Famous brands

- DecArt belongs to universal formulations, it is distinguished by a white tint in the finished form, after complete drying, the layer becomes transparent. It is used for joining various surfaces, except for polyethylene.

- VGT water-dispersion type, connects smooth surfaces with low absorbency, suitable for polyethylene.

- Polax is a mastic on an acrylic water-dispersion basis, used for laying slabs, laminates, etc.

- ASP 8A provides a durable layer that resists aggressive substances while maintaining all its properties.

- Axton belongs to the universal means, it is used for fastening wooden, plaster, polystyrene elements.

- Rainbow-18 serves as a bonding base for all facing raw materials, as well as drywall, wood, concrete, etc.

- MasterTeks is an acrylic-based adhesive and sealant used for reliable sealing of various materials, applicable for indoor and outdoor use.

Advice

The main requirement when using acrylic glue is to observe safety precautions, even if it is a harmless composition.

- The presence of personal protective equipment is a mandatory item for working with this substance.

- Surfaces requiring gluing should be prepared for application of the composition, remove dust, dirt and other contaminants, that is, clean the old finish and thoroughly degrease with alcohol or solvent. The use of a primer is sometimes acceptable. In addition, the parts to be bonded must be dry and tight, not contain loose elements. The glossy surface is treated with a fine abrasive.

- Works are carried out at a temperature of + 5º - + 35ºC, excluding direct sunlight.

- The dry mixture must be diluted in strict accordance with the instructions, preferably with water at room temperature.

- Excess mixture that appears on the surface should be immediately removed with a dry cloth, otherwise it will be very difficult to wash off the glue after drying.

How to use acrylic glue is described in the video.

Varieties of compositions

Now you need to figure out what types of acrylic glue are. First of all, it is divided into one-component and two-component. In the first case, the composition is completely ready for use. In the second, it must be diluted with one more component - a catalyst.

In addition, acrylic based adhesives can be classified differently. For example:

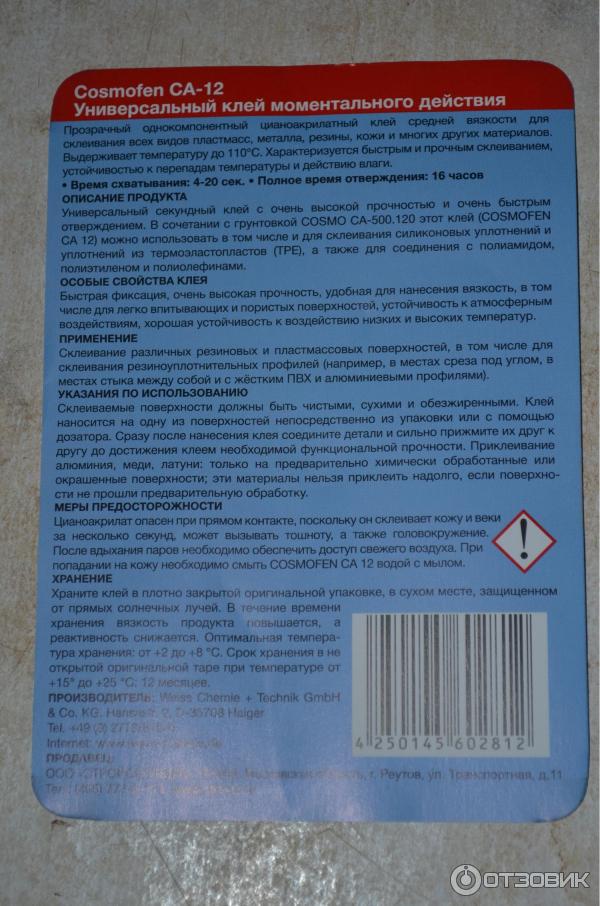

1. Cyanoacrylic. It is considered the safest, as it does not contain solvents. At the same time, he grasps very quickly. Most often, these adhesives are one-component. You can use the compound to connect small plastic, metal, leather or rubber parts.

2. Modified. It is most often two-component. That is, before on the surface of the processed you apply glue to the product, it must be covered with an activator. Sometimes both components can be premixed.

3. Ultraviolet curing. This glue is used to bond glass or other transparent products. It hardens under the influence of ultraviolet waves of a certain length. However, the fixation of objects quickly occurs only in the place on which the rays acted.

