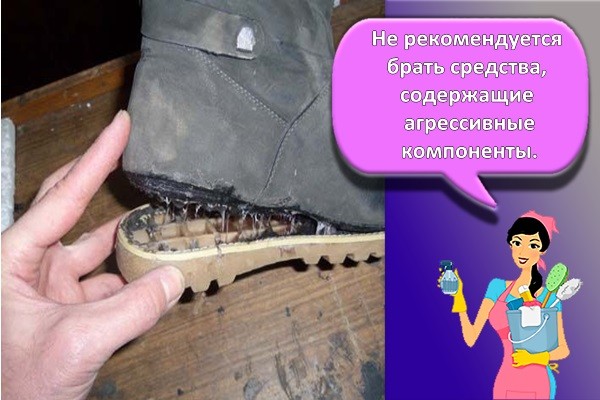

What is the best glue not to use?

The range of adhesives goes far beyond the listed means and some of them can also cope with the task. In order not to confuse you, we decided to point out which adhesives should not be used categorically, since they either will not provide sufficient strength, or will further spoil the pair being repaired.

- PVA glue does not have water resistance, so the boot will fall apart after the first puddle.

- Superglue (glue Moment, Second, etc.) assumes a rigid connection, and the sole and boot material deform when walking. The material simply cannot cope with such a load.

- Ceiling tile adhesive in practice, he copes with the repair of leather, textile and rubber products, but leaves stains on them that cannot be removed.

The best all-purpose shoe adhesives

Often the composition of all adhesives is the same. Moreover, the quality of each product is different. Below are the most common options that should always be at hand with a home craftsman.

KENDA FARBEN SAR 30E

Differs in universal properties. Can glue a wide variety of materials. Suitable for repairing shoes made of natural or artificial leather, rubber, textiles. Differs in fast bonding of different surfaces. The seam is durable, resistant to high humidity and low temperatures. It will take two days for the adhesive to dry. After that, you can use your shoes.

Universal adhesive for shoe and leather goods production.

Universal adhesive for shoe and leather goods production.

Among the advantages are:

- application in professional workshops and at home;

- high efficiency and quality indicators;

- resistance to temperature extremes;

- there is no unpleasant odor when gluing.

Disadvantages:

rather high cost of one tube.

Moment "Marathon"

Quickly glues different surfaces, therefore it is suitable for quick gluing of shoes. Differs in ease of use. The composition does not spread, as it has a gel structure. Not intended for gluing polyethylene or PVC. It is used for gluing fabric, wood, rubber and other materials from which shoes are made. Freezing possible. After that, it heats up quickly enough at room temperature, without losing its quality indicators. The packaging looks red.

Moment Marathon is a special shoe glue that is perfect for fixing any type of shoe made of various materials in any combination.

Moment Marathon is a special shoe glue that is perfect for fixing any type of shoe made of various materials in any combination.

Pros:

- there are different volumes of tubes;

- allows you to quickly repair the desired product;

- economically distributed over the work surface;

- characterized by high strength and efficiency.

Minuses:

unpleasant smell when gluing.

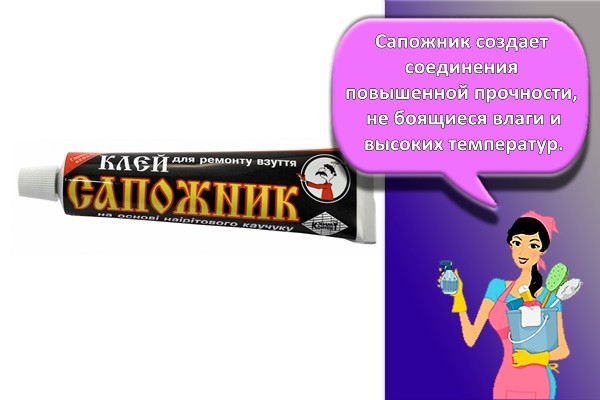

Nairit

Designed to work with a wide variety of materials. Differs in high quality bonding of rubber, fabric, leather, wood. It has elasticity, therefore it does not break the seam. There are two methods of surface treatment. With cold pasting, it will take 24 hours for the adhesive to dry, with hot pasting - about four hours. In order to give the mixture the required viscosity, you can use additional components (gasoline, acetone).

