How to remove the film

As soon as the bark of the wounded skin is fully connected with the film, it must be safely removed; there is no need to reapply the adhesive mixture. No effort is required to remove the film. There are several ways to remove it:

The film can be perfectly disposed of with water. First, you need to wash your hands thoroughly to prevent infection from entering the wound. The area near the wound should also be washed with soapy water. The dry film layer is softened with hot water. Then fresh glue is applied to it to soften the old layer. The soft agent is very easy and painless to remove.

Also, since the product is based on ethyl alcohol, it can be removed with an alcohol-based liquid.

It is necessary to blot a cotton swab in an alcohol solution and carefully wipe off the remnants of the film.

Acetone is another aid for getting rid of drug residues. The product is moistened with a cotton swab and gently applied to a dry film

However, this option is not suitable for people with sensitive skin.

Instructions for the use of Desmokol

Where and how is Desmokol glue applied?

This adhesive has an extremely wide range of applications. It is used for fastening:

- PVC parts;

- any kind of thermoplastics;

- polyurethane;

- rubber.

In the manufacture and repair of shoes, glue is also used for stitching. With its help, polyurethane and PVC soles are often attached to fabrics. It is also great for bonding metal, glass, plastic and leather.

How to properly glue shoes with Desmokol?

The instructions for use of this adhesive product say that the surface must be properly prepared before using it. Preparation involves the following steps:

- first, all dirt must be removed from the surface;

- after that, the remnants of the old adhesive mixture are removed from the material;

- additionally, the coating must be treated with fine-grained emery paper;

- at the final stage, it is necessary to degrease.

After that, using a hair dryer or any other heating device, you need to heat the treated surfaces to + 80 ° C and press them firmly against each other.

A high-quality adhesive product immediately forms a strong bond that does not require the use of clamps, vices and other weights for auxiliary compression. You can use sealed shoes after 24 hours.

How to pour and how to dilute the glue?

Polyurethane glue Desmokol can be poured from a canister or jar into any plastic bottle. But at the same time it is necessary to screw the lid tightly, because pressure is generated in the container, which will not lead to rupture of the container.

If preference was given to a granular product, then pure acetone must be prepared to dilute it. The components are mixed in a ratio of 1:10, i.e. in 200 ml of acetone, add 20 g of adhesive granules.

Dilution should be carried out at an air temperature of + 25… + 30 ° C. The granules are placed in acetone and left in it for 6-8 hours. During this period, the granular product should swell completely, forming a solution with a non-uniform consistency. The working mixture must be thoroughly mixed so that it becomes liquid.

Instructions for repairing rubber shoes at home

To glue rubber shoes in a domestic environment, you must first prepare the surface of the product to be treated. The place of damage on the wading boots is wiped dry and, if possible, degreased with acetone. Directly gluing shoes is performed according to the following step-by-step instructions:

- The damaged area is compressed so that the porous surface of the material is outside.If this is not done, the shoes will not be able to glue well.

- A thin layer of solution is applied to the surface, wait 5 minutes and repeat the procedure. Then the joint is connected by pressing it with the application of force.

- Leave the shoes for a day, since this time is necessary for the EVA glue to completely dry.

In the process of repairing rubber shoes, it is imperative to apply glue in thin layers. An excessive amount of mortar will reduce the quality of setting of individual parts of the material.

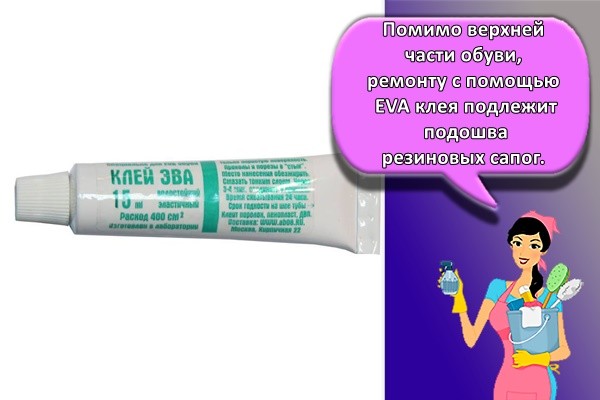

In addition to the upper part of the shoe, the sole of rubber boots is also subject to repair with EVA glue. To restore the structure of the sole and eliminate the detected damage, the area is processed on a specialized sharpening machine to ensure smoothness. Since the use of a patch in this situation is impractical due to the risk of rapid wear, it is preferable to use an adhesive solution. It is applied to the damaged area and a silicone shoe sealant is applied on top. After waiting for the substances to dry completely, you can continue to use rubber boots without fear of quick wear and getting wet when in contact with water.

