Varieties of adhesives for carpet

Carpet adhesives are generally versatile and can be used on a variety of textile materials. Modern carpet glue ensures reliable fixing of the canvas to the floor, steps and even to the walls of the room.

Despite the fact that the compositions of different manufacturers of adhesives are different, their lines contain mixtures that are similar in the set of components and additional inclusions.

Acrylics do not contain solvents and can be used for a variety of coatings, including quartz vinyl sheets, needle-stitched materials, PVC-based roll coatings, PVC cork products, various types of linoleum and plastic cladding (from 0.7 mm thick). Also, acrylic glue is ideal for carpet. Its main advantages are environmental safety, ultra-high adhesion, adhesive qualities and the presence of thermoactivated seams.

In some series, there are modifications of acrylic compounds, which, thanks to additional components, provide stable and durable seams and a high degree of adhesion.

There are also models of so-called “sticky” compounds, due to which the adhesion strength of floorings made of textiles, PVC, plastic vinyl is achieved, in addition, it is possible to use them for textile boards based on polyvinyl chloride. "Velcro" are characterized by a short drying period (no more than 25 minutes), and further products fixed with this composition can be easily removed. Such carpet glue can be washed off with a detergent with the presence of alkalis in the composition, it also excludes the formation of traces from walking on the coating.

In each of their lines, manufacturers also offer water-borne compounds for reliable gluing of carpet thicknesses, other textile products and PVC boards. They are easy to fit, have strong seams, instantly bond the coating to a “rough” base and are also fireproof.

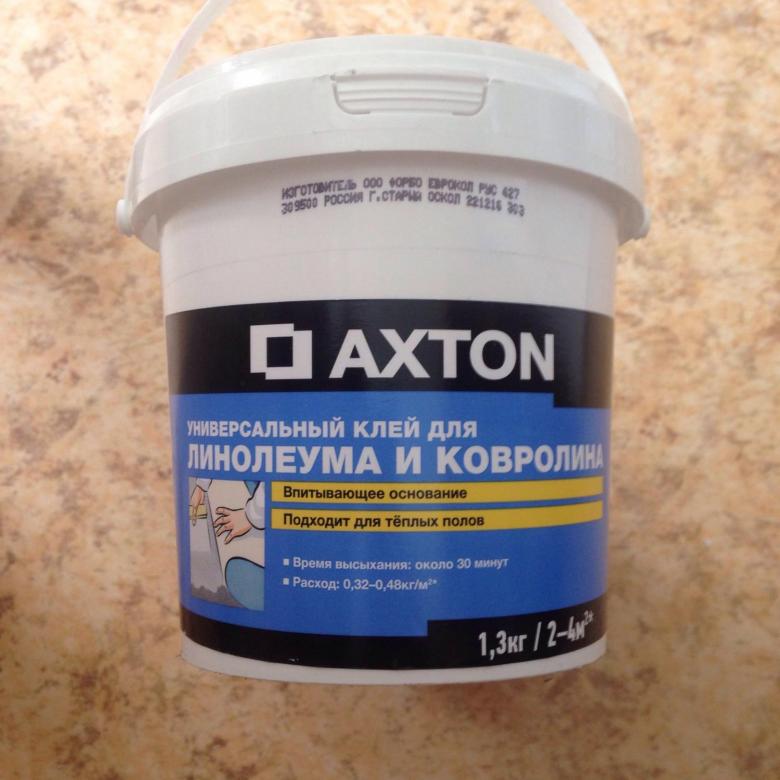

There are also many universal acrylic compounds diluted with water. They are used for the application of felt carpets, homogeneous and heterogeneous coverings, as well as needle-punched boards, standard linoleum and PVC wall thickness up to 0.7 mm. Such adhesives have good adhesion, thermoactivation and strong seams that do not lose their sticky properties for a long time. They also have a long service life, are often used in "warm floors" and property.

The series of contact adhesives are also universal. They are used for the installation of cladding materials such as linoleum, laminated panels, carpets, edge profiles, mounting plates, skirting boards and wood-based coverings. The contact composition is easy to apply, moisture resistance, and its exposure is on average 30 minutes.

Contact formulations in the form of a jelly are available as a separate variety on the market. In addition to carpets, they are used for laminated panels, linoleum, rubber bases, metal building materials and cladding products. During operation, the moisture-resistant adhesive does not form threads, does not flow over the surface and is very light when laid on vertical planes.

