Repair of displays and faulty gluing errors

If, when gluing the display or touchscreen with a sealant, an inaccuracy was made and you need to separate these two elements for the purpose of subsequent repair, we recommend purchasing a separator without a pump and a special molybdenum wire for separating the screen and touchscreens. With the help of these devices, this operation can be done without damaging the elements, which significantly reduces the cost of repairs if it is necessary to eliminate minor imperfections of the screen. Also keep in mind that when heated to 80-100 C, the B7000 glue becomes plastic, it can be glued and freely removed from the surfaces and, if necessary, fix the gluing defect.

Touchscreen repair

Subsequently, you can take a new kit without restrictions and glue the touchscreen, without losing the quality of the screen display. Using professional B7000 glue will provide a higher quality repair than other options.

What are the areas of application of glue for touchscreens in other areas

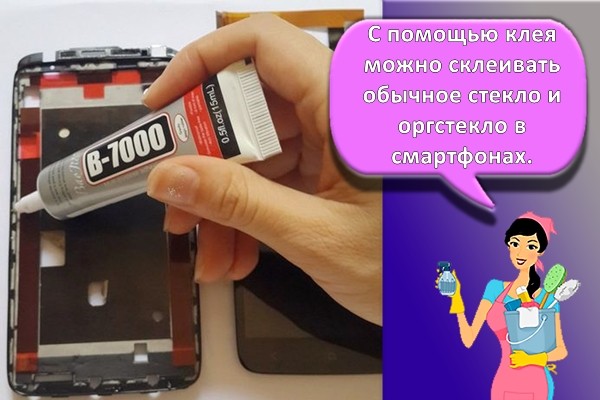

Despite its fame as a special adhesive for touchscreen sealant, B7000 is a multi-purpose compound designed for gluing glass, metal surfaces, plastic, wood, as well as elements of electrical boards and other electrical accessories. Its expected qualities include high bond strength. A truly finished seam is comparable in quality to a cast material and may even surpass the elements to be bonded.

Regular users note the absence of visible sizing seams and the absolute transparency of the finished contact layer. Accordingly, with its help you can glue expensive things, as well as firmly fix the elements made of glass, metal and plastic relative to each other. This possibility significantly expands the scope of use, but only emphasizes the special repair properties that make it irreplaceable in the service business.

By gluing electrical components, it is possible to ensure a strong contact between conductive surfaces with full conductivity. This quality contributes to the widespread use of glue in precisely the professional repair of communications equipment, laptops, computers and other hardware purposes.

Application of B7000 glue in needlework

In many types of needlework, gluing of certain types of accessories to jewelry, toys, and so on is very often used. Many needlewomen prefer to use the B7000 glue to create their unusual masterpieces. It can be used for gluing cabochons, rhinestones, beads and beads. It is widely used in the kanzashi technique, scrapbooking. Thanks to this glue, handicraft fittings adhere very well and hold for a long time. This allows craftswomen to create unusual jewelry, toys, jewelry, which are highly valued as handicrafts.

Comparison of adhesives

Which glue from the following is better, how to choose the right one? Below is a comparative table of the main characteristics of materials:

| E-6000 | B-6000 | T-8000 | E-8000 | B-8000 | B-7000 | E-7000 | T-7000 | |

|---|---|---|---|---|---|---|---|---|

| Viscosity | 3200 | 4500 | 3800 | 3800 | 3800 | 3500 | 3500 | 7000 |

| Colour | Transparent | Transparent | Transparent | Transparent | Transparent | Transparent | Transparent | Black |

| Bonding time, hours | 24 – 72 | 24 – 48 | 24 – 48 | 24 – 48 | 48 – 72 | 24 – 48 | 24 – 48 | 24 – 48 |

| Hardness (Shore scale), V | 70 – 85 | 70 – 85 | 70 – 85 | 65 – 80 | 70 – 85 | 70 – 86 | 70 – 87 | 70 – 88 |

| Surface drying, minutes | 10 | 3 – 5 | 3 – 5 | 3 – 6 | 5 | 3 – 6 | 3 – 6 | 3 – 6 |

| Storage temperature, degrees | 10 – 30 | 10 – 30 | 10 – 28 | 10 – 30 | 10 – 30 | 10 – 30 | 10 – 30 | 10 – 30 |

The Chinese company Zhanlida produces adhesives with enviable regularity, perhaps, in the near future, products of the 9000 - 10000 series will appear on the market.