When treating the sole of rubber shoes with EVA glue, it must be borne in mind that the anti-slip characteristics of the solution are insufficient. To compensate for this disadvantage and comfortable operation of the shoe, it is recommended to glue only minor damage or restore only special ribbed soles, which are characterized by increased grip on the ground.

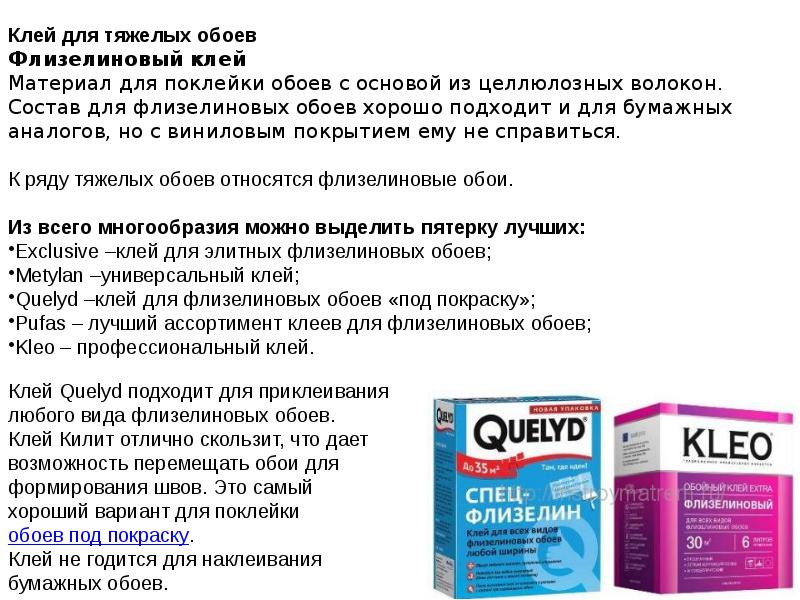

Desmokol shoe bonding technology

To use Desmokol glue, you do not need special skills and abilities. You can easily make a fairly strong connection yourself. To do this, you need to study the instructions for use on how to glue with Dismakol.

It consists of several stages:

- Initially, you need to prepare the work surfaces. To do this, they are cleaned of dirt, dust, plaque. Next, they need to be degreased. Wipe with a cloth soaked in gasoline or acetone.

- To achieve a high adhesion rate, you need to go over the working surfaces with fine sandpaper.

- Shake the container with glue. Apply an even layer of adhesive to the surfaces to be joined. Wait 10 minutes.

- Apply a second layer of adhesive. Wait another 10 minutes.

- Heat the prepared parts with an industrial vein to 80 degrees. Force to squeeze them together.

- Wait 5 minutes, release the glued product.

Dilution of glue

If the adhesive was purchased in the form of granules, it is necessary to mix it correctly with a solvent so as not to spoil the substance. This requires the purchase of pure acetone. Then the liquid is mixed with dry granules - 200 ml of acetone and 20 grams of dry matter.

After mixing, wait 8 hours. Further, the mixture must be thoroughly stirred to obtain a homogeneous solution.

Storage and handling of adhesive

In order for Desmokol glue not to deteriorate ahead of time, to retain its properties, it is necessary to adhere to some rules.

These include:

- The temperature range for storage is from 20 to 25 degrees Celsius above 0 ° C.

- Shelf life without violating the integrity of the package, in compliance with the temperature regime - 12 months.

- It is strictly forbidden to store the packaging near heating devices, open sources of fire.

If the integrity of the packaging has been broken, you need to buy a new adhesive.

Alternative uses

CMC glue is used not only for wallpapering walls. Due to its high adhesive characteristics, this product is used in various sectors of the national economy.

Construction

CMC is added to tile mortar, gypsum or cement putty. This glue is mixed into the mortar used for laying foam blocks or aerated concrete.

