Safety engineering

All work related to the use of cyanoacrylate glue must be performed outdoors. Indoor work is only allowed with forced ventilation.

Do not allow the glue to come into contact with the skin, eyes, digestive system.

The glue that has dried in the tube must not be squeezed out by force, otherwise an uncontrolled stream of the product may get into the eyes. In this case, the spout is gently pierced with a pin (preferably a hot one).

Do not tear "glued" fingers by force or cut with a knife. This will only damage the skin. For such cases, acetone (or a similar agent) applied to a napkin is used. The acetone will soften the glue, but not instantly. This will take some time (in difficult situations up to an hour).

It is strictly forbidden to wear cotton clothing (in particular gloves) when working with glue. When the glue comes into contact with the cellulose of the tissue, a reaction occurs with the release of a large amount of heat. This can cause burns.

Application area

The properties of the glue allow it to be used in different areas and industries:

At home, the mass is able to connect all non-porous surfaces, including rubber, to insulate wires

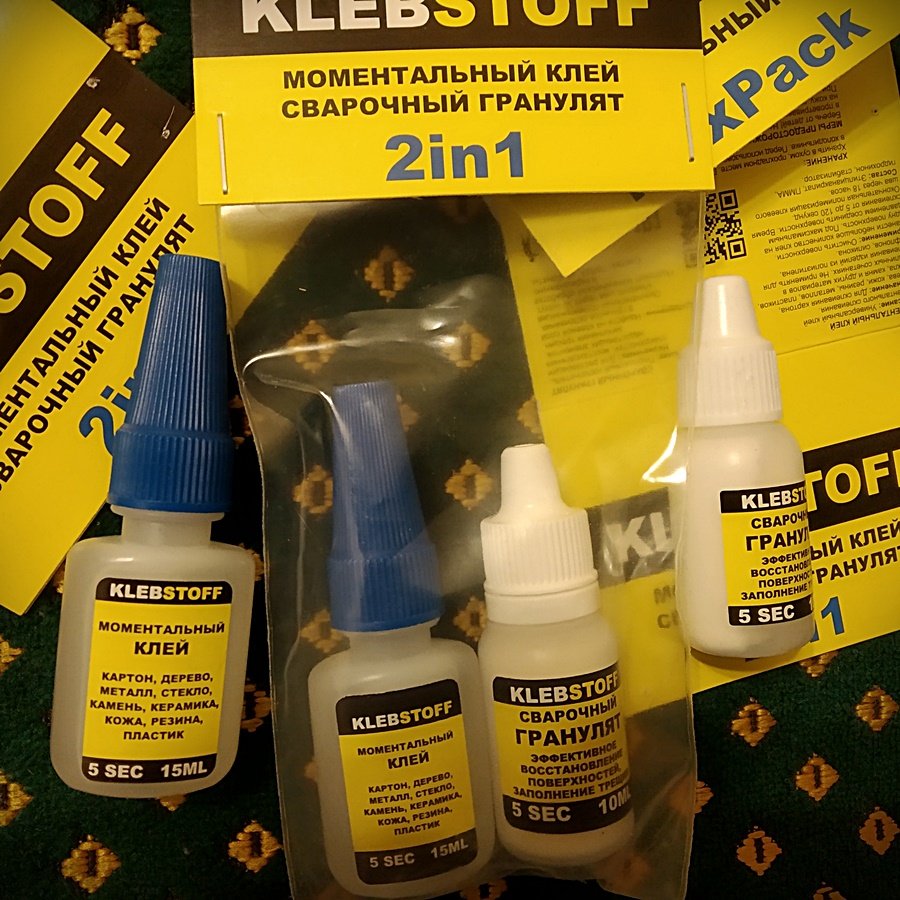

For a more durable grip, you need to pay attention to the brand of the product.