So, the adhesive composition has been selected, the carpet has been purchased - now you need to lay the flooring.

Basic requirements for the adhesive

In some rooms, the floor surface is covered with carpet. This carpet needs to be fixed well so that it does not pile up or deform. You can glue the carpet to the floor using double-sided tape.True, much better adhesion to the surface will be provided by the glue. With the help of such a substance, you can lay the track on steep steps or on slippery surfaces.

> For carpet, choose a glue that will dry for one hour. This time is enough to eliminate errors or remove defects that have appeared. A product that dries and hardens quickly is not suitable for gluing. In a short time, the track will not have time to attach to the floor.

In this case, it will saturate the carpet and penetrate the front surface, leaving stains. The main requirements for carpet glue are: drying speed (not less than an hour), simplicity and ease of use, excellent adhesion to any surface, the coating must remain elastic after hardening.

Carpet glue consumption

First of all, the consumption of glue for this type of work depends on the size of the room.

Therefore, it is important to know the area of work with an accuracy of a meter. Otherwise, you will have to urgently buy glue

It should be borne in mind that it is undesirable to glue the work begun.

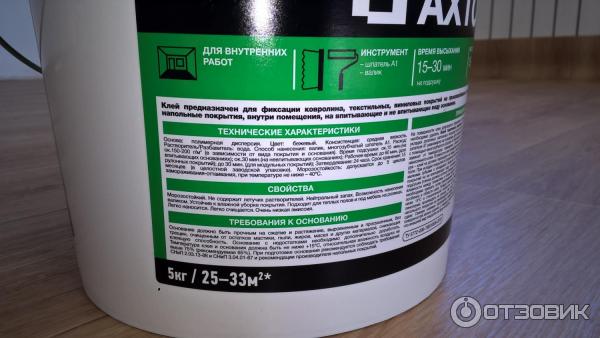

The glue itself requires about half a kilogram per 1 m2 of the room. However, this figure may vary depending on the manufacturer. For this reason, the recommended ratio of the dilution of the dry mixture to water and the amount of glue per 1 m2 of the room is written on each package.

Trade marks

Many companies are engaged in the production of glue. Below is a list of the three most popular brand names:

- Leroy Merlin. The adhesive from the renowned trading group Leroy Merlin is renowned for its versatility. It is perfect for both carpet laying and linoleum work. Packaged in 14 kg packages, which is extremely convenient for large volumes of work. Bonding strength and adherence to standards is a classic inherent strength of this brand. Long service life and no shrinkage give this adhesive a distinctive feature. But at the same time, the negative aspect is the volume of the package. 14 kg means a minimum of 20-25 m2 of work. Therefore, in rooms with a smaller volume, there will be difficulties with its further storage.