4. Latex based adhesive. It can be used in any environment. At the same time, it will regularly serve for a long time and is safe for health.

5. Acrylic water based dispersion adhesive. It is mainly two-component. Such a composition has a fairly high adhesion and is environmentally friendly.Such glue hardens only after evaporation of the water contained in the product.

6. For tiles. Moreover, this facing material can be attached both to the floor and to other areas. Such glue fixes the tiles well, is easy to apply and sticks to almost any substrate.

Working with glue

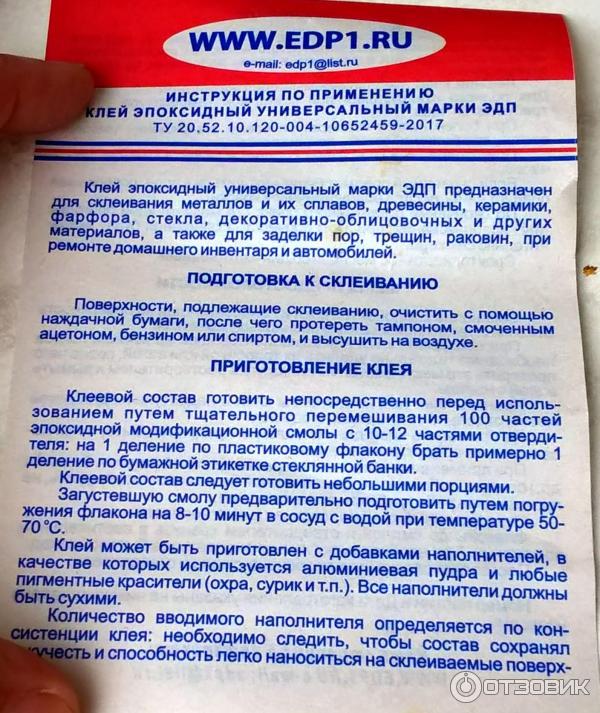

How to use silicone adhesive? Difficulties with the repair of various products will not arise, even a beginner will cope. But the efficiency of labor will depend on the quality of the preparation of the foundation.

It is important that the base is dry, clean and smooth. It must be degreased before use, this will help to improve the quality of adhesion.

You can degrease the surface using any suitable agent - a detergent solution, a special composition. After degreasing and drying, the edges of the joints can be pasted over with paper tape, so it will be possible to avoid blemishes, blots, the layer will be applied evenly.

Further, the order of work is as follows:

- cut off the spout of the glue, if it is sold in a small tube, or open the cap (it is better to use a special dispenser for glue, it will not allow excess funds to come out);

- when working on a large area, it is worth purchasing a glue gun;

- apply the material to one of the surfaces to be bonded and fix them or lay an adhesive seam;

- surfaces should stick in 10-30 minutes, as indicated in the instructions;

- you can fully operate the product after a day, during this period polymerization will occur.

Raising the room temperature by 5 degrees from room temperature speeds up the polymerization by half. The thickness of the adhesive layer more than 20 mm does not make sense, since the product will not solidify in the depth of the seam. Excess glue must be removed immediately with a cloth or spatula.

Variety of types of adhesives

The company's arsenal contains not only glue and various adhesives. The brand is engaged in the production of technical compositions that provide protection and support the functioning of mobile devices.

Screw sealing

Such funds are available in the form of liquid solutions. Also on sale there are tapes that provide sealing of screw connections. These substances enter the space between the threads, forming an impermeable layer. Loctite sealants help prevent fittings from loosening. They prevent leakage of technical substances. Screw sealants are distinguished by the following characteristics:

- withstand prolonged exposure to high or low pressure;

- do not crack during temperature fluctuations;

- have excellent adhesion characteristics, allowing you to attach metal and plastic;

- produced in the form of one-component solutions or sealing tape;

- do not shrink;

- provide protection against corrosion;

- do not dissolve with alkalis, gasoline and oils.

Flanged Seals

When applied, such substances polymerize, forming a sealed seam between the elements. It appears in the gaps between parts. Such means protect the devices from liquid leaks. They also allow you to avoid the loss of technical gases. In addition to the sealing layer, the substances create a coating that protects the surface from corrosion.

