Areas of application of "Bustilat"

The glue is used for arranging various coatings inside the house, if a strong fixation of finishing materials is required. Due to its elasticity, the glue seam will serve for a long time, because it is not subject to destruction by vibrations, vibration, mechanical stress. The tool is perfect for such bases:

- concrete;

- wood;

- bricks;

- Fiberboard, chipboard;

- stone;

- plaster.

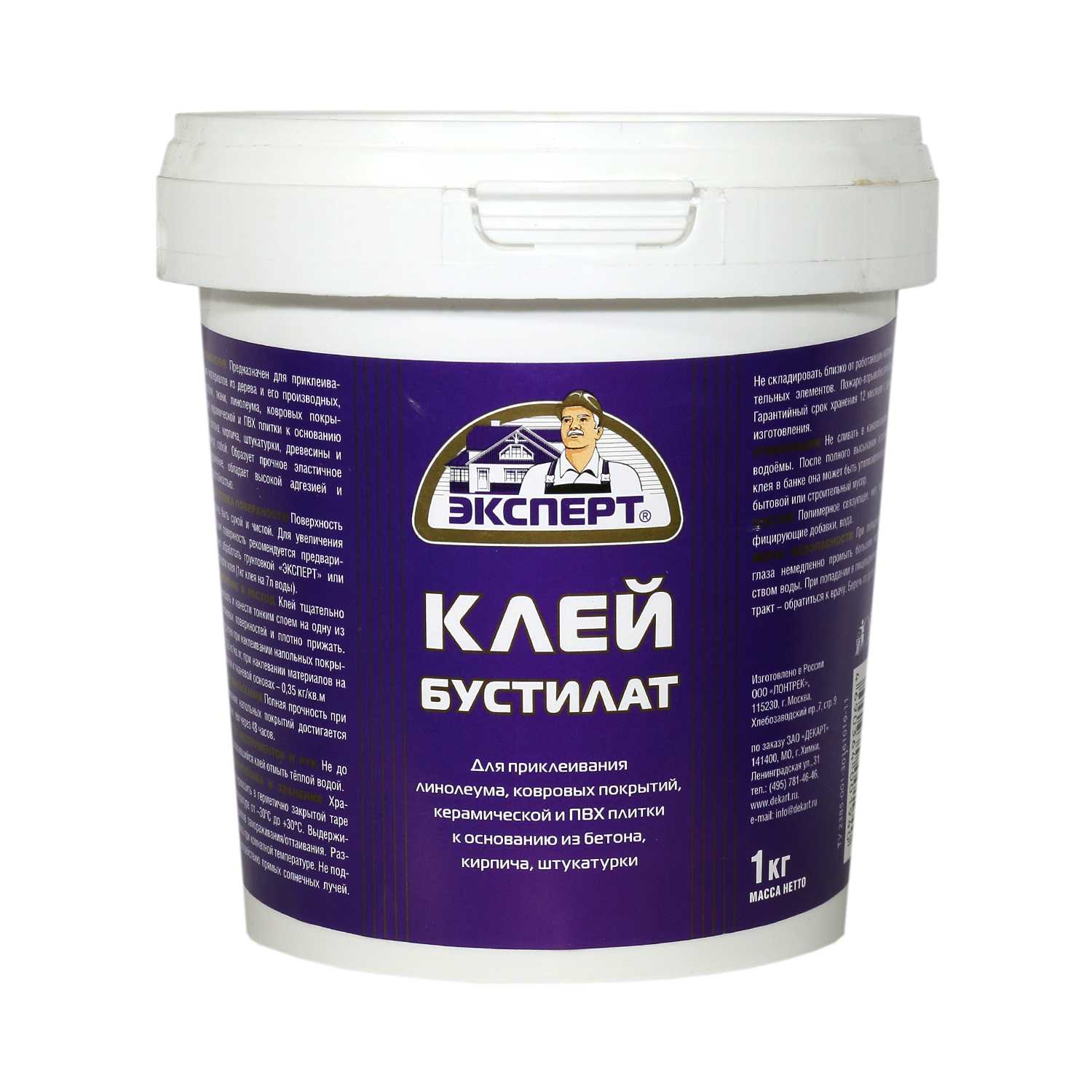

"Bustilatom" is used for gluing wallpapers of different types, including the heaviest ones. It is suitable for fixing carpets, other pile coverings, linoleum with a fabric and felt base. The glue is suitable for fixing polymer and ceramic tiles, panels, stucco moldings, baguettes and other decor, wood finishes. Also, the glue is useful for working with asbestos-cement slabs. Another tool is added during various repairs to cement, which will increase the strength of the mortar or screed.

