Varieties, composition and technical characteristics of wallpaper adhesives

Chemical enterprises produce their own type of CMC for different types of wallpaper. The characteristics of each are indicated on the label or packaging. In any composition of the base substance, there must be at least 50 percent, and the proportion of sodium chloride must be 21 percent. The moisture content of the mixture is up to 12 percent. The solubility of the powder is 96 percent.

CMC differ in composition and percentage of carboxymethyl cellulose. Almost all manufacturers produce universal glue that can be used to glue all types of wallpaper. For each finishing material, its own solution is prepared, in which water is taken in more or less quantity.

For light thin wallpaper

For the thinnest paper wallpaper, it is recommended to use KMTs Burny, KMTs-N, KMTs-1 (Shaving). In shape, the glue is a powdery substance of white or pink color, without any smell. Before use, the powder is diluted in water according to the instructions for use. The adhesive solution applied to the surface dries for a long time. During the period of the repair, they make sure that there are no drafts in the room.

Middle weight

Non-woven wallpaper is considered slightly heavier than paper. For their gluing, KMTs-N or KMTs-N Super-Max, Mini-Max, Extra Fast are used. This product is a fine granular powder. The packaging must indicate the type of wallpaper for which the adhesive is used. Any glue is diluted with water according to the instructions.

Thick heavy wallpaper

The inil wallpaper is considered the heaviest. For pasting the surface with thick wallpaper, KMTs Super strong is used. For pasting the surface with thick wallpaper, KMTs Super strong is used. leaving the adhesive, sometimes PVA glue is added. Externally, glue for heavy wallpaper looks like a white pulp. Before use, the product is diluted with water at the dosage indicated in the instructions.

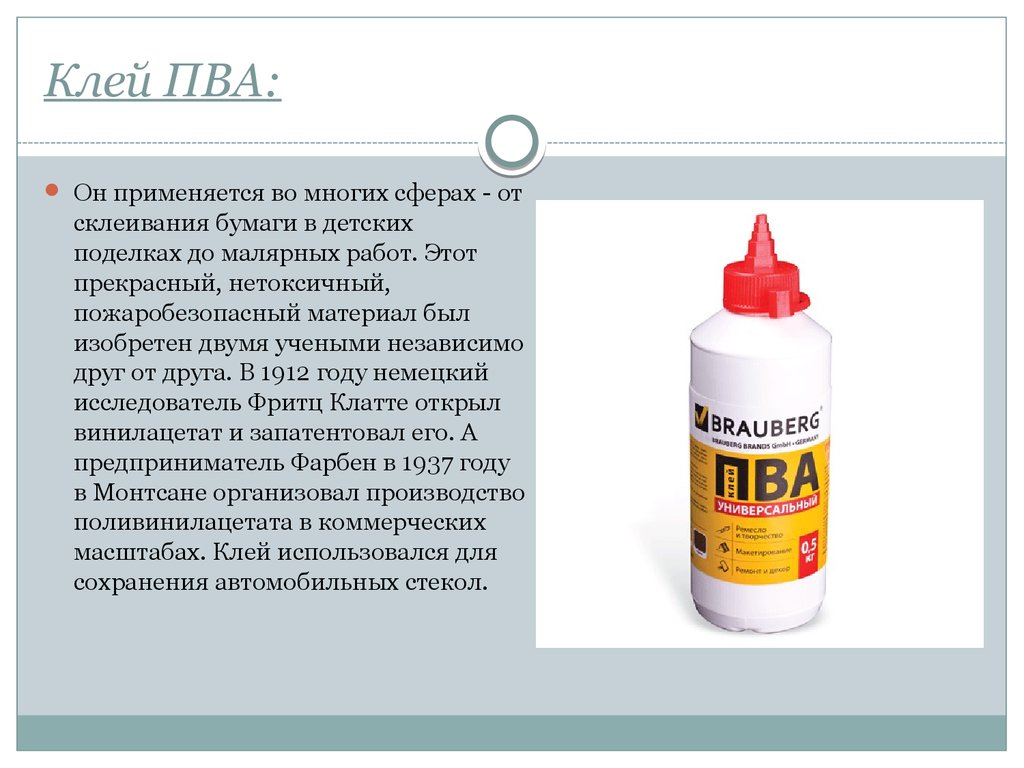

AKFIX 705 (glue + activator)

Product description

Akfix 705 Express Glue Kit The kit consists of a viscous cyanoacrylate gel and an activator aerosol. Two-component cyanoacrylate-based adhesive is used for fast and reliable bonding of solid wood or plywood parts and elements, as well as synthetic materials (MDF, chipboard, PVC, rubber, etc.). Akfix 705 glue has excellent technical characteristics when gluing various types of materials, is characterized by very fast and durable gluing, resistance to temperature changes and moisture.

