High-tech aluminum bonding with cold welding glue

Cold welding of aluminum is the connection of parts using a special adhesive mixture. Thanks to her, a reliable connection is obtained without heating the metal.

An epoxy compound acts as a bonding mixture. It is a thick mass that resembles mastic in consistency. Cold welding for aluminum consists of an epoxy resin saturated with metal powder. Due to its content in the resin, the strength index of the hardened composition increases. The glued area can be stronger than the material itself.

In addition to the main component (epoxy resin), there is a second component in the package. This is a special hardener, which, when mixed with "epoxy", reacts and the composition begins to harden. In a period of time from 10 to 30 minutes, the master must have time to apply resin to the parts and connect them. Next, you need to press the individual parts together for 15-20 minutes (in some adhesives, the fixing time for hardening reaches 40 minutes).

It is important to remember that both high-temperature and cold welding are harmful processes that require individual protection of the human body. When interacting with adhesives, it is necessary that the room is well ventilated, there is no open fire nearby

A respirator should be worn to protect the respiratory system. To avoid irritation of the mucous membrane of the eye, it is advisable to wear safety glasses. If epoxy is swallowed, go to the hospital immediately.

Adhesive mixtures have a number of serious advantages:

- There is no need to buy additional equipment and search for network connection points.

- Anyone can work with epoxy without any skills. The packages contain step-by-step instructions. The same cannot be said for welding with electrical equipment.

- The hardened adhesive forms a strong seam, which is slightly inferior to welding joints.

- The hardened formulations are resistant to corrosive processes, moisture, oils and fuels.

- After 20-60 minutes, a strong bond is obtained.

- Cold welding is considered an economical option for repairing a variety of equipment.

When using automatic welding machines, the metal to be joined is exposed to high temperatures and strong deformation. Cold welding is devoid of these disadvantages. However, the adhesive should not be used when repairing high pressure vessels and containers that are subject to frequent changes in environment (humidity, temperature).

What compositions will help

Aluminum can be fixed in different ways. They can be made from resin or polymers.

Resin based

Today on sale there are many means for fastening aluminum elements, which are made on the basis of resin.

Mastix

This compound helps to glue aluminum and restore various connections. The fixed elements are even able to withstand the effects of low temperatures. The product can be used on damp surfaces. The substance helps to quickly and reliably fix the elements.

Cosmopur 819

This substance is a polyurethane solution. It creates a viscous seam between the parts. The tool helps to deal with gaps. Also, with its help, it is permissible to glue the corners. The composition is allowed to be used for fixing structural and other elements.

Astrohim ACE-9305

The tool helps to cope with various breakdowns. Its use helps to achieve high strength of aluminum parts or alloys. The composition is capable of withstanding a wide temperature range.Cold welding with this tool helps to restore broken elements - for example, threads.

Epoxy Metal Moment

This is one of the most popular mixes and is a two-component formulation. The adhesive provides secure adhesion to aluminum and other metals. Also, with the help of a substance, it is possible to attach metal elements to glass, marble and many other materials. The composition helps to cope with cracks.

Abro steel

This tool is considered a universal composition. It can be used to repair household equipment. The adhesive is suitable for fixing liquid tanks. This provides an excellent seal. The composition helps to fix metal, ceramic, wooden elements. Also, the tool fixes products of different types.

Permatex Cold Weld

It is a two-component, heat-resistant agent made on the basis of epoxy resin. It quickly solidifies and is fireproof. The substance helps to stick together various materials, including aluminum. The composition is polymerized within a quarter of an hour. At the same time, it is able to withstand prolonged heating up to +149 degrees. The formed seam is very strong.

Titanium

This inexpensive product is characterized by high resistance to various mechanical loads. That is why glue is so popular with many craftsmen.

Wurth liquid metal

This cyanoacrylate agent is produced by a German company. It is considered the best solution for fixing metal surfaces of various elements. The composition quickly solidifies. Therefore, it is permissible to use it for quick repairs. The result is an inconspicuous seam. Thanks to this, it is possible to fasten not only metal. It is an excellent adhesive for transparent materials.

Cosmo PU-200

It is a two-component, high strength product that features a polyurethane base and does not contain solvents. The composition has excellent heat resistance parameters. He is able to withstand the influence of external factors. After complete hardening, the seam can be painted.

The composition is used for fixing gypsum fiber boards, wood, aluminum, laminate. With its help, it is possible to restore and fill the assembly seams. Moreover, their width should not exceed 0.8 centimeters.