Types of glue

There are several varieties on sale that differ in properties. The choice of a specific model depends on the needs and operating conditions

It is very important to buy the right brand so that it can tolerate the climatic conditions in the area of use well. The following modifications are available:

- - glue "Bustilat-M" - is a special frost-resistant mixture;

- - glue "Bustilat-N" - designed for materials with poor adhesion and contains special additives that increase the adhesiveness and the level of strength of the glue seam;

- - glue "Bustilat-D" - has enhanced durability and is used specifically for mounting heavy materials or for gluing to the substrate;

- - glue "Bustilat-Lux" - is used for gluing polymer materials.

Within the framework of one modification, varieties with a numerical designation may also occur, which will indicate the degree of manifestation of the main distinctive property. In general, it should be noted that the existing models allow you to fully cover the repair needs for the installation of finishing materials. At the same time, Bustilat glue for linoleum and other elements will cost much less than modern substances. The economic indicator is very important, so this glue simply does not have any competitors in this sector.

Features and specifications

Bustilat belongs to one-component adhesives. It does not contain solvents.

Latex is used as a base in the production of glue. Chalk, modified cellulose, preservative, water, thickener, as well as special additives are added to the base. The result is a thick creamy mass with optimal properties, grayish-white color, without a pungent odor.

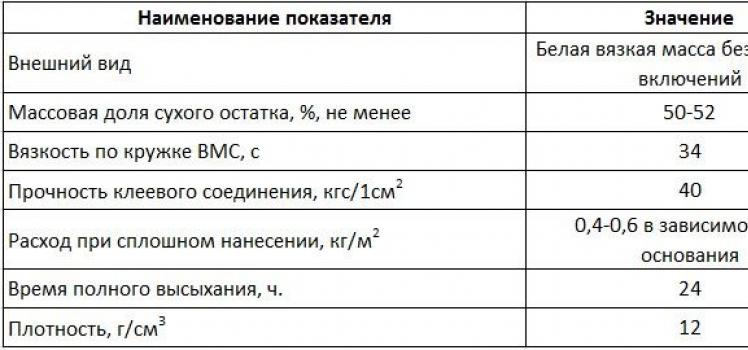

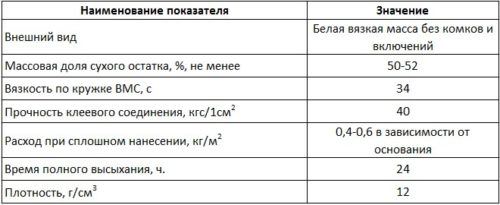

Characteristics of the bustilate glue

In addition to environmental friendliness, such characteristics of Bustilat glue are attracted as the ability to dry quickly, high bond strength, excellent adhesion rates, as well as:

- Profitability. On average, the consumption of glue is from 80 to 200 g per square meter.

- The time for complete hardening is from 1 to 1.5 days.

- No need to restore the adhesive layer if you need to correct the mistakes made. This condition can only be fulfilled until the initial applied adhesive layer has completely dried.

- Lack of color on the surface of the material (paper, non-woven wallpaper) after the glue has hardened.

- Non-flammability and lack of reaction to open fire.

Based on the characteristics presented, the reputation of a reliable all-purpose adhesive is well deserved. However, there are some disadvantages that affect the possibility of using Bustilat, depending on the conditions:

- If there are special requirements for durability, then in this case this glue is significantly inferior to multicomponent mixtures.