Application area

It is used for gluing any wood materials. Suitable for MDF, chipboard, wood, plywood, rubber, most plastics, leather, etc. It is used in the manufacture and repair of furniture. Especially suitable for fast bonding. Designed for fast (in seconds) and reliable connection of solid wood or plywood parts and elements, as well as synthetic materials (MDF, chipboard, PVC, rubber, etc.). The two-component cyanoacrylate adhesive is widely used in the automotive industry, electrical engineering, household appliances, bonding of various plastics, metal, signage and displays, thermal enclosures in the advertising industry, etc. Bonding ABS, aluminum, stainless steel, fiberglass, FRP, FRT, wood, cold rolled steel, hydrocarbon steel, nylon, polyurethane and other materials.Quickly bonds a wide variety of surfaces, including aluminum, steel (both galvanized and uncoated). Ideal for bonding small to medium sized components. Perfect for gluing glass, transparent plastics used in illuminated advertising, for gluing boxes, shelves, remotes, etc. Also suitable for bonding stone and wood products.

Physical properties

- The curing speed does not exceed 8-10 seconds.

- Adhesive for instant bonding of all types of plastic, metal, rubber, leather, MDF, chipboard, wood and many other materials.

- Does not run off vertical or upside-down surfaces.

- Suitable for bonding elastic materials or joining materials with different coefficients of expansion.

- Has increased peel strength compared to other adhesives.

- Provides exceptional bond strength.

- Suitable for bonding pre-assembled parts.

- Ideal for adjacent plastic parts.

- Suitable for bonding natural and synthetic rubber.

- It has strong vibration resistance and butt joint resistance.

- Does not contain solvents.

Directions for use

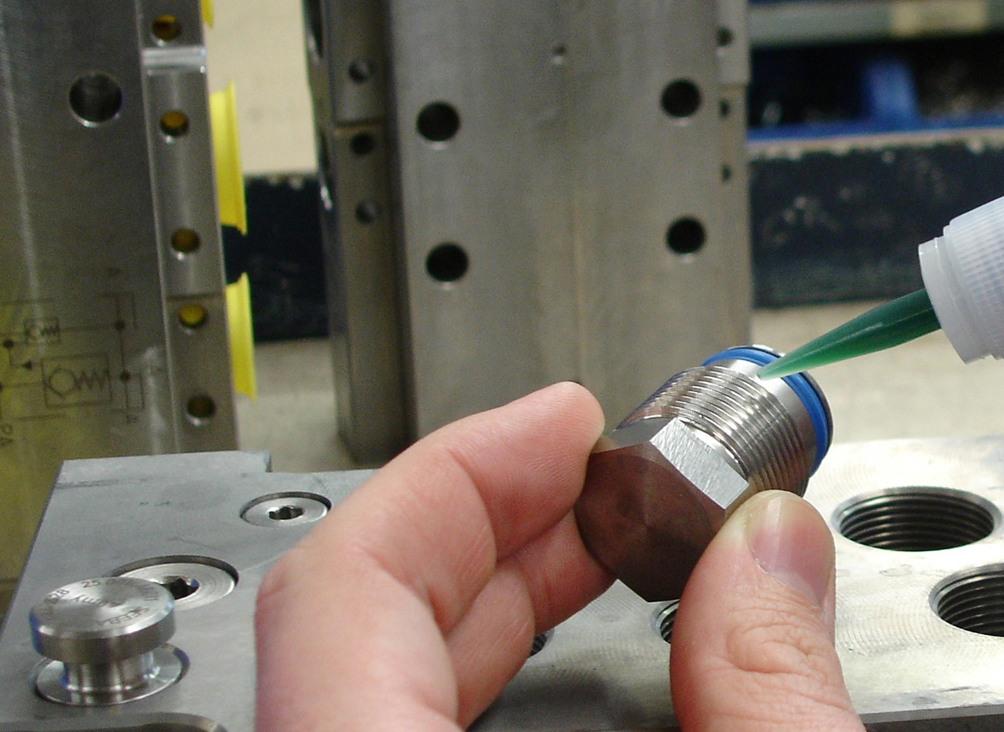

- Surfaces must be clean, dry and free from grease;

- The glue is applied to only one of the surfaces;

- Spray an aerosol on one surface and apply glue on the other

- Press tightly together

- Use at temperatures from +5 to + 40 ° C

Security measures

Use only with exhaust ventilation. Avoid getting the glue in your eyes or inhaling its vapors. Do not swallow. May cause skin irritation.First aid:if dizziness or other unpleasant effects appear, you need to go out into the fresh air, consult a doctor if the unpleasant sensations persist. Wash the skin contact areas with water and soap. If glue gets in your eyes, rinse them with water for 15 minutes. Keep the glue out of the reach of children! Use only for its intended purpose.

Return to catalog

Home / Related products / Porilex glue

Glue Porileks- specially designed for the installation of thermal insulation materials from foamed materials, products from polyurethane foam and foam rubber.

