The better to glue ceramics and porcelain

I would like to extend the life of ceramics. It is not only used for its intended purpose, but also decorates the interior with its originality and uniqueness. It is difficult to say which is better than ceramics or porcelain in terms of quality and durability, it all depends on various factors.

How to glue porcelain and ceramics? What kind of glue for porcelain and ceramics to choose? Or throw away the broken product? Throw away the broken vase or not? If not, how to glue a ceramic vase?

Don't rush to throw it away. You can always throw it away. First you need to try to glue the product, and if nothing works out, then you can throw it away. Throwing out is the last thing left to do.

How to glue ceramics

Various adhesives are used to repair ceramics. There are a huge variety of tools for repairing ceramic dishes on the market.

Ceramic tableware

The following adhesives of Russian production for the repair of ceramic dishes are offered for sale - "Secunda", "Super-moment", "Cyanopan", "Skley", "Power", "Monolith", "Elephant". There are also imported glues for gluing. The best waterproof ceramic adhesive is MARS.

Waterproof glue

For ceramics used for storing food, you can use PVA glue for gluing. However, it is recommended that after gluing the ceramic cup be covered with a layer of varnish. For gluing ceramic products, you can use epoxy glue, F-2 and BF-4 adhesives.

How to glue porcelain

The following range of adhesives for porcelain is on sale - STANGE, "cosmofen ca-12", you can also use "RAPID". Carbinol glue should be noted among Russian-made adhesives. Also, instead of glue for porcelain repair, you can use EPOXY GLUE epoxy resin produced by BONDO, BIZON or similar adhesives.

China

For bonding porcelain, you can use gypsum-based cement. To do this, add the protein of 1 egg to the gypsum powder and mix very well. The resulting glue can be used to glue porcelain. Moreover, the gluing procedure should be carried out very quickly, because this glue hardens quickly.

For gluing, you can make other glue at home. To do this, mix 1 protein and soda. Belov beat until foam, without adding soda. For one day, the whipped protein should stand, and only then add soda to the settled protein and mix. Soda should be added so much that a mass similar in consistency to a regular dough is obtained.

Very often food glue is recommended for repairing porcelain, one that is easy to make at home.

To do this, you should:

- Take 1 liter of water. Add 100 gr. To the water. Sugar, 100 gr. lime (necessarily slaked). Put the resulting mixture on fire and believe on low heat for about 3-3.5 hours. The main thing when "cooking" is that it does not boil.

- Cool the resulting broth and let it stand for a few more hours.

- The water that remains after settling must be drained.

- Add 0.5 kg to the mixture. tile adhesive. Mix well and leave to stand again for 10-15 hours.

- If there is excess water, then it must be drained. Boil the resulting mass 1 more time.

- Cool down. The porcelain glue is ready.

This glue is ideal for food utensils.

Universal adhesives for both materials

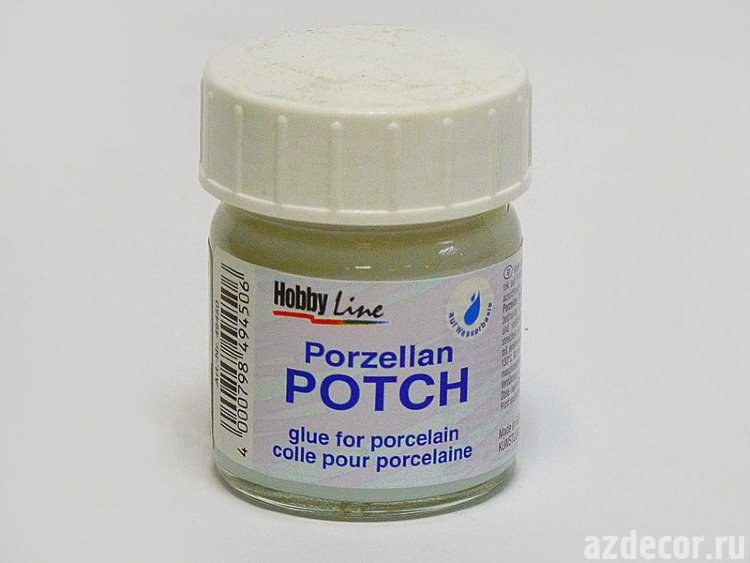

There are a huge number of all-purpose adhesives. These are adhesives that can be used to glue both porcelain and ceramics - casein glue, epoxy adhesives. The most popular is Porcelan Potch glue. Food grade glue is very often suitable for bonding both ceramics and porcelain. For example, the recipe described above can be used as an adhesive for ceramics and porcelain.