Flanged substances are characterized by the following features:

- do not react to the influence of reagents and industrial gases;

- do not crack with significant temperature fluctuations;

- do not suffer from pressure fluctuations;

- produced in the form of silicone and anaerobic solutions;

- do not shrink and expand;

- anaerobic compounds provide a rigid adhesion, silicone ones are used for moving elements;

- due to the liquid consistency, microscopic holes and cracks are filled, independently distributing over the surfaces;

- do not require additional tightening of the thread;

- help replace gaskets made from other materials.

Elastic industrial seals

Such funds help to protect the elements of mechanisms from the influence of harmful factors. They protect parts from high humidity, air, gases. Also, substances protect against solid elements.

These funds are characterized by the following features:

- in case of deformation, the seals restore their shape;

- produced in the form of one- or two-component liquids;

- they have excellent adhesion to different materials - they may differ in density or texture;

- do not crack at low temperatures;

- are not subject to destruction by water, ultraviolet radiation, exposure to air;

- are distinguished by high vapor permeability.

Description and purpose

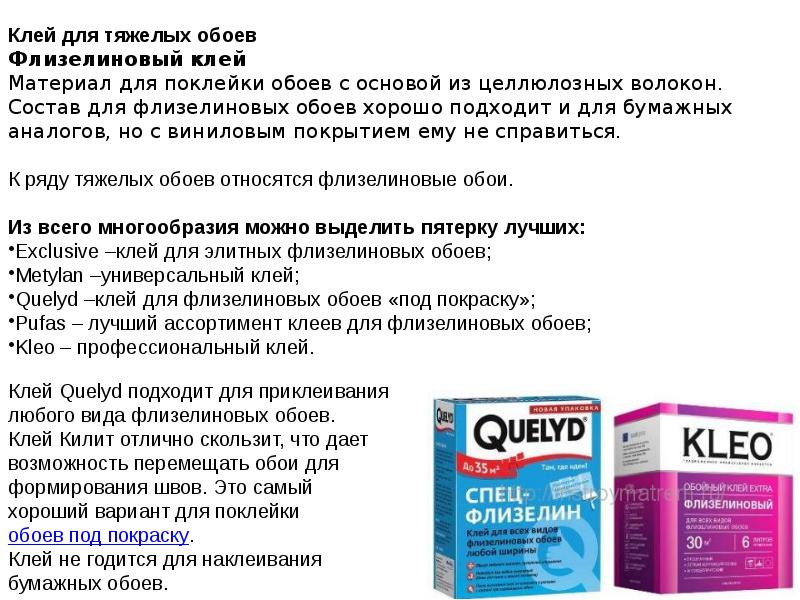

The adhesive mixture of the French company KLEO was developed for high-quality application of wallpaper on walls. The company is considered the best in the construction market, offering quality and affordable products. A large assortment makes it possible to choose the right composition that is suitable for the selected type of wallpaper.

In order not to be disappointed with the work done, it is worth approaching the choice of materials with responsibility. There are several types of Cleo wallpaper glue: for non-woven, paper and photo wallpaper. Professional craftsmen most often use glass wallpaper glue.

On sale, the adhesive mixture is presented in a package with a volume of 250 g. The powder is protected by two sealed bags and a cardboard box, which does not allow moisture to penetrate inside. The glue is diluted directly before gluing the wallpaper on the wall on its own.

The main feature of Cleo is the ease of application and ease of use. After the glue-based solution has completely dried, there are no foreign odors and stains, and the walls are protected from the development of fungi and mold. The prepared solution can be stored for 10 days in a hermetically sealed container.

Material characteristics

In shoes, with prolonged wear, the sole often comes off. This is due to the rupture of the nylon threads with which it is sewn. In repair shops, for restoration, nairite (shoe) glue is used - a one-component material. Chloroprene rubber (nairite) is used in its production. It looks like a translucent resin, its color is light yellow. Also included are:

- organic solvents;

- iron salts;

- chlorinated polymers;

- vulcanizers.

The glue can be used to treat the seams on shoes - it is water-repellent and prevents the product from getting wet. After the film dries, there are no toxic substances harmful to humans. At the same time, the sealing of the gluing site is excellent. Usually adhesives of this type are sold in large containers, but many brands are presented in small tubes. Shoe masters prefer products from Poland and Italy. Much cheaper, but lower quality Turkish-made compositions.

Here are the main characteristics of nairite glue:

- the share of non-volatile components - 24%;

- density - 0.85 g / sq. cm;

- delamination index - 62 N / cm during the day;

- maximum opening time - up to 65 minutes;

- reaching the maximum strength of the adhesive layer - 190 minutes;

- heat resistance - 75 degrees.