Polyurethane mixtures

There are many effective polyurethane formulations on the market today. They all differ in composition and properties.

One-component

These products are made on the basis of polyurethane. They are solvent free. Such substances are used on exposed parts, which are first moistened with water. As a result, the substance reacts with the wet surface. As a result, the glue becomes hard. This helps to achieve a firm hold.

2-component

In addition to the polymer, the composition contains a hardener. Such products do not require the use of water. Typically, these substances are used indoors. These types of adhesives are resistant to oils, fungal microorganisms, and mold. They are also considered to be highly heat-resistant and highly elastic.

Cold welding

The adhesive is two-component substances made of epoxy resin and steel powder. The product can be produced in the form of a liquid or a mastic.

The use of modern technologies implies the addition of various additives to the composition. With their help, it is possible to increase adhesion and resistance to aggressive factors. Also, such components increase the operating temperature range. Sometimes such adhesives are superior in strength to the metal elements to be glued.

Advice

The main requirement when using acrylic glue is to observe safety precautions, even if it is a harmless composition.

- The presence of personal protective equipment is a mandatory item for working with this substance.

- Surfaces requiring gluing should be prepared for application of the composition, remove dust, dirt and other contaminants, that is, clean the old finish and thoroughly degrease with alcohol or solvent. The use of a primer is sometimes acceptable. In addition, the parts to be glued must be dry and tight, not contain loose elements. The glossy surface is treated with a fine abrasive.

- Works are carried out at a temperature of + 5º - + 35ºC, excluding direct sunlight.

- The dry mixture must be diluted in strict accordance with the instructions, preferably with water at room temperature.

- Excess mixture that appears on the surface should be immediately removed with a dry cloth, otherwise it will be very difficult to wash off the glue after drying.

How to use acrylic glue is described in the video.

Review of popular brands of professional glue

For those who do not know which brand of glue is better to choose, below is an overview of the most popular brands, with a brief description of their advantages and disadvantages.

Moment Super Epoxy Metal

Brand advantages:

- makes it possible to glue a metal part to surfaces made of a different material;

- tolerates temperature fluctuations well;

- affordable price.

Disadvantages:

due to its versatility, it has an average quality of adhesion of parts, compared to profile grades.

Maple-812

Semi-professional adhesive, the advantages of which include:

- versatility of application;

- low cost.

Disadvantages:

not recommended for gluing things that undergo periodic changes in shape.

VK-20

A heat-resistant substance with the following strengths:

- ease of use;

- good adhesion properties;

- withstands exposure to temperatures up to 1000 o.

VS-10T

Another heat-resistant compound capable of maintaining the quality of fastening of parts for up to 5 hours, with constant heating up to 300 o. Not expensive and sold in convenient, economical packaging.

K-300-61

This substance is difficult to find in the public domain for the average layman, since the glue belongs to the category of special means. It has high adhesion properties, for which it is so highly appreciated by specialists.

Weicon VA 110

One-component adhesive that cures when exposed to pressure and humid air. It reacts well to temperature extremes and has increased resistance to the effects of various chemicals on it.

Disadvantages:

price.

Strong steel stick renewal

An epoxy adhesive designed for the organization of quick repair of damaged areas, including damage partially or completely under water. Suitable for working with:

- concrete;

- metal;

- tree;

- ceramics;

- fiberglass.

Minuses:

very expensive.

Weicon RK 1500

A two-component, heavy-duty adhesive suitable for a wide range of materials, including glass and plastic.

Epoximaxx

Epoxy resin of various colors and consistencies, most often used to create:

- decorations;

- fillings;

- panel.

Can be used as a waterproof varnish.

Poxipol

Cold welding from the Poxipol brand, among the advantages of which they note:

- ease of application to the work surface;

- high speed of solidification;

- versatility.

Poxipol is non-flammable and does not contain any solvents.

Bison Super Glue Gel

Adhesive for installation work, famous for its versatility and high strength of the joint. It is a little expensive, but it fully justifies the money spent on its purchase.

Art etching

This type of electroplating method is quite popular nowadays. With its help, you can make author's drawings, engraving, art prints, ornaments on any metal blank.

And the result is a very clear, beautiful pattern. So to speak, a work of authorship that you can keep or donate.

The original image itself can be drawn independently or printed (using a laser printer) on paper. Next, stick adhesive tape on the surface and wash off the paper with hot water. As a result, the image should remain on the scotch tape. Leave to dry. In the meantime, it is necessary to prepare the metal surface on which the drawing will be applied - degrease it with alcohol.