Precautionary measures

In the process of polymerization of VK-9, phenols and formaldehydes, harmful to health, are released. Even slight vapors can cause an allergic reaction in people with weakened immune systems in the form of itching, rash, rhinitis. If glue gets on the skin, if it is not removed, it can cause a chemical burn, which takes a long time and is difficult to heal.

Splashes of epoxy that have got into the eye cannot be removed on their own. You will need an urgent appeal to an ophthalmologist. The manufacturer's instructions indicate that it is not recommended to work with resins for persons under 18 years of age.

To protect against vapors and skin contact with resins during mixing and handling, it is necessary to:

- Respirator. Type: gas mask. Filter element: activated carbon, oxygen cartridge.

- Safety glasses.

- Overalls.

- Gloves.

This degree of protection is necessary when pouring large areas, when harmful emissions can have a disease-causing effect on the liver, heart, and stomach. For small jobs, latex gloves and glasses are sufficient.

Epoxy adhesive: precautions

In the process of working with any building materials, one should not only adhere to the instructions for use, but also observe precautions. With adhesive solutions, this rule cannot be ignored, since hardening in a matter of seconds on the skin, the product can cause a lot of inconvenience and pain.

Fundamental rules:

A mask equipped with a charcoal filter will protect you from harmful vapors and dust, while it is advisable to perform work in a well-ventilated area.

Wear rubber gloves on your hands before mixing resin and hardener.

Do not use utensils intended for storing or preparing food as a container for mixing epoxy.

If the glue gets on your skin, you should immediately rinse the area with soapy water, so it is important to have a container with the prepared liquid on hand.

If the glue or resin is difficult to squeeze out of the tube, you need to warm it up a little in hot water or on a battery. Under no circumstances should you use a water bath, open fire, oven or microwave for this .. If you know how to glue with epoxy glue, repairs will bring only pleasant results and leave pleasant memories, you just need to arm yourself with instructions for use and the necessary skills

If you know how to glue with epoxy glue, the repair will only bring pleasant results and leave pleasant memories, you just need to arm yourself with instructions for use and the necessary skills.

Terms of use

It is most convenient to apply silicate glue with a brush, spray gun. The latter method not only makes the work easier, but also reduces the cost of funds due to the uniformity of the glue line. In industry, some parts are coated with liquid glass by dipping.

Features of the use of the composition are as follows:

- all surfaces are well degreased, cleaned of dirt, dust;

- the base should be flat, smooth;

- if necessary, prime the products 1-2 times, let the soil dry completely;

- apply a layer of glue, without drops and streaks, without missing areas;

- if the dimensions of the product are significant, apply a second layer of glue after some drying of the first one and only then carry out the bonding;

- leave the product to dry completely without moving, touching.

If plaster or cement mixture is being prepared for pouring, the adhesive composition is introduced into it in a volume of 25% of the total mass. First, a cement-sand mixture is diluted, and only then liquid glass is added to it. For the manufacture of an antiseptic coating, silicate glue 1: 1 is poured into the primer, after which the agent is applied to the walls, floor, ceiling.