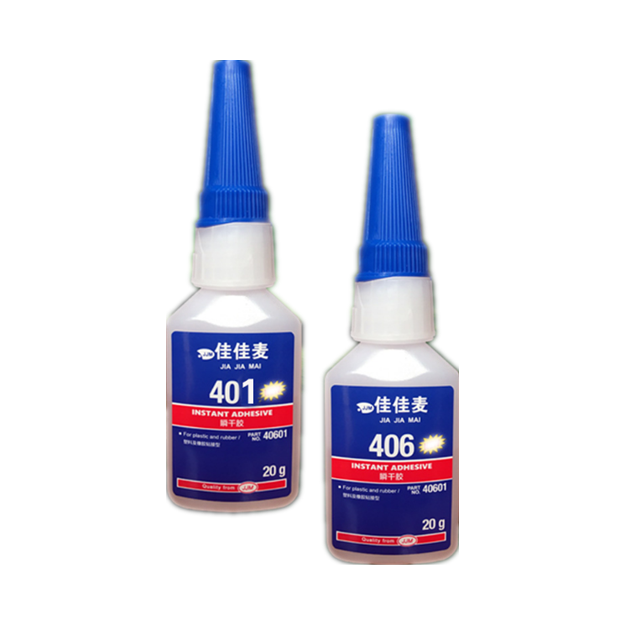

Industrial insulation of wires. For this, universal products or CK Loctite 406 brands are used.

In instrument making, parts are glued together, damage is repaired.

The garment industry uses glue to bond fabric, leather, and foam materials.

It is used in cosmetology for nail and eyelash extension

But at the same time, the mass must contain acrylic. In this case, the application of the mass will not cause deformation of the nail and for removal it is enough to apply an organic solvent. Also, cyanoacrylate glue is used by nail design masters.

Useful video on the topic:

Cyacrine glue: features and composition of the substance

Cyanoacrylate adhesive is characterized by a high level of adhesion to a wide variety of surfaces. All this is possible thanks to the copolymers that are part of any cyanoacrylate two-component adhesive. Each manufacturer has its own unique glue recipe, as well as the secrets of its manufacture. This information is kept secret from competitors. The main feature of such adhesives is the ability to perfectly hold surfaces together, even materials that differ in quality and structure. These reagents are also characterized by a long service life.

The main component of the glue is cyanoacrylate

The glue is based on cyanoacrylate and acids derived from it. They can reach up to 99% of the total volume. The composition of the glue also includes plasticizers and thickeners, which give it additional properties such as water resistance, heat resistance, adhesion. In order for the adhesive to withstand vibration better, abietic acid is used in combination with glycerin.

Cyanoacrylate is designed for bonding hard, porous and even elastic surfaces that can be in any position. The main active component of the glue can be various monomers:

- ethyl ether shows itself perfectly on a variety of materials and practically does not wear out;

- methyl ether promotes adhesion of metals and duroplasts;

- butyl ether is an ideal substance for use in the medical field and special equipment;

- propyl ether is sometimes necessary for bonding metals and various elements exposed to high temperatures;

- compositions based on alkoxy ether do not have an unpleasant odor, but this is achieved by reducing the reliability of the compounds by 20-30%.

If the atmosphere is too cold or dry, an adhesive activator must be used.

The principle of operation of the cyanoacrylate based adhesive is that it begins to set when exposed to ordinary water or weak alkali. When gluing with a very thin layer of the substance, the setting process can occur without the participation of the cyanoacrylate glue activator.

This is interesting: How to calculate the consumption of water-based paint per 1 m2?

How to dissolve and dilute?

You can simply wipe off the superglue stain. This can be done if the fabric is strong enough and does not break. The remaining parts can be removed (washed off) with white spirit. This allows small particles to dissolve on the fabric and thereby eliminate the powdery adhesive layer. But it so happens that the adhesive is on the hands or somewhere else on the skin.

The usual solvent for paints and varnishes, kerosene, gasoline, vegetable oil, alcohol is useless to try. The simplest solution is to wait a few days. Then the cyanoacrylate will come off by itself with normal washing. Acetone can be used as a cleaner, but you need to be careful when removing glue from the body, plastic or other organic materials.

Problems when paying with bank cards

Sometimes, when paying with Visa / MasterCard bank cards, difficulties may arise. The most common ones are:

- The card has a restriction on online purchases

- A plastic card is not intended for making payments on the Internet.

- The plastic card is not activated for making payments on the Internet.