Nairite glue is widely used in shoe workshops.

Nairite glue is widely used in shoe workshops.

Advantages:

- there are no harmful toluene-based solvents in the composition;

- it is reliable and durable;

- it is used to perform various household tasks.

Disadvantages:

high price.

Glue "317"

Household universal glue. They can glue a variety of materials: leather, rubber, glass, synthetic substances. For example, it is used to create landscaping decorations. Available in 40 ml tubes.Among the features, it quickly freezes.

Glue "317" is a polychloroprene quick-setting, universal glue based on neoprene or polychloroprene rubber.

Glue "317" is a polychloroprene quick-setting, universal glue based on neoprene or polychloroprene rubber.

Advantages:

- creates a strong connection;

- no need to wait a day for gluing;

- has a dense consistency;

- affordable cost.

Disadvantages:

leaves yellow marks.

Some methods

When repairing leather surfaces, you often have to deal with scratches, cuts, and even holes when you have to put a patch. There are several time-tested methods that can help you prolong the life of your favorite item.

Patch out

To repair the product using the “outward patching” method, cut out a piece of a material that matches the color and texture of the material slightly larger than the hole to be closed. Glue is applied to the prepared surfaces, the patch is pressed from the outside and placed under the load until completely dry.

Bonding the leather of a jacket with a patch from the inside

If the damage is small, it makes sense to put a patch on the wrong side. In this case, the patch is placed under the gap, and the edges of the torn item are tried to be placed as close to each other as possible so that the defect is invisible. The glue is used according to the instructions.

Break the corner

If you catch a nail with your sleeve, you can get damage in the form of a corner. Such a defect is eliminated by using a patch from the inside. The torn area is glued to the attached patch, the edges of the gap are glued together joint-to-joint.

Tearing off a whole piece

In the event that part of the material is missing, you can restore the thing in different ways: find the most similar patch, mask the defect with applique, replace the whole piece of clothing. If the hem of a long leather coat is damaged, it makes sense to completely shorten it and thus update your wardrobe.

Cut on the jacket

To make the cut on the leather surface invisible, the base is glued under the damaged area, and the edges of the defect are fastened together. At the same time, the glue is conveniently applied with a toothpick. The thing is left under load until the composition is dry.

The best polyurethane adhesives for shoes

Another category in demand is polyurethane adhesives, which have long proven themselves as high-strength agents for working with porous materials. It follows that it can be used to repair shoes made of rubber, polyurethane and similar materials. This view is also in demand in a professional environment. The disadvantage is the difficulty of cleaning from products, so you need to be extremely careful when working with it. The review includes the nominees with the best characteristics, approving reviews from masters and users.

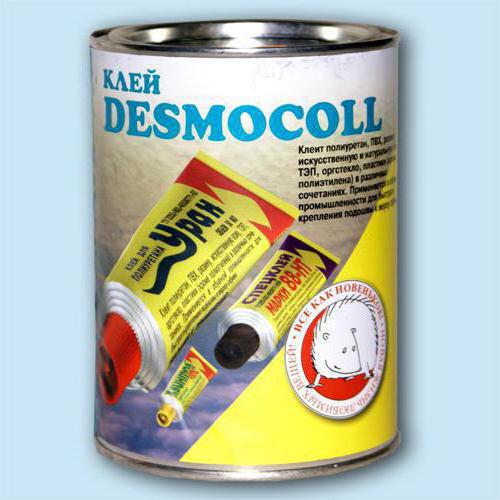

Desmokol

A domestic manufacturer offered such a high-quality, reliable glue, in the development of which polyurethane synthetic resins were involved. Since it is most often purchased by workshops, as well as factories for industrial purposes, it is supplied in bulk tubes. The seams do not burst in the cold and are moisture resistant. After application, the composition may swell slightly, therefore it is used on porous materials. But he also shows himself well in working with metal, plastic, glass.