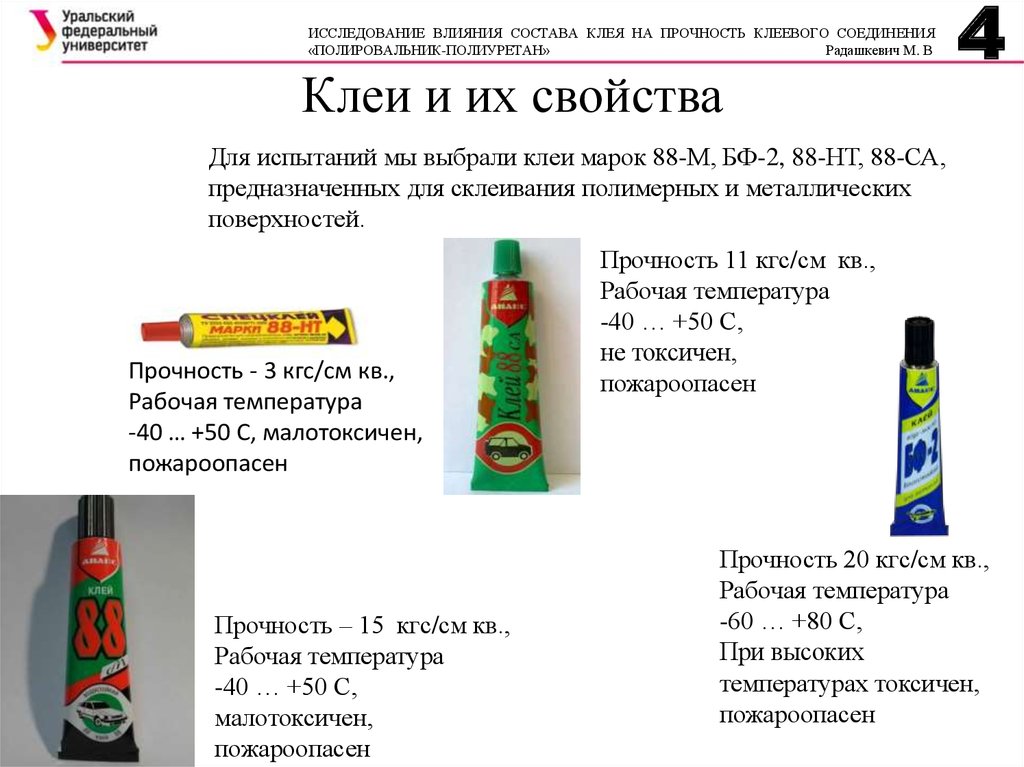

Popular brands of adhesives

There are several well-known brands of products that can be found on sale - Kenda Farben, Eva and others. The most popular ones are described below.

"Nairit-1"

Glue 88-P1, or "Nairit-1" is a very durable, high-quality product. After drying, a thin layer creates a flexible seam that does not burst, does not crumble even in winter. 88-P1 on shoes retains operational properties for a long time. It is best to apply the cold gluing method to this material. You can use the shoes after a day (with the hot method - after 3 hours), but the reliability of the joint will be higher.

SAR-30E

SAR-30E is produced in Italy, it is the best nairite glue, according to many masters. The tool is suitable for the most expensive leather goods, eco-leather, nubuck, with its help you can perfectly glue rubber soles, insoles, and fit heels. With the hot method, use the shoes after 3 hours, with the cold method - in a day.

"Rapid-5"

This product is Russian, its price is lower than that of imported counterparts. The composition includes a special rubber compound. The material is widely used to repair any footwear, it is no less popular for gluing plastic, rubber, metal in everyday life.

"Anles"

This material is also produced in Russia. They can be used to glue parts and soles to leather or synthetic shoes, fabric pairs. It is best to use the hot gluing method, then it will be possible to safely use the products at temperatures of -40 ... + 70 degrees.

Peculiarities

In comparison with similar products, Desmokol glue has 6 advantages:

- The composition is transparent, the bonding area after the repair remains invisible. This makes it possible to restore things or shoes, giving them their original appearance.

- The glue is not afraid of water. The universal product connects surfaces with a moisture content of less than 25%.Therefore, "Desmokol" is used to repair ammunition for hunting and fishing (suitable for gluing patches on rubber boats).

- The composition does not crack under the action of loads, does not crumble when the air temperature drops to 0 ˚С.

- The glue is practical to work with. It takes some time for Desmokol to completely dry. This makes it possible to correct the connection point.

- Durability and strength of joints. The materials glued together with the composition form a single whole.

- The connection is durable and elastic. Shoes after repair do not cause discomfort.

The disadvantages of Desmokol glue include flammability, since the product is based on a solvent.