Manufacturing of finishing and building materials

Glue is mixed into clay or cement, gypsum mixture in the manufacture of finishing building materials.CMC increases the strength of the finished product and improves its performance characteristics.

Chemical industry

In the paint and varnish industry, CMC is used as a thickener. Carboxymethyl cellulose is the basis for the manufacture of facade and various water-based paints. This substance is used in the production of various synthetic detergents.

Mining of oil and gas

Carboxymethyl cellulose is used as a stabilizer for highly mineralized clay suspensions. This substance is used as a regulator of the properties of drilling fluids when drilling oil and gas wells.

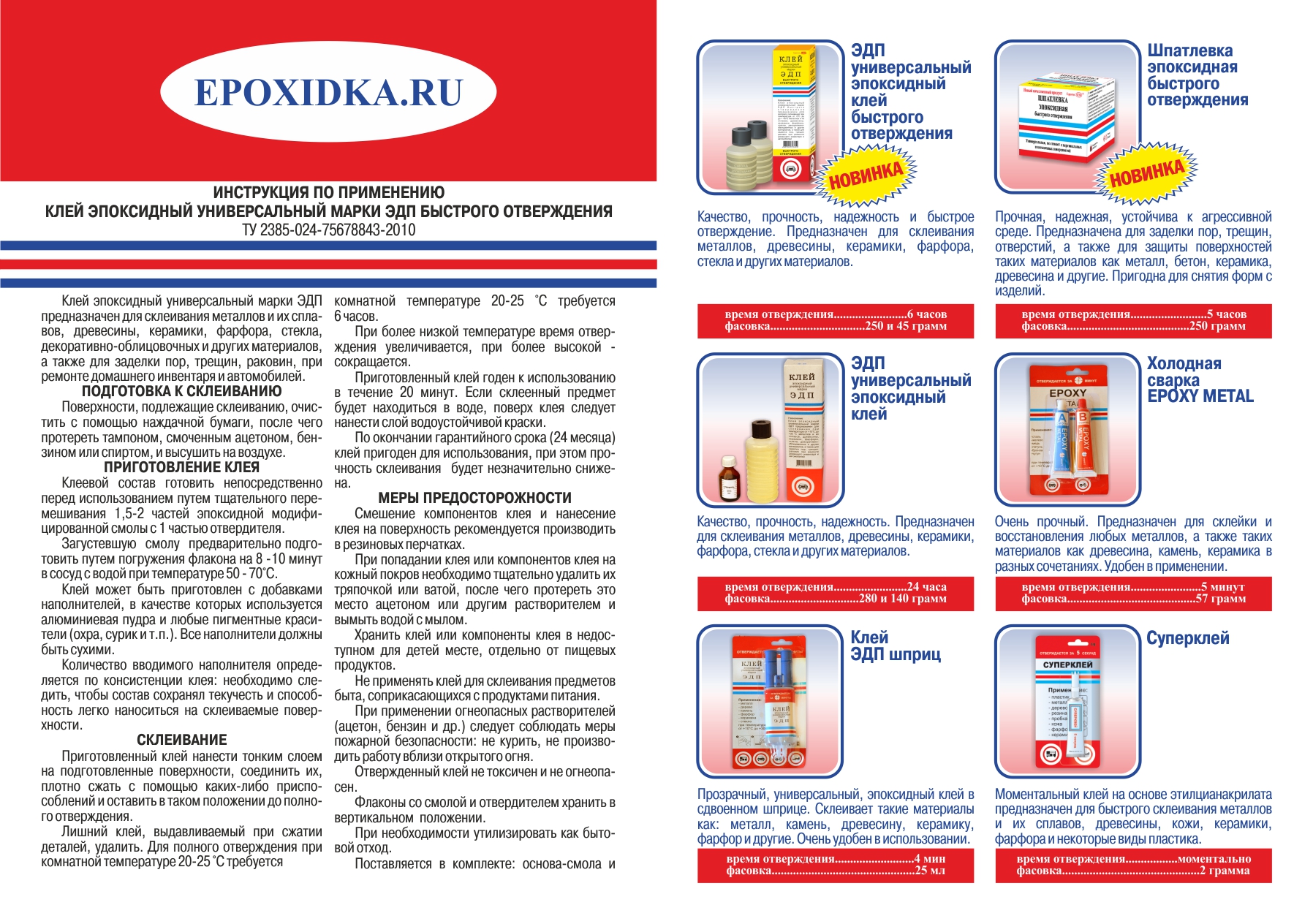

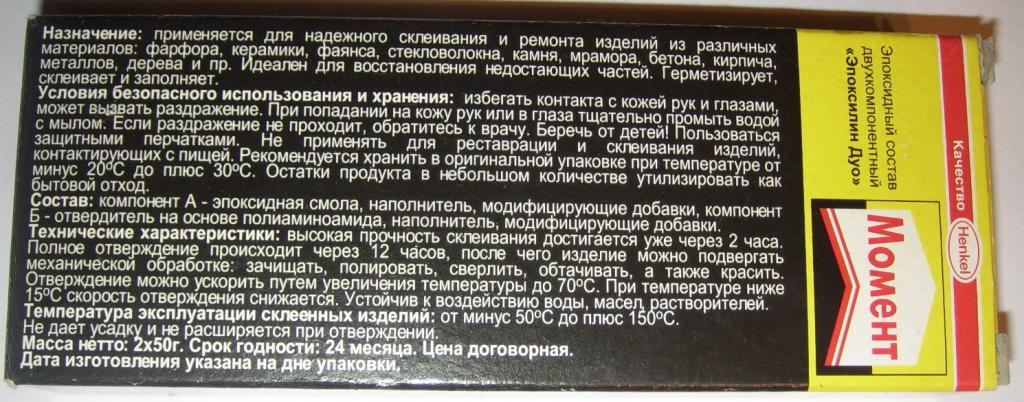

Instructions for use

In order to correctly use epoxy glue of a universal class, the instructions for use for it must be carefully studied. Only with strict compliance with it will the work be carried out at the highest level. The process itself is carried out in the following stages:

- Preliminary preparation of surfaces. They are cleaned with sandpaper, degreased.

- After the working surfaces are completely dry, the gluing process begins. An adhesive base is being prepared. The resin is mixed with the supplied hardener in a strictly specified proportion (in the classic version, 1 part of the hardener is used for 10 parts of resin). The catalyst is carefully added to the resinous substance and thoroughly, slowly mixed.

- The working surfaces are lubricated with an adhesive mass. Then they snuggle tightly against each other.

- The glued surface is fixed and left motionless until the mass is completely polymerized.

It takes a certain amount of time for the glue to cure completely.

Precautionary measures