- There are not enough funds on the plastic card.

In order to solve these problems, you need to call or write to the technical support of the bank in which you are served. The bank's specialists will help you solve them and make the payment.

That's basically it. The whole process of paying for a book in PDF format on car repair on our website takes 1-2 minutes.

If you have any questions, you can ask them using the feedback form, or write us a letter at

Properties and specifications

Today, the production of cyanoacrylate glue is carried out by many well-known companies. Their main property is high adhesion to a large number of surfaces: wood, glass, metal, plastic, rubber. It is also worth noting that such compositions are absolutely not affected by water, oils, gasoline or various alcohols.

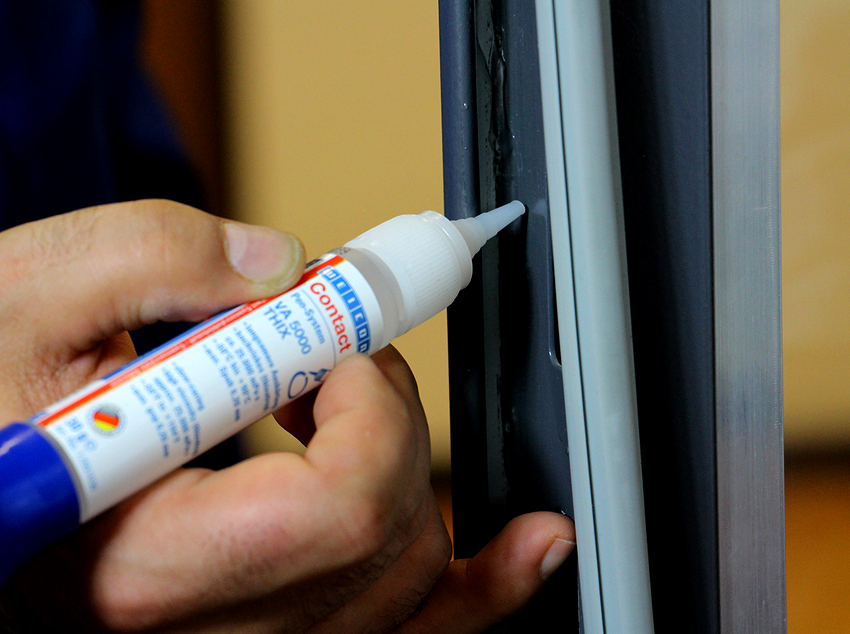

Cyanoacrylate adhesive works well with gaps of less than 0.1 mm. It can be used for gluing tight surfaces. However, there are high viscosity formulations that are suitable for working with gaps of about 0.25 mm, while their consumption per m² is about 300 g. If it is necessary to close a large gap, usually Cosmofen or CA-4 is used.

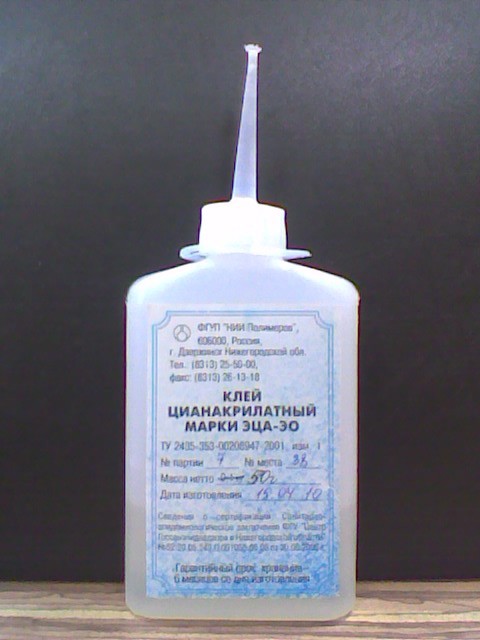

The technical characteristics of cyanoacrylate glue determine the scope of its use.

State. It is a dense mass with a high degree of viscosity. Many options are transparent.

Package. It is sold in a fully sealed container.

The package contains instructions for use with a description of precautions.

Solidification. At room temperature and low humidity, the curing process takes place within a few seconds.

With an increase in humidity, this process is carried out almost instantly.