According to consumer reviews, the highest quality and strongest B-7000, which practically does not react to tearing, but can be easily removed when heated with a hairdryer.

What is a touchscreen?

Touchscreen is a word derived from two English words touch and screen. Touch means touch, screen means screen.In short, a touchscreen is a screen that responds to touching with your fingers, that is, a touchscreen. In addition to your fingers, you can touch the screen with a special pen, stylus or pen.

The specified device was first created in the seventies of the twentieth century. And it appeared on sale ten years later, in the eighties.

At first, touch screens were only used in medicine and industry. Further, according to the demand, various kinds of phones, tablets, game consoles, payment terminals, computers and smartphones began to be manufactured for use by the average consumer. In fact, the touchscreen completely replaces unnecessary devices: keyboard, mouse, joystick. Many users have appreciated this user-friendly quality.

Nowadays there is hardly a person who does not know what a touch screen is. From young children to elderly grandparents, everyone has learned to use the touch screen.

The main advantages of touchscreens are convenience and ease of use, functionality and compactness.

But, like any device, touch screens tend to break. This can be facilitated by inaccurate use of the touchscreen. In no case should you put pressure on it or use any other mechanical effect. Someone may accidentally drop it on the floor, someone will get wet in the rain, and so on. There are many situations when it becomes necessary to change the touch screen - touchscreen. Typically B7000 multipurpose quality adhesive is used for this.

Analogs

Many people may be interested in the question of how the B7000 glue can be replaced. Analogs can be purchased in special stores. These include: glue B6000, B5000 and others.

Let's take a closer look at the B6000 glue. This tool is used for gluing glass, plastic, fabric and other types of materials. It contains epoxy paste. The waterproof agent is a Chinese product. Available in tubes of nine, fifteen, twenty-five and one hundred and ten milliliters. Prices vary from one hundred to four hundred rubles, respectively. After application, it instantly begins to harden. For complete adhesion, it is recommended not to use the product for ten hours. This glue is used in service workshops and centers. Transparent in color. Remains pliable even after complete drying. The transparency of the composition allows the surface of the glued materials to be painted in the desired color.

The next analogue of B7000 glue is B5000 glue, also made in China. It is used for gluing the screens of phones, tablets, laptops and so on. The glue is transparent in color, does not leave unnecessary marks, and has high adhesion strength. Prices in stores are almost the same: depending on the volume of the tube, around 100-390 rubles.

F6000, E6000 and so on can also be attributed to analogues. There are a lot of them.

Like B7000 glue, analogs have a metal fixture so that the glue is distributed accurately, and after use the tube closes tightly. This is necessary for greater safety and increase the shelf life of the adhesive.

Description of glue

This irreplaceable composition is made in China, the basis of its composition is an epoxy resin with a gel-like density. The action of the glue is similar to double-sided tape, but it has a more significant strong adhesion and is easily dismantled again.

The 7000 glue is used for gluing almost any material:

- glass;

- wood;

- plastic;

- ceramics;

- metal, etc.

It is packaged in thick polyethylene tubes of different packaging, the tip of which is made of metal, which allows it to be conveniently applied to the exact place in the regulated quantities (as needed).

Convenient to apply with a dedicated tip (click to enlarge)

Convenient to apply with a dedicated tip (click to enlarge)

The characteristics of this sealant make it a practical and versatile household item.

It is important to know that the main feature of the b 7000 is the re-bonding of parts. That is, after use, it can be heated to a temperature of 80 (or 100) degrees, it will become plastic and unstick with little effort.

