Types of carpets

The material presented on the shelves of car dealerships can be divided into 2 groups. The first group includes all products consisting of two layers. The second group includes three-layer products. The basis of all products is a rubberized fabric, and the upper part is made of synthetic pile.

Three-layer products have another layer that is located between the rubber base and the synthetic pile. In the manufacture of this layer, polymeric materials are used, which, after curing, become moisture-proof.

Three-layer products have a higher pricing policy. If we compare them with two-layer counterparts, then it is worth noting that they are more wear-resistant and have a longer operating period. In addition, moisture that gets on the mat along with the shoes does not get on the floor of the car, which protects it from corrosion.

Autocarving has a wide variety of design solutions. It all depends on the manufacturing technology of the upper layer of the product. The cheapest floor coverings are made using the needle-punched method.

The essence of this method is that several layers of synthetic fiber are applied to the base. Then it is processed with needles, on the edges of which there are notches. After such processing, synthetic fibers are tightly intertwined with the base. To make the product more durable, its canvas is glued to a rubber base. Then, they are sent under the press.

In view of its budgetary pricing policy, needle-punched carpets are the most popular. It is abrasion resistant and has increased durability.

A little more expensive is a tufted car carpet, which looks more interesting than a needle-punched one. Its production technology assumes that synthetic pile is inserted into the base. Then, the base is fixed with an adhesive. The result is a looped fiber. However, it is more difficult to care for it than for a needle-punched one.

The most expensive type is woven. It is usually placed in executive cars. In the manufacture of the product, jute cloth is used. It is 100% environmentally friendly and highly durable. Such a product has a long service life and is resistant to abrasion. Woven car mats have one drawback - high pricing policy.

Views

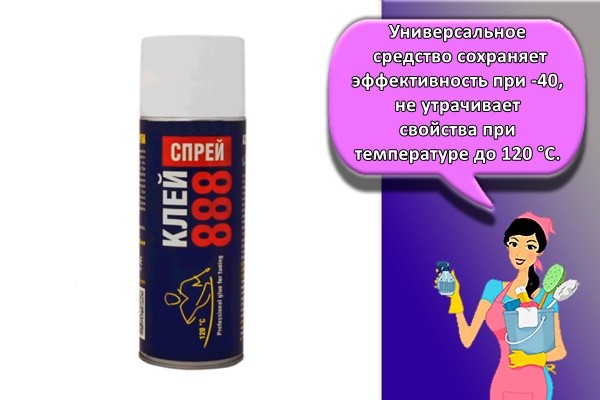

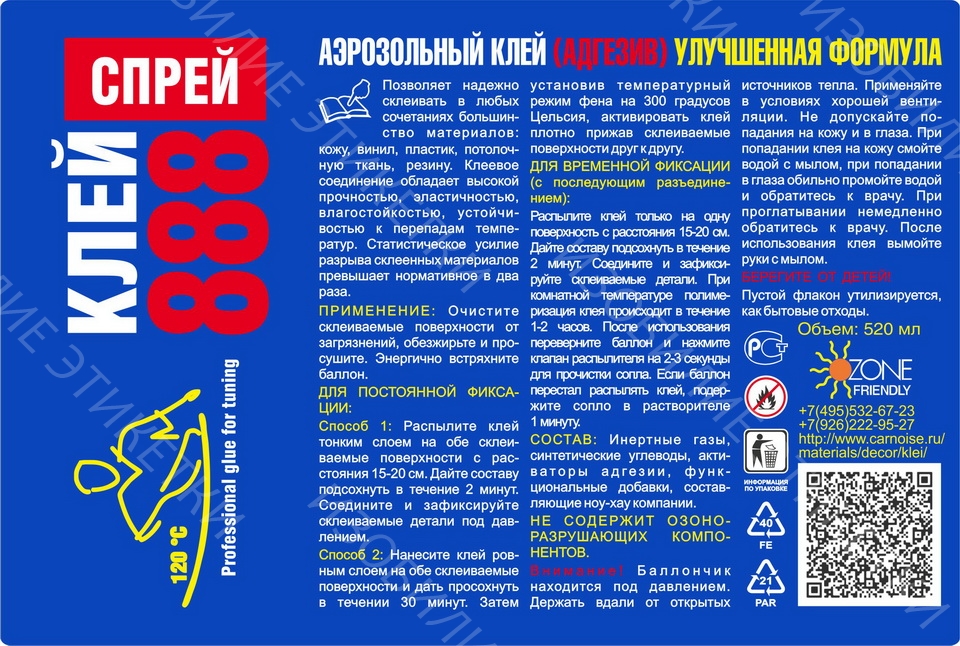

The industry produces temporary adhesives of various properties. They can be moisture resistant, have increased resistance to temperature extremes, be immune to the action of oils or various types of petroleum products. Means with increased resistance in everyday life or for creativity are not used. An exception is attaching decor on the street in preparation for the holiday.