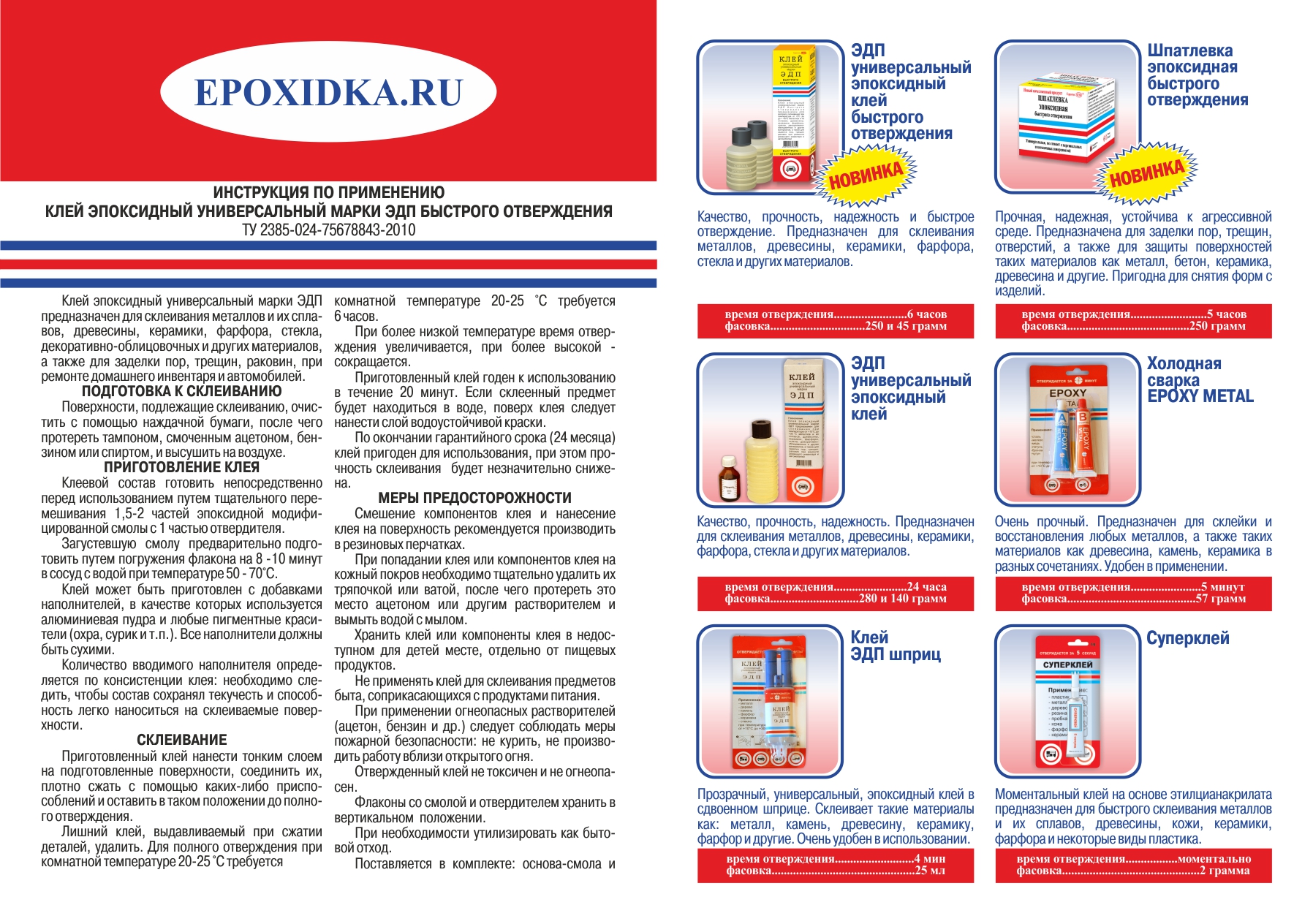

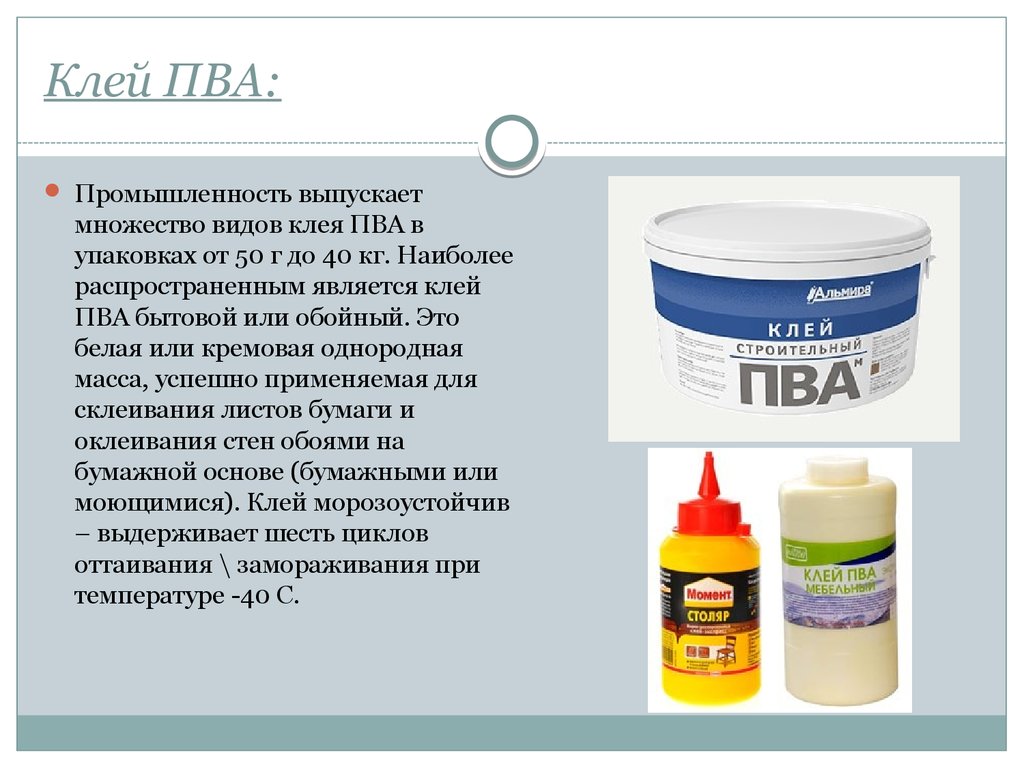

Varieties of PVA, characteristics, instructions for use

There are various types of PVA, which differ in technical characteristics.

PVA construction glue

Building adhesive is an emulsion made of polyvinyl acetate and additional components that increase the thickness of the adhesive. A distinctive feature of such a solution is considered its yellowish tint.