Then glue the scotch tape with a pattern to the surface of the workpiece, while releasing air bubbles from under it. Excess glue and everything unnecessary, except for the image itself, is removed with a hot awl.

Etching is carried out in the same way that has already been described above - electroplating.

Attention: during this process, there is a possibility of the release of harmful gases, so it is better for people to leave the room. Thus, etching aluminum at home is quite feasible.

It is only necessary to follow all the most important precautions!

Thus, etching aluminum at home is quite feasible.

It is only necessary to follow all the most important precautions!

What glue is used for furniture edge

Most often used as furniture edges:

- melamine - made of decorative paper impregnated with melanin, has a self-adhesive layer;

- PVC edging - flexible tape of different profiles;

- ABS plastic is an environmentally friendly, impact-resistant border (chlorine free).

> In order to repair an edge made of polyvinyl chloride or ABS at home, use PVC glue or popular compounds marked "for PVC" - "Moment", "88-Lux" and others. They are convenient to use, quickly and easily fix the edge, inexpensive and safe.

If the repair is carried out by professionals, then they use hot melt adhesives, which become elastic after heating, and when cooled down, they quickly harden. This property is obtained from the thermoplastics included in their composition of ethylene-vinyl acetate. To use such glue for the edge, special equipment is required, therefore the composition is used in production, where the function is put on stream or is performed at home using a special glue gun. Kleiberit products are well known among professionals.

What glue is right

Manufacturers offer many varieties of adhesives suitable for bonding paper and cardboard. The composition of the funds is different, so they must be used correctly.

Glue stick

In children's creativity, this type of tool is often used. The advantage of the glue stick is that it:

- easy to use;

- economical in consumption;

- firmly glues different types of paper, cardboard, textiles.

The product does not stain the child's hands, it does not stain clothes.

A glue stick is used to temporarily fasten the sheets, to decorate the applique. Do not use the product for bulky crafts, since the parts will quickly move away from each other after drying.

PVA

This material is based on polyvinyl acetate, a substance with excellent adhesive properties. The harmless adhesive does not have a pungent odor. It is used for gluing natural material onto cardboard. During application with a thin layer of PVA, it prevents the paper from deforming. Already after 3-4 minutes, the glue dries partially, leaving no stains. The product is left for a day under a press for better bonding. The convenience of applying strips of glue is noted, since the product is packaged in bottles with a nozzle.

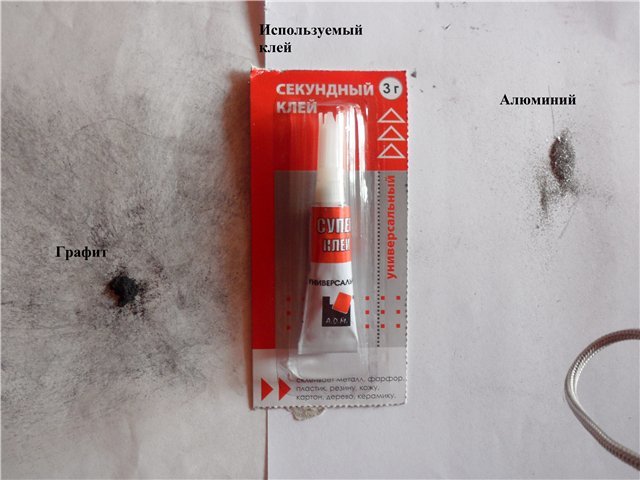

Super glue

The adhesion force of the cyanoacrylate substance, which is used for the manufacture of the adhesive composition, is great. The viscous mass grabs instantly, so you should connect the parts of the object correctly immediately. Then it will be more difficult to correct the situation.

The disadvantage of the material is that when gluing, you can connect the skin of the fingers. Then it is difficult to wipe off the pieces of glue from it. And the product has a pungent smell, so it is better to deal with the connection in a ventilated area or in the fresh air.

Gum arabic

The glue composition is made from arabic gum diluted in water. Its advantages are that it:

- harmless to human health;

- has a high degree of adhesion;

- reliable and gives strength to the seams to be glued.

It is difficult to obtain ready-made glue. More often it is prepared independently by mixing 10 grams of gum in 20 milliliters of water.

Acrylic

A feature of acrylic adhesives is that they hold together even thick cardboard with high quality. They produce glue in tubes, hence the convenience of applying the product. But since the base in the material consists of water, a large amount of the applied substance leads to deformation of paper crafts.