KK 100 Gunold

Gunold temporary fixing spray adhesive provides good temporary fixation of applications or other decor, prevents stretching and deformation of the fabric base. Often used to stiffen fabrics in machine embroidery. Provides good temporary fixation of applications or other decor, prevents stretching and deformation of the fabric base. Often used to stiffen fabrics in machine embroidery.

The manufacturer of the temporary adhesive KK 100 Gunold indicates that the product is non-toxic and odorless. Suitable for work in rooms where ventilation is difficult. May create a rubbery effect when applied liberally to the substrate.

It is important to check the expiration date before use. Expired adhesive leaves stubborn stains

Pencil 7.5 g Scotch 36307D

A low-tack compound capable of joining elements several times.It is used when assembling mock-ups and sketches when you need a short-term connection of components. In everyday life, a 7.5 g Scotch 36307D pencil is used to glue receipts and notes. Odorless, easy to remove from surfaces without leaving stains. It is produced in the form of a dense sticky substance.

Adhesive spray 3m Scotch Weld 75 for temporary fixation aerosol 500 ml

Aerosol spray is intended for short-term fixation of light layouts and stencils. Versatile. Suitable for all materials.

Be careful: 3m Scotch Weld 75 Temporary Curing Adhesive Spray 500 ml aerosol contains flammable substances. The product must not be sprayed near open flames.

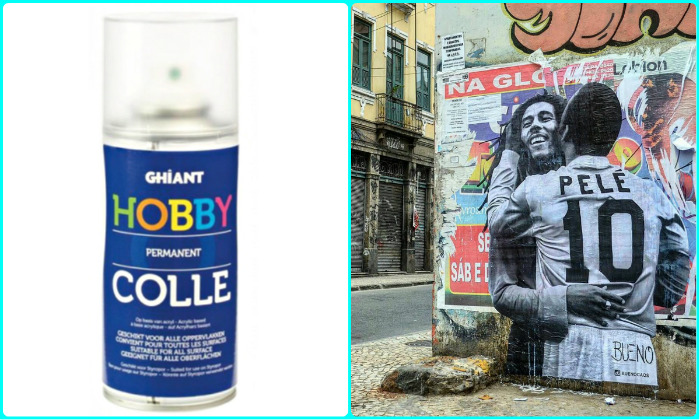

Repositionable 150 ml

Aerosol glue for temporary fixing Hobby Colle Permanent Repositionable 150 ml is well sprayed, does not absorb and does not deform the thin base of parts. Used to join thin sheets for a short time.

Hobby Colle Permanent 150 ml is applied in a thin layer to the surface of one of the connecting elements, ensuring a secure hold. The glue is suitable for joining fabrics, tracing paper, polystyrene, polyethylene.

UHU Tac Patafix PROPower

Extra strong Velcro, produced in pads. Temporarily attaches items weighing up to 3 kg. Can be used multiple times. Resistant to temperature fluctuations and ultraviolet radiation.

UHU Tac Patafix PROPower temporary adhesive tape is often used when decorating celebrations and holidays on the street.

Idea Decoupage

Temporary fixing spray Idea Decoupage is able to repeatedly fasten stencils, applications or details of models. The temporary fixing aerosol adhesive is sprayed evenly from the can, forming a thin adhesive layer on the base. Bonding can be done after a few seconds. It is well removed from the surface.

Takter

The aerosol is used in screen printing, embroidery and tailoring. Suitable for all types of fabrics. Colorless and non-marking.

Spirit 5 strong

Aerosol adhesive for temporary fixing of cellophane, paper, fabric, plastic, cardboard. Convenient for sewing, for creating collages, appliques.

Krylon Easy-Tack

Reusable aerosol adhesive Velcro. After it, no stains remain on the paper or parchment. It does not contain acids. Soft materials will not wrinkle when first applied.