As a rule, polyurethane compounds have a weak effect on the skin, but stronger on mucous membranes. Being neutral substances, they do not cause allergies either.

However, precautions should be followed

If the composition gets on the skin, wash it off quickly with soap and plenty of water. If an allergic reaction is observed, it is necessary to consult a doctor.

In shoe production, more serious precautions should be taken: wear a respirator, transparent glasses, work in overalls. The room must be periodically ventilated and ventilated.

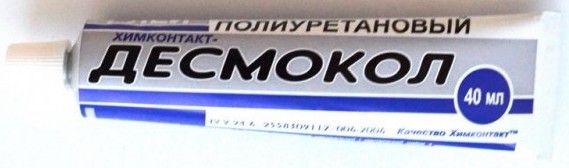

Glue "Desmokol": instructions and reviews

Description and purpose

The adhesive mixture of the French company KLEO was developed for high-quality application of wallpaper on walls. The company is considered the best in the construction market, offering quality and affordable products. A large assortment makes it possible to choose the right composition that is suitable for the selected type of wallpaper.

In order not to be disappointed with the work done, it is worth approaching the choice of materials with responsibility. There are several types of Cleo wallpaper glue: for non-woven, paper and photo wallpaper. Professional craftsmen most often use glass wallpaper glue.

> On sale the adhesive mixture is presented in a package of 250 g. The powder is protected by two sealed bags and a cardboard box, which does not allow moisture to penetrate inside. The glue is diluted directly before gluing the wallpaper on the wall on its own.

The main feature of Cleo is the ease of application and ease of use. After the glue-based solution has completely dried, there are no foreign smells and stains, and the walls are protected from the development of fungi and mold. The prepared solution can be stored for 10 days in a hermetically sealed container.