Dextrin

Previously, a paste made from flour or potato starch was used to glue paper elements. Now, in the production of dextrin glue, they act on starch with high temperatures. Within 1.5 hours in a cabinet that is heated to 160 degrees, starch is split and converted into dextrin. The resulting substance is dissolved in water and a little glycerin is added. The product is used for gluing paper.

Spray adhesive

The new glue-spray was highly appreciated, because it is evenly sprayed from the can onto the sheet. At the same time, there are no traces left on the hands, table, clothes. Quickly adhere when sprayed on fabrics, all types of paper.

Joiner

This type of glue is natural and differs in that it firmly adheres parts of the object.

It is important that the product is transparent. Long-term storage of a substance in a liquid state leads to the formation of mold inside the bottle

It is better to purchase the glue in the form of a brownish powder and dilute with water, slowly heating the mixture in a water bath. For 1 part of the substance, 2 parts of water are needed.

Photo glue

It is better to glue photographs into an album with rubber glue. Even after drying, if necessary, you can remove the photo, and clean the cardboard surface of the album with an eraser.

Home technology

To glue parts of a silicone product to each other, you need to follow the step-by-step instructions. Before starting work, the surfaces are thoroughly cleaned of dirt and dust, after which they are allowed to dry. The product to be glued is covered with a thin layer of adhesive solution and applied to the second surface.

Most types of adhesives dry at room temperature. It is recommended not to use the glued product within 24 hours after work. If the seam is uneven, it is allowed to separate the surfaces with chemicals and re-do the work.

Share link:

Types of glue and their manufacturers

Initially, two-component formulations were invented. They came with a primer, which was applied in a thin layer, giving backing before applying the adhesive (mainly cyanoacrylate composition). That is, the primer serves as a kind of surface solvent to create a strong joint.

The negative side of using such adhesive masses is toxicity. The primer, when interacting with polymers, releases substances hazardous to the body. It is not safe to use such connections at home.

The new type of glue is made from methacrylate. This is also a two-component mass, but without a harmful primer.

Manufacturers:

Weicon Easy-Mix PE-PP instead of a primer uses very small glass balls, which are distributed over the polyethylene, thereby increasing the wettability, adhesion. There are no toxic compounds, so the product is applicable in a domestic environment. Before applying, it is not necessary to clean the surface, only from strong dirt. The paste is ready to use, dosing and mixing takes place at the same time, there will be no error in the ratio.

BF-2 has a viscous texture of a red-brown hue. Possesses moisture resistant, inert, universal properties. The composition includes toxic aldehydes, phenol.

V-Strong GELIAHAO 302 is a two-component product based on acrylate. Provides increased seam strength. The consistency is transparent, hardening occurs in 4 minutes, so there is enough time for correcting.

Features of this method

The solutions used contain from four to ten percent sodium. The alkali pickling temperature is approximately 40-90 degrees Celsius.

If necessary, a moisturizer or special additive is used to obtain a light foamy coating on the workpiece.

The average temperature at the height of the process is sixty degrees. It is with such thermal indicators that a high-quality surface cleaning occurs.

The optimum purity indicators for aluminum are 99.5%, and the concentration of caustic soda solution is 10, 15, or 20%.

Thus, during the reaction, aluminum dissolves in sodium hydroxide, while hydrogen is released. As a result, a composite aluminate is formed, and it exists only in an alkali solution.

Rating of the best

The choice of glue for securing the elements plays a leading role in preparing for the creative process. Each needlewoman empirically chooses the most suitable and convenient glue for herself. But there are indicators and characteristics that distinguish some brands from others:

- Mod Podge PLAID - American-made. In the last 2-3 years, the analogue has been produced in China. When buying, check the manufacturer with the seller. The original glue is universal. It can be used for finishing metal, wood, cardboard, glass plastered and varnished surfaces. Mod Podge PLAID - Suitable for securing napkins, paper, fabric. In addition to adhesion of elements, it can be used as a topcoat. The composition can be removed within 15–20 minutes with soap and water. The final adhesion takes place within two days. Forms a matte finish. Packing price 236 g. From 1050 rubles.

- Decola is a Nevskaya Palitra manufacturer. Its cost is relatively low, therefore it is suitable for craftsmen with no experience to get their hands on. Universal compound, used for working with wood, metal, lacquered, leather, canvas, glass and ceramic substrates. used for adhesion of napkins, paper, fabric. Does not deform cardboard substrates. You can choose a glossy or matte effect. The cost of the bottle is 70 gr. - from 100 rubles.