- If the work is planned to be performed in an unheated room, it is better to choose a different composition, since Bustilat quickly freezes due to the presence of water in the composition. There is no reaction to low temperatures only after the adhesive layer has completely solidified.

Material care

Oilcloth is a very unpretentious type of facing. As it gets dirty, it is simply cleaned with water and any detergent. Some stains are difficult to wipe off. In such cases, you can use alcohol-based formulations or regular vodka.

Oilcloth has won the love of customers due to its economy and ease of installation. Such a coating is easy to re-stick or replace individual areas. It does not require any special maintenance and is completely waterproof. With the help of the film, you can quickly and effortlessly change the annoying design of the bathroom.

In addition, the choice of such materials is very wide. This provides the owners with the opportunity to implement any creative ideas during the renovation of the bathroom.

An assortment of self-adhesive films Choosing an oilcloth for lining the walls of a bathroom Oilcloth with a backing Plastering of bathroom walls

Instructions

In order to determine how much oilcloth you need, take measurements of the room, that is, the number of pieces for pasting should be equal to the number of meters of wall length (you can not take into account window and door openings).

If the room was previously papered, then completely remove all previous coatings. If there is paint on the walls, moisten them with water and remove the napkin, plaster, paint, and then dry thoroughly.

Now take the oilcloth sheets themselves and spread them with glue evenly over the entire area, without missing a single section, otherwise bubbles may result.

If you glue oilcloth

on chalky whitewash, then first apply glue to the walls with a handwheel brush, otherwise, when the layer dries, it may begin to lag behind the plaster. Apply glue to both the wall and the canvas, and then smooth it out with gauze.

Start from the corner. If you are overlapping, always face the edge of the sheet towards the window. Apply the cloth smeared with glue from top to bottom, from the ceiling to the floor. In order to smooth the edges, use a roller or rag, while making sure that the pattern on the adjacent panels is correctly aligned.

Glue the oilcloth strips with a slight overlap, coat the edges well. Use a damp cloth to smooth out and wipe off any glue that has come out. Take strips of paper, grease them with wallpaper glue and apply over the formed seams. After they dry, slightly moisten with water and remove. Secure the top of the oilcloth in the ceiling area with strips of paper that will match in color or, conversely, create a contrast.

Related article

After you have mastered the technique of gluing wallpaper on a flat wall, it's time to learn how to glue the corners. At first glance, there is nothing complicated in this process. However, upon closer examination of the case, this process becomes a real curse for some. Therefore, it will be useful to read this article to the end. Below are some guidelines for wallpapering corners.

Instructions

I would like to say right away that it is extremely undesirable to glue the whole canvas into a corner. In practice, there are very few absolutely straight nodes in apartments. That is why, with almost one hundred percent probability, the corners of the wallpaper will wrinkle, the strip will be skewed, and the next strip will also lie unevenly. What can I say? The process stalled, the mood soured and you had to run to the store for a new roll of wallpaper. A depressing prospect. Therefore, to prevent such excesses from happening, glue the corners correctly.

So, what is the basic principle of wallpapering corners? The canvas should be glued in such a way that there is a small overlap on the adjacent wall (literally 1-2 cm). The next strip will already lie on the other wall to the end-to-end corner and you will get an even corner. If you are pasting heavy wallpaper (vinyl, non-woven and other similar), then it is necessary, using a plumb line and making a centimeter overlap on the adjacent wall, stick a strip of wallpaper strictly vertically.

These were the basic requirements for the wallpapering process in the corners. These requirements are true for both paper and other wallpapers. The only exception is glass fiber. They will have to be cut exactly along a plumb line running right along the corner. Here the whole "trick" is that glass wallpapers are glued exclusively for painting, so the joint of two canvases in the corner after the wallpaper painting process will become almost invisible.

Related Videos

how to glue fiberglass in corners in 2019

In the process of gluing wallpaper, novice repairmen often have doubts about the strength of the glue used. At this moment, first of all, they remember about PVA glue. But how justified is its use?

How to use?

For laying linoleum or carpet, the adhesive solution is applied to the floor with a spatula.