Thanks to this feature, he uses it in service centers, since, if necessary, replace broken glass and covers in the use of gadgets. It is required to preheat the surfaces, peel them off and free them from the softened glue.

The composition of the glue is non-toxic and can be easily removed from surfaces (skin of hands) and there is no need to use additional heating devices.

Also, the composition is absolutely transparent and thick, which allows it not to spread and lie on the details in a neat dense slide.

Subtleties of application

These are the basic rules for how to use the B7000 adhesive. The instructions for use reveal some more nuances of working on connecting surfaces, although the general rules are similar to using any other glue. After applying a certain amount to the places to be glued, the product should begin to dry out a little - this way it will turn out to protect it from flowing out and falling into unnecessary niches with a little pressure. To avoid smudges on the screen, you need to wait about 30 seconds.

Sometimes troubles happen, and the glue still seeps beyond the boundaries of the parts to be glued. But this can be removed very easily in the case of the B-7000. Simply roll the adhesive sealant with your fingers, it will separate from the surface and turn into a ball. At the bonding site, you can hold a thin pointed match, a toothpick or a needle, this will help remove excess substance.

Do not be afraid that the substance gets on electrical contacts, since dielectrics do not conduct current, to which group B-7000 belongs. The adhesive sealant for gluing touchscreens will not transfer voltage to the phone case. Do not apply the product to wet surfaces, as the effectiveness of the connection is completely reduced. After joining the planes, they are pressed or fixed with an improvised means, for example, an elastic band or tape, and left in this form for half an hour. After applying the glue, a protective cap is put on it, so you can save the remnants of the product for further use.

What are the types of glue for assembling sensor modules

You can glue the sensor module onto a special narrow double-sided tape, but such a connection is not considered reliable, so professionals use glue for this purpose.

The following types of glue are used to assemble sensor modules in repair shops:

UV loca tp 2500f glue is an innovative ultraviolet-curing transparent glue designed for gluing glasses and sensor modules of smartphones of all brands. TP-2500F is UV-cure and has a high bond strength. Under an ultraviolet lamp, the glue hardens in 10 minutes.

The b7000 touchscreen adhesive is a versatile adhesive ideal for gluing screens to phone frames, repairing body parts and electronic components. B7000 has good adhesion, can be used for bonding glass, metal, plastic, ceramic, rubber, etc.

The B7000 is sold in 15 and 50 ml tubes. At the end of the tube there is a thin metal nozzle, through which it is convenient to apply a thin layer of glue, and a smooth metal pin is provided in the cap that prevents the glue from hardening in the tip. Full hardening time: from 24 hours to two days. The glue becomes plastic when heated to a temperature of 80 degrees.

VIDEO REVIEW

Example of work using touch glass adhesive

To glue the touch screen of a smartphone using TP-2500F glue, you must:

- remove the damaged sensor module, preheating it with a hair dryer (the glue seam does not lend itself to any chemicals, it can only be broken by heating.);

- carefully remove traces of the old adhesive;

- degrease all glued surfaces with alcohol;

- apply a small amount of UV loca tp 2500f (1.5-2 grams) in the middle of the module in the shape of the letter "X";

- place the touch module on the screen;

- press the touch glass with even efforts, distributing the composition between the parts to be glued;

- wait a few minutes for the gel to spread over the entire bonded surface;

- place the device under a UV lamp for 7-10 minutes (if there is no lamp, you can dry the module in direct sunlight - the fixation time will depend on the light intensity).

To achieve the strongest and most durable connection, the surfaces must be perfectly clean and the adhesive layer must be thin.

Attention! TP-2500F is aggressive, therefore bonding should be done with rubber gloves and goggles

To glue the screen to the smartphone frame using b7000 glue, you need:

- remove the damaged glass (for this, it should be evenly heated with a hair dryer to a temperature of 60-80 degrees);

- remove all remnants of the old adhesive, degrease and dry the parts to be glued;

- apply glue in a thin layer around the entire perimeter of the frame, wait one minute;

- carefully place the sensor module on the frame, press it slightly;

- fix the details (for example, with masking tape) and leave to dry for a day;

- remove excess glue (hardened smudges) with your finger by rolling.