Instructions for the use of "Desmokol"

There are three ways to apply polyurethane glue to the surface and glue the parts.

- The usual way. The surfaces to be glued are cleaned and degreased, after which a thin layer of glue is applied to them. After 10 minutes, the procedure is repeated two more times and the surfaces are pressed against each other.

- With heating. The cleaned surfaces are lubricated with an adhesive and after 10 minutes they are heated with a hair dryer to 80 ° C.

- Wet way.The surfaces are thoroughly cleaned and moistened with water. Glue is applied in a thin layer, the parts are squeezed and placed under a press. The resulting grip will be the tightest and most reliable.

What rules must be observed when working with Desmokol glue and how to pre-process the glued surfaces, the author of the site figured out

To achieve a reliable connection of surfaces, which allows you to provide your favorite shoes with a second life, is possible only by thoroughly cleaning the parts from dust and dirt, old glue, and pieces of material. After cleaning, the surfaces are treated with sandpaper and degreased.

When the preparatory work is over, glue is applied to the parts with a layer of 2-3 mm and the composition is allowed to dry for 7-10 minutes. If the material to be treated is too porous and the adhesive has completely absorbed, you can apply an additional layer and wait a little again. As a result, the adhesive layer should dry out and not stick to your fingers.

Desmokol glue for shoes will provide the best connection if heated to 80 ° C. For these purposes, you can use an industrial or home hair dryer, as well as other heating devices. The heated surfaces are pressed against each other as tightly as possible. Usually, high-quality glue does not require the installation of additional weights or clamps, but some craftsmen use some kind of weights for safety.

Shoes can be put on one day after the repair.

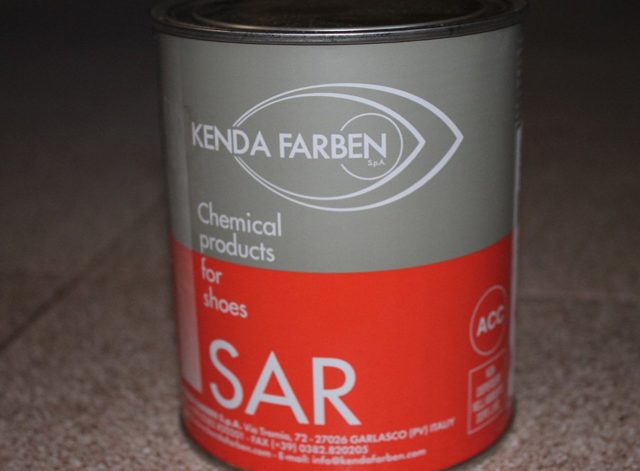

Characteristics of the adhesive

Desmokol or SAR-306 consists of polyurethane resins in an organic solvent. The composition includes additional modifying additives, which makes it possible to use it not only for repairing shoes, but also for other products made of polymer materials - boats, for example, a water mattress, and so on.

Shoe repair

However, first of all, the tool is intended specifically for repair and has all the necessary qualities for this.

- The composition is completely transparent, so that after repair the seams and joints are invisible to the eye.

- The polymer composition is not afraid of moisture in any form, so it can be safely used when repairing shoes, rubber boats, fishing boots, PVC products, and so on. Moreover, it can glue wet materials - up to 25%.

- Desmokol shoe glue for shoes is distinguished by excellent frost resistance, since an organic liquid acts as its solvent. The material does not absorb moisture and is therefore insensitive to frost.

- The glue seam retains its elasticity, so that boots and boots after repair will still be comfortable to wear.

- The disadvantages of the material include its flammability: like any other composition based on an organic solvent. He burns.

It is very easy to work with the composition, you just need to follow simple instructions. It takes some time for the glue to dry, therefore, if it turns out that the glued parts are not connected correctly, it is always possible to correct their relative position.

Glue in a tube

Desmokol is produced in different forms:

- metal tubes with a volume of 50 ml;

- liter metal containers;

- Euro bucket - 20 l;

- metal barrels - 200 l.

The adhesive is stored in a sealed package at temperatures from +10 to +25 C. It is impossible to leave the material near heating devices or other heating devices. The shelf life after opening the package is 12 months.