Porzellan Potch glue

General description and properties of polymer glue

It is recommended to understand the general description and properties that polymer-based adhesive liquids have.

Water resistance

One of the advantages of such adhesives is that they are water resistant. Therefore, after application, a strong seam remains on the treated surface, which does not absorb moisture. Due to their water resistance, the mixtures are often used for outdoor renovations. For example, they can be used to fix thermal insulation sheets for insulation made of foam or polystyrene.

3> Environmental friendliness

It is very important that the adhesive used is environmentally friendly. Mixtures made on the basis of polymers are considered completely safe, since there are no toxic components in their composition.

Such mixtures are made from antimony oxide, which prevents the fire of the glue line.

Heat resistance

High-quality adhesive mixtures made of polymers are resistant to temperature changes. After drying, the glue applied to the surface withstands temperatures from minus fifty to one hundred and eighty degrees above zero. Such resistance to temperature changes allows you to use adhesive mixtures outdoors, even in winter.

Frost resistance

Adhesive mixtures, in the creation of which polymer substances are used, cope well with frost. They do not lose their elasticity and do not crack after being applied to the surface, even when the temperature drops to 45-50 degrees below zero.

Versatility

Another important advantage of adhesive mixtures is their versatility, thanks to which such means can be used for gluing various materials. Polymer compositions are used when working with products that are made of wood, ceramics, plastic, plastic, glass and even metal.

Electrical conductivity

Such compositions for gluing various materials have high electrical conductivity. Electrical conductivity is ensured due to the fact that the composition contains a lot of metal particles. Also, in the manufacture of funds, special electrically conductive powders are used, among which graphite, palladium and silver can be distinguished.

Thermal conductivity

All polymer adhesives have an increased level of heat conduction. This is achieved due to the fact that during the creation of funds a special substance is added - boric nitride. It is thanks to this component that the manufactured adhesives have heat-conducting properties.

Fire resistance

Many adhesives have a serious drawback due to their tendency to catch fire. However, blends made from polymers are flame retardant.

Reliability

One of the main advantages of adhesives is their high reliability. The glued materials are connected so firmly that it will be impossible to separate them even by heating the adhesive seam. On average, the adhesion strength is maintained for ten years. After that, the seam begins to unstick.

Setting speed

People who choose their own glue often pay attention to such a property as setting speed. Polymer adhesives do not set as quickly as other products

This allows you to correct the position of the materials to be glued within 20-30 minutes after applying the mixture.

Fast drying

Polymer-based adhesives differ from most other products in their speed of drying. After application, the seam dries completely within an hour. However, if the liquid was applied to a wet surface or under low temperature conditions, the solidification rate increases by one and a half times.

How to glue

To choose the glue for such a job, it is worth distinguishing what the product consists of.Porcelain and ceramics have their own characteristics, which means that the bonding material is different. Consider some types of glue, we will figure out what is the difference between such works.

What glue to repair ceramics

Ceramics are very durable, but over time or due to negligence of the owner, they often break, break. You do not need to immediately throw out your favorite, valuable items.

Recommended adhesive for gluing:

- The most effective Russian manufacturers are: Super-moment, Second, Monolith.

- The best imported waterproof glue is Mars, very fast and easy to apply.

- Ceramic products are glued using epoxy glue or resin.

- For dishes, use ordinary PVA, only after repair it should be opened with varnish.

Glue moment

In addition to gluing ceramic dishes, ceramic glue is used in construction, for fixing tiles. It is divided into three types: mastic, dry and epoxy. The mastic contains glue and chemical impurities. Used for fixing tiles on a flat surface. Such materials do not damage walls that cannot tolerate moisture, but they are not heat-resistant.