It is recommended to use the product for its intended purpose 48 hours after bonding.

Theoretical part

Any material should start with theory. If you came here from a search engine by entering the query "how to replace the screen on a phone with your own hands" - new knowledge will definitely not hurt. If the purpose of reading the material is to obtain some new information, in addition to those learned earlier, this subheading need not be studied.

The touchscreen display of a modern smartphone is a complex device consisting of several functional elements. The main ones are the matrix and the touchscreen; frames, keys, backlighting elements and, of course, loops, in the amount of 1 to 3-4 pieces, can also be present.

Matrix - a liquid crystal or LED panel that houses an array of pixels that form an image. On the front side it is covered with a very thin layer of glass, on the back it has a stainless steel case. It is also equipped with a ribbon cable for connection to the board, it may have other small elements on it.

Touchscreen (sensor) - a transparent glass touch panel that covers the entire front of the smartphone. It is a thin sheet of glass (less often - plastic), on which a transparent layer of conductive material is applied on the inside, and oleophobic spraying on the outside (optional).

In some cases (recently - more and more often), the touchscreen and the matrix of the smartphone are one whole. They are delivered as a single module and change together. This design is called OGS.

OGS-screen (from the English one glass solution - a solution with one glass) is a type of smartphone screen in which the sensor and the matrix are connected together in the form of a "sandwich". A distinctive feature of OGS-matrices is a very thin layer of coating that protects pixels, since the main element of their protection is the sensor.

Whether it is possible to replace the phone screen on your own depends on the reader's ability to work with tools and the type of matrix. Some smartphones lend themselves very well to home repair, while with others - not even every SC master can handle it. What screens can be replaced even without experience, and which ones should be entrusted to a specialist, will be discussed below.

How to remove glue from skin?

Some people, after getting glue on the surface of their hands, try to apply mechanical action to get rid of sticky plaque, use sharp objects that easily injure the skin. Some take sandpaper, nail files, knives.There is an "Antiklei" agent on the market, which makes it very easy to clean the B7000 glue. Therefore, so that there are no problems, you need to buy this drug in a hardware store before changing the touchscreen, then the need to get rid of the remnants of glue on your hands will not be a problem. To do this, apply the product to a sponge or napkin and wipe your hands or body parts that have gotten glue.

Features of the B7000 application

B7000 glue is supplied in polyethylene tubes of different weights, which have a sharp tip, convenient for dosed and precise application. The operating temperature to which it is required to heat the glue to acquire plasticity is 80-100 C; after cooling, the glue acquires exceptional strength as a connecting layer, which is the reason for its universal application.

B7000

What is the sequence of repairing a broken glass of a smartphone or tablet, see the photo and instructions:

- heat the surface to the required temperature and separate the screen and glass surfaces from each other, this can be done using a special separator and wire;

- clean the contact surfaces completely before re-bonding;

- wait for complete drying;

- apply glue to the glass and wait a few minutes (to avoid smudges);

- you need to glue, carefully connecting the elements, then press firmly;

- roll the screen with a roller for a snug fit;

- leave the mobile device in a resting position for 24 hours;

- the device can only be used after 48 hours;

- Excess glue from the phone until complete polymerization is removed by rolling, the cracks are cleaned with a needle.

Bonding of plastic and decorative clay

Unique flowers and decorations are made by craftsmen from decorative plastic or, as it is also called, clay. Thin petals are glued, pretreated with acetone or another solvent. This is done so that after working with the material with your hands, there are no greasy prints on it. The finished fixed product can be used after the above time has elapsed, due to the fact that the glue is not toxic, plastic clay jewelry, rings, earrings are allowed to be worn even by small children, they can also play with them.