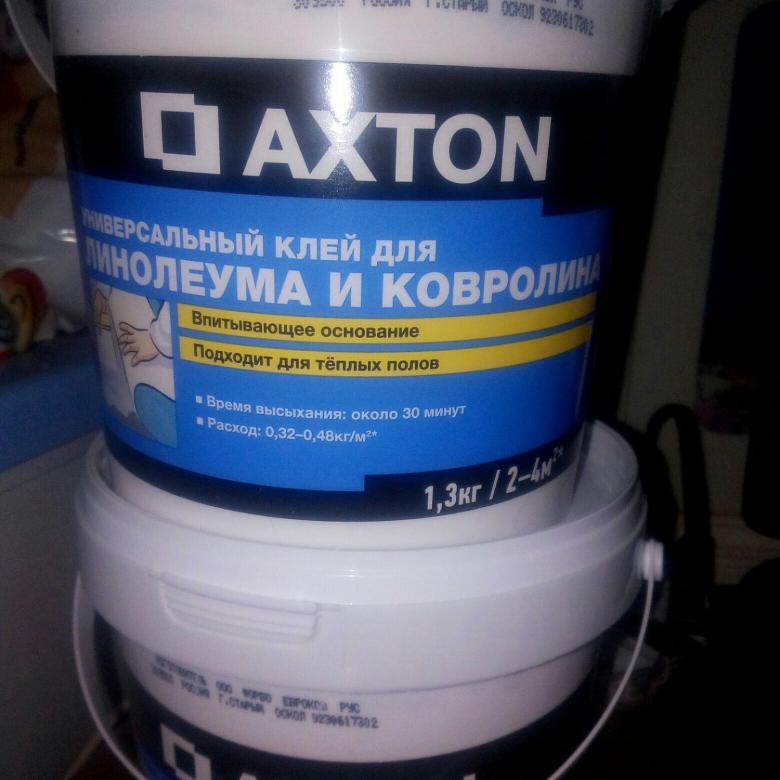

- Homakoll glue. Special solution for floor coverings of various substrates. The advantage is that Homakoll glue is resistant to surfaces that absorb water. Examples of such surfaces are: wood, chipboard, fiberboard, concrete and cement screed. Thus, the glue is universal for all coatings, which undoubtedly allows it to be used in any work. A significant plus is the absence of volatile fumes harmful to humans. However, there are some drawbacks. The glue is packed in standard buckets weighing 1.3 kg. On the one hand, this seems like a plus, since you can accurately count the number of buckets needed. But on the other hand, these are inconveniences during transportation, as well as high costs due to the packaging used. Compared to the first representative, the price of Homakoll glue is 200 rubles more for the same volume.