Immediately after that, the finishing material is laid on the base.

The cladding must be firmly pressed against the base. Upon completion, it is necessary to leave the finish for three days, until the glue is completely dry. The optimal consumption of the composition in this case is from 0.5 to 0.7 kilograms per m2.

Expert advice: You can add cement mortar to the glue. This will help speed up the hardening process of the layer if it is necessary to carry out the work as soon as possible. Proportions - 1: 1. To prepare the mixture, it is necessary to mix one part of cement and three parts of sand.

When using an adhesive for laying ceramic tiles, the composition must be carefully applied to the back of the finishing material. The optimum layer size is about 203 millimeters. After that, the tiles must be firmly pressed against the wall and fixed in this position until the glue sets. Full hardening of the glue occurs after three days. At this time, in no case should the finish be influenced. One square meter consumes from 0.4 to one kilogram of glue.

"Bustilat" is actively used for the installation of wallpaper from various materials.

If the glue thickens over time, thin it slightly. Add a seventh part of pure water to the composition, this is the maximum allowable volume. If the product is fresh, then you do not have to dilute it.

It should be noted that the hardened layer of "Bustilat" cannot be removed with hot water, therefore it makes no sense to remove old wallpaper and treat the base in this way.

The most popular, affordable and effective method is mechanical cleaning, which is carried out with a metal spatula or sharp scraper. You can also use a grinder with a special attachment in the form of a metal brush. This method will help to get rid of the glue residues, however, a lot of dust and noise appears during operation. Protect the respiratory tract with a respirator while working.

The second way is to moisten a cloth with water and heat the cloth. with a hair dryer or iron... Under the influence of temperature, the crust of the layer acquires elasticity. It is an efficient and quiet process, but time consuming.

- Ventilate the area thoroughly before starting work.

- The work surface should also be prepared by removing dirt, traces of grease and various compounds. If necessary, a priming procedure is carried out (if the base has a porous structure).

- Be sure to read the instructions for use of the product. All necessary information is indicated on the packaging.

- The price of the glue depends on many factors: the manufacturer's margin, the percentage of the store, the type of composition.The minimum price for a kilogram is about 100 rubles.

During the repair, you cannot do without adhesives. This is justified by the fact that the use of elements such as nails or screws can make the material look unsightly. In order not to spoil the appearance of the room after renovation, Glue Bustilate is often used: we learn the main properties and use cases below.

The glue is used for gluing wood and ceramic products, wallpaper, linoleum and other structures. It should be noted that this substance has existed on the market for about 50 years, however, even today the use of Bustilat glue has not lost its popularity. This proves that bustilate is a high quality material that is available for any category of builders, as well as for those people who make repairs with their own hands.

Varieties

Varieties of glue bustilate (click to enlarge)

Varieties of glue bustilate (click to enlarge)

There are different types of glue on the market. The choice will depend on what types of work will be carried out. Below are the main types of adhesive.

- "Omega". This type is used for fabric or felt material. For example, it will perfectly adhere fabric wallpaper to the wall. In this case, spots will be absent, since the substance will not penetrate deep into the tissue. Perfect for paper handling. It will help you glue chipped tiles or broken wooden objects.

- "Bustilat-M". Able to glue concrete, brick, ceramics. Withstands very low temperatures. Used for decoration with tiles and wallpaper, can glue linoleum. This glue is perfect for wood. Sometimes used for priming walls.

- "Bustilat-N". It has excellent elasticity and retains its adhesive properties even when the object is deformed. Can adhere materials that do not adhere well. For example, these include synthetic coatings.

- "Bustilat-D-super". Prevents the development of mold in the material. With this glue you can attach vinyl linoleum. It is also suitable for polymeric materials with a flat surface. This substance is non-toxic and safe. There is no difference between an expensive adhesive and Bustilat-D-super. He does his job well.

- "Lux". Used for materials with a polymer base. These include siding.

Watch the video to know how to glue linoleum to them:

Bustilat and PVA are often confused. Both are used in construction and can bond the same materials. But these adhesives have different compositions and technical characteristics.