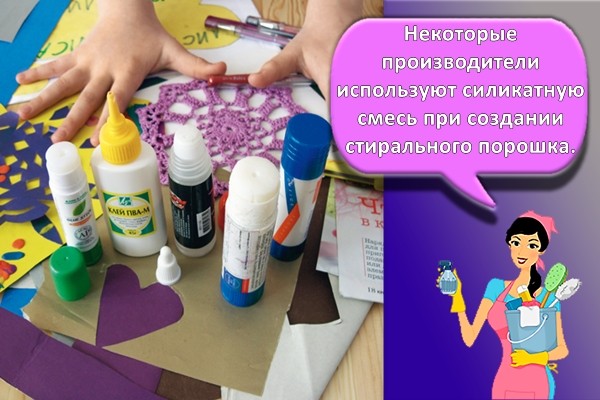

PVA stationery glue

For gluing cardboard and paper products, use a special stationery solution. In the construction industry, it is contraindicated to use it, since it is not able to provide a reliable and strong grip. The stationery glue mixture is produced in small bottles with dispensers.

Such a composition has several features that you should familiarize yourself with:

- stored for a long time;

- dries up within 2-3 hours;

- easy to wash off.

PVA

PVA liquid glue is considered a versatile tool that is used both in everyday life and in the construction industry. The high density of the composition allows it to be used for gluing linoleum, carpets, wallpaper, ceramic plates and metal sheets. When working with heavy products, this tool cannot be used, since it will not cope with the loads.

PVA-M

This adhesive is distinguished by its adhesion speed and high adhesion level. During its manufacture, components are added that increase the density of the composition and make it more reliable. Such glue adheres perfectly to products made of the following materials:

- glass;

- plastic;

- ceramics.

Also, many people use PVA-M if you need to glue something to paper. The properties of this superglue make it suitable for use in the construction industry.

What is the difference between PVA glue and PVA-M

To figure out which glue is better to use, you need to familiarize yourself with the differences between PVA-M and PVA. The main distinguishing feature of the funds is their density. PVA-M is thicker, and therefore many use it during repairs in an apartment.

PVA-Contact

When working with wood, PVA-Contact is often used, which has good adhesion. Among the advantages of the solution, it is distinguished by its resistance to high humidity and sudden changes in temperature. During the manufacture of the Contact, plasticizers are added, which increase the density of the composition. Such glue is used during repairs when gluing photographic paper and vinyl wallpaper.

Universal

Before using PVA-Universal, you need to figure out what such a tool is used for. It is used when carrying out internal repair work. Such a tool can adhere products made of fabric, cardboard or paper. Also, a universal composition is added to cement mortars during the laying of ceramics or tiles.

The main technical characteristics of the glue:

- curing time after application to the surface - 18-20 hours;

- the consumption of the composition is 100-200 grams per square meter.

Polyvinyl acetate adhesive

Polyvinyl acetate glue is a product that does not have a pronounced aroma and color. At room temperature, the solution is quite rare, but when heated to 50-60 degrees, it becomes more elastic. There are several cases in which a polyvinyl acetate mixture is used:

- bonding glass, iron, paper or natural leather products;

- fastening MDF sheets to plastic surfaces;

- gluing wood.

Household wallpaper PVA glue

For gluing wallpaper and gluing other materials made on a paper basis, wallpaper glue is used. Using such a composition, wallpaper can be attached to wood, concrete and other surfaces that are covered with plaster.

People who have not previously used household PVA are interested in how to use this solution. When using this product, the glue is applied only to the paper surface. It is not worth treating the walls with a solution, as this will deteriorate the quality of adhesion.

Superglue PVA

Most often, superglue is used when repairing or assembling furniture. The advantages of the composition include its heat resistance, strength, resistance to dampness and ease of use. Superglue has a shelf life of 20-25 months. However, if you store it in rooms with temperatures below 1-5 degrees Celsius, the shelf life will be reduced to 10-12 months.

Wood glue

When working with wood, various adhesives are used, however, the joiner's variety is considered the most suitable. It is an elastic and high quality glue that is popular with people working with wood. Its advantages include:

- profitability;

- elasticity;

- resistance to high humidity.

Application

The substance has become widespread in a large number of areas of human activity. The glue is used in office work, construction, industry, as it is an inexpensive and highly durable agent.

In industry

Liquid glass is often used in the production of various building structures and ceramic products. Due to its high fire safety index, the substance serves as one of the main components of impregnations and additives. In the metallurgical field, the solution is mixed with the sputtering composition of the electrodes, which are used to perform welding.

The chemical and foundry industries also use large quantities of liquid glass for production purposes. During the construction of transport, glue is used to connect various components.

It is important to take into account that various substances are used in industry and in everyday life. To connect large and heavy structures, glue is used, which is more like a solution in consistency and appearance

The material for industrial work contains additional components, which significantly increases its strength.