Advantages:

- Fast connection;

- Versatility;

- Long-term;

- Plastic;

- Works like a sealant;

- Inexpensive price tag.

Disadvantages:

- Surplus is difficult to remove;

- Pronounced odor.

Masters classify polyurethane glue DemoSkol for shoes as professional products, they recommend following the instructions at home. First, the place for the seam is cleaned, degreased, then a thin layer is applied for 10 minutes. If necessary, you can repeat the procedure. The boots do not need to be firmly held for traction, but the disadvantage will be the difficulty of removing residues, a specific smell.

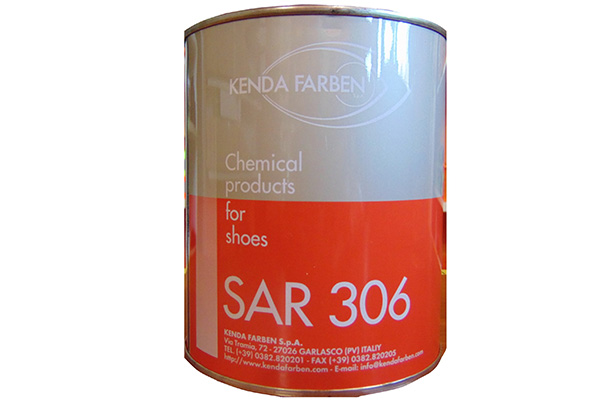

Sar 306

Such a product has a wide range of applications. It can be applied to textiles, natural or synthetic leather, rubber, glass, plastic, wood and metal.Sar 306 also demonstrates good results when working with PVC, TPE, polyurethane (we are talking about shoe soles). Large packaging, high quality allow the use of glue in leather goods workshops, repair and industrial plants.

Advantages:

- Resistance to different temperatures;

- Seam strength;

- Moisture resistance;

- Fast setting;

- Lack of a pronounced odor;

- Durability.

Disadvantages:

Expensive price tag.

This is one of the best offers from the manufacturer for home, professional use. The main thing is to follow all the rules from the instructions in order to get the proper result. An important condition for this will be degreasing, cleaning. Unlike the previous nominees, there is no smell, and the composition contains only one active element. The only disadvantage buyers note is the expensive price tag.

The best water-repellent impregnations for shoes and clothes

Seam grip

Such polyurethane glue is most often used to repair rubber, fiberglass, and leather products. It dries shortly after application, leaving an elastic, durable seam. In the course of wearing shoes, it does not crack, does not dry out. On average, after repair, you can use the shoes for their intended purpose in 12 hours. Demonstrates resistance to moisture, temperature extremes, therefore it can be used to repair winter boots.

Advantages:

- Reliability;

- Ease of use;

- Elasticity;

- Strength;

- Endurance;

- Durability.

Disadvantages:

Price.

For a neat application, you can use a brush and then leave the product to dry for 12 hours. Here you do not need to press until the moment of coupling, the composition will cope with this task itself. Users have repeatedly praised the seams for their elasticity and long service life. The only thing that can confuse the buyer is the expensive price tag.

How to remove glue from shoes

Before gluing the shoes, you need to clean them of the old glue. Methods differ depending on the material, as it can be damaged.

How to remove glue from leather shoes

You can remove old glue from shoes using a special tool that is sold in a specialized store. Apply the cleaner to the glue and let it soak for 10-15 minutes. Then remove the remnants of the substance from the shoes with a soft sponge.

Alternatively, you can use a nail file. Try to clean only the glue in a circular motion so as not to damage the skin.

How to remove superglue from suede shoes

Suede is able to withstand any chemical reaction, therefore to remove glue use ammonia or acetone. Steam the area before sanding to soften the surface. Then apply the cleaner and remove the remaining glue with a soft sponge.

How to remove adhesive from nubuck shoes

Nubuck is a substitute for suede, so the elimination methods are similar. In specialized stores, various creams and liquids are sold for cleaning and restoring lint on shoes. Their use will protect the shoes from negative reactions.

