm should be glued onto an elastic mortar;

- when fixing the floor covering to a cement-sand screed, you must choose a mixture with high adhesion rates in relation to the base surface.

The matter does not end with the choice of the brand of glue, it is still necessary to use the composition correctly, observing the temperature regime of laying the parquet and the operating conditions. If the glue breaks down at low temperatures, then it is undesirable to use it in houses with irregular heating. In this case, in winter in frost, parquet boards or dies can fall off. When covering a heated floor, it is also necessary to take into account the properties of the adhesive to withstand temperature fluctuations. The choice of adhesive is based on many factors. In general terms, the parquet mix should be strong, of high quality and elastic, then it can last as long as possible.

The use of adhesive mixtures for different types of coatings

The fact that parquet glue, depending on the type of components used, is used to fix certain types of coating has already been mentioned above. But you should understand in more detail which variety is best used in specific situations.

Industrial parquet laying

This industrial-type flooring is specially designed for high traffic and heavy loads. Given that this material is quite new, there are no clear recommendations on the use of an adhesive mixture. But practice shows that a two-component polyurethane compound is best suited for this task.

Fastening a solid board with a width of more than 12 cm to the screed

In such a situation, it is important that the mixture is elastic and as strong as possible. These requirements are met by a polyurethane compound.

You can use glue for solid boards when laying directly on the screed, but depending on the operating conditions, it is sometimes recommended to use the Multimol underlay.

Fastening coverings to the screed, except for boards with a width of more than 12 cm

In this case, two options are offered: you can use a two-component polyurethane compound and fix the coating directly on the screed, and the parquet glue will be consumed less intensively; the coating is laid on the Multimol substrate, but the adhesive mixture is consumed twice as much. Under such conditions, it is recommended to choose the second option.

Laying, except for a massive board, 12 cm wide on a fragile screed

Parquet adhesive must have excellent adhesion due to the low strength of the substrate, therefore it is recommended to use a one-component type of mixture. At the same time, the increased elasticity will eliminate the risk of deformation of the coating due to rupture along the glue.

Fastening a massive board with a width of more than 12 cm to plywood sheets

Under these conditions, it is important to provide vertical pull-out strength. One component type solid board glue should be used

Laying boards less than 12 cm wide against plywood sheets

An elastic and sufficiently strong adhesive can reduce the tension between the substrate and the finishing material. For such a task, both one-component and two-component compositions are suitable.

The adhesive must be flexible and tough to reduce stresses between the plywood and the board during periods of moisture.

The adhesive must be flexible and tough to reduce stresses between the plywood and the board during periods of moisture.

Installation of parquet board / glued to plywood

Large-format finishing material does not tolerate moisture well, which means that dispersion compositions will not work. The best solution for DIY installation is an elastic and durable glue.

Laying maple and fruit wood block parquet on plywood

The named material is unstable when operating conditions change. This means that dispersion compounds for fixing block parquet should be avoided.

If the parquet is made of fruit wood, the glue should not contain water in the composition.

If the parquet is made of fruit wood, the glue should not contain water in the composition.

Fastening the lacquered coating on the underside

In this case, there is a high probability of delamination of the structure under the influence of pull-off loads along the lacquer interlayer. To determine the quality of an adhesive that has suitable properties (resistant to pull-off loads), it is recommended that you conduct a test yourself. A one-component adhesive is usually suitable for these conditions.

If a layer of varnish is applied on the back of the parquet board, then before starting installation, you should check any type of adhesive for vertical separation.

If a layer of varnish is applied on the back of the parquet board, then before starting installation, you should check any type of adhesive for vertical separation.

Fastening plywood sheets in different ways

If you plan to lay the substrate with your own hands on a screed without special fasteners, you need to use a highly elastic composition. When the question of how to glue plywood to concrete is being decided, they also consider a combined mounting option: self-tapping screws and glue. In this case, the requirements for the mixture are lower, which means that a water analogue can be used.

General requirements for adhesives

Parquet glue, regardless of the chosen installation method and purpose, must meet the following requirements:

- Give minimal shrinkage. That is, the consistency should not sharply decrease in thickness after hardening. This can be influenced by factors such as the chemical composition, the performance of the substrate and the creation of the mortar in accordance with the basic rules.

- Elasticity. During operation, the parquet will change its linear dimensions. This can be due to 2 reasons: thermal expansion and hygroscopicity of the wood. Due to heating and cooling, the parquet board can increase or decrease in parameters. If the underfloor heating system was installed, and it is not recommended for block parquet, then the difference in values can be significant. The wood's ability to absorb moisture will affect the rate at which the planks resize.

- Long service life. When a piece of natural parquet is chosen as a floor covering, you want to provide it with high-quality fastening and durability. Usually such floors are used in very expensive houses, mansions, premises and offices of companies, their cost is very high and not available to everyone. Therefore, if the lamellas quickly peel off, then as a result, a complete dismantling and a new laying of the coating will be necessary.

- The minimum amount of water. Natural parquet made from quality wood, like other sawn timber, is capable of absorbing moisture.Prolonged exposure to liquid can cause visual changes in the material, warpage. Therefore, the parquet glue must be chosen by carefully studying the composition and water content in it.

- Environmental safety, the absence of an unpleasant odor are also important points when choosing an adhesive. Government organizations control the toxicity of glue compositions, including fumes that are unsafe for humans. Therefore, on sale you can find all formulations that are designed to work in enclosed spaces. In addition, parquet is a dense material that blocks the penetration of air through it.

If you know and take into account all the listed requirements for substances, then you can find the optimal glue for a parquet board. However, it is not enough to glue the parquet board with high-quality glue to ensure the strength and durability of the flooring.

The correct choice of glue is a very important condition in the work, but far from the only one that can ensure a long service life, without the appearance of defects in the parquet floor.

This is interesting: Cork underlay for laminate, pros and cons: we consider the main thing