At home

What glues the mortar is a popular question among product buyers. Among household tasks, the most common is the use of liquid glue in the office. The material is used in office activities for gluing documents, folders and other paper stationery. For paper and glass, the substance is most suitable due to the structure of the outer surface of these materials. Also, liquid glass is suitable for use in solving household tasks in an apartment, garage and in the country.

Preparation for product operation

- Pull the edges of the disposable packaging in opposite directions (Fig. 6) from the side of the combined pusher piston.

- Place the fingers of one hand on the flange of the syringe cylinders.

- Holding the syringe-cylinders by the flange, having previously removed the thumb from the combined piston, we pull the syringe-cylinder by turning the disposable package inside out until the fastener is opened.

- We press on the plunger, down and towards the syringe cylinders, while pulling the syringe cylinders out of the fasteners by the flange (Fig. 3, 4, 5).

- We put the applicator on the tips of the syringes (Fig.

so that the plunger snaps into place on the applicator (fig. 9).

so that the plunger snaps into place on the applicator (fig. 9). - A tip (spray) is screwed onto the applicator (fig. 8.9).

- The device is now ready for use.

Distinctive features of the brand

The popular brand Loctite was created in the USA.The adhesive was obtained from scientific research in the field of bonding agents. Developments have also been carried out to create their solvents. An innovative breakthrough was the mortar that was used to fix screw connections. With its help, it was possible to fully interlock the threaded parts.

In the late nineties, Henkel bought the Loctite brand. All rights to the results of scientific research were transferred to her. Nevertheless, to this day, Loctite is considered a successful department of the company. It is engaged in the production of adhesives for various materials.

Review of popular brands

There are eight common manufacturers that produce high-quality adhesive products.

Multi Spray

This is an English manufacturer known for the high quality of its products. The adhesive spray is used to bond plastic, plywood, veneer or wood surfaces. It is also used to paste over cement or brick coverings.

Abro

American company engaged in the production of adhesive products, which is popular among builders. The containers with glue are equipped with a special nozzle that allows you to spray it on the surface. The main feature of Abro is that it dries quickly after application.

Tuskbond

Synthetic compound based on phenolic rubber and polychloroprene. Tuskbond products are free of CFC and therefore odorless.

Scotch weld

People looking for a universal fixing compound should look to Scotch Weld. When used correctly, it will be able to connect almost all common materials.

In order for the product to reliably glue the parts, it must be applied to both surfaces.

Presto

It is a versatile adhesive spray suitable for gluing wood, leather, plastic, cardboard or paper. Thanks to the installed aerosol can, the composition can be used for processing large objects.

Done Deal

If you need to glue large items together, you can use products from Done Deal. Such adhesives set quickly, within fifteen minutes. They not only glue the surfaces, but also seal the application sites.

Penosil

For outdoor work, Penosil adhesives are often used. They are ideal for secure attachment to façade surfaces of insulating panels. These are used in the manufacture of thermal insulation.

3M

This adhesive is classified as a permanent fixing agent. Therefore, they use it to attach more durable and heavier materials. It can also be used when working with paper, since it does not seep into it and does not warp its surface.

Views

The industry produces temporary adhesives of various properties. They can be moisture resistant, have increased resistance to temperature extremes, be immune to the action of oils or various types of petroleum products. Means with increased resistance in everyday life or for creativity are not used. An exception is attaching decor on the street in preparation for the holiday.

KK 100 Gunold

Gunold temporary fixing spray adhesive provides good temporary fixation of applications or other decor, prevents stretching and deformation of the fabric base. Often used to stiffen fabrics in machine embroidery. Provides good temporary fixation of applications or other decor, prevents stretching and deformation of the fabric base. Often used to stiffen fabrics in machine embroidery.

The manufacturer of the temporary adhesive KK 100 Gunold indicates that the product is non-toxic and odorless. Suitable for work in rooms where ventilation is difficult. May create a rubbery effect when applied liberally to the substrate.

It is important to check the expiration date before use. Expired adhesive leaves stubborn stains

Pencil 7.5 g Scotch 36307D

A low-tack compound capable of joining elements several times. It is used when assembling mock-ups and sketches when you need a short-term connection of components. In everyday life, a 7.5 g Scotch 36307D pencil is used to glue receipts and notes. Odorless, easy to remove from surfaces without leaving stains. It is produced in the form of a dense sticky substance.

Adhesive spray 3m Scotch Weld 75 for temporary fixation aerosol 500 ml

Aerosol spray is intended for short-term fixation of light layouts and stencils. Versatile. Suitable for all materials.

Be careful: 3m Scotch Weld 75 glue spray for temporary fixation aerosol 500 ml contains flammable substances. The product must not be sprayed near open flames.