How to remove glue from fabric shoes

At home, you can use acetone, but only for unpainted fabrics. A safer method is to use a special "Contact" or "Minute" tool. Apply it over the remaining glue and let it sit for 10-15 minutes, then rinse off with a damp sponge.

How to remove glue from leather substitute shoes

Many people believe that leatherette can be treated with the same means as real leather, but this is not the case. The skin substitute is more whimsical; accordingly, it is necessary to remove the glue without the use of potent reagents. Make a soapy solution, dampen a rag with it and apply it in a circular motion to the old glue.

How to remove glue from varnished shoes

Take a pinch of table salt and cover the area with old glue. Then moisten a cotton ball with an alcohol solution and cover the salt with it for 2-3 hours. Then wipe with a soft sponge. Use mineral oil as the alcohol equivalent.

Methods for removing glue from the sole

In specialized stores, you can purchase the appropriate solvent, which effectively removes adhesive residues from labels and inserts on the sole. But there are also methods and with the use of funds that are in everyone's home. For example, rubber glue can be removed effectively with an eraser, while a harder substance can be cleaned with a nail file or sandpaper. Remove any adhesive residues from labels or price tags with cologne, alcohol or acetone.

Shoes can be restored using special means or using home methods, but you should not do this without knowing what material it is made of, since you will only aggravate its condition. Follow the instructions and your shoes will look like new.

Rating of quality shoe adhesives

Despite the same composition, not all substances are released by strong and long-term adhesion. Consider the brands that are most popular with both beginners and professionals.

"Contact"

The composition of the substance is similar to the Moment glue, but it costs less. "Contact" does not freeze quickly, but it is elastic and strong. The disadvantages include weak resistance to frost, so it is recommended to use it only for summer shoes.

"Desmokol"

The glue is distributed only in large packages, as it is intended for professionals. It is resistant to moisture and frost, and the transparency allows you to fix the seams even on the outside of the shoe. Desmokol is one of the best means for repairing shoes, but you need to use it carefully, otherwise you can irreparably damage the material.

"Moment Droplet" shoe

One of the cheapest means for gluing shoes. Its advantages are as follows:

- resistance to water and frost;

- elasticity;

- long-term;

- good adhesion to all materials.

Of the shortcomings, only an unpleasant odor and opacity can be noted, which will allow the material to be glued only from the inside.

"Super Moment"

The tool is suitable only for temporary fixation, since it does not stand out for its good elasticity and high bond strength. It quickly hardens and crumbles at low temperatures. If you want to qualitatively restore the gust and not damage the appearance of the shoe, then use a suitable glue.

"Second"

The glue contains polyurethane, which means that it is important to use it for shoe repair. In addition to rubber, textiles and leather, it also firmly fixes wood, therefore it is considered universal. The disadvantage is that it dries quickly, so use it carefully.

"Eva"

Thai glue is designed to bond rubber, textile, leather and foam footwear. Resistant to low temperatures, therefore it is often used for fixing the material of winter shoes. Another advantage is the transparent color, which allows you to restore shoes without traces.

"Moment Marathon"

The substance is used in professional workshops, however, compared to pure polyurethane glue, it is less demanding. The main advantage is super moisture resistance, therefore, with regular interaction with water, it will not delaminate. The disadvantages include the presence of a pungent odor, so use a protective mask when joining the material.

"Nairit 1" (88 L1)

The adhesive is widely used in professional workshops as it is both practical and effective. It firmly connects shoe elements made of any material, and does not lose its strength for a long time. Elasticity allows you to restore gusts in places of bending, respectively, microcracks will not appear for several seasons.

Nairit 1 is applied hot and cold, but this only affects the speed of solidification. The standard consistency hardens for a day, while the warm one is completely set after 5 hours.

UHU Schuh & Leder

German glue has unique properties.In addition to good elasticity and strong adhesion, it is able to withstand high temperatures, but with low temperatures, the opposite is true, up to a maximum of -30 degrees. The substance most firmly fixes soft to hard material.