The shelf life of these funds is different. "PVA" is stored for less than six months. Bustilat glues better. But as for environmental friendliness, "Bustilat" is still inferior to "PVA", which is therefore used in children's institutions.

Glue Bustilat: application

Before using the adhesive, you need to carefully prepare the surface:

- remove dust and dirt from the surface;

- if necessary, the surface can be washed;

- if the surface is porous, then it must be opened with a primer;

- the room temperature should be positive;

- prepare the glue by mixing it thoroughly.

Working with floor covering

To glue linoleum or carpet to the floor, apply a thin layer of the adhesive mixture to the floor using a spatula. The prepared, flattened coating is neatly laid in its size on the floor covered with glue.

Each centimeter of the covering is carefully pressed to the floor and smoothed out. It is advisable not to enter this room for 72 hours in order to allow the glue to dry completely. To glue the floor covering, you need to know that the consumption of the adhesive mixture for such work is 500-700 grams per square meter.

Laying tiles

To lay the tiles on the wall, you need to put 1-3 mm of the composition on the back side of it. Depending on the condition of the wall, an adhesive may also need to be applied to it.

Align the tiles and press them slightly against the wall. It is advisable not to touch this surface for 72 hours so that the adhesive layer is completely dry. And the consumption of glue per square meter ranges from 400 to 1000 grams.

Wallpaper gluing

If you have just discovered the glue, then you do not need to dilute it with water. And if you already had it open and thickened a little, then it is advisable to dilute it. The homogeneous mass obtained after mixing is applied in an even layer on both surfaces using a brush or roller. For ten minutes, after that, you just need to wait, and then glue the surfaces. You need to get rid of all air bubbles with a dry towel or a special spatula.

If you have just discovered the glue, then you do not need to dilute it with water. And if you already had it open and thickened a little, then it is advisable to dilute it. The homogeneous mass obtained after mixing is applied in an even layer on both surfaces using a brush or roller. For ten minutes, after that, you just need to wait, and then glue the surfaces. You need to get rid of all air bubbles with a dry towel or a special spatula.

There should be no drafts in the room where the work was carried out. It is advisable to close the room for a whole day. The consumption of busylate for wallpapering a room will be 300–400 grams per square meter. You can also use PVA glue.

Instructions for the use of glue

Before carrying out work, you need to take care of good ventilation of the room by opening the doors and a window.

To prepare the surface for gluing, it must be cleaned of dust and dirt. If the substrate is porous, it is recommended to pre-prime it with a special solution.

Linoleum works

- For gluing linoleum or carpet, the adhesive composition is applied in a thin layer to the floor with a spatula, and a prepared coating is laid on top of it.

- Next, you need to carefully press it to the base and leave it for 72 hours to dry completely.

- In this case, the consumption of glue will be about 500-700 grams per square meter.

To speed up the drying of the glue when gluing linoleum or tiles, you can add cement mortar in a ratio of 1 to 1. Prepare the mortar from 1 part cement and 3 parts sand.

Working with tiles

- When using glue to decorate the walls with tiles, you need to apply the composition with a layer of 1-3 mm on the back of the tile.

- Next, press it down well against the wall. Drying takes place within 72 hours, and the glue consumption varies between 400-1000 grams per square.

Wallpaper

- For gluing wallpaper Bustilat need not be diluted if it has not thickened. Otherwise, add 1/7 of the water to the composition, but do not overdo it.

- The glue consumption will be 300-400 grams per square meter.

Bustilat and PVA - what's the difference?

Construction PVA and Bustilat are two common adhesives that differ in chemical composition and some performance characteristics.

Both compounds glue the same materials and surfaces, and their advantages include low cost, but there is a slight difference between them:

- Bustilat glue is stored longer than PVA (12 and 6 months, respectively);

- PVA is more environmentally friendly, so it is not prohibited to use it when repairing child care facilities;

- in adhesion, Bustilat is slightly superior to PVA.

As you can see, the differences between the two adhesives are insignificant, so you can choose any of them for repair work.

Are there any analogues?