Composition and characteristics of glue

The glue "Desmokol" contains polyurethane resins, organic solvent and various modifying components. This tool is widely used in the repair and manufacture of shoes. Due to its ability to reliably bond various types of surfaces, the glue is used to adhere the upper part made of leather or fabric to the sole made of polyurethane, PVC, rubber or thermoplastic. When molding PVC soles, Desmokol glue is also added, which significantly increases the strength of the joining of materials.

The adhesive composition has many advantages over other similar substances.

- The glue is completely transparent, therefore, after the repair, the connection point is invisible, which allows you to completely restore the original appearance of shoes or other products.

- Polyurethane adhesive is water resistant. With this tool, you can glue surfaces with a moisture content of up to 25%. Desmokol glue is often used to repair rubber boats, hunting and fishing equipment.

- The universal adhesive does not collapse in the cold and does not crack under the influence of heavy loads.

- It is convenient to work with glue, since it takes some time to completely dry it, which means that it is possible to adjust the gluing site if necessary.

- Durability and reliability of the connection. The two materials glued together by Desmokol make up a single whole.

- The seam turns out to be not only strong, but also elastic, without excessive rigidity.

On sale, glue can be found in different packages and conditions. For home repairs, small tubes of 50 ml or jars with a capacity of 1 liter are most convenient. On an industrial scale, drums of 20 or 200 liters are used.

There is glue in the form of granules that you need to dilute yourself with a solvent. The cleaner the solvent, the higher the quality of the adhesive.

Specifications

Compared to other similar products, polyurethane "Desmokol" is a glue that has higher reliability and ductility and is capable of repelling water.

The composition is available in the form of a gel or granules, the volume of the package may also differ:

- tubes (minimum volume - 50 ml);

- metal cans with a capacity of 1 liter;

- eurobucket (volume 20 l);

- barrels with a volume of 200 liters.

Granular glue will need to be self-thinned with a solvent before use. In this case, the quality of the resulting composition will directly depend on the purity of the solvent.

Analogs

BF-6 glue has been used in medical practice since the middle of the last century. And although it is a unique remedy for wound healing, there are several drugs with a similar effect on the modern pharmaceutical market:

- Liquid bandage "Doctor Goodman". The product is produced in the form of an aerosol consisting of a liquid polymeric substance. In contact with the skin, it has an antiseptic and wound healing effect.

- Bandage "Pentazol". The form is similar to the previous product. It accelerates the healing process of wounds and disinfects the affected skin.

- It should be said that these two agents do not form a film on the surface of the epithelial tissue. But the medicinal substance 3M Cavilon, although it is produced in the form of an aerosol, but, like the BF-6 glue, forms a transparent film over the wound, thereby reducing the risk of infection to a minimum. The advantage of this product is the absence of ethyl alcohol in its composition. Therefore, when applied to the skin, there is no burning or tingling sensation.

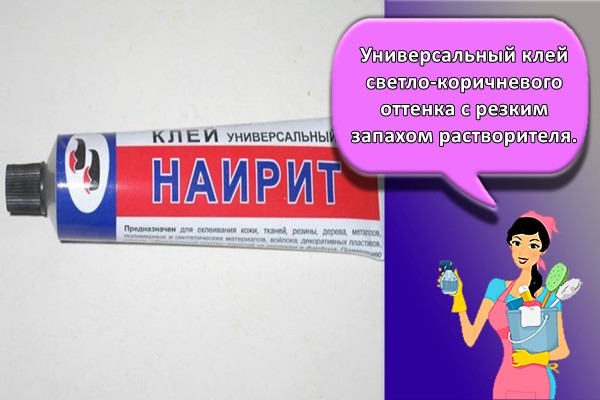

Material characteristics

In shoes, with prolonged wear, the sole often comes off. This is due to the rupture of the nylon threads with which it is sewn. In repair shops, for restoration, nairite (shoe) glue is used - a one-component material. Chloroprene rubber (nairite) is used in its production. It looks like a translucent resin, its color is light yellow. Also included are:

- organic solvents;

- iron salts;

- chlorinated polymers;

- vulcanizers.