Kenda Farben SAR 306

It is used for bonding various materials, but shows the best results when joining leather. Kenda Farben shows good resistance to water and temperature extremes, sets quickly and lasts several seasons.

Additional tips and tricks

When starting to repair a leather product at home, you need to remember a few simple rules:

With the help of glue alone, as a rule, small damage is eliminated; in the case of a large defect in size, it must be sewn up or use an additional patch.

The container with glue must be closed immediately after taking the required dose of the substance, otherwise the composition will dry out quickly.

If the substance needs to be diluted, take a small amount, which will be sufficient for a single use.

When applying the glue with a brush or roller, it must be cleaned with a solvent after work.

It is imperative to observe safety precautions: if the composition is flammable, it must be applied away from open fire.

Glue from foreign manufacturers can be called differently, so you should carefully study the description.

If the liquid leather or patch is slightly different in color from the main product, after repair, you can correct the shade with spray paint.

When choosing glue in a store, you need to pay attention, including the size of the tube and the presence of an applicator or a sharp tip for ease of application.

If you need to purchase glue for leather, a variety of assortment on store shelves will allow you to choose a substance that is most suitable for a specific material and a specific task.

It is enough to carefully study the instructions, paying attention to the composition and characteristics

p> Share link:

Review of popular brands

There is a wide variety of adhesives on the market used for temporary fastening of materials.

2M Scotch Weld

The product comes in an aerosol form that can be used to attach a variety of materials, including fabric and plastic. This adhesive is suitable for fixing labels and is used in silk screen printing. After application, the spray does not harden over time.

"Marabu-Fix It"

Aerosol of this brand is used for fastening:

- plastic;

- paper;

- cardboard;

- wood;

- glass.

This spray is capable of fixing these materials to the fabric. The adhesive does not stain and can be washed off with cold water.

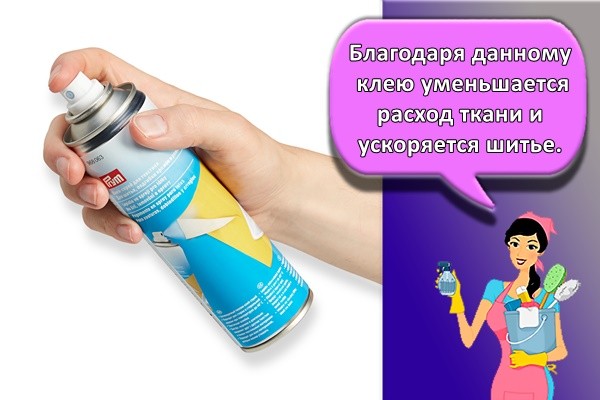

"Prim"

Like the previous one, this aerosol is used when working with tissues. The adhesive holds the material securely and can be washed off with water.

"Idea Decoupage"

Italian high-quality compound, with which cardboard, fabric and polyethylene can be repeatedly glued to each other. "Idea Decoupage", due to the specified properties, is widely used in design.

"KK"

A transparent adhesive is produced under the KK brand, which is used when working with small decorative details and non-woven fabric. This product is also used for fixing stretch fabrics and knitwear.

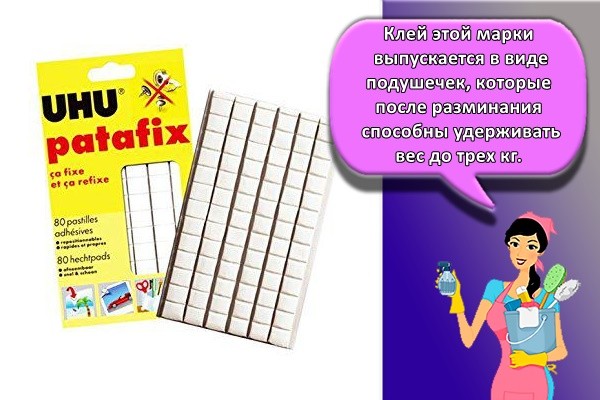

"UHU Tac Parafix PROPower"

The glue of this brand is produced in the form of pads, which, after kneading, are capable of holding a weight of up to three kilograms. Unlike other similar products, this composition tolerates contact with water well and does not change properties when exposed to direct sunlight. Therefore, glue is also used for finishing external surfaces.