Scope of use

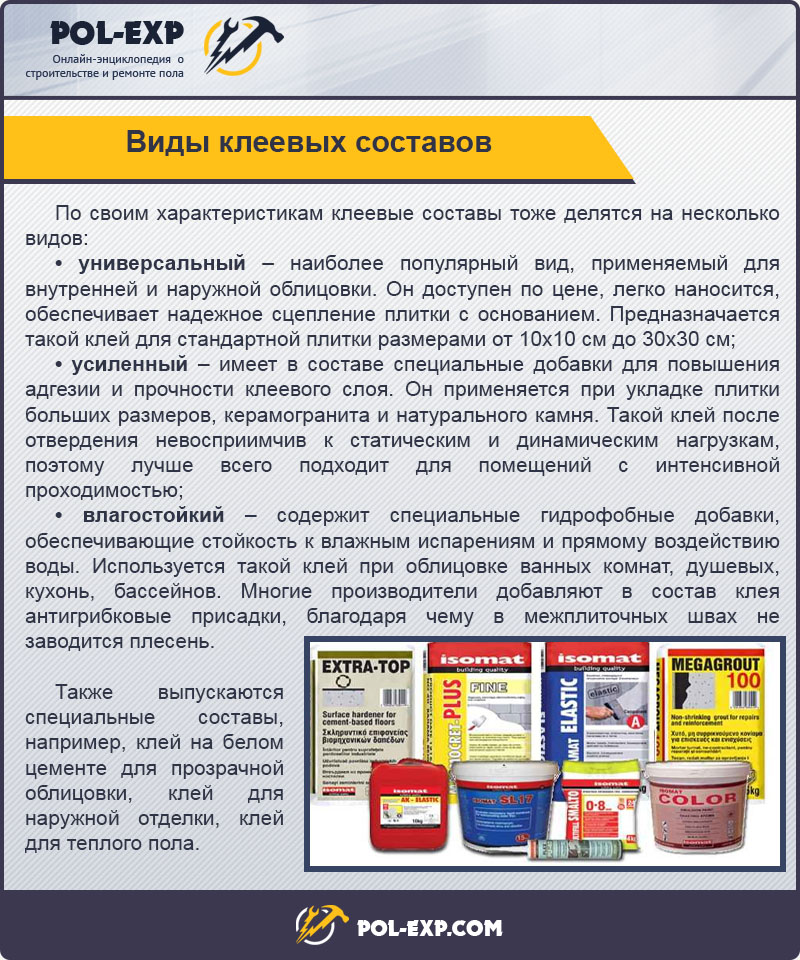

Due to the fact that the composition of the glue is inert, it does not enter into violent chemical processes with many substances, the solution can be modified with the help of fillers. This gives the substance new properties, expands the scope of its application, without changing the adhesive properties.

To give additional volume during construction and installation work, chalk, metal, quartz or glass shavings are added to the solution. When installing a tile cladding, PVA is added to the cement mortar to increase the adhesive properties.

In the carpentry industry, glue is used as a primer for wood. It gives the wood water-repellent properties, protects against mold and mildew deposits, and prevents cracking.

The solution is widely used in applied art, including children's art. Replaces varnish when applied in several layers.decoupage glue, scrapbooking, used for crafts using the papier-mâché technique.

Varieties and characteristics of PVA

The structure and chemical composition of the glue allows you to independently modify the solution. But today in stores there is a wide selection of all kinds of formulations for home and industrial use.

Domestic

This type is used for gluing wallpaper on paper, silk, vinyl backing. It can be used as a primer for plastered brick, concrete, gypsum surfaces. Does not change color, does not stain materials.

It is used for fixing cardboard, paper, leather, fine suede for decorative purposes.Provides high adhesion of synthetic, lint-free fabrics of medium density.

Sold in containers from 0.4 liters. The most famous names:

- Kapral V-10. Price 1L. from 110 rubles.

- White House: 0.9 l. from 110 rubles.

- Profilux: 0.9 l. from 130 rubles.

Clerical

It has the lowest adhesive properties among other types. It contains water in the base, therefore it is unstable to temperature extremes and storage below zero. Viscous white composition, non-toxic, odorless. Can be used by children under the supervision of adults from 3 years old.