Epoxy is the most versatile material for bonding or bonding. It is resistant to moisture, acid and alkali, and has a flexible structure. Suitable for any material of which the walls are made. The joints that remain between the tiles are often filled with the same adhesive. It is very convenient and practical.

What glue to glue porcelain

Porcelain is more fragile and beats more often, you need to monitor the safety of such dishes. For repair use:

- Epoxy glue or resin.

- Domestic manufacturer's material: carbinol glue.

- Gypsum-based cement. A good analogue of standard glue, the main advantage of which is that you can cook it yourself.

- Homemade glueing material, only protein and soda are required for cooking.

- Regular food grade glue.

Cold porcelain cooking

First you need to figure out what cold porcelain is. This is a sculpting mass from which flexible, light parts of various figures are well formed. In needlework, such porcelain is used most often, because its preparation does not require any hard-to-find materials. All recipes are simple, they may contain special glue, or be absent altogether.

Cold porcelain figurines

The glue for cold porcelain must be selected with particular care. If it turns out to be of poor quality, instead of good work, you can end up with something unpronounceable. For such work, ordinary PVA is great. Any kind of such material is heat-resistant, which is one of the main selection criteria. An exception is clerical, afraid of frost and heat.

Current companies that are popular:

- Moment is a common material, it is in good, frequent demand among needlewomen and craftsmen.

- Tytan is less famous, but after working with him, they leave good reviews.

- PVA glue manufacturer Lacra - there is a furniture and universal, a widespread series.

- Thesis and Expert, good materials, are not as popular as the previous ones, but those who used them were satisfied. Therefore, the firms received good reviews.

Regardless of the manufacturer chosen, PVA glue will glue cold porcelain perfectly, the work will turn out neat, there will be no problems with the subsequent restoration of the product.

PVA glue manufacturer Lacra

How to process cold porcelain without glue?

Cold porcelain without glue is usually used by needlewomen to create figurines, home decorations, just to please the eye, calm nerves or keep themselves occupied in their free time. A few simple recipes that you can make at home without much effort and effort.

The simplest recipe for which you need: a quarter glass of water, soda and starch. Mix all this and put on low heat.Bring to a boil, wait until the resulting mixture becomes thick. Such a mass is easily separated from the walls of the dishes, you can pick it up, sculpt any product. As you can see in the photo, the work is neat and does not require a lot of time.

Types of adhesives for porcelain and ceramics

If the product is broken, do not rush to throw it away immediately. There is a special glue for porcelain that will help you do the restoration yourself. To restore a porcelain or ceramic piece, you need to choose one of the brands of glue for a specific case.

UHU Porzellan Keramik is a transparent super glue that makes the seam invisible. At the same time, the thinner the adhesive layer is applied, the faster and more reliably it will set. Such a fixation will withstand only an insignificant effect of the liquid, therefore the glued product can be washed, but cannot be used as a full-fledged container for liquid.

ABRO EC-510 is a two-component epoxy resin based food grade adhesive. Reliably restores the integrity of glass and porcelain cups. After drying, it remains transparent, so the seam is not visible. To prepare the adhesive, you need to mix both components.

It is important that the gluing process must be carried out quickly, because this type of glue hardens in 5 minutes.

Super Moment is a universal cyanoacrylate adhesive. It glues all types of materials in seconds

Before use, be sure to read the instructions.

This is an incomplete list of all existing adhesives. There is a wide range of products in this category to choose from on the market.

Before gluing porcelain dishes, it is important to clean the product from grease and dirt using a degreaser.

How can porcelain be glued?

So, on sale you can find a huge assortment of adhesives than glue porcelain in order to reliably glue a porcelain cup and other utensils

Pay attention to the following adhesives:

- STANGER;

- Cosmofen CA-12;

- Araldit Rap> The presented list consists of funds from foreign manufacturers, and among Russian manufacturers, carbinol glue is considered the best. Also suitable is epoxy resin EPOXY GLUE, which is easy to purchase in any construction and utility supermarket.

To restore porcelain figurines at home, cement made on the basis of gypsum is also used. To prepare such a mixture, you need to drive 1 chicken egg into the gypsum powder and mix well. So, it will be possible to easily glue any porcelain products.