An important feature of the glue is its property of softening when heated, therefore, any decorative product can be disassembled and remade in a different form, which is very important for creative people.

Analogs of glue

There are similar adhesives that are produced by the same company in China and differ in some technical characteristics and name.

E-7000 and T-7000

E-7000 glue is positioned as a means for rhinestones and jewelry. It is sold in tubes of 10-50 ml, the price for the largest package is about 440 rubles. It is part of a new generation of epoxy-based adhesives, has high adhesion rates with all types of materials. E7000 is absolutely transparent, invisible even on thin light-colored fabrics.

Among other things, the product can be used for gluing other materials:

- glass;

- plastic;

- wool;

- metal;

- neoprene;

- ceramics.

The glue will probably come in handy in the house. Other areas of its use:

- nail design;

- repair of electronics, equipment, footwear;

- gluing photo frames and phone screens.

The fine needle-tip delivers the glue conveniently in small portions to avoid sagging. The composition is non-flammable, waterproof, the resulting seam is flexible, elastic. Drying time - 24 - 48 hours.

T-7000 glue can serve as a substitute for B-7000: they have the same basic purposes of use (gluing touchscreens, mobile communication modules). A distinctive feature is black color, which is convenient when repairing dark cases. T7000 is resistant to moisture and mechanical stress. When gluing, you can apply fixation with any convenient object or double-sided tape. The product is a complete analogue of the B-7000, only it is produced in black.

T-8000, E-8000 and B-8000

The T8000 sealant adhesive is virtually indistinguishable from the B-7000. It is widely used in everyday life, but its main purpose is gluing touchscreens. It works like double-sided tape but is much stronger. When repaired again, the T-8000 can be easily removed by heating and rolling. The setting time is 3 - 5 minutes, the final drying period is 24 - 48 hours.

E8000 glue contains acrylic, due to which it is more viscous than B-7000. Penetrates slightly worse into porous surfaces, but more resistant to external factors. E-8000 can also be used for joining glass, metal, fiberglass, brick, ceramics. Suitable for leather, rubber, wood, vinyl. A distinctive feature of the material - when heated to +100 degrees, the glue seam becomes soft, plastic, easily removed.

There is another tool on sale for sealing and gluing touchscreens with B-8000 frames. Designed to repair iPhone parts, guaranteed not to corrode surfaces. Glue B8000 is removed after heating with a hair dryer, it is absolutely transparent. The basic properties of the glue are similar to those of B-7000. The polymerization time is 48 - 72 hours.

E-6000 and B-6000

Materials of the 6000 series are the predecessors of new adhesives with indexes 7000 and 8000. E6000 is a universal adhesive for home, household and industrial use, it can glue the following products:

- rhinestones and metal fittings;

- felt, wool, other fabrics;

- stone and plastic.

The E-6000 is the most popular among hand-made craftsmen, widely distributed all over the world. Available in convenient packages - small, medium, large, the most cost-effective package is 110 ml. The product does not flow, leaves no residue, its consumption is very low. It sets quickly in the air, therefore it is recommended to glue the parts precisely so that they no longer move. Final polymerization takes place in 24 - 72 hours.

Crystal clear glue B-6000 is designed to work with mobile phones, jewelry, bijouterie. Contains acetone, as evidenced by the characteristic odor. The product contains epoxy resin, but its adhesive properties are enhanced by the presence of silicone. The glue line will be waterproof, vibration-resistant, elastic. Complete polymerization occurs in 48 hours. B6000 can dry out severely if stored improperly.

Obsolete V-5000 glue

The B-5000 brand is now out of production and has been replaced by newer materials. Previously, the B5000 was designed for gluing touchscreens with frames. Transparent, release form - 110 ml tube. The tool was distinguished by the need for a longer fixation - up to 20 minutes, otherwise the properties were similar.