Suitable for fixing all types of paper, including glossy ones. Leaves no residue after drying. May turn yellow over time. It delaminates if stored incorrectly. It is produced in bottles and tubes with conical dispensers with a volume of 40–270 g. Most Popular:

- Kores: 55 gr. from 90 rubles

- Attashe 65 gr. from 25 rubles.

- Comus 85 gr. from 30 rubles.

- Polipax save 85g from 20 rubles.

Universal

Article PVA - MB is used to fix dissimilar materials of different densities: wood, cardboard, textiles (except for woolen fabrics), leather and thin suede. It is used as a component for diluting putties, primers, cement mortars.

Possesses an average degree of adhesion and resistance to temperature fluctuations. Analogue PVA - M is less durable, but cheaper. Suitable for more porous materials and as a top coat instead of decorative varnish. PVA universal glue is produced in containers with a volume of 0.4 to 3 liters:

- Moment Wagon: 750 gr. from 190 rub.

- Tex: 3 kg. from 200 rubles.

- Lacre: 0.9 kg. from 70 rubles.

Superglue PVA

Contains reagents that form an elastic and very strong seam that can withstand dynamic loads. It is used for installation, minor repairs and restoration of vertical tile cladding with a size of 10x10 cm. Resistant to moisture (up to 3 degrees) and temperature extremes.

Used for fixing glass, ceramics, wood, rubber. Suitable for outdoor use, furniture manufacturing, textile and footwear industries. Leaves no residue, does not stain materials. Available in packs from 125 gr. up to 4 kg.

- Super PVA Moment: 250 gr. from 180 rubles.

- Novokhim PVA Super: 2.4 kg. from 520 rub.

- White House: 0.9 l. from 120 rubles.

- PVA glue Beam: 125 gr. from 35 rubles.

PVA construction glue

Possesses a higher degree of adhesion and resistance to moisture (up to 4 degrees). It is added to mortars in the form of a transparent emulsion. When dry, it does not shrink, does not crack, and withstands dynamic loads. Does not lose its properties at temperatures from +70 to -40˚С.

PVA construction glue is economical in consumption and serves as the basis for the preparation of assembly mixtures, paint fixer for outdoor work, fixation of vertical and horizontal tile cladding. It dries up under normal conditions within 6-8 hours. Produced in liquid form with a volume of 1 to 20 kg. or as a redispersible powder.

- Construction tex: 3 kg. from 270 rubles.

- Akvest: 1 kg. from 90 rubles

- Construction rainbow: 10 kg. from 520 rub.

Primary requirements

When choosing an adhesive used for interior decoration, it must be borne in mind that such compositions must meet the following requirements:

- non-toxic;

- provide reliable adhesion to the surface;

- evenly distributed over the finishing material;

- do not leave behind stains.

An important condition is the selection of glue, taking into account the type of finishing material. In particular, the white compound is not recommended for fixing the black paneling.

The following materials are used in car interiors:

- Carpet. The most affordable finishing material that wears out quickly.

- Alcantara. An expensive synthetic material with increased durability.

- Leather. Environmentally friendly finishing material with a service life of 10-12 years.

- Eco leather (artificial leather). With proper care, the service life does not exceed seven years.

- Flock. Relatively cheap material that is difficult to work with.

- Velours. Maintenance-friendly material that can last less than four years.

When choosing an adhesive composition, in addition to the above factors, it must be borne in mind that the product must withstand regular temperature changes.

How and why to dilute

During storage, the composition can thicken, even with a tightly closed lid. Stationery and household solution can be diluted with water. To do this, add a few drops of liquid to the substance and stir.

The construction or wallpaper version can be sold in powder form. The wallpaper component is diluted with water in the proportions indicated on the package. How to dilute the building composition is indicated in the instructions.

To increase the density and volume of stationery PVA, starch, soda, semolina, gelatin are poured into it. Any dry pigment or gel dyes are added to change the color.

We advise you to watch the video instruction:

Simple Tips

Recommendations come down to simple ways. A foamy upholstery cleaner like Runway helps keep your carpets cool for a long time. Thanks to it, cleaning does not take much time, the drug does an excellent job of removing dirt and dust. You can also use your usual dish detergent or Vanish. Dilute a drop, add a little water, foam and apply to a vacuum-cleaned surface. Then go through the vacuum cleaner again, removing excess foam. The interior will be clean and smell good.

When buying a carpet, it is important to go to trusted car dealerships, which will help to avoid fakes and cheap glue bases. This is a justified, cost-effective purchase, because the coating will last for many years.