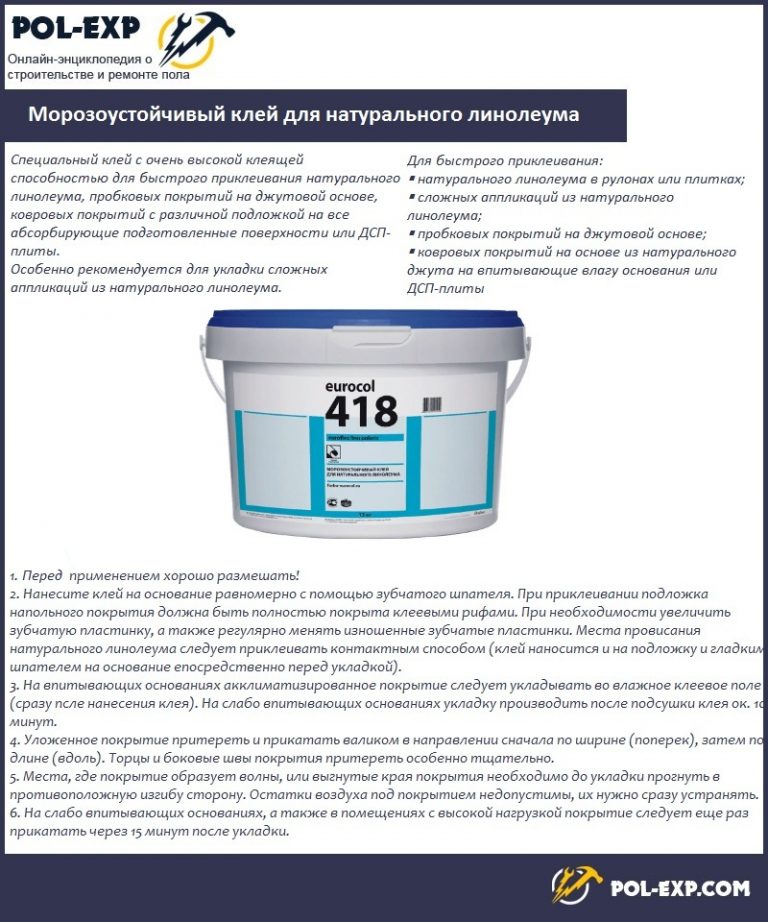

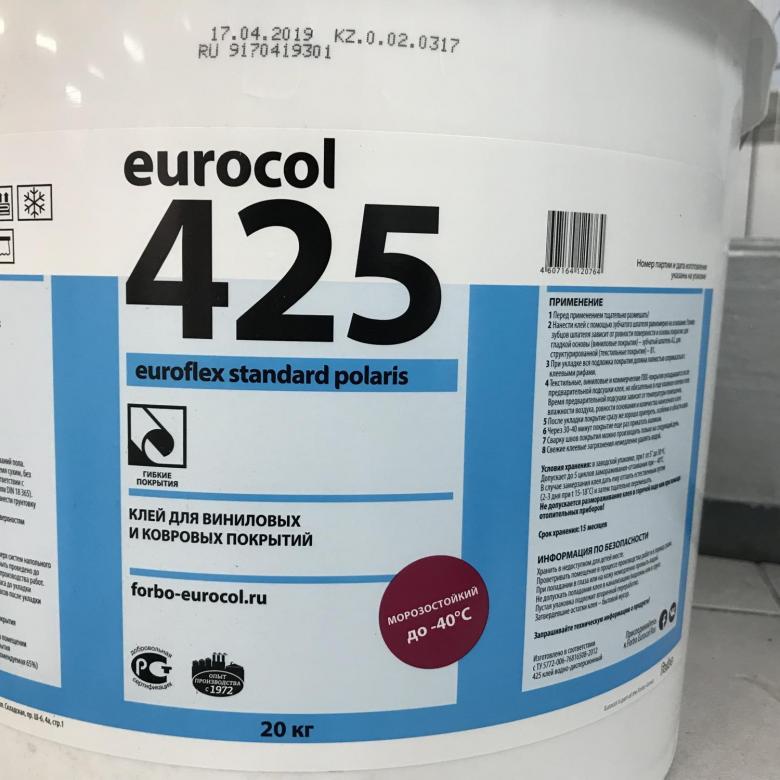

- Forbo glue. Last, but not least, a representative of this type of goods. Over the years, Forbo glue has become the standard of German quality over the years of use by experienced craftsmen. This representative does not have substances harmful to humans, as proven by expert commissions. Easily fixes carpet and linoleum on any surfaces. After drying, the glue strips remain strong and elastic for a long time, which preserves the coating for a long time. An important advantage is the reduced consumption per 1 m2. For a high-quality coating, you need only 0.45 kg. The manufacturer thought about different amounts of work. Therefore, the glue is available in volumes of 13 and 20 kg. The price is comparable to the first representative and is equal to 2 thousand for a package of 13 kg.

As you can see, the choice of glue is wide, and quality and reasonable cost are inherent in each representative. Therefore, when choosing, you can rely on your own preferences.The main criterion is only compliance with the instructions and the sequence of work.

The main - Materials - Glue for carpet: types and tips for choosing

Carpet is a floor covering that is used in residential and office premises, in cars and ships.

Carpets are produced on jute, rubber, foamed, rubberized, felt, etc. basis. The flooring looks good and lasts a long time if properly installed and cared for. It is placed on warm infrared film floors.

Bonding linoleum to a concrete floor

Concrete substrates include those in which cement has been used. They are able to draw in and hold liquid materials. If linoleum is kept "for centuries", this property will come in handy, but if you need to regularly update the coating, this property will be harmful. Therefore, such requirements are imposed on compositions for gluing coatings to concrete. They must:

- allow, if necessary, to remove the material;

- hold firmly, do not allow the linoleum to shift during operation;

- do not destroy the coating, do not wash out modifying additives from it.

It is best to buy linoleums with fabric insulation, alkyd (glyphthalic) for a concrete floor. If you purchased a flooring without a base, for its installation you will have to lay a layer of fiberboard, chipboard, OSB.

How to properly glue linoleum to concrete? Here's a step-by-step guide:

- Carefully prepare the base - clean it from dust, dirt, stains, dry it, remove the baseboard. If there are cracks more than 2 mm deep, they must be repaired with a mortar. The temperature during work is not lower than +15 degrees. Leave the purchased material in a warm room for 2 days without unrolling the roll.

- Drill holes for skirting boards and sills, if necessary. Trim the canvas around the perimeter. If the linoleum is laid in a single piece, the uneven edges will be covered with a skirting board. A gap of 0.5 cm must be left between the wall and the canvas.

- Prime the concrete floor with a composition that is suitable for this purpose and does not contradict the components of the adhesive. Usually, compatibility is reflected on the packaging of the products. Some experts also primed the seamy side of linoleum, but this is not necessary.

- Then you can proceed with the installation of the coating. Fold back half of the linoleum, apply a thin layer of glue with a spatula. When it is indicated that the composition can be applied with a mesh, this is done. This is usually only allowed in small spaces. Then, if indicated in the instructions, wait until the glue dries slightly.