Selection Tips

I would like to emphasize right away - when choosing glue, buy it only in specialized stores. This rule will be the same for any product, but with regard to the adhesive, especially

It is especially important to choose glue for expensive work - repairing your favorite gadgets

If you can purchase a B7000 for repair, this will be an ideal option, as you have already seen in the research process. However, you can also use analogs - B5000 or B6000. In the first case, the glue is a composition that has been used by electronics repairmen for many years, and the second type has the most frequent method of use - the restoration of jewelry.

Any of these three adhesives will allow you to get the job done with ease, taking precautions and meticulous work. An easy option for home repairs is a film, but you still need to select it by size or find a universal product

Similar adhesives

As with any other product, b 7000 glue has analogues. So a good option is to replace this sealant - this is a similar tool T - 7000, which is also suitable for use for gluing touchscreens. The difference is that the content is black, which allows the glue to be invisible on dark surfaces. But this product cannot be disassembled when heated.The tube also has a handy dispenser that helps to evenly distribute the required amount of glue. Its use is similar to the scheme of the previous version.

Analogue glue T-7000 (click to enlarge)

Analogue glue T-7000 (click to enlarge)

In addition to this instance, glue B - 8000 is deservedly considered an analogue, as well as special double-sided tape for these purposes. Multipurpose adhesive E - 8000 has industrial standards of reliability. After complete drying, it retains water resistance and plasticity, having a transparent structure.

It must be used only in ventilated areas to avoid toxicity.

As you can see from the instructions and from the experience of consumers, the 7000 glue is effective for repairing touchscreens and modular sensor technology. It creates an elastic anti-vibration film of soft consistency. Undeniable ease of use and strong connection of surfaces help repairmen to easily eliminate breakdowns of electronic mobile equipment, even if this action has to be repeated. In addition to repairing parts of mobile devices, glue can be used in handicrafts, joining fabrics, PVC materials, providing them with a strong and durable bond.

How to perform screen replacement

The biggest problem when replacing a touchscreen is disassembling your smartphone. This procedure is individual for each model, you may have to contact the manufacturer or download a detailed repair manual for the device (and such data is not always provided by the manufacturer).

Here are the basic steps to help you figure out how to change the touchscreen on any smartphone:

Step 1. Disassembling the phone. As a rule, most models of smartphones are disassembled in the same way: in one of the corners of the device (as a rule, in the place of the connector for charging or connecting headphones) there is a hidden, secret groove in which a bolt is hidden that fixes the case and the board. Unscrew it using a special small screwdriver.

Step 2. Removing the old screen. Next, you need to separate the broken screen from the control board. Before removing the shield from the module, disconnect all supply cables and loops. Then warm up the glass a little with a special or stationary home hair dryer. The maximum heating temperature should not exceed 90 degrees, otherwise it may damage the board itself.

note

Do not use open flame for heating - you will irreparably damage your device. When replacing a smartphone screen with your own hands, follow basic safety rules.

Step 3. Next, you need to fix the board. Basically, a special stand is used for this, but you can fix the phone on large yews, after wrapping the sponges with a soft cloth.

Step 4. Now you need to separate the glass from the touchscreen matrix. To do this, you can use thin synthetic floss, fishing line, and even dental floss. Using a metal wire will damage the die in this case. If you don't have any string, you can use a guitar pick or plastic card.

Step 5. Now you need to remove the old glue. For this, special degreasing agents are used that cannot damage the device board. Remains of glue are removed with a silicone sponge or synthetic cloth (cotton fabrics will not work, as they will leave lint).

Step 6. Apply the adhesive selected from the list above in an even, thin layer over the entire surface of the matrix. Apply the glass, after aligning it to all edges of the board, and press firmly for a short time.

Step 7. Let the glue dry, if necessary, fix the adhesion effect by irradiating the screen with an ultraviolet lamp.

Now the board with the new shield can be reinserted into the case. As you can see from the material presented, replacing the screen on a smartphone with your own hands is not such a complicated procedure.

note

Remember that in the event of any repair work on your phone, any warranty conditions and obligations from both the manufacturer and the store will cease to apply.