How to glue yourself

Materials and tools that will be needed to restore the brake pads:

- to remove the remnants of worn linings - a milling machine, but if this is not possible, you can arm yourself with a hammer and a chisel;

- grinder, grinder;

- degreasing agent (gasoline, acetone);

- new overlays;

- adhesive, sponge or brush for applying it;

- hacksaw for cutting metal blanks;

- vise or clamp;

- Microwave oven or oven.

The process of installing overlays consists of 7 critical points:

- Removing worn out brake linings. If it is not possible to turn to car service workers for help, old rivets are knocked down on their own with a hammer and chisel. Alternately, carefully, with well-aimed blows.

- Cleaning the surface of the shoe being repaired. During the operation of the vehicle, rust and debris accumulate under the heel, which must be disposed of. The part is cleaned in one of the following ways:

- grinder;

- holding the block in a vice, the surface is treated with a grinder using disc or petal circles with sandpaper;

- using sandpaper. In this case, the stripping process will be delayed.

- Wipe the treated surface with a soft dry cloth and then degrease. Bonding manipulations are carried out no earlier than 5-6 hours after the removal of fatty substances.

- Using a sponge or a brush, without saving, apply the composition to the pad and pad (it is recommended to carry out the procedure in one direction). There should be no glue-free areas on the surfaces to be bonded. In this case, the temperature in the room should not be lower than +24 ˚С.

- After 1 hour, the procedure with the application of the composition is repeated, kept for another 60 minutes.

- With a confident movement, press the parts to be glued together. You need to clamp them with 2 small clamps. The adhesive streaks are cleaned off.

- The device is placed for 2 hours in an oven preheated to 180 ˚С. After cooling down, the mechanism is ready for operation.

If there is no oven, the structure is set aside until the glue is completely dry, for at least 12 hours. The more time passes, the more reliably it will stick together.

What is the material

Carpet carpets differ in structure, thickness, and have different ductility. The cheapest upholstery fabric is made from fiber, the density of which per square meter does not exceed 450 g.Many car owners prefer to sheathe the interior of a material that is made of polypropylene. The pile length of this type of carpet reaches 6 mm.

Carpet has a lot of advantages compared to other materials used to upholster car interiors:

- Absorbs noise.

- Does not absorb dirt, does not collect dust.

- Does not electrify, does not fade.

- Keeps you warm.

Although the fabric is made from synthetic fibers, it does not cause allergies, does not irritate the skin or the respiratory tract. Carpet sheathed the ceiling, the inside of the trunk, covered with a subwoofer, acoustic shelves. The material does not mold, does not deteriorate from moisture.

Differs in the increased flexibility of Madeleine, which is most often sheathed in the trunk. The material is liked by motorists because:

- easy to stick:

- has a beautiful smooth surface;

- keeps warm.

Carpet is inexpensive, but absorbs noise in the cabin. The floor in the car is often covered with linoleum, which adheres well, does not lag behind moisture, withstands overloads, but deforms when sand gets in, and solid particles accumulate.

Additional tips and tricks

When starting to repair a leather product at home, you need to remember a few simple rules:

With the help of glue alone, as a rule, small damage is eliminated; in the case of a large defect, it must be sewn up or use an additional patch.

The container with glue must be closed immediately after taking the required dose of the substance, otherwise the composition will dry out quickly.

If the substance needs to be diluted, take a small amount, which will be sufficient for a single use.

When applying the adhesive with a brush or roller, it must be cleaned with a solvent after work.

It is imperative to observe safety precautions: if the composition is flammable, it must be applied away from open fire.

Glue from foreign manufacturers can be called differently, so you should carefully study the description.

If the liquid leather or patch is slightly different in color from the main product, after repair, you can correct the shade with spray paint.

When choosing glue in a store, you need to pay attention, including the size of the tube and the presence of an applicator or a sharp tip for ease of application.

If you need to purchase glue for leather, a variety of assortment on store shelves will allow you to choose a substance that is most suitable for a specific material and a specific task.

It is enough to carefully study the instructions, paying attention to the composition and characteristics

Share link:

Reasons to renew your salon floor

Over time, the interior of the car loses its former freshness. Dirt appears on the floor. With regular cleaning, the casing wears out, gaps appear. The old carpet is easy to replace yourself. Respect for the car does not save it from wear and tear. The material falls into disrepair under the influence of factors that cannot be avoided.