Temperature range. All one-component and two-component cyanoacrylate compounds can withstand temperatures from -60 to +80 degrees. Special heat-resistant compounds are capable of not losing their qualities even at temperatures of +250 degrees.

Considering cyanoacrylates, it is also necessary to indicate their advantages and disadvantages.

The positive aspects include:

- very fast solidification (within a few seconds);

- reliable grip of the connected elements;

- fixing different materials to each other;

- ease of use;

- invisible seams;

- the ability to use on porous, inclined planes;

- there is no need for lengthy surface preparation.

You also need to be aware of the cons:

- difficulty working at high temperatures;

- cannot be used to join Teflon or silicone surfaces;

- not suitable for gluing parts that will subsequently have a large fracture load;

- large gaps cannot be filled with such glue.

This is interesting: Fiber cement panels for exterior decoration of the house - convenience and practicality

Cyanoacrylate: properties

Cyacrine glue is a mixture with high adhesion to glass, metal, ceramic, wood, polymer, fabric, cardboard and rubber surfaces.

Good adhesion to vulcanized rubber and galvanized products. Cyacrine is inert to most organic substances on gasoline, oil, alcohol and other such bases.

When working with him, one should not forget about safety measures. Before gluing, be sure to wear a respiratory mask, gloves, glasses to avoid harmful effects of the agent on the epithelium and mucous membranes.

Why are such actions necessary? Cyanoacrylate adhesive can be harmful to health. If the composition accidentally gets on an open area of skin or mucous membranes, it will destroy tissues, leaving wounds.

Its fumes cannot be inhaled, because they are poisonous to the respiratory tract. Therefore, protective equipment, overalls, room ventilation are the main conditions for safe work.

Specifications

All joints bonded with cyanoacrylate are very strong. They are resistant to the influence of the atmosphere and mechanical stress.

The main technical characteristics include the following:

- Physics of composition. By consistency, it is a thick one-component mixture. Colorless, has a high viscosity. It is sold in sealed packaging with data on the end date of use. There are detailed instructions indicating the necessary safety measures for correct operation.

- Solidification. It should be cured at a temperature of 18 ℃ to 25 ℃ for a couple of minutes. In rooms with high levels of humidity, the curing process is much faster.

- Temperature variations. They retain their characteristics at temperatures from -60 to +80 degrees. A special mixture is used for the operation of the glued product in case of serious temperature extremes. It will not lose its properties for a short time in the intervals from -200 ℃ to + 300 ℃. However, under prolonged temperature loads, even such cyanoacrylate will lose its adhesive properties.

Advantages and disadvantages

Cyacrine glue is resistant to any organic solvents and has good electrical insulating properties. It interacts with many materials, but it cannot be used for bonding polyethylene and fluoroplastic.

It is quite ergonomic, as it is consumed very slowly. This is evidenced by the reviews of those who have already worked with cyacrine. Such compositions harden very quickly. It usually takes just a couple of minutes to secure the seam securely.

Among the cons are:

- relatively high price;

- slight fragility;

- low impact resistance;

- instability during long-term storage;

- high adhesion to human skin, so work can only be carried out in protective equipment.

Scope of use

Cyanoacrylate glue is used in industry, construction and everyday life. They are used to connect parts in the electronics and instrumentation industries in order to carry out an effective repair of any type of equipment. It can also be used as an alternative for soldering boards and microcircuits.

Thermal conduction properties are appreciated in the manufacture of thermistors and transistors.The assembly of plastic and metal-plastic structures is carried out with him. In the sewing industry, fabric, leather and foam materials are reliably bonded with cyacrine glue.

It connects well plastic parts, and even colored ones, where the appearance of the glued product is especially important. Cyanoacrylate holds the seam for a long time, does not allow its destruction, and withstands the influence of external conditions.

How to dissolve and dilute

Before work, it is necessary to take responsibility for the preparation of the workplace, since there is a high probability of glue getting on the surface that does not need to be glued.

It must be remembered that without damaging the surface, it will not be possible to remove or dissolve the dried mass; mechanical interventions will be required.