The glue can be used to treat the seams on shoes - it is water-repellent and prevents the product from getting wet. After the film dries, there are no toxic substances harmful to humans. At the same time, the sealing of the gluing site is excellent. Usually adhesives of this type are sold in large containers, but many brands are presented in small tubes. Shoe masters prefer products from Poland and Italy. Much cheaper, but lower quality Turkish-made compositions.

Here are the main characteristics of nairite glue:

- the share of non-volatile components - 24%;

- density - 0.85 g / sq. cm;

- delamination index - 62 N / cm during the day;

- maximum opening time - up to 65 minutes;

- reaching the maximum strength of the adhesive layer - 190 minutes;

- heat resistance - 75 degrees.

Instructions for use

For reliable adhesion of parts, it is necessary to first clean the glued surfaces from dirt and dust, material residues. After that, the surfaces are cleaned with sandpaper and treated with acetone or alcohol. There are three different ways of gluing surfaces using Desmokol glue.

- The easy way. A thin layer of adhesive is applied to the surfaces to be glued, after 2-3 minutes the operation is repeated, after which the surfaces are pressed against each other with maximum force.

- Wet way. The surfaces are moistened with water, after which Desmokol is applied with a thin layer and the parts to be glued are placed under a press or clamped with clamps.

- With heating of the glued surfaces. The surfaces lubricated with an adhesive composition are kept for 10 minutes, after which they are heated with a hairdryer to 80 ° C and also clamped with clamps.

Professionals say that the best results are obtained after using the wet method. After using any of these methods, it is advisable not to use the product earlier than 24 hours.

Varieties, composition and technical characteristics of wallpaper adhesives

Chemical enterprises produce their own type of CMC for different types of wallpaper. The characteristics of each are indicated on the label or packaging. In any composition of the base substance, there must be at least 50 percent, and the proportion of sodium chloride must be 21 percent. The moisture content of the mixture is up to 12 percent. The solubility of the powder is 96 percent.

CMC differ in composition and percentage of carboxymethyl cellulose. Almost all manufacturers produce universal glue that can be used to glue all types of wallpaper. For each finishing material, its own solution is prepared, in which water is taken in more or less quantity.

For light thin wallpaper

For the thinnest paper wallpaper, it is recommended to use KMTs Burny, KMTs-N, KMTs-1 (Shaving). In shape, the glue is a powdery substance of white or pink color, without any smell. Before use, the powder is diluted in water according to the instructions for use. The adhesive solution applied to the surface dries for a long time. During the period of the repair, they make sure that there are no drafts in the room.

Middle weight

Non-woven wallpapers are considered slightly heavier than paper ones. For their gluing, KMTs-N or KMTs-N Super-Max, Mini-Max, Extra Fast are used. This product is a fine granular powder. The packaging must indicate the type of wallpaper for which the adhesive is used. Any glue is diluted with water according to the instructions.

Thick heavy wallpaper

The inil wallpaper is considered the heaviest. For pasting the surface with thick wallpaper, KMTs Super strong is used. For pasting the surface with thick wallpaper, KMTs Super strong is used. leaving the adhesive, sometimes PVA glue is added. Externally, glue for heavy wallpaper looks like a white pulp. Before use, the product is diluted with water at the dosage indicated in the instructions.

Manufacturer

The manufacturer of the Cosmofen product is the Weiss company from Germany. The Russian analogue of "Cosmofen" is the "Rezolen" glue, which has the same scope as "Cosmofen".

Rezolen glue is chemically resistant to alkalis, acids, oil products, sea water. The operating temperature ranges from -60 ° C to + 280 ° C. The maximum operating temperature is + 320 ° C. It has high abrasion resistance and elasticity. The form of sale is a package of 50 ml.

Another worthy analogue is the Rtline glue, which is widely used both in everyday life and in industrial production.Due to its similar composition, properties and quality characteristics, it has the same wide range of applications as Cosmofen and Rezolen.

Desmokol characteristics

Finished dry joints remain transparent and moisture resistant. Desmokol glues wet surfaces (no more than 25%), this confirms its effectiveness in the repair of inflatable rings, mattresses, boats, bicycle cameras. The formed adhesive film is not afraid of severe frosts and ensures the tightness of the coating during temperature changes.

The glued joint remains elastic and durable even under mechanical stress. You can correct the position of the parts until the seam is completely dry. If the parts are glued indoors, it must be ventilated or with a working ventilated system.