Bustilat's glue has almost no analogues, if we take into account the price-quality ratio, but there are improved varieties of the adhesive composition.

Different types differ in such parameters as:

- thermal resistance;

- frost resistance;

- insensitive to moisture.

Let's consider the main varieties:

Bustilat-M

An adhesive with frost resistance properties suitable for bonding decorative tiles, synthetic carpets, heavy wallpaper and linoleum, and is often used for priming interior and exterior walls of buildings.

Bustilat-N

This adhesive is used for gluing tiles, heavy wallpaper, borders and linoleum without an underlay. The material has high waterproofing properties. To obtain the desired viscosity, Bustilat-N must be dispensed with water according to the instructions before use.

Bustilat-D-Super

This type of glue is characterized by improved adhesion, minimal toxicity and non-flammability. It is considered the best option for gluing linoleum or wallpaper.

Bustilat-Lux

It is designed for gluing decorative and building materials based on polymers, PVC films, various types of wallpaper and linoleum. Bustilat-Lux is often used in construction fields, but it is also used by carpenters and joiners.

How to remove the old Bustilat from the walls?

When it is necessary to remove the wallpaper glued to Bustilat and remove the remaining glue, you need to prepare. Immediately, we note that it is pointless to try to soak frozen Bustilat - even hot water does not soak it.

The only possible and effective method is mechanical removal of wallpaper and glue.

You can use a metal scraper or a sharp trowel.

The glue is well removed with a grinder with a metal nozzle in the form of a brush, but this work is very dusty, so you need a respirator.

There is another trick you can use to remove Bustilat: wet a rag and place it on the surface, then iron or heat it with a hair dryer. The glue will soften and you can peel it off with a spatula. The work is not fast, but not dusty.

"Bustilat" is a synthetic universal construction adhesive designed for gluing wallpaper, carpets, fiberboard, chipboard, asbestos-cement and ceramic and polymer tiles, linoleum. Glue "Bustilat" allows you to easily connect walls, floors and ceilings with decorative elements and at the same time not spoil them with unnecessary holes. The adhesive is intended for indoor use only.

General information about "Bustilat"

"Bustilat" is a universal construction adhesive of synthetic origin. Good adhesion performance and healthiness are the main qualities that make it suitable for use inside human habitation. The glue cannot be used outdoors, but indoors it is used to decorate walls, floors, ceilings, it allows you to securely fix decorative elements and not drill unnecessary holes. Bustilat is an invention of Russian scientists from the Mosstroy Research Institute, but now it is produced by different companies:

- "Bright colors";

- VGT;

- "Expert";

- "Aquest";

- Roda Color;

- "Satellite";

- "Aquit";

- Diola, etc.

The most popular is the Lakra M 20 glue from the Lakra manufacturer, which can be found in any hardware store. Quality glue always has a certificate of conformity. Many companies produce glue in accordance with GOST 24064-80, but its release is also permitted according to specially developed specifications.

This is interesting: Choosing a tile adhesive for outdoor work: we consider it in detail

Storage

Glue "Bustilat" is stored in a hermetically sealed container and protected from high temperatures.

For this substance, multiple freezing (up to 5 times) with its further thawing at room temperature is permissible during transportation and storage.

The substance is thoroughly mixed before use.

Duration of storage in factory sealed packaging at an ambient temperature of + 5-20 degrees C is 12 months from the date of manufacture.

Installation of floor, wall or finishing coatings indoors is not always possible with fasteners. Despite a wide selection of screws, nails, bolts, studs, self-tapping screws, their presence can significantly spoil coating appearance and complicate its further operation. The use of adhesives helps to solve the problem. Especially appreciated are universal adhesives suitable for gluing wallpaper and floor coverings, placing decorative elements from various materials. So, the use of Bustilat glue in the process of laying linoleum gives a high-quality coating due to a number of technical characteristics of the adhesive.

The domestic manufacturer offers many options for the bustilate glue.

Advantages and disadvantages

To compile this list of pluses and minuses, experts studied reviews from real buyers, expert opinions, as well as the data declared by manufacturers.