There is another way to make your own glue, which will allow for the restoration. This will require 1 protein and baking soda. Beat the egg white well. and leave it on day. Then, only after standing, add soda in small portions, kneading the mass. In consistency, the mixture should resemble dough.

In addition, the restoration is carried out with food glue. So, it will not be difficult to make it yourself.

- Take 4 tbsp. water, add 1/2 tbsp. l. sugar and lime. Only slaked will do.

- Then the mixture must be boiled for 3 hours, but do not boil.

- Cool the composition and let it brew for a couple of hours. Moreover, if excess water appears, then it is drained.

- Add 500 grams of tile glue, stir and leave overnight.

- If excess liquid re-forms, then carefully drain the unnecessary through cheesecloth.

- Boil the mass again over low heat, and only after that start using it for its intended purpose.

Adhesive for bonding ceramics

Often, ceramic dishes are glued with various adhesives purchased in the store on the advice of sales assistants. Cyanoacrylate-based super glue can be used to put ceramic utensils back into use. In addition, epoxy glue from Russian manufacturers is also suitable for such purposes.

Also in the public domain, you can find other adhesives that will help restore the plate and other products:

- Second;

- Monolith;

- Super moment;

- Elephant;

- Mars waterproof glue.

Universal adhesive for ceramic and porcelain products

For the restoration of combined products, you should use universal compounds that will help restore the integrity of the dishes. So, let's determine the best way to glue ceramics and porcelain at home:

- Russian-made casein or epoxy adhesive. Affordable price is perhaps their main advantage.

- Porcelain Potch from the Hobby Line brand. This glue varnish is imported to Russia from Germany. Serves as the optimal universal remedy.

Material characteristic

Keeping items made of ceramics and porcelain in the house, it is worth studying the technical properties of the material. Information about the basic characteristics of the material will help you to properly care for the products and choose the glue if you need a minor repair or a complete restoration.

Porcelain

Porcelain is one of the varieties of ceramics. Products from this material are obtained by sintering high-grade white clay with an admixture of feldspar, quartz and a number of other additional components. After firing, the resulting material acquires a white tint, a structure that is translucent in a thin layer, water resistance and resonance upon tactile contact. Most often, decorative figurines and dishes (cups, saucers, decanters) are made from porcelain.

There are several types of porcelain, which differ from each other in the nuances of production and characteristics of the material. The main types are:

- Soft. It is fired at a lower temperature, due to which the material is not completely sintered and partially retains its porous structure. Most of the products made of soft porcelain are creamy, which looks more interesting than milky white. Adding paints for painting allows you to give products a unique structure.

- Solid (high temperature). In production, this variety is considered the standard due to its structure. The material has an increased mass, white color with a shade of gray, opacity. The technology for creating a solid look is complicated by the need for firing at a temperature of about 1500 degrees.

- Bone. This type is produced by analogy with hard, but burned bone is used in production. Due to the peculiarities of creation, bone china has high strength, while it is distinguished by its white color and transparent structure. The strength of the material is ensured by the melting of the base ingredients during firing.

Ceramics

Ceramic is one of the most common materials for making kitchen utensils, including utensils, as well as many other products. The material is valued for a number of positive characteristics, including strength, heat resistance, safety for humans and the environment, and aesthetic potential. The presence of these qualities determines the widespread use of ceramics.

Ceramic products are made by shaping and firing clay or clay substances. Mineral supplements are often used as additional components. Ceramic food-grade dishes are glazed to improve aesthetic characteristics.

The causes of cracks and chips

Despite their hardness, earthenware and porcelain remain fragile materials.

With a point mechanical or thermal effect, the porcelain product easily cracks and even splits into several fragments. And the question arises: how to glue the toilet?

Most often, the following reasons and actions lead to a violation of the integrity of the toilet:

- hit with a hard object;

- sharp temperature drop;

- installation errors.

When a bottle of hairspray regularly falls on the lid of the cistern, sooner or later the lid will crack.

When installing a toilet in a new apartment or when replacing an old product, you must strictly follow the sequence of actions and be careful.

The video shows the installation process of the toilet.

You need to know that a reliable fixation of the plumbing fixture to the base can be done with bolts, glue or liquid nails.