You can remove the composition from the plane with a sharp knife blade, while you need to be careful to less scratch the surface. The rest of the material is wiped off with white spirit

If the skin of your hands is dirty, then you need to wait until the crust dries up and begins to peel off. After that it is necessary to remove the frozen layer from the skin.

The inertness of cyanoacrylate prevents the adhesive from interacting with gasoline, oil and solvents.

Often in the instructions for the glue, Dimexidum is mentioned as one of the means for removing the glue. But with this tool you need to behave carefully, as it is of an unpleasant odor, toxic.

Terms of use

Cyanoacrylate glue is very easy to use; no special skills are required to work with it. Gluing is recommended as follows:

- the bases must be washed and cleaned (drying is optional, moisture serves as a catalyst for the polymerization process);

- a thin layer of glue is applied to one of the surfaces;

- the parts to be glued are quickly connected and held in the required position for a few seconds.

It is recommended to use the thing after gluing not earlier than in a day.

But you always need to observe safety measures: glue "Sekunda" based on cyanoacrylate quickly sticks the skin together. Before starting work, you need to stock up on gloves (just not from cotton fabric, which provokes a thermal reaction) and a solvent. Dimethyl sulfoxide, acetone or nitromethane can be prepared as a solvent.

In case of contact with the skin and sticking of fingers, one of these solvents can be used to wet the formed film or quickly dilute the hardening mass with it to prevent the hardening process, and then mechanically remove it from the skin. If the eyelids are stuck together (this happens if mistakes are made during eyelash extensions), you can use dimethyl sulfoxide in a diluted form (1 part of the drug to 10 parts of water). When removing the cyanoacrylate compound from the face, keep the eyelids tightly closed and avoid getting the solution into the eyes.

Solubility

Methyl cyanoacrylate (the base of the most common and cheapest adhesives) dissolves slowly in water and is not waterproof.

Ethyl cyanoacrylate does not dissolve in water, ethanol and many other substances, but, on the contrary, instantly solidifies in the places of contact with them. Dissolves in nitromethane in cyanoacrylate removal fluids. In liquid form, we will readily dissolve in acetone. It dissolves well with acetonitrile.

Also, to obtain a glue seam of high water resistance, propyl cyanoacrylate is also used, which is significantly more expensive.

Cyanoacrylates dissolve well when exposed to concentrated dimethyl sulfoxide (DMSO); the solution can be removed with an absorbent material. DMSO, freely sold in pharmacies (inexpensive drug "Dimexid") and not aggressive towards materials common in everyday life, completely dissolves the glue seam filled with it in a few hours without mechanical stress. To remove cyanoacrylate, the commercially available Secunda glue remover, the so-called anti-glue (based on propylene carbonate), is also effectively used.

Features of choice

Today the construction market offers the buyer a wide selection of various adhesives of the cyanoacrylate type. The choice of this or that option will be determined by the features of the surfaces that need to be glued.

Cyanoacrylate second adhesive demonstrates high adhesion to a variety of materials. For example, they are very effective when working with metals or glass. However, according to the manufacturer's instructions, such a product cannot be applied to polyethylene and fluoroplastic.

The use of low-viscosity products gives a person the opportunity to obtain high-strength adhesive seams, provided that the surfaces are well joined. In other words, they do an excellent job with gaps of no more than 0.05 mm.

Substances with high viscosity are mainly used for bonding parts with a gap of up to 0.3 mm.

Kernil glue, belonging to this group of adhesives, is a new generation substance. Its innovative formula provides the surfaces to be bonded with the highest possible strength, which is why it is often used for bonding PVC boat fabrics.

Features and Benefits

Cyanoacrylate glue is classified as a universal compound capable of joining even materials and substances of dissimilar structure.

Its main advantages are:

- fast hardening;

- high reliability of connections;

- long-term operation of the seams;

- stable quality of the material itself.

Weaknesses include:

- restrictions on operation with significant clearances;

- unsuitable for all joints that are exposed to fracture;

- destruction of the joint at a temperature of 100 degrees;

- inability to connect silicone, polyethylene, tetrafluoroethylene, polypropylene;

- dissolution in acetone.