- Olki is a versatile component that can be used as a topcoat. Creates a matte protective layer. Serves for fixing fabrics, paper, napkins on wood, metal, glazed and glass surfaces. Does not change color over time, does not crack. Packing price 33 ml. from 45 rubles. Olki decoupage glue varnish loses its properties at temperatures below –3⁰С. Consider this when transporting.

- Decoupage glue Ferrario LA DORATURA. It is used for coating substrates with hydrophobic properties. The glue is based on alcohol, which increases the drying speed up to 35 minutes. It is used for surface finishing with gold leaf and gold leaf. Does not require additional finishing fastening. The price of a tube is 75 ml. from 570 rub.

- Daily Art glue is suitable for the finest textures (rice paper, napkins). Easy to apply, forms an even layer without creases and irregularities. The combination of water and acrylic base allows it to be used to create crafts from glass, metal and plastic blanks. Available in matte and glossy composition. The cost of the bottle is 60 ml. from 150 rubles.

Epoxy adhesive: composition and properties

Epoxy adhesive epoxy is a synthetic thermosetting product. The product is a combination of the main element of epoxy resin and additional substances such as solvents, hardeners, plasticizers and fillers.

Solvents for epoxy adhesive:

- xylene;

- acetone;

- alcohols.

To obtain the highest quality adhesive material, it is necessary to take no more than 3-5% solvent in relation to the volume of dry resin. Since the solution is difficult to remove from the adhesive joint, the amount of solvent should not be exceeded.

It is important to consider that alcohols accelerate the hardening of epoxy glue.

Epoxy fillers:

- powdery components: aluminum oxide, carbon black, vanadium, beryllium and zinc oxide, aluminum or nickel powder;

- carbon and glass fibers;

- fabrics made of synthetic or glass fibers.

Esters of phthalic and phosphoric acid act as plasticizers. Experts recommend using oligomeric and polymeric plasticizers, using oligoamides and oligosulfides, since their use affects the physical and mechanical properties of the epoxy material, allowing them to regulate and improve the quality of adhesion.

With the successful connection of the necessary components, an adhesive mass should be obtained, which will have the following qualities:

- frost resistance - the glue can withstand temperatures up to -20 ° С;

- heat resistance - usually up to +250 ° С, depending on the filler;

- plasticity - the already hardened composition is elastic, therefore, with a slight displacement of the parts, the seam does not break;

- glue tolerates atmospheric, gasoline and oil exposure well;

- the product is resistant to cracks and shrinkage;

- under the influence of detergents and household chemicals, the glue does not decompose;

- water-repellent effect - the structure of the glue provides the details with high-quality waterproofing;

- good interaction with various surface structures.

Disadvantages:

the glue is not suitable for working with polyethylene, teflon and silicone;

in the work you need to be extremely careful, since the composition hardens very quickly and if flaws are detected, it will be incredibly difficult and costly to fix them;

it is important to observe safety measures in working with the material, since if it gets into the eyes or on the skin, it will be very problematic to wash the glue.

Results with the considered method

It was experimentally recorded that a solution of caustic soda, with its intensive use in the process of etching, begins to "absorb" aluminum. And this happens until the amount of caustic soda decreases to one fourth of the original volume. And after that, the process will continue with free caustic soda, fluctuating in its quantity. And this, in turn, depends on the temperature, frequency of use and the intensity of stops (pauses).

In this case, the hydrate will slowly sink into the sediment or form crystals at the bottom and / or on the sides of the container. The resulting hydrate will be dense enough to be difficult to remove. Sometimes it just strives to settle right on the surface of the heating coils.

There is another important point regarding the aluminum content. During etching of products made of this metal in caustic soda, it is necessary to strictly observe the ratio of the amount of aluminum and soda. Because the more aluminum there is, the slower the process itself will be. From the point of view of practice, it becomes clear that it is necessary to constantly increase the amount of caustic soda as the amount of aluminum in the container increases.

Thus, the process of etching aluminum with alkali can be continued continuously. And the loss of caustic soda will occur only due to its entrainment with steam.

This method is really applicable from the point of view of practice. But there are several nuances that should not be forgotten: from time to time, remove the hardened hydrate precipitate; clean the filter; remember that the container in which the process is carried out, with its constant use, can serve no more than two years.

For the rest, no complications were found regarding the use of this method.