Types and properties of polyurethane glue

Before using a sealant, you need to familiarize yourself with the distinctive features of its varieties.

One-component

A one-component polyurethane adhesive is a synthetic mixture made from isocyanates. Outwardly, it looks like a thick and viscous liquid, which is colored gray with a slight whitish tint. To make the adhesive more viscous, a little acetone or other solvents may be added to it. The tackiness of the glue is increased by the addition of synthetic-type resins.

One-component mixtures are sold ready-made. Their hardening begins after contact with water. Also, hardening can begin if the air humidity exceeds 65%.Before using a one-component product, this feature must be taken into account.

Two-component

By the name of the glue, it is clear that it contains two active substances at once. The first component is the combination of polyhydric alcohols with polymers. These trace elements are responsible for the viscosity of the composition, elasticity and strength. The second component is diisocyanate, which is used to dilute the product.

The two-component adhesive has a wide range of applications. Its components ensure high reliability of the connection. The original grip of the glued components will not loosen even after decades. It is resistant to high humidity, high and low temperatures.

Bonding cork panels

Cork panels

Before gluing the cork to the wall, you need to study the features of the material and the composition of the glue used.

Cork panels come in the form of paper-backed wallpaper or slabs. You can glue them yourself. The main thing is to choose the right glue and carry out the work in accordance with the instructions. If the weight of the canvas is small and the surface is suitable, then a water-based adhesive.

The water-based adhesive is safe. But if the room is humid, then it is better to use a solvent-based composition.

It is important to remember about the toxicity of its composition and work in a respirator

The cork is pressed against the surface. Drying time is no more than 12 hours.

Table Tennis Glue

Bostik glue

In the past, organic glue was used for table tennis. It is currently banned. Water-based table tennis glue has a yellowish color and smell of ammonia. After drying, a very sticky film appears on the surface.

Bonding procedure:

- Apply a little glue to the middle of the sponge.

- Align with a special brush or swab.

- Roll the pad onto the board.

The consumption of water-based table tennis glue will be 2 times less. Rubber from such a composition does not fold.

Glue for gilding

Glueing

Potal is thin sheets of alloys. Such material is used for silvering and gilding plaster moldings, ceramics, plastic, cardboard, metal, wood, glass. For the procedure to be done efficiently, you need to choose the right glue. The composition is used on different bases.

Water-based glue for pottery is used quite often. There are several varieties of this glue. For example, white Permacoll glue discolours after drying. To decorate surfaces without a primer, use a paste. Delicate artwork is done with tube glue, pencil or marker.

Potal

The water-based adhesive does not need to be diluted with water, it has the required viscosity. After a layer of glue has been applied, gilding is carried out. You need to see the time in the instructions on the package. The humidity and temperature in the room must be taken into account.

Bead glue has different brands. Gold leaf is glued with the universal Ferrario compound. The composition "Tair" is used for transfer and loose leaf veil.

What about the final product?

The most popular acrylic resin product is artificial stone. It is used in different ways, as it has many positive qualities. The first thing worth mentioning is the chemical indicators. The made artificial resin stone does not react to many chemical compounds, which increases the service life and increases market demand. This is what acrylic resin manufacturers focus on.

As already noted, the use of such resins helps to completely eliminate the formation of pores. As a result, such a stone becomes hygienic. Bacteria do not grow in it and nothing multiplies on the surface. As a result, the area of use is expanding not only on a production scale, but also in personal use.

Another indicator is maintainability.Since the stone is artificial, the appearance of chips or cracks on it is simple and easy to clean using a sandpaper or grater. Therefore, making any design from it or in the process of finishing is profitable and simple. In addition, more serious damage is removed and a similar acrylic resin stone is inserted.

Many craftsmen believe that artificial stone made from such materials is good at work. It turns out to implement any projects of complex shape and configuration. Nothing gets in the way - plane and volume. From acrylic stone you can find stairs, fountains, sculptures and the like. The most interesting thing is that a figure of any size is assembled. For this, the individual parts are glued together, and the joint is simply sanded. As a result, nothing is visible, as a monolith is obtained.