The practicality and reliability of the adhesive has been confirmed by several decades of its use.

That is how long the product has been on the shelves of Russian stores. For such a long period of time, professionals have carefully studied the effectiveness of the product and confirmed it in practice. Despite the huge selection of adhesives, consumers still choose Bustilat.

Due to the absence of toxic and hazardous elements in the composition, the glue is considered a safe product. This characteristic allows you to safely use the composition in residential buildings.

The price of the products is affordable for the average consumer, and given the popularity and widespread use of glue, it will not be difficult to find it in any specialized store.

The adhesive layer has excellent elasticity.

Even with deformation of the elements and surfaces to be glued, the glue will retain all the technical characteristics and, most importantly, the bonding properties.

Regardless of where you use the composition, the glue will fulfill its obligations to the fullest. Whether it is wallpaper, tiles or other individual materials, the composition will firmly bond the elements to the base.

To appreciate the full range of product advantages, purchase only certified goods. On the Russian market, glue from the Lakra trademark is widespread. If in doubt about the quality of the goods, check with the sellers for certificates.

There were no significant drawbacks to this composition, but the product has certain drawbacks.

"Bustilat" cannot be used at subzero temperatures, given the fact that there are many adhesives on the market that can tolerate this temperature indicator. During its existence, many improved analogs have appeared on the market, which surpass the product by certain indicators.

Precautionary measures

Bustilate glue is a synthetic mixture based on a chemical compound. Therefore, when working with this type of glue, it is necessary to follow some rules for its use. Remember to protect your hands with gloves when handling this substance. After finishing work and complete drying of the glue, be sure to ventilate the room. If you accidentally get glue in your eyes, rinse immediately with warm, clean water, and then try to see a doctor.

Before pasting with such materials, it is necessary to prepare the surface: seal the grooves in the wooden chopped walls with plaster lime-gypsum or gypsum-sand mortar, or seal it with slats, and then revet the walls with plasterboard sheets.

Fastening with nails

... If chintz with an ornament or pattern is used, it is necessary to achieve their combination when preparing the panels. Having cut the material into pieces of the required length, the cloth is sewn to the size of the wall, in which holes for windows and doors are cut out. First, the panel is attached at the top, near the ceiling, pulling it tight. Nails are driven in at least 25 cm later. After that, the panel is fixed at the bottom, near the baseboards, making sure that the material is stretched without wrinkles near the window and door openings. Especially good for corners.

Velvet is upholstered in the same way.

Chintz and velvet can be nailed without sewing the panels, in separate pieces, hammering nails into the edges. The edges can be laid one under the other and the nails can be arranged in one row; you can also nail the edges of each panel separately.

Gluing

... For this purpose, various adhesives and mastics are used, but the usual one is best. flour paste or starch with the addition of 100-150 g of wood glue to it (per bucket of paste).Gluing on the paste is convenient because, if you need to remove chintz or velvet, it will be enough to moisten them with water, and as soon as the paste gets wet, they can be easily removed. It is not always possible to soften other types of adhesives and mastics.

It can be glued with large panels or separate canvases, the latter are more convenient to use. It is impossible to smear the fabric like wallpaper: the paste will penetrate the front surface and when ironed it will shine. Therefore, the surface is covered with prepared paste and allowed to dry until it is tacky, that is, to such a state when fingers will still stick to it, but without the paste sticking to them. A fabric is laid on this paste and smoothed well. The velvet is smoothed through the paper, or blows are applied to it with a dry cutting brush. Hands should always be clean and dry, without any traces of paste.

You cannot drive a nail into stone, brick, concrete surfaces, but even though it can be easily driven into plaster, it can also be removed very easily. Therefore, one should do so. Thin slats with a width of 20 mm or more are made and the material is attached to their back side with thin studs, and then the strip with the material is attached to the wall. They are also attached below. If the material is nailed to the face of the batten, it will not fit snugly against the wall.

The slats are attached to the walls like this. First, holes are drilled or punched in the walls, wooden plugs are inserted there so that they hold firmly, and nails are hammered into them - through the rail.