Moisture, dirt, dust accumulates on the floor, deforms the coating of shoes, as well as various objects. Dry cleaning eliminates the problem of a dirty interior, but quickly wears out the finish.

The main reason for the uplift of the floor in the cabin is the desire of the car owner to update the car's trim.

There are two options to choose from for renovating the interior floor:

- Nappy.

- Smooth.

The choice of adhesive and the method of facing depends on the selected material.

Fleecy coatings

Hairy Carpet - Suitable for the car interior. It is produced in the form of a roll and belongs to carpets. Available in various pile lengths. Has a wide range of palettes. Auto lovers prefer to purchase gray and black material. Dark shades are practical. Carpet pasting requires accuracy.

Smooth surface coatings

Avtolin is a multilayer material with an abrasive, reinforced, primer and carrier layer.Independent work is excluded, the cladding is carried out by professionals.

Avtoline is preferred to use in public transport, as it can withstand heavy loads. The production uses environmentally friendly components. Resistant to temperature changes.

Madeleine - the material is easy to use for a beginner. Due to its flexible structure, it is often used for lining the trunk. Has characteristics:

- Does not allow heat to pass through.

- Absorbs noise.

- Color variety.

- The surface can be smooth and with an embossed pattern.

- Small price.

- Common in automotive stores.

Car owners like to lay PVC-based linoleum on the floor.

Material characteristics:

- Low price.

- The ability to work independently.

- Wide range of.

- Various color solutions.

- Antistatic effect.

- Tolerates excessive moisture.

The disadvantages are:

- Solid material, not moldable.

- The coating quickly deforms from the ingress of abrasive particles.

- Moisture accumulates under the material during temperature changes, which leads to corrosion.

Carpet is preferred by car owners. Has clear advantages.

Instructions for gluing a car bumper with your own hands

When starting to repair a bumper, you need to perform a number of steps step by step. Compliance with the instructions will help to avoid common mistakes and achieve the desired result with a minimum of time and effort. The basic bonding process consists of preparation, joining parts and work to restore the appearance.

Preparatory work

The initial stage of repair is to prepare the working surface. The bumper is inspected, washed from accumulated dirt, the edges and edges are treated with an abrasive material or a cutter. Then, with the help of special chemicals, degreasing is carried out.

Bonding cracks on the bumper of a car

When gluing cracks on a cracked bumper, it is necessary that the amount of adhesive solution on the parts is optimal. Insufficient thickness of the adhesive layer will lead to the fact that after the solution dries, the materials will not obtain identical physical characteristics. Differences in rigidity lead to the destruction of the paintwork after all work is completed, even with a slight external impact.

The glue is applied in an even layer on two parts, which will be connected to each other. To strengthen the seam from the inside, the crack can be sealed with a metal or synthetic mesh. The final hardening of the solution occurs over a different period of time, depending on the characteristics of the substance. To prevent the parts from moving after gluing, you must first ensure their reliable fixation in place, and carry out the work without removing additional fasteners.

Priming and painting

After gluing the damaged bumper, it remains to carry out the final work to restore the proper appearance of the part. First of all, for the restoration, the excessively applied amount of material is removed by cutting or processing with a grinder. Then the entire surface of the bumper is cleaned and the resulting irregularities are removed, using a putty if necessary.

Having leveled the surface of the bumper, proceed to painting the part. The procedure is carried out in accordance with the standard plastic painting technology. At the same time, it is allowed to use enamel and paint in work that are not intended for plastic, but in this case, you will need to add a plasticizer. To give the surface of your car bumper a rougher finish, it is best to use a structural paint. If the task is to paint the bumper in body color, then you must first apply another additional layer of primer, and then proceed to painting.

Share link:

What compositions to use for a car salon

When choosing an adhesive for a car interior, it is necessary, among other indicators, to take into account the temperature difference to which the material will be exposed. As a rule, formulations based on polychloroprene or polyurethane are used.

Mah 800 * 213 glue (based on polychloroprene)

The composition, originally from Germany, is applied to both glued surfaces. It has earned the recognition of professionals due to its high quality fixation and insensitivity to high and low temperatures.