Acrylic resin is a unique substance. Therefore, as already noted, any color scheme is created. As a result, when making building materials from it, a color is also chosen. For this, the required pigment is taken. Thanks to this, artificial acrylic stone can be found in any composition.

Acrylic resin production

You need to know the manufacturers. There are many of them, because such masses are in demand. These are different countries:

- Tennants GmbH. Germany.

- VELOX GmbH. Germany, one of the best for today.

- FSUE Research Institute of Polymers named after V.I. Academician V.A. Kargina (Dzerzhinsk, Russia). This product is in demand on the market.

- ELEKTROISOLA, Tabor (from the Czech Republic).

- Suter Kunststoffe AG. From a Swiss supplier.

- GRUPA EXLAK. Poland creates an equally high quality product.

But where is acrylic resin most commonly used? It is effective in the process of creating plastics. In addition, it is suitable for polymer composite materials: artificial stone and marble, fittings, decorative items, etc. Today, this component is considered the most popular in the creation of self-leveling floors and paints and varnishes.

Advantages and disadvantages

CMC is only diluted with water at room temperature. You do not need to add any other substances to prepare the solution. The adhesive mixture is easy and quick to prepare. There are no toxic additives in it. The mass is homogeneous, colorless, without lumps and sediment. The adhesive mixture can be used in any room, even in a children's room. When dry, the solution does not emit any toxic substances to the body.

The adhesive mixture itself, prepared from white powder and water, is colorless. It has no smell. Some manufacturers tint the powder pink to show where the glue is applied to the canvas or wall. The adhesive solution ensures the adhesion of the wallpaper to all types of surfaces. The main thing is to clean the wall from crumbling particles before repairing. CMC can be used even in rooms with high humidity.

Insecticidal and antifungal additives are added to the glue. For example, boric acid salt, aluminum-potassium sulfate, carbolic acid. Such substances improve the quality of the adhesive mixture, do not allow fungi, mold, and insects to multiply under the wallpaper.

The CMC has disadvantages. This glue takes time to swell. Usually about 2-3 hours. Modern formulations have a shorter swelling period of only 15-20 minutes. True, the price of such products will be higher. After pasting the walls, you need to wait at least 3 days for the glue to dry completely. While the substance dries, there should be no drafts in the room. The repair itself is best done in the summer, so that the wallpaper dries naturally, without turning on electrical appliances.

p> Share link:

What is this material?

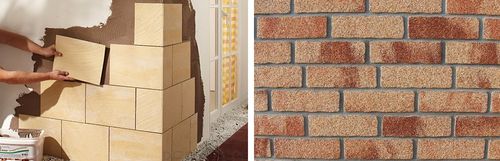

It is known that cladding made of marble, basalt or sandstone has a decent thickness and weighs a lot. Accordingly, this material is rather difficult to lay, although, of course, it is very beautiful. Such a tile cannot be thin, since the material, for all its hardness, is rather fragile and requires careful handling.

Flexible stone material

There are 2 main manufacturing methods:

- The older way is from sandstone. The latter is mined in quarries and a very thin layer is cut off from its surface. A slice of sandstone is fixed to a fabric base, and then used as a facing material: glued to the wall like wallpaper. The cut is very thin and therefore retains some flexibility. Acrylic adhesive is used for the manufacture of flexible stone. This production technology is followed, for example, by the tile manufacturer Gleega Stone.

- There is another method of production - from bulk materials. In this case, fine marble or basalt chips of fine fraction are glued to the fabric base. Using material of different shades, textures and sizes, you can create patterned tiles with a fantasy pattern.

Method of gluing flexible stone

This manufacturing method is much simpler, and the resulting material is much more decorative. In addition, finished products can be dyed. You can make tiles from crumbs with your own hands.

Wall décor

In the video, the process of pasting with this interesting material is presented in all details.

Scope of application

The main area of use of the product is shoe repair. It can firmly adhere leather to leather, artificial materials, nubuck, shoe fabric. You can also connect the fabric base to the inside of the shoe, glue heels on the heels, attach the soles. It is permissible to glue in zippers instead of sewing in.

Among other things, it is possible to use a means for fastening any parts from:

- rubber;

- wood;

- metal;

- felt;

- plastic;

- glass;

- ceramics;

- porcelain.

With the help of the material, you can stick on the base decor in construction - molding, plastic corners, tiles. The highest quality is produced in banks, it is he who connects the parts most reliably. Adhesives in tubes are used for those products that are subject to less friction, pressure (for example, tops of boots).