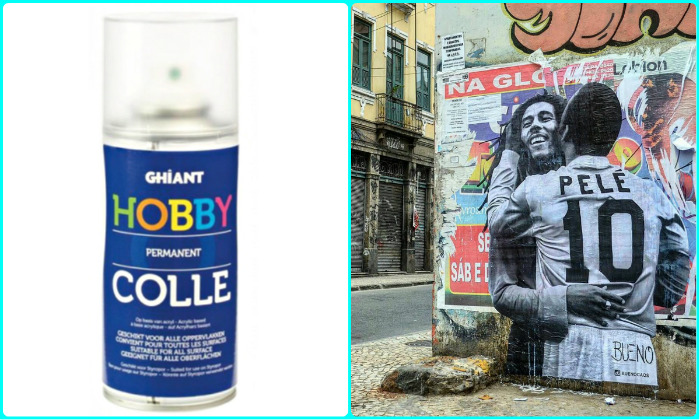

Repositionable 150 ml

Aerosol glue for temporary fixing Hobby Colle Permanent Repositionable 150 ml is well sprayed, does not absorb and does not deform the thin base of parts. Used to join thin sheets for a short time.

Hobby Colle Permanent 150 ml is applied in a thin layer to the surface of one of the connecting elements, ensuring a secure hold. The glue is suitable for joining fabrics, tracing paper, polystyrene, polyethylene.

UHU Tac Patafix PROPower

Extra strong Velcro, produced in pads. Temporarily attaches items weighing up to 3 kg. Can be used multiple times. Resistant to temperature fluctuations and ultraviolet radiation.

UHU Tac Patafix PROPower temporary adhesive tape is often used when decorating celebrations and holidays on the street.

Idea Decoupage

Temporary fixing spray Idea Decoupage is able to repeatedly fasten stencils, applications or details of models. The temporary fixing aerosol adhesive is sprayed evenly from the can, forming a thin adhesive layer on the base. Bonding can be done after a few seconds. It is well removed from the surface.

Takter

The aerosol is used in screen printing, embroidery and tailoring. Suitable for all types of fabrics. Colorless and non-marking.

Spirit 5 strong

Aerosol adhesive for temporary fixing of cellophane, paper, fabric, plastic, cardboard. Convenient for sewing, for creating collages, appliques.

Krylon Easy-Tack

Reusable aerosol adhesive Velcro. After it, no stains remain on the paper or parchment. It does not contain acids. Soft materials will not wrinkle when first applied.

Composition and properties of various varieties

There are six main types of adhesive mixture, which differ in their composition and properties.

Cyanoacrylate mixtures

It is a versatile compound that is used to bond most surfaces. The peculiarities of cyanoacrylates include the fact that no solvents are used in their manufacture. Thanks to this, the glue has no toxicity and is completely safe. It is often used to make toys for children and carry out renovations in an apartment. Among the disadvantages of cyanoacrylate mixtures, one can single out the fact that they solidify too quickly.

With addition

Some adhesives add additional components that improve their properties. Most often, special plasticizers are added to such liquids. They are used to make the mixture harden faster and be more elastic.

In addition to the plasticizer, solvents are added to the glue. These products must be used carefully, as they become more toxic.

Water-dispersive

It is a two-component adhesive mortar that is distinguished by its fixing properties. Due to its high efficiency, the glue is used for external and internal installation and repair work.

The main advantage of water-dispersion products is considered their versatility, thanks to which it is possible to fix almost any materials. They are best used for bonding wood, stoneware, drywall and plywood.

With the effect of ultraviolet hardening

These are one-component adhesives that begin to cure only after exposure to ultraviolet rays. They are used when gluing surfaces made of metal and glass. For working with wood, such products are not suitable, since they are weakly connected.

For tiles

Sometimes, during renovation work, people are laying tiles. To attach it to the surface, you must use special adhesives. They can be used to attach materials made of stone, clinker, ceramics and granite. If you add an elastomeric agent to the mixture, then waterproof glue will help attach materials such as:

- drywall;

- wood;

- Chipboard.

Modified

It is a high quality adhesive that looks like a milky white mass on the outside. They use modified glue to bond textiles, paper, fiberglass, cardboard and plasterboard. Also, such liquids are used as an additive in other types of adhesives to improve their quality and fastening properties.

All materials, except wood, are bonded with modified adhesive liquids. Therefore, it is not recommended to use them during installation work.

Instructions for use

In order to correctly use epoxy glue of a universal class, the instructions for use for it must be carefully studied. Only with strict compliance with it will the work be carried out at the highest level. The process itself is carried out in the following stages:

- Preliminary preparation of surfaces. They are cleaned with sandpaper, degreased.

- After the working surfaces are completely dry, the gluing process begins. An adhesive base is being prepared. The resin is mixed with the supplied hardener in a strictly specified proportion (in the classic version, 1 part of the hardener is used for 10 parts of resin). The catalyst is carefully added to the resinous substance and thoroughly, slowly mixed.

- The working surfaces are lubricated with an adhesive mass. Then they snuggle tightly against each other.

- The glued surface is fixed and left motionless until the mass is completely polymerized.

It takes a certain amount of time for the glue to cure completely.

It takes a certain amount of time for the glue to cure completely.