In total, after chemical etching of the aluminum billet, its surface must be thoroughly rinsed, neutralized and clarified with a 15-20% solution of nitric acid.This process is called pickling.

Review of popular brands

There are eleven popular manufacturers of rubber mixtures, whose products are most often used.

Rubber cement

It is a high quality compound made from natural rubber mixed with solvents. Rubber Cement is most commonly used to bond elastic products. After drying, the glue layer resembles rubber in its consistency.

4508

People who are interested in waterproofing products should pay attention to 4508. It is used in the manufacture of products made of rubber

4508 does not lose its properties on contact with water and therefore can be used when repairing wetsuits or rubber boats for fishing. Among the disadvantages of the funds are the fact that it quickly ignites if it is near a fire.

88 CA

It is a versatile adhesive that is used for bonding metal, wood, glass, concrete, fabric and plastic surfaces. 88 CA is resistant to temperature changes, so it can be used at temperatures ranging from minus fifty to plus sixty degrees. Store 88 CA in dark rooms, protected from children.

Loctite

It is a one-component adhesive mixture that only begins to cure at room temperature. Therefore, experts recommend using Loctite only indoors. Suitable for gluing wood, metal, plastic and rubber surfaces. The advantage of Loctite is that it hardens in 10-15 seconds after use.

"Gum"

Fans of elastic products should turn their attention to "Gummi". It is used in the repair and manufacture of products from durable fabric or rubber.

Also "Gummi" is suitable for gluing cardboard, paper, wood and natural leather. Among the advantages of the glue are resistance to low temperatures and high humidity.

"Radical"

People who are going to repair a wetsuit should use Radical. It is ideal for restoring water supplies as it is highly resistant to moisture.

"Mark A"

Such a tool is used during the manufacture of rubber or leather shoes, bicycle tubes and tires. "Grade A" contains components that exhibit increased adhesion to glass, leather, wood, rubber, paper and foam rubber. Resistant to low temperature and high humidity values. Thanks to this, it is used both indoors and outdoors.

88n

It is a yellowish homogeneous mass in which there are no foreign inclusions or lumps. 88n is recommended for bonding materials such as plastic, leather, rubber, wood, ceramics, glass, porcelain and paper. The mixture hardens within ten hours after application. During long-term storage, a little sediment may appear in the liquid, but it does not affect the properties of the glue in any way.

GOST 2199-78

According to GOST, adhesives made from natural or synthetic rubber can be used in several areas of activity. They are used in the manufacture of leather furniture or footwear. Also, glue is often used to make rubber products that are often in contact with water.

Plasti Dip

Such a product is made on the basis of an aqueous emulsion containing bitumen-type polymers. Plasti Dip is used for bonding thin rubber materials, paper or wood. The composition is durable and shock-absorbing.

Rubber cement

Rubber cement is often used to restore rubber products. It is often used to repair punctured inflatable boats, bicycle tubes or mattresses. The advantages of Rubber cement include fast solidification, reliability and resistance to moisture.

The best choice for decor

A large selection of materials for decorative techniques makes it possible for everyone to find something to their liking.

And here it is important to decide on the glue to create unique crafts, pleasant gizmos for the whole family.

Glossy Accent by Range

Many people use non-toxic and transparent glue when working with various materials: paper, cardboard, glass, acrylic. It is convenient to use the composition by gluing bulky decorations in the form of buttons, beads, artificial flowers to the products.

Universal polymer

The main advantage of the polymer adhesive is that it can glue any surfaces. Even thinly applying the product, you can achieve the strength of the resulting product.

Professional binding

The water dispersion agent is produced by the "Decor Factory" company. The glue is based on synthetic white resins. The glue is intended for bookbinding. It is used in decorative crafts, gluing paper, cardboard, glass, plastic. If you dilute the product in water (30 grams of glue per 10 grams of water), then it can be used using decoupage technique.

Typographic

Bookbinding glue is sold in powder form. It is diluted with water and used for:

- gluing the spines of books;

- creating notebooks, brochures;

- weave books.

Apply adhesive solution in scrapbooking, applications. It has a high adhesive power. In addition, the composition can be easily washed from hands, brushes, and does not stain the paper.

Tacky glue original

An absolutely harmless product makes it possible to use not only paper, but also ceramics and fabric in crafts. The economy of the glue is noted. After working with it, no yellowness remains on the products. Paper parts do not get wet and do not warp after the composition dries. Packaged in tubes, the product is easy to use.