Specifications

Acrylic adhesive is produced in several variations. Each has its own properties, purpose.

There are masses with one-, two-component composition. One-component, suitable for use, since they do not require additional preparation, the mass is ready for use. Two-component formulations are diluted to the desired state with water before use. The readiness of the mass is determined by its liquid consistency, colorlessness or yellowish tint.

Consumption of acrylic substance is in the range of 150-500 grams per m2. This indicator depends on the structure of the plane to be glued, its readiness, the type of mass.

Each brand assumes its own ultimate strength, it can be from 5 to 25 kg per cm2.

The time for complete drying depends on the conditions created, the type of glue. It can take from 10 minutes to two days.

Use at temperatures below 7 degrees is not recommended.

Composition

The basis for the manufacture of acrylic adhesives is acrylic resin, various additives. A positive feature is the absence of solvents in the composition, which create a pungent odor and are dangerous to the body. They have been replaced by organic compounds that include aromatic, chlorinated hydrocarbons. These elements evaporate quickly when dry, do not contain toxins, and do not affect the body.

Plasticizers, fillers, additives, thickeners are added to the composition of acrylic glue. They are needed to reduce shrinkage, flexibility of the material, for the convenience of working with the mass, and imparting additional properties.

Release form

Acrylic glue is produced in two versions: ready-made, dry. The second type is packed in bags of 1–25 kg. To obtain a ready-made solution, water is added, stirred to the desired consistency. It is necessary to consume the finished mass in half an hour, so you should not cook a large volume at once.

The finished version is used immediately after opening the container. Large volumes are produced in cans, barrels, small in tubes.

Interesting video on the topic:

Appointment

Such a product is manufactured for work in the construction, repair and installation areas. Acrylic is suitable for joining dissimilar surfaces, even with uneven substrates. Suitable for joining ceramic, mirror bases, flexible stone, gluing linoleum, carpet, foam, etc. also perfectly connects wood, MDF, chipboard, laminate.

Since there are no toxic compounds, work can be carried out in living rooms.

Main inherent indicators

Acrylic resin is a type of acrylic resin, but with a different composition and quality. This prevents the formation of pores in the original product. The absence of monomer is observed after polymerization. If we compare acrylic resin with other similar components, then it has the least amount of chemical additives. In addition, the speed of hardening is higher. This allows for faster work on the creation of the final product.

Experts believe that the shelf life, as well as the spectrum of application of acrylic resin can be different. There are also artificial substitutes. There are many domestic and foreign suppliers of these products on the market. From this, it is possible to generalize the positive aspects of the material and bring them into uniform indicators:

- The absence of styrene indicates complete safety and environmental friendliness.

- Residual monomer - minimal (non-toxic material).

- The shelf life is longer compared to other similar materials.

- Physicochemical indicators are high.

- When buying, you can get a discount on the product.

Popular varieties

There are five popular types of glue that are used most often.

"Nairit-1"

The "Nairit-1" glue is considered to be of high quality and effective. Its main advantage is considered to be a flexible glue seam, which does not deteriorate even under the influence of low temperatures. "Nairit-1" is recommended to be used for shoe repair.

Sar-30E

It is an Italian adhesive that many consider to be the best rubber adhesive. The tool is distinguished by its versatility, since it is suitable for gluing many materials. It can be used to glue heels, insoles and rubber soles. Freezes Sar-30E quickly, within two hours.

"Rapid-5"

This is a Russian adhesive that is often used when repairing shoes. The popularity of Rapid-5 is due to its low cost in comparison with foreign counterparts. This glue is made from a rubber compound that firmly adheres metal, rubber and plastic.

"Anles"

This glue mix, like Rapid-5, is produced in Russia. Anles is most often used to glue shoe soles made of synthetic fabric or natural leather. When using such a tool, it is recommended to use the hot gluing technique.