"Repositionable"

The aerosol adhesive, produced in a 150 ml container, is suitable for temporary bonding, including thin materials. The components of the glue do not penetrate deep into paper or fabric, do not deform the latter.Also, this product can be used to bond foam and polyethylene.

"Takter"

The aerosol of this brand is widely used in needlework, cutting, sewing or screen printing. The product does not harm any type of fabric, providing reliable fixation of materials.

Spirit 5 Strong

The word "Strong" in the name indicates that the adhesive also provides a secure bond. But, despite this, this tool is suitable for fastening, including thin materials: cardboard, paper, cellophane and others. Spirit 5 Strong is most effective when creating collages and appliques. The tool is also used for sewing.

"Krylon Easy-Tack"

The aerosol adhesive is acid-free and does not penetrate deeply into the structure of the material. Thanks to this, thin fabric or paper is not deformed after processing.

How to remove residues from nail plates

It is not difficult to remove tips and onlays without damaging your nail plate. It is more difficult to remove the remnants of the glue to which they were attached. For this procedure you will need:

- acetone nail polish remover;

- nail remover;

- cotton disks;

- hand cream;

- hot water;

- foil;

- sticks for manicure.

It is worth performing a number of sequential actions:

- Place a few drops of nail remover under each plate.

- Lift up and remove pads with an orange stick.

- Polish the spots with glue.

- Dip your hands and a bottle of nail polish remover into hot water.

- Apply the heated product to a cotton pad and apply to the nails.

- Wrap each finger in foil for 20 minutes.

- Clean the glue with a disc and rinse with water.

- Treat with moisturizer.

Shoe repair rules

Preparation of contact areas is done in the following sequence:

- dry and clean from dirt, if necessary, clean with sandpaper;

- degrease with alcohol (solvent, cologne) and wipe dry with a clean dry cloth;

- apply glue in one or several layers depending on the desired joint strength and dry for 5-15 minutes;

- with considerable effort, connect the surfaces and fix with clamps or a load for a day.

A strong smell is emitted from the glue, so the room must be ventilated.

If the adhesive is selected in accordance with the recommendations, then the shoes will serve no less than new ones. There is no need to save on the quality of the glue - the cost of purchasing it will pay off with interest.

Criterias of choice

The correct concept for choosing your own shoe glue is to set a specific task. For fixing inside the insole, the usual version of the product is suitable. If the sole has come off, then it would be better to purchase a reinforced composition. A quality product cannot spoil the materials. During the repair process, shoe parts retain their appearance - their deformation is unacceptable. The seams must remain elastic, and the fixation must be of high quality and hold for a long time. The joints after repair with expensive, good composition are frost-resistant, moisture-resistant, elastic, wear-resistant.

Which shoe glue should be used depends on the materials to be joined. Many types are suitable for rubber, leather, fabric, felt, suede, synthetics. But to attach the sole of a boot made of polyurethane, not everyone can do it. If the repair is planned to be done for a short time, then you can purchase an inexpensive tool. In this case, it is recommended to use epoxy adhesive. For long-term wear, it's worth investing in the more expensive option. Famous brands should be preferred. For what purposes one or another shoe glue is used, you can understand by studying the instructions for use or reading the information on the packaging.

The choice depends on the materials to be joined; Preference should be given to well-known brands

Principle of operation and scope

Regardless of the type of glue, this product has the following characteristics:

- colorless and odorless;

- the ability to glue materials lasts a long time;

- after application does not leave marks on the material;

- with prolonged contact with air, the adhesion of the created joint gradually decreases.

The principle of operation of such an adhesive is as follows: after applying an aerosol, a sticky layer forms on the surface of the material, due to which individual parts of fabric, plastic, and so on are connected. In addition to the spray, this product comes in the form of pencils and pads. Thanks to this, the area of application of the glue is not limited only to cutting and sewing.