- Press the flooring to the floor, smooth it out. For this it is best to use a construction roller ("rolling pin"). Expel all accumulations of air, moving from the center to the edges. Do the same with the second half of the coating. Bring the edge under the doorframe. Do not walk on the floor for 1-2 days.

In large rooms, you have to glue two or more pieces of material. The technology is the same, but no glue is applied to the edges (by 15 cm), the canvases are overlapped by 3 cm.The joint line is cut along two canvases at once, having previously drawn an even strip and pressing it with a metal ruler or temporarily fixing it with double-sided tape. This work is carried out after the glue has completely dried. Further, bending the edges, they are glued with compounds of the "cold welding" type. After pressing and rolling the joint with a rubber roller, remove excess glue. The load is applied, left for 2 days. Then you can install the nut.

Selection guide - properties of the base ↑

The choice of carpet directly depends on the purpose of the room in which it is planned to be used and on the base on which it is planned to be laid. Laying does not require major surface preparation, it can be laid on top of parquet and linoleum, or you can remove the old coating and lay it directly on the concrete base, without particularly bothering to level it.You should not use carpet only in the bathroom, kitchen and places with constant high humidity, there are more practical coatings for them.

If, for some reason, you plan to lay the carpet on a more expensive flooring, such as parquet, then it makes sense to use a felt-based carpet, since a hard-backed covering can scratch the varnish and costly repairs will be required. It is possible, however, to use special substrates, but these are additional costs.

For rooms through which many people pass every day, it is convenient to choose a carpet with a rubber or rubberized base. It washes well, is not afraid of moisture, is wear-resistant, and retains its original appearance for a long time. This carpet is used in hallways, public buildings and even outdoor summer areas. It is also suitable as a carpet in the car.

Carpet is able to add comfort to the interior, but at the same time it is practical and functional.

Carpet is able to add comfort to the interior, but at the same time it is practical and functional.

Carpet on a natural jute or felt base requires careful maintenance and only dry cleaning, so it is inappropriate to lay it in places with high traffic, but if you are looking for a beautiful, warm and comfortable floor covering in a bedroom or office, it will be quite appropriate. For children's rooms, it is better to choose a synthetic-based coating, no matter how paradoxical it sounds. There are several reasons: they do not cause allergies, are easy to clean, attractive and soft

It is only important to pay attention to the quality of the material. Carpets made in the USA and Western Europe are considered the best.

The video material will help to prioritize the important issue of choosing a carpet:

Floor is an important element of the living space of the house. The mood of the residents and the "mood" of the interior depend on what type of finishing will be chosen for it. A successful floor covering should not only please the eye and be pleasant to use, it should correspond to the functional purpose of the room. Carpet is a covering that can make the interior cozy, fill the space with warmth and at the same time remain practical and functional.

Two-component polyurethane carpet adhesive

There is another glue method, in which the carpet is processed with a two-component polyurethane glue, consisting of a polyurethane monomer and a hardener, which are connected only before use.

Such glue sets in about an hour, so the worker has almost no margin for error.

But the glue fully gains strength only after a few days. Its use is especially appropriate when laying the coating on a vertical or uneven surface. They can perfectly glue fragments of material.

Advantages of two-component adhesives:

- Since the glue hardens as the reaction between the components proceeds, and not due to the evaporation of the solvent, the change in moisture content does not affect the strength of the connection.

- The material retains its elasticity even after hardening.

- After chemical crosslinking, the polymer becomes capable of working even at rather high temperatures.

- If additives are added to the glue, then it can work even in frost.

But for the sake of objectivity, it should be noted that polyurethane two-component adhesives have certain drawbacks that limit their use.

- When working with reactive adhesives, you have to be more strict with safety measures, while the room must be well ventilated, since the hardener itself is a poisonous substance.

- The coating, fixed with two-component glue, is rather difficult to dismantle, and you have to grind off the remaining glue from the base surface with grinders in order to adhere the next coating to the concrete.

- This glue is much more expensive than PVA water dispersion glue.

Installation of carpet on two-component polyurethane adhesive

Knowing how to properly glue the carpet on polyurethane glue, it is important to calculate its exact amount so that the prepared adhesive mixture will last about 40-50 minutes of working with it. The technique of using the glue itself does not differ from that used for water-dispersion compositions, with the only difference that instead of a brush, a spatula is used here

Consumption of two-component polyurethane glue - no more than 0.2-0.4 kg per square meter.