When bolts are used, they must be tightened evenly so that there is no additional stress in the body of the toilet.

It should be emphasized that a crack in this case may appear after a certain period of time.

If glue is used for fastening, it is very important to follow the technology for preparing the surfaces to be glued.

How to glue a cracked toilet?

When starting to repair the toilet, you need to securely fix the seat so that it does not dangle or remove it altogether. The whole gluing procedure consists of three steps.

Before performing them, you should prepare all the materials and tools necessary for this.

And despite such an abundance of choice, there are many recipes with which you can make glue yourself.

It is not forbidden to use "homemade" means, but it is preferable to use factory materials.

Before embarking on this painstaking and demanding procedure, you need to prepare appropriately.

For work you will need:

- special glue;

- sanding paper;

- solvent;

- narrow spatula;

- soft tissue;

You can use the hair dryer you use to dry your hair.

Surface preparation

Regardless of whether the porcelain toilet will have to be glued or earthenware, the surface of the fragments to be glued must be cleaned and degreased.

For this, fine-grain sandpaper is used. Then the surfaces to be glued are wiped with a soft cloth and treated with acetone or gasoline.

Seam bonding

The sequence of actions is determined depending on the type of glue. Most often, the glue is applied (including to the tank) in two steps. After applying the first layer, you need to pause.

They need to be pressed against each other as tightly as possible.

Final finishing

It is very important to press the parts to be joined and keep them in this position for a certain time. This period is indicated in the instructions for use of the glue, which is always printed on the package.

After the seam is completely dry, it should be treated with an emery cloth.

This period is indicated in the instructions for use of the glue, which is always printed on the package. After the seam is completely dry, it should be treated with an emery cloth.

Then it must be degreased and another layer of glue applied.

This completes the toilet restoration process.

Storage:

After use, the adhesive must be covered and stored in a cool place (refrigerator, etc.).

Products made of porcelain and ceramics can be glued with adhesives "Mars", "Polyvinyl acetate", BF-2, "Rapid", MC-1, "Mekal", "Kittifix", "Supercement", Ago "," Elastostil-2 ", EDP , EPO, Latex and Unicum. However, it should be borne in mind that Supercement and Ago adhesives form insufficiently strong seams, BF-2 glue is colored, and polyvinyl acetate glue is not water-resistant.

When gluing porcelain with Rapid, Ago, Mars, MC-1, Latex, Unicum, Kittifix and Mekol adhesives, degrease the surfaces with a swab moistened with acetone, apply a layer of glue on both surfaces and give dry it for about 20 minutes. After that, a second layer of glue is applied, the surfaces to be glued are connected, pressing them strongly against each other using a rubber band, clamp or some other device, and they are kept in this position for 3 hours. The final setting of the seam takes 2 days.

When working with "Rapid", "Ago", "Kittifix" and "Mekal" adhesives, you can use another method: grease the degreased surfaces with glue only once and immediately join them by squeezing them with a tourniquet or in a clamp.

Porcelain can be glued with Elastostil-2 glue. It is a two-component, waterproof adhesive that is sold packaged in two aluminum tubes. Before use, the contents of the tubes are mixed in a 1: 1 ratio and mixed thoroughly.The surfaces must first be degreased and dried thoroughly. The prepared glue is applied to both surfaces and the parts are squeezed.

Within 3 days, while the glue seam sets, in no case should water fall on it.

Strong and water-resistant glue seams are provided by adhesives EDP, Mekal, EPO, Mars, Rapid, Cattifix, Elastostil-2, Latex and Unicum.

For gluing sanitary ware made of porcelain and ceramics, in addition to traditional adhesives, there are also compounds that you can make yourself.

For gluing glass or porcelain products that will not be exposed to heat, you can prepare a paste of gypsum and quicklime: 50 g of gypsum, 10 g of quicklime, 1 egg white and 10 g of water are mixed immediately before use.

For gluing porcelain or ceramics, 10 g of kaolin and 1 g of calcined borax are mixed with water to a paste-like state. Products glued with such a paste are fired over high heat until they are light red. The seam is heat and water resistant.