Cutting and sewing

Adhesives capable of temporarily fixing materials are used when cutting and sewing for:

- fixing the stencil to the fabric;

- fixing applications and other decor;

- keeping the material on the surface while sewing;

- fastening of non-adhesive non-woven fabric, so that stretching of the material can be avoided.

Thanks to this glue, fabric consumption is reduced and sewing is accelerated. The effectiveness of means for temporary fixation is also revealed when working with materials whose edges are crumbling. It is difficult to sew zippers or buttons on these fabrics. In this case, temporary glue helps, which prevents shedding of the edges.

Needlework

When working with materials manually, it is not always possible to secure individual parts with a hoop and other devices. In this case, glue for temporary fixation helps, which gives the tissue the necessary rigidity in a certain place.

However, when using this product, you need to pay attention to the characteristics. In some cases, the adhesive provides increased rigidity, due to which the needle does not pass through the material

With the help of this composition, you can temporarily fix small decorating details (beads, and so on), which are then sewn or otherwise fixed on the base. Also, this glue simplifies a process such as patchwork. Means for temporary fixing and for working with skin have proven themselves. In this case, mainly high-quality products are used, which decompose on contact with air. Such tools make it possible to manufacture complex products with many small details.

Wall newspaper decoration

As in the case of needlework, this glue helps to correctly distribute sheets or figures on paper or other surface, without damaging the base. When decorating wall newspapers, this feature allows you to beautifully place all the elements.

Room decor

Using such an adhesive, you can temporarily fix decorative elements on furniture, curtains or walls and see how the general appearance of the room will change without harming the surfaces.

Holidays decoration

Temporary fixing agent allows you to decorate walls and other objects located in the room. After the holiday is over, this decor can be removed without harm to surfaces and reused in the future.

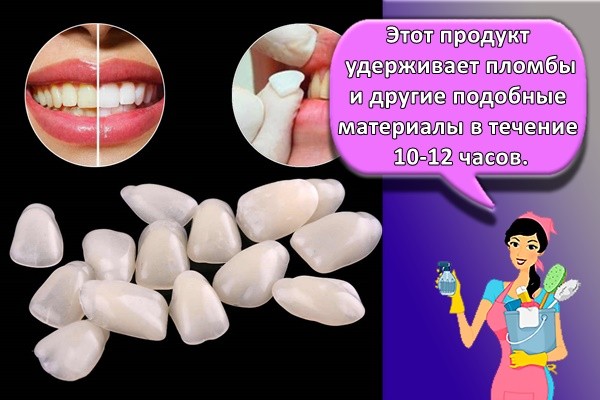

First dental aid

Unlike other popular adhesives, the temporary retainer can be used to attach removable dentures or crowns. This product will hold fillings and similar materials for 10-12 hours. For fixing dentures, it is recommended to take a hypoallergenic adhesive.

Assembly and minor repairs

Often, during the repair or assembly of items, it becomes necessary to hold small parts. In this case, you have to call an assistant. But if the repair (assembly) is carried out alone, then a means for temporary fixation can also hold small parts.

The best professional adhesives for shoes

UHU Schuh & Leder

Such a tool demonstrates reliability in gluing any hard materials. As soon as it is applied, everything dries up after a short period of time. After repeated tests, good resistance to moisture and thermal effects was found. The manufacturer has set a record temperature threshold of +125 degrees. Schuh & Leder can be used by both professionals and beginners.High elasticity will not allow dissimilar surfaces to stretch, dry out, burst.

Advantages:

- Increased thermal stability;

- Reliability;

- Easy removal of residues;

- Elasticity of the seams;

- Endurance to salts, acids, alcohols, alkalis.

Disadvantages:

- Price;

- Inconvenient tube.

Before use, shoes must be cleaned and dried. For good elasticity, it is best to apply several thin coats and allow them to dry. And unlike many professional options, this one is easily removed with ethyl acetate or butanol. Users consider the price tag to be a disadvantage, although some consider the tube inconvenient to use.