Video on how to glue the carpet:

Advantages and disadvantages of wall decoration with carpet

The carpet on the wall looks original and unusual. Carpet finishing allows you to solve the following tasks:

Thermal insulation and a cozy look of the wall. Bedroom wall cladding is an alternative to carpet hanging the bedside wall in the bedroom. For such cases, natural materials are chosen. Tufted carpets with medium pile on a jute or felt basis are the best solution. There are many design options for carpets, so you can create a plain surface with a rich texture or choose a material with a pattern or decorative print. Wall decoration with carpet will look completely different than a regular carpet.

Carpet in a recording studio

Carpet in a recording studio

Noise isolation. Carpet on the floor and walls will make the background noise in the apartment of the panel house more comfortable, and for musicians this material is a good alternative to soundproof mineral panels.

The disadvantages of using carpet are both in its properties and in the difficulties of choosing a method of installation:

- Carpets have the same ability to accumulate dust as ordinary carpets. The disadvantage is the need for constant maintenance of the coating.

- The choice of installation method and its skillful implementation largely determine the appearance of the wall with carpet, the durability of the finish and the possibility of dismantling. It is this question that is most difficult for inexperienced craftsmen who decided to decorate the wall with carpet.

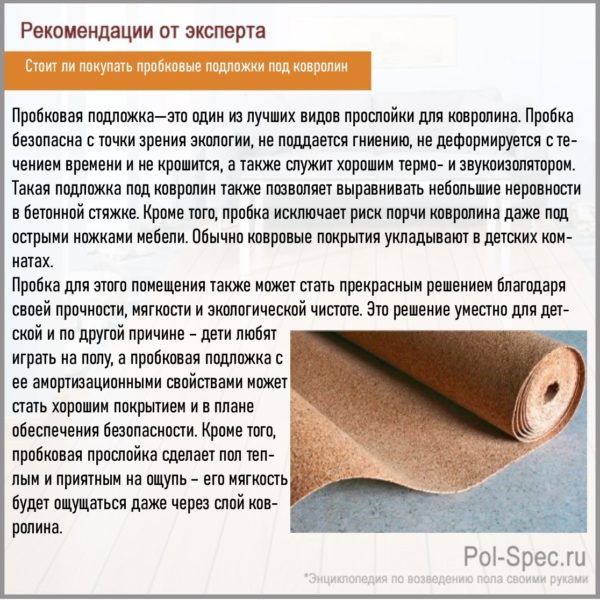

Cork substrates

The main advantage of substrates made from pressed cork bark chips is the environmental properties of natural materials. The porous structure of the products contributes to the normalization of microclimatic conditions in the rooms, provides reliable heat and sound insulation. Special impregnations prevent the development of mold, mildew, protect against rodents, and increase the fire safety of the material. Among other things, the anti-static properties prevent dust accumulation on the floor surface. Basically, cork substrates are designed for laminate and parquet flooring, but there are also options for carpet.

Should you buy cork carpet underlays?

Portuguese companies are famous for the highest quality cork products:

- I The company has been manufacturing cork products for over 150 years. The material for the substrates is produced in the form of rolls of 10 m². Despite the small thickness of 0.2 cm, the products are quite strong and resilient, capable of withstanding an average load.

- The manufacturer produces the material with a layer of 0.2 and 0.3 cm. The main feature of the product is the self-leveling property - the substrate quickly regains its shape regardless of the pressure applied to the surface.

- The thickness of the products is from 0.2 to 0.4 cm, rolls of 10 m². Differs in the use of exclusively natural materials in the production, a long service life of products up to 20 years.

Cork backing materials can be produced as pressed boards or rolls. The products are somewhat inferior to synthetic counterparts in strength, elasticity, but surpass them in environmental qualities and are quite suitable for coatings in living rooms with a moderate load.

Cork underlays for carpet are produced both in the form of pressed plates and in the form of rolls, but they are quite expensive.

Carpet underlay

About species

The carpet is divided into several types.It all depends on what materials it was made of and in what way.

Let's start with the materials. To create this type of flooring, three types of materials are used. It:

- Natural wool is one of the most expensive materials. But its main advantage is environmental friendliness and fire resistance. At the same time, it wears out rather quickly.