For gluing porcelain, you can prepare the following paste: mix 20 g of ready-made casein powder glue with 8 g of silicate glue. In this case, the glued product will not be afraid of water, since a sufficiently waterproof glue seam will be obtained.

To glue porcelain items, you can also prepare a composition of wood glue: add 12 g of starch and 7 g of chalk to the solution of wood glue. The resulting mixture is thoroughly mixed. The glue is not heat resistant.

For gluing glass objects on 20 g of dry casein glue, take 100 g of liquid glass. When gluing glass with such a composition, a contact method is used: a layer of glue is applied to both surfaces to be glued and allowed to dry slightly. After that, the objects to be glued are connected and heated up strongly.

Porcelain and faience can be glued with a paste, which is obtained by introducing gypsum into a 3% gelatin solution. The pasta is prepared just before consumption. On the basis of gelatin, another glue is also prepared for gluing porcelain and faience: a 25% gelatin solution is mixed with an equal amount of vinegar essence.

In life, situations often arise when urgent repairs need to be made in the bathroom and it is not known how to glue the toilet.

This happens when you carelessly handle bathroom and toilet equipment. Practice shows that abruptly lowering the toilet seat can inadvertently damage it.

This plumbing fixture is strong enough to withstand heavy loads.

At the same time, you need to know that there are toilet bowls on the market manufactured using different technologies and by different companies.

Products have various designs and methods of fixing in a certain place.

How to glue ceramics to ceramics step by step

How can ceramics be glued

How can ceramics be glued

Ceramics are much more difficult to bond than porcelain.

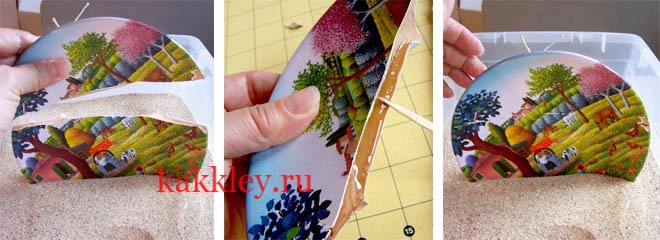

Therefore, you should be guided by the basic rules:

- We clean the glued surfaces from dirt and dust.

- We degrease the component parts of the object, and then dry them well.

- Apply a thin layer of ceramic glue to the desired area.

- If the parts to be bonded are uneven, apply a second layer of adhesive.

- Connect the parts to be glued by pressing them down with force.

- Fix the product in a clamped state for such a period of time, which is indicated in the instructions of the glue.

- It will be possible to use the item again after a couple of days, when the glue is finally set.

To fix the product to be glued, you can use a tourniquet, and if the item is small, stick it into a container with sand. This will contribute to reliable adhesion and tight connection into a single whole of all parts.

Glue the broken pottery

Glue the broken pottery

How to glue porcelain

To repair a porcelain product you will need:

- epoxy glue such as EDP,

- container for diluting glue,

- stick for applying the composition.

Operating procedure:

1.Mix the resin and hardener in a 1:10 ratio and heat with a household hair dryer.

2. We apply the composition to the place where we will glue the fragments. We leave for a few minutes.

3. We connect the fragments of the broken product.

For complete drying, it is necessary to stand for 24 hours.

How to glue faience and ceramics

For gluing ceramics and earthenware, you need to adhere to the same rules. First, prepare the connecting parts by cleaning them from all kinds of contaminants, degreasing them with a solvent and drying them.

If you need to glue small pieces together, choose a glue based on cyanoacrylate. It is packaged in small tubes and is suitable for single use only.

If you have to glue large parts, you can weld the glue yourself.

- Use six pieces of liquid glue,

- Two pieces of sifted river sand and,

- One piece of crushed glass. Such a composition will endow the glue with strength and quality, but after gluing the seam will remain noticeable.

VIDEO ON TOPIC

A simple option for self-preparation is casein-based glue. To prepare it, you will need water, borax, casein, a few drops of formalin. This mixture will harden in 2-3 hours. And yet, many resort to gluing ceramics and faience with a gypsum-based adhesive solution.

Do not rush to throw out the damaged item, be it a porcelain vase, ceramic cup, earthenware sink. Try to breathe a second life into your favorite interior item on your own.