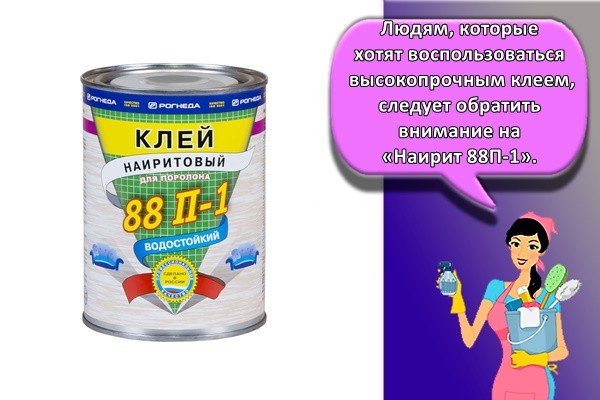

"Nairit 88P-1"

People who want to use high-strength glue should pay attention to Nairit 88P-1. The advantages of the tool include:

- the strength of the glue line;

- resistance to temperature extremes;

- moisture resistance;

- fast drying.

What can glue

There are fourteen materials that can be glued with nairite glue.

Skin to skin

Experts recommend using an adhesive for joining leather surfaces. It adheres to the skin due to its elasticity and fast drying rate after application to the surface. The surfaces to be glued do not lose their elasticity after treatment with a liquid, and therefore the connection is considered reliable.

Artificial materials

The adhesive made from rubber is suitable for bonding artificial materials. These include the following:

- Polyethylene. It is a common material used to make packaging products.

- Polystyrene. Polystyrene sheets are used in the construction industry for insulating premises.When attaching them to surfaces, they use nairite glue.

Nubuck

It is a common material used in the manufacture of furniture and footwear. The following types of nubuck can be glued with glue:

- Natural. Used to create shoes.

- Artificial. It does not allow air to pass through and therefore is used to create furniture.

Shoe fabric

The fabrics used in the footwear industry are particularly durable and quality. Some of them are glued together with nairite glue when making shoes. Such materials include:

- Rogozhka. Closed footwear for children and summer shoes are made from it.

- Felt. Woolen material used to insulate shoes.

- Calico. The inner insoles are made from it.

Heel heels

All shoe heels have special heels that make them more durable. These products are made from different materials:

- plastic;

- wood;

- rubber;

- metal.

Such products are attached in various ways, but adhesive mixtures are most often used.

Soles

The outsole is the part of the sole that ends near the heel. It is installed to make the shoe sole stronger. Waterproof nairite glue is used to attach the outsole.

Rubber

Rubber is an elastic material that is made natural rubber... Rubberized products are often used in the production of furniture structures or footwear. For fixing rubber to surfaces, it is better to use nairite glue mixtures.

Wood

Wood materials are distinguished by their versatility, as they are used in various fields of activity. Most often, wood is used during the manufacture of furniture. It is better to use adhesive mixtures for fixing small wooden components.

Metal

Many people think that metal products need to be fastened with screws or strong bolts, but this is not always the case. If the iron structure or part is not very heavy, it can be attached with a rubber-based adhesive.

Felt

It is a common fabric material made from sheep wool. It is used to create handbags or clothing items. It is also used in the manufacture of furniture items. For fastening the felt, not only threads are used, but also nairite glue.

Plastic

Plastic is a modern polymer material that has a high level of elasticity and strength. Today this material is popular, as many different items are made from it. To attach plastic to something, rubber glue is often used.

Glass

Sometimes people have to deal with gluing glasses. Most often, such a need arises if it is necessary to install a glass insert on the door. Nairite glue will help to attach it to the structure.

Ceramics

Ceramics is a dish that is made from clay substances mixed with mineral components. Such products are highly durable, since during the manufacturing process they undergo a firing procedure. However, despite this, ceramic structures may break and have to be glued together. Rubber glue will help to glue ceramic products.

Porcelain

Porcelain dishes are made from porous white clay, to which feldspar and quartz are added. During the manufacturing process, the products are fired, due to which they become moisture resistant and waterproof. If the porcelain is broken, it can be glued with nairite adhesives.

Product advantages and disadvantages

So, acrylic glue has certain advantages. Among them are:

- Reliability of fixing elements.

- Environmental safety of the composition, which makes it possible to glue even children's toys.

- Acceptable cost.

- A huge number of varieties, among which you will find exactly the option that you need.

- Good resistance to environmental influences.

- Load distribution over the entire surface of the elements.

- Ability to use to connect any materials.

- Some types of compounds are used for bonding products with an uneven surface.

As for the shortcomings, they also exist. Acrylic glue has a rather unpleasant odor that disappears over time. In addition, the glued part is already quite difficult to move from its place if it is necessary to correct it. And another flaw should be called a small thickness of the glue seam.