- Polypropylene. It is a cheap material and is most commonly used in carpet yarns. In terms of its performance, the material is mediocre.

- Polyamide. This material is completely synthetic, but has such advantages as elasticity, wear resistance and fire resistance. At the same time, synthetic fibers can adversely affect human health.

In some cases, in the production process of carpet, they resort to a combination of materials that have been mentioned above. Moreover, the materials are combined in different proportions.

Any carpet has a base. For its manufacture, materials such as:

- Jute. It is a natural fiber that is environmentally friendly. At the same time, jute is afraid of moisture. If the carpet with a jute base remains wet for a long time, it will lead to rapid abrasion of the fibers and destruction of the primer layer.

- But a material such as felt has good moisture resistance. It is made from synthetic fibers. Felt base is very warm and cozy. She is not afraid of mechanical stress. Felt is most often used to create a secondary base. Felt-backed carpet is perfect for laying on parquet flooring.

- The rubber base is hard. It does not deform due to mechanical stress and does not slip on the floor. Carpet with such a base is laid in rooms with high traffic.

- A material like action backing is synthetic jute. It features incredible strength and good moisture resistance. This stuff doesn't go astray. As a rule, such carpet is laid in office premises, since, due to its increased rigidity, it is completely unsuitable for residential premises.

The carpet is divided in plain sight and according to the manufacturing technology. Actually, it directly affects the quality indicators of the coating, its cost and appearance. Carpets are made in several ways. It happens:

- Woven.

- Tufting.

- Needle-punched.

- Flocked.

Additional tips and tricks

KN-2 rubber mastic is produced as a ready-to-use dark mass. The surface to which the glue is applied is first thoroughly cleaned of dirt and leveled. True, minor defects can not be eliminated. The elastic mass will penetrate into any crevices and level the base on its own. To save glue, it is better to treat the surface with a primer before applying the substance.

This adhesive is based on a high rubber content. Due to this feature, KN-2 can be used for gluing rubber products. Typically, this mastic is used to securely fix linoleum or rubber-based carpet to the floor. You should always remember that the KN-2 glue contains a solvent. It is advisable to wait 15 minutes after applying the mass to the surface. During this time, the toxic vapors of the solvent will have time to evaporate. After application to the surface, the glue hardens after 7 hours. True, for the mass to dry completely, you need to wait 24-72 hours.

A rubber-based product of the KN-2 brand is used simultaneously for gluing materials and providing waterproofing. When hardened, this substance becomes similar to rubber. The adhesive can be used as a cushioning material.

All cracks and places where the adhesive penetrates are protected from moisture penetration. The viscous mass penetrates into any pores.After drying, it hardens and does not change its properties either under the influence of moisture or as a result of a sharp increase or decrease in temperature.

It is a universal product for gluing various materials and protecting the premises from water penetration. The mastic can be used at any stage of construction and repair work. Toxic substances evaporate a few hours after the application of KN-2. True, this glue is undesirable to use in the kitchen or for gluing kitchen items.

Share link:

How to apply tile adhesive

The use of glue differs depending on its purpose.

Preparation of the base

The bases, with the exception of heat-resistant glue, are prepared in the same way:

- cleaned of dust, greasy stains, oil paint;

- remove crumbling plaster;

- level the surface with a plaster mixture;

- irregularities up to 10 millimeters are smoothed out with an adhesive on which the tile will lie;

- impregnate porous surfaces with Hercules primer.

Leveling work is performed 72 hours before the start of facing work. The floors are smoothed with a coarse Hercules leveler. The warm floor is pre-heated and cooled. When gluing the cladding to all types of adhesives, except for heat-resistant, the tiles are not wetted.

Before starting laying a stove or fireplace, the base is moistened with water. Clay solid bricks, before glue is applied to them, are immersed in water for 8 minutes, refractory bricks - for 10 seconds. The side parts of the stove, fireplace are cleaned from traces of lime, dust, the seams of the old masonry deepen to 7-8 millimeters. The prepared surface is moistened with water, preventing it from drying out while laying the tiles. Tile tiles are soaked in water for 2-3 minutes before laying, ceramic tiles - for 10 seconds.

Preparation of the solution

The solution is prepared according to the instructions. The dry mixture is poured into water in the specified proportion and kneaded by hand or with a mechanical mixer until a homogeneous mass is obtained. The solution should stand for 7 minutes, after which it should be mixed again.