Most other organic solvents will not damage cyanoacrylate adhesive. It adheres well to a wide variety of surfaces and is consumed in relatively small portions. The composition does not have allergic properties and is a dielectric.

Varieties of Permabond

- Permabond 735 is black in color with improved impact and tear strength. It can be used to join steel, aluminum, rubber, plastic.

- Permabond CSA accelerates hardening, shapes the edges and bonds porous surfaces. Manufacturers offer this composition in the form of aerosols, so it is convenient to apply it to the surfaces to be glued.

- Permabond 2010 is recognized as an ideal bonding agent for porous surfaces, and is also suitable for bonding inverted and vertical materials.

- Permabond 2011 does not flow, suitable for joining difficult surfaces. In particular, it is perfect for sculpting from various materials or, for example, for restoring elements of kitchen utensils. Just imagine how ugly a shiny smudge looks on your newly glued favorite teapot. With this composition, its formation can be easily avoided.

- Permabond 4 C20 is a one-component, easily pressure-cured to form a thin film between the parts to be joined. Designed for high speed production line applications to increase productivity. It can be used to glue various plastics, metals, rubber used in the manufacture of medical equipment.

As you can see, there are a lot of varieties of composition. In particular, they are pleased with their wide functionality. Therefore, in any life situation, you can choose exactly the option that will be optimal for connecting parts. And if in some cases ordinary PVA glue is suitable, then during complex restoration work you cannot do without cyanoacrylate, because it reliably fixes the parts with a guarantee that they will be able to perform their functions for a long time.The main task of the buyer is not to fall for a low-quality counterfeit, since recently a lot of cheap substitutes have been sold, which, at the most, are able to glue a couple of sheets of paper. In this case, we are not talking about any wood and even more so metal. Purchase the composition only in a trusted hardware store.

Application

Cyanoacrylate adhesives easily bond non-porous and water-containing materials. They set in less than a minute, and the maximum tensile strength is achieved in a few hours. However, the shear strength of the adhesive bond is low, so superglue is sometimes used as a thread lock or for fixing a workpiece on a lathe.

Octyl 2-cyanoacrylate - the least toxic of cyanoacrylates - is used for medical purposes to seal wounds and to stop bleeding. During the Vietnam War, it was used to provide first aid for injuries. Despite the potential toxicity, it does not irritate the damaged areas of the skin and tissues, and is used by many with success at their own peril and risk to seal cracked heels, wounds, and stop bleeding after injections. In this case, you need to apply a drop of glue, and, pulling out the needle, immediately after applying the drop to the injection site, press it with a sterile napkin. The technique is effective for non-clotting of blood due to the characteristics of the drug, injection errors or the state of the body, in which half an hour of application of an alcohol swab does not stop bleeding due to persistent passivation of the injection tunnel by the flowing drug. When pressed, the tissue paper instantly adheres, creating a round plastic patch. Excess paper is neatly torn off along the contour, pressing with a finger on the stain itself (so as not to rip this "patch" along with the rest of the napkin). After a few days, the napkin will fall off as the skin regenerates. In rare cases, a burn is possible, since the adhesive on the napkin during the polymerization process can become very hot. It may be worth pressing down with a piece of ice or a cold spoon. Solves the problems of long-lasting healing skin lesions, for example, burns on the bend of the finger, glues cracked nails.

Cyanoacrylate vapors are used to detect fingerprints on objects. The method gives good results, especially when using cyanoacrylate vapors in a vacuum chamber.

Tips and tricks for using Moment cyanoacrylate glue

When working with cyanoacrylate glue, it is important to strictly adhere to the instructions and personal safety rules. All gluing operations must be performed only in a well-ventilated area, since glue vapors are very toxic, poisonous, and violation of operating conditions can cause great harm to health

Cyanoacrylate adhesive should not come into contact with the skin and mucous membranes.

Before using the reagent, you must read the instructions that are in the package, because different types of glue are designed for gluing certain surfaces

It is important to pay attention to the indicated storage terms and conditions, as well as the peculiarities of use.

When working with Moment cyanoacrylate glue, you must adhere to the instructions and personal safety rules

The process of using glue looks like this:

- It is imperative to clean and dry the surfaces to be glued.