Some strengthen the panels by hanging them on a strong thread. Near the corner, nails are driven into the wall from above and below. A thin strong nylon thread (fishing line) is passed through the sewn cloth, pulled tight, fastened firmly to the nails and straightened the material. This is how they are attached on all four sides of the wall.

It is advisable to first carry out a test gluing by gluing a small piece of chintz onto cardboard or plywood.

Pasting walls (ceiling) with oilcloth

... Oilcloth is much easier to stick than chintz and velvet. Adhesives and other contaminants can be easily removed from its front side. In practice, it is glued in the same way as linkrust, only it is not soaked in water.

Oilcloth can cover not only walls, but also floors. However, it is not recommended to cover the walls to the full height, but 1.5-1.7 m from the floor, as if arranging a panel. Oilcloth can either be glued or nailed.

Normal nails are used. Oilcloth is cut into canvases of the required length, hung on the walls, attaching in several places with nails at the top and bottom. From above, the edges are closed with a layout, that is, with a rail not more than 30 mm wide.

It can be painted with oil or enamel paint or varnished. In order for the edges to fit snugly one to the other, they have to be cut along a ruler.

Oilcloth is glued to the floor on strong adhesives, mastics or pastes.

Advantages and disadvantages

The advantages of Bustilat include the following:

- Composition safety. The substance does not harm the human body.

- Ease of use. The tool can be combined with different types of materials. This is very convenient, since only one composition is enough for the repair. In such a situation, there is no need to buy several special tools.

- Excellent elasticity and high adhesive properties. Thanks to this, it is possible to achieve high strength of the fixing of materials over a long period of time.

- Low shrinkage and excellent adhesion. These parameters provide high reliability of the coupling with natural and artificial materials. As a result, it is possible to obtain a strong and even seam.

- Multifunctionality. The composition can be used as an adhesive or a primer. It can also act as a waterproofing mixture.

- Affordable price. This is due to cheap raw materials and optimization of the production process.

The product has no major flaws. The only drawback is considered to be low durability.In this case, it is worth giving preference to modern multicomponent formulations.

Types of glue

The chemical industry does not stand still. Modern compounds are added to many formulations of drugs that are used in everyday life. The famous glue has also undergone a change. To improve its moisture resistance and frost resistance, special additives were added to its composition.

Depending on the use of the adhesive composition, its varieties are distinguished:

- "Bustilat-M" - the adhesive composition includes frost-resistant additives. It is used as a primer and as an adhesive. Linoleum, carpets, various types of tiles and wallpapers are glued.

- "Bustilat-N" is specially designed for materials with poor adhesion. It contains special additives that increase the stickiness and the level of strength of the glue line. It is used for gluing linoleum without a base, synthetic carpets, non-woven wallpaper, etc.

- "Bustilat-D-super" - has increased strength. It is specially used if you need to fix heavy materials or for gluing linoleum to a sub-base.

- "Bustilat-Lux" - this type is intended for joining polymeric materials: PVC films, linoleum, etc.

One type of adhesive can have different numerical values that indicate the degree of manifestation of the main distinctive property. Thanks to its varieties, all repair and finishing work can be completely done. It is worth considering that if Bustilat is used for linoleum and other various elements, then it will cost much less than other modern substances. This fact remains very important; This glue simply has no competitors in this sector.

Conclusion

Clay Bustilat has been known to people for a very long time. It is reliable, durable, and most importantly - an inexpensive material that is used for pasting wallpaper, linoleum and other various materials. The main condition when working with it is positive temperature in the room

.

Glue bustilate how it looks

When renovating an apartment and decorating the premises, you can give a zest to the design using a variety of finishing materials, including oilcloth or fabric (chintz, satin, velvet). Oilcloth can be pasted over all walls of a room or only part of the surface. You can glue such material with mastic, special glue, or just nail it down with carnations, although now it is so rare to attach the coating to the walls. How to glue oilcloth on the wall

to be practical and beautiful? What can we give?

APARTMENT REPAIR, HELPFUL TIPS, HOUSE AND FAMILY

How to glue oilcloth on the wall