Work instructions

A metal notched trowel is used to apply the glue. The thickness of the applied layer depends on the width of the notch. The solution retains its adhesive properties for 10-20 minutes. During this time, you must use it completely. The thickness of the adhesive layer is from 1 to 5 millimeters. The minimum layer is applied when tiling with tiles larger than 40 centimeters, in swimming pools and during outdoor work.

The tiles are laid with a distance of 2-3 millimeters, using signal flags. The veneer can be repaired within 10 minutes. Remove excess glue no later than 30 minutes after starting work. Sealing of seams on wall coverings - after 1-2 days, on floor coverings - after 2-3 days.

When laying the oven, a trowel and jointing are used. The thickness of the joint is 7-10 millimeters. Drying of the oven takes 72 hours, during which it warms up several times. For the first time - no more than an hour, up to a temperature of 100 degrees, in subsequent - with an increase up to 3-5 hours and an increase in temperature up to 300 degrees.

Furnace lining is possible after a month of regular use. The surface is leveled with adhesive using a smooth trowel. The laying scheme is marked. The mortar is applied with a notched trowel, the damp tile is pressed into it and held for 2-3 seconds. Excess glue is removed immediately. The next tile is indented from the first by 4-5 millimeters. Seam sealing - 2 days after the end of the cladding. The first short-term firebox - after 3 days.

Polyurethane foam underlays

One of the most affordable options for a carpet underlay is polyurethane foam. Compared to analogs, this material has such advantages.

- The optimal ratio of cost and quality of products.Despite the lowest price among similar materials, polyurethane foam has suitable performance characteristics for arranging carpet underlays.

- Average elasticity values create sufficient cushioning to make movement on the floor comfortable, and the carpet cloth retains its qualities for a long time.

- The insulating properties of the material contribute to the absorption of sound, retains heat well.

- The material is strong enough, resistant to stress, moisture, temperature changes.

- Light weight simplifies installation of the substrate, transportation of material to the place of work. Laying polyurethane foam is quite accessible to the layman.

- The porosity of the polyurethane foam contributes to the air exchange process in the room.

Polyurethane foam substrates have a low cost, retain heat well and perfectly soundproof

Among the brands of polyurethane foam products for substrates are in high demand, the quality is characterized by the products of the Russian-Dutch company Comfort. The Elite series is represented by material, a square meter of which costs about 200 rubles. Thickness - 0.5 cm, density is 630 g / m². The sound insulation index reduces the overall noise level in the room by 26 dB. Products with a thickness of 0.8 cm have higher insulating characteristics, but such products are more expensive - about 290 rubles per m².

Polyurethane foam of the Luxe series is presented in three options - 1, 1.2 and 1.6 cm thick. The price of the first type of products is about 330 rubles, the second - 390, the third - up to 440 rubles per m². The material density index of 1260 g / m² determines the high strength of the substrate. The sound insulation index is 32 dB. The technical characteristics of the products of this series allow the flooring to withstand large external loads for more than a dozen years.

The products of such companies are very popular:

-

The manufacturer's products are impregnated with special compounds against microbes, fungi, and mold. The products are sold in rolls of 25 and 10 m². Material thickness - 1.2 cm. Designed for residential premises with a cement or wooden floor, creating underlays for carpet with a pile height of no more than 2 cm.

- HC-Blue. In addition to antifungal impregnations, a reinforcing mesh and viscose fibers are added to the material, which increases the strength of products, resistance to wear and abrasion. Such products are designed for a period during which 4 replacements of worn carpet canvases can occur. Thickness - 0.75 cm, the recommended height of the carpet is up to 2 cm. Suitable for all types of installation.

- The company applies innovative technologies in the production of polyurethane foam. With a thickness of only 0.3 cm, the material is strong enough, elastic, suitable for "warm" or "floating" floor systems. Another distinctive feature of the product is the self-leveling function, which allows you to smooth out all the unevenness of the base, to achieve the most even coating surface.

A special adhesive is used to attach the polyurethane foam pad to the base of the floor. Typically, a reliable connection requires 0.8-1.2 kg of adhesive per square meter. Polyurethane foam can also be used for flooring options without fixing, by pulling.

A special glue is used to fix the substrate to the subfloor.