Moment Marathon

This Momentum for Shoes glue is specially designed for repairing different pairs, taking into account the characteristics of the materials. A thin layer and a few minutes will be enough for the seam to firmly bond the surfaces and any damage. The bonding site cannot be destroyed by water, aggressive chemicals, or temperature changes. Thick dense consistency does not leave streaks.

Advantages:

- Dosage control;

- Super moisture resistance;

- Suitable for all shoe materials;

- Fast setting;

- Economical consumption;

- Low price tag.

Disadvantages:

- Acrid odor;

- Narrow focus.

Due to the inexpensive price tag, economy, as well as a durable result, such a tool is in high demand.

After each use, it is important to seal the lid tightly to prevent drying out.

DoneDeal

One of the most versatile high-quality adhesives, also used in the repair of inflatable boats, sports equipment, travel equipment and more. Its powerful composition guarantees strong adhesion of different materials to each other, for example, plastic with wood or metal with rubber. The seam is so strong that it can withstand temperatures from -45 to +105 degrees. After gluing, the boots can be worn for several more seasons.

Advantages:

- Ability to adhere dissimilar surfaces;

- Versatility;

- Convenient tube;

- Ease of use;

- Connection strength;

- Endurance of temperatures, moisture.

Disadvantages:

- Strong smell;

- Not always available in stores.

In the course of using such a product, it is important to apply a thin layer to both surfaces to be joined. It will be possible to use the shoes for their intended purpose in 12 hours

If it is necessary for drying to come faster, the glue is heated to 70-80 degrees. The disadvantage can be considered a pronounced smell, as well as the fact that not always such a product can be found on sale.

Kenda Farben SAR 30E

The best quality is offered by an Italian manufacturer. Today, it is SAR 30E that is most often used in shoe factories and production. It was originally developed to bond leather to any material. The adhesive also exhibits high strength when working with wood, glass and other hard surfaces. The seizure takes place within a few minutes after application, and you can put on the shoes within 4-6 hours after the repair.

Advantages:

- Resistance to frost, heat;

- Fast setting;

- Moisture resistance;

- Lack of odors;

- European quality.

Disadvantages:

- Not always on sale;

- High price.

Before using the surface, it is important to degrease, clean. To obtain a strong, elastic seam, 2-3 layers are applied at intervals to dry.

If the product is heated to 90 degrees, the shoes can be used after 4 hours. Buyers choose it because of the reliability of the manufacturer, lack of smell. But it is not always possible to find it on sale, and the price tag is not cheap here.

What to use for gluing the soles?

If you do not want to ruin your shoes, it is recommended that you select a special adhesive. Typically, the packaging contains a corresponding mark. You can choose one of the following options:

- "Moment Marathon". The substance is designed specifically to repair cracked soles.It is characterized by high resistance to humidity and other adverse weather conditions. Can be used in hot weather or in severe frost. It is not recommended to use for some types of materials. This listing is on the packaging, so please read it carefully before purchasing. Simple enough to use. It will be possible to wear shoes within a day after gluing.

- Desmokol. Used to repair shoes. Helps against cracked soles. More suitable for synthetic materials and suede. Sold only in specialized stores. Used in practice by professional workers.

- "Shoemaker" or "Nairit". The composition uses natural materials that provide high adhesive properties. It makes it possible to easily glue the cracked shoe sole. It can be used for gluing the inside of boots, as well as small cracks. It is recommended to leave the work for a few days to dry completely. Failure to do so could result in rapid re-failure.

- Epoxy resin. It is a powerful adhesive. It has a high density, which is suitable for boots that are actively used every day in aggressive conditions. It will take several days for a wet surface to dry completely. The shoes can then be worn at their usual pace.

- Bonikol or Kenda Farben. Imported industrial products that are used in professional handicrafts. Suitable for problem areas, gluing heels, soles, socks, insoles. One of the best ways to glue the soles of your shoes at home.