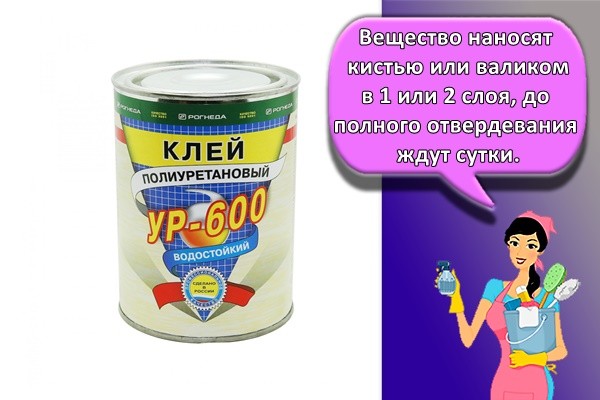

Polyurethane UR-600 ("Rogneda")

The drying rate of polyurethane compounds is slightly lower, but this does not affect the adhesion strength. The substance is applied with a brush or roller in 1 or 2 layers, waiting for a day until complete hardening.

Clay 88-Luxe ("Rogneda")

Despite the fact that this composition is not afraid of moisture, its fixing properties are not the best. In addition, the substance is characterized by a pungent unpleasant odor.

Wrapping process

Everything that is available for dismantling is removed before pasting with the carpet. This makes it more convenient to work, and the material lays down smoother.

The surfaces are washed, cleaned of paint (again, if it remains), dried, sanded and degreased. For plastic, gasoline can be used as a solvent;

A piece of the desired size is cut from the roll with a small margin. If there are difficult places on the part (for example, a lamp shade on the ceiling), the workpiece is applied to it and in the right place is made, either a cruciform incision, or a hole slightly smaller than required;

The workpiece to be processed is covered with a thin layer of glue - it will act as a primer;

After the application has dried, the surface is coated again. Some adhesives require similar processing and the carpet itself - you need to read about this in the instructions for the composition;

The material is applied to the part and leveled with a rubber roller so that there are no air bubbles left under the cover;

You need to act, starting from the middle and moving to the edges, similar to how they work when gluing wallpaper;

The edges are folded down. If they are too long, they are trimmed and fixed on the wrong side;

Certain difficulties can be caused by elements with a complex configuration - with protrusions and depressions. Before pasting them, the carpet must be additionally prepared;

A pattern is made of thick paper, repeating the outlines of the fitted part;

The carpet is cut according to the pattern with a margin of 2-3 cm from all sides;

The material is well sprayed with water from a spray bottle;

The workpiece is pulled over the part; on the back, you can temporarily secure it with tailor pins.

After drying, it will be stretched in the right places, which will ensure a tight fit with the carpet of all the bumps and grooves. You can use a household hair dryer to speed up drying. Remove the workpiece carefully so that it retains its shape and glue it immediately. So that you finally understand how to glue an automobile carpet, and gain some skills, you need to start with the least complicated parts.

Door inserts or thresholds are ideal for training - they have the most primitive forms, and you can grasp the principle of the upcoming work with minimal effort and loss.

What damage to the bumper can be glued at home

Without the help of car service specialists, it is possible to eliminate different types of bumper defects. The easiest way to restore restoration is scratches, which can be almost imperceptible superficial or deep, reaching the inner layer of the part. Repair in the second situation will be more difficult, since deep scratches often turn into cracks. In case of through cracking of the bumper, it is not recommended to use the car until the problem is completely eliminated, since while the car is moving, a vibration load is applied to the front of the body, which can cause the crack to expand. This will affect the condition of the entire case and its performance.

In addition to scratches and cracks, dents, punctures and chips can form on parts. Dents appear as a result of strong external influence and must be corrected. Breakouts and chips are often caused by a collision with an oblique obstacle.

How to glue leather to different surfaces

Combining leather with decor from various natural and artificial materials, you can get very interesting and unique handmade products. Massive jewelry looks beautiful and unusual, for example, leather pendants with wooden or plastic beads, as well as panels and other home decor items.

Wood

The easiest way to glue the leather to the wood is with double-sided tape, but this option is more temporary. For durable souvenirs, you can use a thermal gun or nitro-glue.

Plastic

Very often, the problem of how to glue natural or artificial leather on plastic is faced by motorists who want to patch up the interior on their own. Experienced craftsmen advise using aerosol glue or "Moment".

Textile

PVA does a fairly good job of fixing, but if the material is thin and light, stains may appear. Specialty stores sell transparent fabric adhesives that will provide durability and leave no residue.