- It is necessary to apply the adhesive in a uniform and uniform layer on one of the sides to be joined.

- For better adhesion, the parts are fixed for a while; for better effect, you can place them under the press.

Cyanoacrylate adhesive has excellent technical properties. Thanks to him, the adhesion point turns out to be strong, even when joining materials that are different in structure. It is used at various stages of work, it can be used even after the completion of the assembly of the structure.Cyanoacrylate is designed as a versatile product to meet a variety of needs. On sale there are colorless and colored reagents, compositions of instant and long solidification

It must be remembered that finding how to dissolve cyanoacrylate instant glue is an extremely difficult task, so you need to work with it very carefully.

Downloading the book

After successfully completing the payment (in any way) and returning to the KrutilVertel store from the payment system website, you will be taken to the successful payment page:

The book you bought will be in your personal account, from where you can always download it.

Please note that after making a payment, you need to go back from the payment system website to the KrutilVertel website. If for some reason you did not return back to the site and closed the tab of the payment system with a message about the successful passage of the payment, let us know - we will send you a letter in which you will be given access to download the book

If for some reason you did not return back to the site and closed the tab of the payment system with a message about the successful completion of the payment, let us know - we will send you a letter that will indicate access to download the book.

Application area

The scope of use of cyanoacrylate glue is quite wide; it is used when it is necessary to quickly and firmly connect materials, various parts and parts to each other. The optical transparency and economical consumption of most cyanoacrylates significantly expand the scope of their application in industry, assembly and everyday life:

- cyanoacrylate is used to join parts in the instrumentation and electronics industries, for the purpose of repairing radio, electrical and optical equipment;

- can be a good alternative to soldering when fixing microcircuits and boards;

- heat-conducting adhesives are used in the manufacture of transistors and thermistors;

- effective when assembling structures made of plastic and metal-plastic;

- it is used to join fabrics, artificial and natural leather, foam rubber, creates a connection while maintaining peel strength;

- suitable for quick assembly of products and joining of plastic parts, including on surfaces of rich and bright colors, where appearance is of great importance.

Cyanoacrylate holds the seam, resists destruction for a long time, is resistant to mechanical stress and negative environmental factors.

Adhesive mechanism

"Superglue" is a liquid monomer of some cyanoacrylate (methyl-, ethyl-, etc.) with the possible addition of up to 10% of plasticizers (for example, dibutyl phthalate in glue Cyacrine), activators (with insufficient joint moisture), stabilizers, retarders, as well as ultradispersed silicon oxide for thickening (gel superglue); the adhesive does not contain solvents.

Liquid cyanoacrylate is capable of anionic polymerization under the action of weakly alkaline agents, including ordinary water. The solid hardening of "superglue" in thin layers (within 0.05-0.1 mm) is caused by moisture adsorbed on the glued surfaces or contained in the surface layers of the material (which, along with the effect of animal amines, explains the excellent sticking of fingers). The harmful solidification of the glue mass during storage in a loosely closed container is caused not by the evaporation of the solvent, as in the case of nitrocellulose glue or PVA, but by the effect of atmospheric moisture (as is typical, for example, of silicone sealants); during production, the glue is sealed in a dry atmosphere. Also, according to the manufacturer's descriptions, there is an alkaline cure mechanism associated with neutralizing the acid stabilizer.

For working with cyanoacrylate in thick layers, an amateur method is known with sequential filling of the seam with baking soda moistened with superglue and playing in this case the role of not only a filler, but also an alkaline polymerizing agent. The mixture hardens almost instantly, forming an acrylic-like filled plastic, and in some cases it can successfully replace epoxy compositions, including those reinforced with fiberglass, but safety measures should be taken due to the toxicity of the resulting mixture. Also, finely ground plaster or concrete can be used as a filler, for example, dust obtained when drilling holes in such materials.

Although the initial adhesion of the adhesive occurs in a time from seconds to minutes, for the final set of strength, manufacturers prescribe the exposure of the joint in air without working load for several (up to 24) hours. In the initial state, the glue is almost inactive, and can remain liquid for a long time, and begins to act only after mechanical compression.