Other areas of application

Some people think that display glue is used only for gluing screens, but this is not the case. There are other areas in which such adhesives are used.

Bonding jewelry

Many craftswomen use B-7000 superglue, which dries quickly after being applied to the surface. Most often it is used when gluing plastic jewelry. To securely hold the products together, you will have to apply glue in several layers. One layer will not be enough, since such a seam can disperse with temperature changes.

Working with genuine leather

Super glues are often used when working with products that are made of genuine leather. Most often it is used to create leather wallets, belts, hairpins and jewelry. When gluing the skin, use the compositions E-7000 and T-7000.

Before applying the glue, the leather surface is cleaned with sandpaper and degreased to make the glue seam stronger.

Bonding of plastic and decorative clay

Many ornaments are made from decorative clay and plastic. When gluing plastic and clay products, adhesives T-8000 and B-8000 are used. Before gluing, the surfaces are moistened with acetone to remove fat from them.

Distinctive properties of analogues

Despite the similarity of properties of analogues with B7000 glue, there are still distinctive features. They differ in adhesion properties, that is, adhesion. Some adhesives provide good bonding between materials. Some are even better. They differ in composition, plasticity and speed of hardening. For some, it takes several hours to dry completely, while for others it is advisable to wait forty-eight hours. All of these distinctive properties, of course, affect the price of the adhesive.

When choosing an adhesive, you need to consider the purpose for which it is purchased. B7000 glue is similar in composition to the substance with which the screen of tablets and smartphones is initially glued at the factory level. Therefore, it is considered a product with high quality properties.

UV glue technology - monolithic structure and high reliability of the adhesive layer

When choosing a supplier and products, it is important to purchase high-quality glue for repairing touchscreens, which has not only the declared, but also the expected qualities. Only in this case, the repair will be successful, since in most cases, unsuccessful use can cause significant damage to the appearance and quality of the screen.

High-quality touchscreen repair glue

For work you will need:

- professional glue for touchscreen and display B7000;

- UV lamp for curing in the ultraviolet spectrum;

- small roller for rolling the glued surface;

With this little work package in place, you can successfully replace the display kit, assuring factory build quality. Such repairs will cost much less than purchasing a new screen and sensor. The only thing that can be advised is that the repair of gluing glass should be carried out by an experienced master.

Removing the glue to replace the touchscreen

If it is known that B-7000 glue was used to install the old module, then removing the used touchscreen will be much easier than with other similar tools. For repeated removal, the glass of the phone is heated up to 40 ºС, and it is simply lifted with a little effort. You need to heat it up gradually, directing a stream of hot air slightly to the side, so that the display glass does not crack. This property of the product is very valuable in comparison with factory counterparts. The glass remains intact in most cases, which makes it possible to reuse it in order to save.

Subtleties in the use of glue b 7000

When working with glue in 7000, the usual rules of use apply, as with similar compositions, but there are some nuances in joining surfaces.

The product is quite simple to use and is used according to the scheme that is attached to the instructions for glue b 7000:

- surfaces that need to be glued are pre-cleaned of the previous composition, dirt and dust;

- then the parts are thoroughly degreased and completely dried;

- after complete drying, you can start applying the required layer of glue. It should be borne in mind that before connecting the parts, it is reasonable to wait a few minutes, allowing the composition to harden a little (about 30 seconds) so that it does not fall into unnecessary niches with pressure. This action helps to avoid ugly smudges. Then the surfaces are evenly connected and pressed tightly together;

- pressed surfaces, leave for a certain time (dries in 24 hours) until completely dry. But it is recommended to use the glued product after two days in order to achieve a more reliable connection;

- it happens that during compression, an excessive amount of mass appears, but it is easy to remove it by simple rolling. You can also use a cotton pad dipped in acetone, which will cause the glue to gradually dissolve. And from inaccessible slots, excess can be removed with a needle or toothpick;

The instructions for use, printed on the tube, are available to any user and are easy to use.

Find out more in the video: