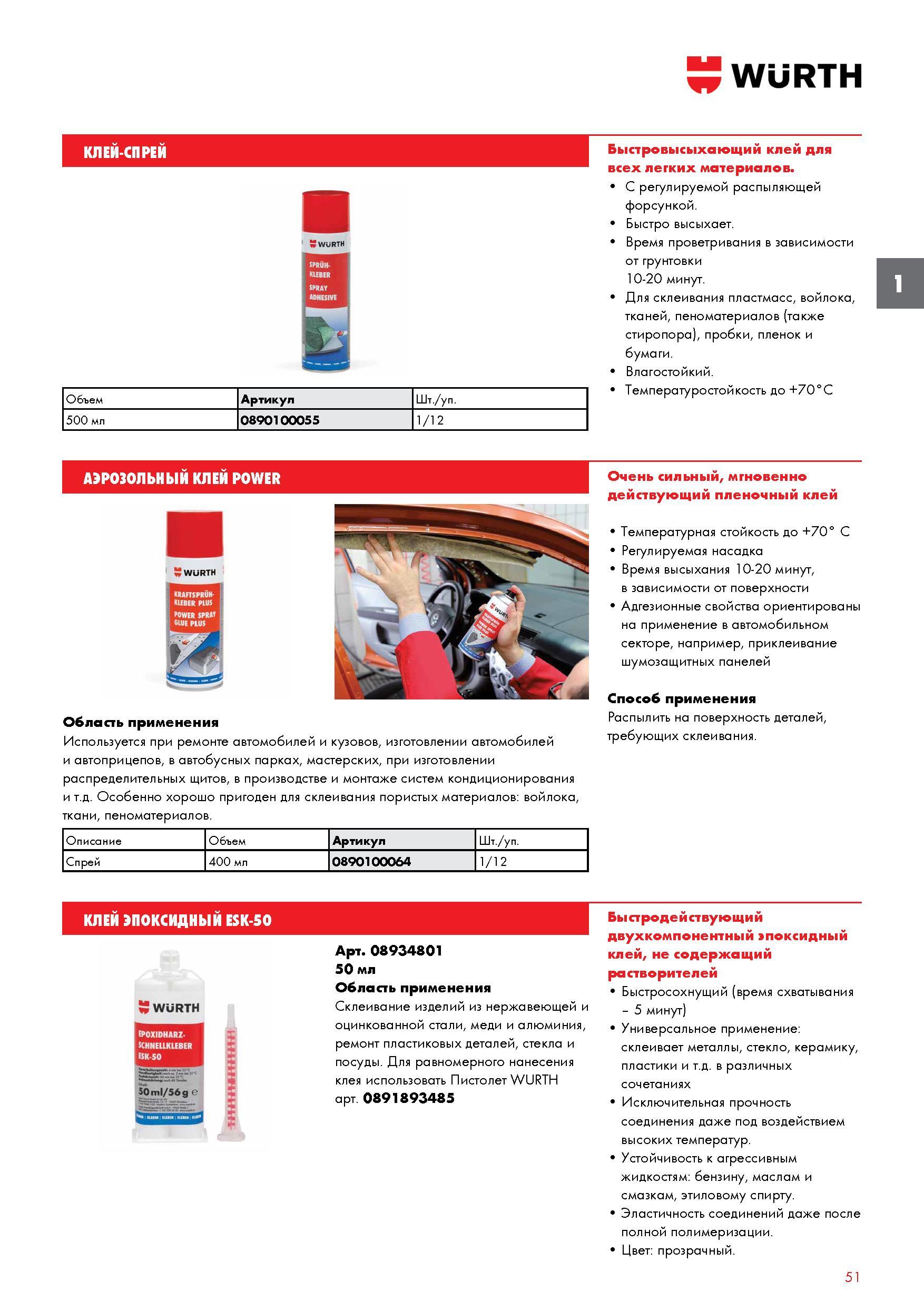

Famous brands producing adhesive sprays

Many newbies get lost when choosing spray glue, going to a hardware store or market. This is due to the large number of products from different manufacturers.

In the opinion of professionals, several names stand out, which are the most relevant, the best. Perhaps the most famous is 3m aerosol adhesive. It is necessary to talk about each of them in more detail.

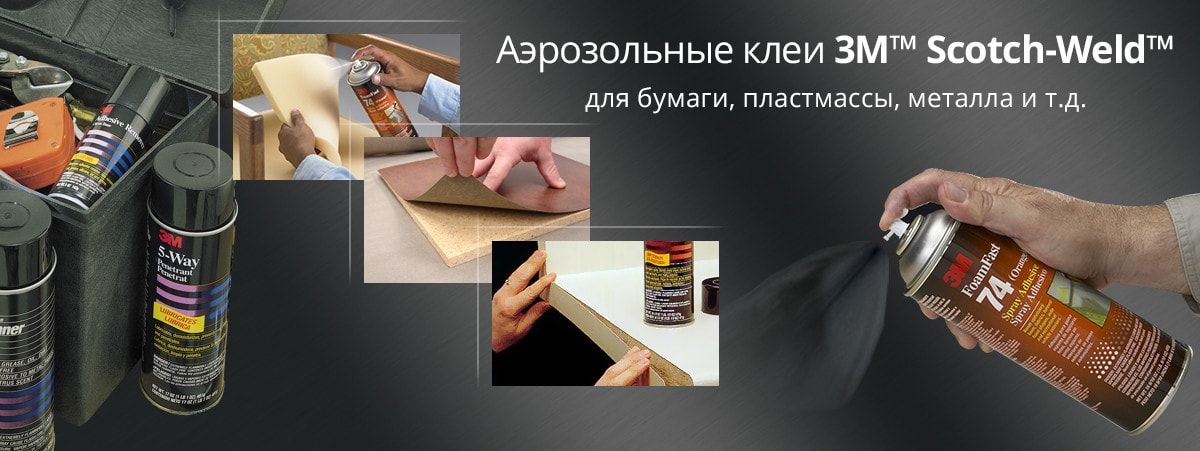

3M Scotch-Weld

Ethyl cyanoacrylate adhesives that have a low viscosity index. Designed for gluing plastic, rubber. Resistant to prolonged exposure to moisture, however, the seams are destroyed by oil, gasoline. The operating temperature of the finished joint is from -30 to +100 degrees Celsius. Does not bleed into porous materials. They can be easily re-glued in case of an error.

Most popular names:

- Glue 3m 77 aerosol.

- Glue 3m 75 aerosol.

The general line is an assembly of both universal and highly targeted adhesives.

Aerosol adhesive Abro

Adhesives of American production. They have several strengths:

- Fast adhesion.

- High adhesion rate.

- Strong finished seam that can withstand heavy loads.

A special cap deserves special attention, which allows you to apply the adhesive mass in a thin layer.

Aerosol adhesive Multi spray

Multi spray aerosol glue has no analogues in the whole world. Its main feature is the ability to independently choose the strength of the seam. The main areas of application are the construction of ships, aircraft. The base need not be cleaned of dust before application. Suitable for gluing any materials.

Aerosol Ghiant Hobby Colle Permanent

An adhesive composition intended for permanent bonding of fabric, paper, cardboard, plastic, foam. Popular in creativity: models, decoupage, decor, etc. Thanks to a special cap, it is evenly applied to the glued surfaces in an even layer. Famous name Hobby aerosol stencil adhesive.

Aerosol Presto

Universal adhesives that are used to join wood, plastic, cardboard, fabric, paper, leather. Before application, surfaces must be cleaned of dirt, degreased. Presto aerosol adhesive should be used for fixing at temperatures from +15 to +25 degrees.

Done Deal Aerosol Adhesive

Done deal aerosol glue is a product intended for gluing leather, textiles, glass, rubber. It is used in repair shops, used for upholstering car interiors. They are made on the basis of rubber with the addition of butane or propane.

Aerosol Krylon spray adhesive

Glue spray, which is intended mainly for decorative work, design work. When working with paper, cardboard, fabrics, it does not leave marks. Before application, the surfaces are cleaned of dust, dirt, degreased. One of the components is an inert solvent that does not damage the foam parts.

Aerosol adhesive Tuskbond

An adhesive composition that is most often used in textile workshops. It can be used to reliably glue leather, fabric, velor, carpet, alcantara. Popular for repairing car interiors.

Aerosol Penosil

The aerosol adhesive most commonly used by finishers and builders. This is due to the fact that insulation materials, foam panels, skirting boards, ceramic tiles, and more are glued with Penosil. For application it is necessary to use an assembly gun.

Adhesive spray UHU Spruhkleber 3 in 1

A universal adhesive composition with which you can glue any materials - hard, soft (exceptions are silicone, polyethylene). The convenient cap allows you to reduce consumption by evenly applying the adhesive to the prepared substrates.

Spray Marabu-Fix it

Adhesive for temporary fixation. It is used for gluing paper, fabric, foil, photographs, napkins, newspapers, stencils. Leaves no residue after removal.

Conclusion

Aerosol adhesives are gaining more and more popularity among amateurs and professionals. This trend is gaining momentum.

With their help, you can easily glue almost any materials together. It is easy to apply them thanks to the special caps, liquefied gas. Adhesives in aerosol cans often have high adhesion to various surfaces and dry quickly after application.

How to make the right choice

Opt for aerosol adhesives for their strengths. These include:

- High strength, at the same time elasticity.

- Fast adhesion.

- Convenient to apply.

- High adhesion rate to various substrates.

- Ability to work with various materials.

- Long shelf life.

- Dosed consumption.

- Safe for the human body (does not emit harmful fumes).

Before choosing an aerosol, you need to decide which materials will be combined most often

At the same time, it is required to pay attention to the operating conditions of the glued parts. The properties of the glue used will depend on this.

General description and properties of polymer glue

It is recommended to understand the general description and properties that polymer-based adhesive liquids have.

Water resistance

One of the advantages of such adhesives is that they are water resistant. Therefore, after application, a strong seam remains on the treated surface, which does not absorb moisture. Due to their water resistance, the mixtures are often used for outdoor renovations. For example, they can be used to fix thermal insulation sheets for insulation made of foam or polystyrene.

Environmental friendliness

It is very important that the adhesive used is environmentally friendly. Mixtures made on the basis of polymers are considered completely safe, since there are no toxic components in their composition.

Such mixtures are made from antimony oxide, which prevents the fire of the glue line.

Heat resistance

High-quality adhesive mixtures made of polymers are resistant to temperature changes. After drying, the glue applied to the surface withstands temperatures from minus fifty to one hundred and eighty degrees above zero. Such resistance to temperature changes allows you to use adhesive mixtures outdoors, even in winter.

Frost resistance

Adhesive mixtures, in the creation of which polymer substances are used, cope well with frost. They do not lose their elasticity and do not crack after being applied to the surface, even when the temperature drops to 45-50 degrees below zero.

Versatility

Another important advantage of adhesive mixtures is their versatility, thanks to which such means can be used for gluing various materials. Polymer compositions are used when working with products that are made of wood, ceramics, plastic, plastic, glass and even metal.

Electrical conductivity

Such compositions for gluing various materials have high electrical conductivity. Electrical conductivity is ensured due to the fact that the composition contains a lot of metal particles. Also, in the manufacture of funds, special electrically conductive powders are used, among which graphite, palladium and silver can be distinguished.

Thermal conductivity

All polymer adhesives have an increased level of heat conduction. This is achieved due to the fact that during the creation of funds a special substance is added - boric nitride. It is thanks to this component that the manufactured adhesives have heat-conducting properties.

Fire resistance

Many adhesives have a serious drawback due to their tendency to catch fire. However, blends made from polymers are flame retardant.

Reliability

One of the main advantages of adhesives is their high reliability. The glued materials are connected so firmly that it will be impossible to separate them even by heating the adhesive seam. On average, the adhesion strength is maintained for ten years. After that, the seam begins to unstick.

Setting speed

People who choose their own glue often pay attention to such a property as setting speed. Polymer adhesives do not set as quickly as other products

This allows you to correct the position of the materials to be glued within 20-30 minutes after applying the mixture.

Fast drying

Polymer-based adhesives differ from most other products in their speed of drying. After application, the seam dries completely within an hour. However, if the liquid was applied to a wet surface or under low temperature conditions, the solidification rate increases by one and a half times.

How to use and store

First of all, you need to read the instructions. No special skills are required for work. Spray glue is not harmful to health, does not create unnecessary pollution during work. However, when working, you should adhere to some rules.

Features of working with adhesive in the form of a spray:

Before gluing, you need to degrease the surfaces and make sure that during the application process they do not get dust particles and lint.

- Shake well before applying.

- Spraying should be carried out at a distance of 20-30 cm.

- You need to wait until it dries completely and only then operate.

- For better adhesion, press the products tightly or use a press.

The can should be stored in a dry and dark room out of direct sunlight. Storage temperature - from +5 to +30 degrees. The period of use is indicated by the manufacturer on the packaging. After its expiration, the spray should not be used, as it loses its adhesive properties.

Spray glue is very convenient and easy to use for various jobs. If, when choosing, take into account the area of use and characteristics, the tool will fully cope with its task. The spray will always be popular due to its invisibility, attachment of a wide variety of materials and the ability to apply in hard-to-reach areas.

Types and application of aerosol glue (25 photos)

Popularity aerosol spray adhesive

can only be compared with PVC glue, and this is due to a number of advantages.

Universal compounds firmly adhere:

- veneer,

- concrete,

- plywood,

- the cloth,

- metal,

- plastic,

- foil,

- tiles,

- stone,

- paper,

- plug,

- cardboard,

- wood,

- felt.

Wherein:

- easy to apply and does not require the use of additional tools in the form of spatulas, tampons and brushes,

- penetrates into any, even hard-to-reach places, evenly applied to complex surfaces,

- you can adjust the spray width, saving material consumption,

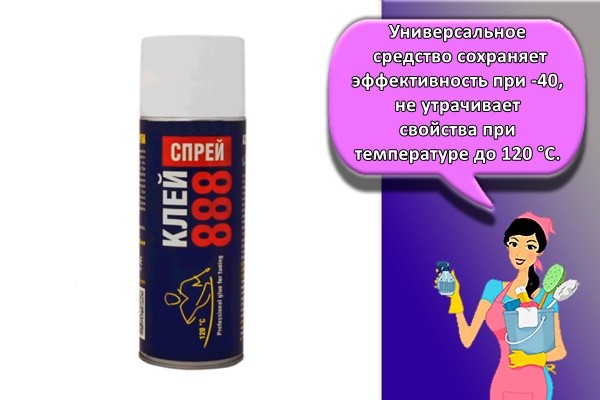

- has high heat resistance,

- does not dry out for a long time during storage,

- does not require long fixation during gluing,

- you can correct the position of the object to be glued until the glue has set,

- is a worthy alternative to double-sided tape,

- adheres materials even to concrete screed.

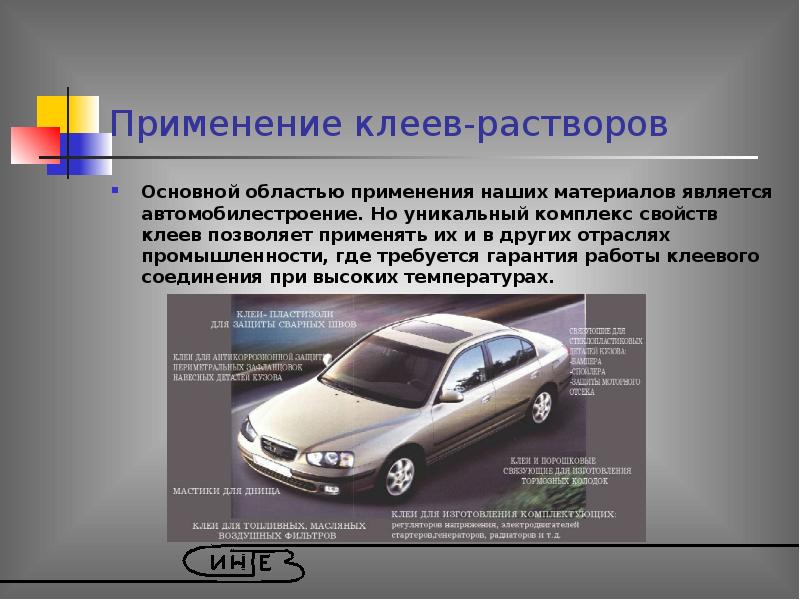

Areas of use:

- furniture manufacturing,

- textile industry,

- production of packaging materials, billboards, leather, fabrics, foam rubber,

- Automotive industry,

- repair and decoration of premises,

- small household work,

- creativity, needlework.

VIDEO ON TOPIC

Varieties

There are six types of glue with the addition of polymers that are used most often.

For interior work

Some funds are used only for internal work. Such mixtures have the following advantages:

- environmental friendliness;

- water resistance;

- ease of use;

- reliability.

However, they are not resistant to temperature extremes and therefore cannot be used for outdoor work.

For external work

Some people have to deal with the arrangement of the facades of residential buildings. To do this, use polymer compounds that are suitable for external work. They are often used to fix insulating sheets, ceramics or mosaics.

Universal mixtures

Universal waterproof glue is used for external and internal work. It contains components that increase the frost resistance of the products and make them resistant to high humidity. Also, the advantages include the balance between product quality and its cost.

Mounting solutions

Sometimes you have to use special mounting solutions. They are used for gluing heavy products, fixing facade parts or building up chips. Such solutions are used not only in various industrial fields, but also in everyday life. The advantages of mounting tools include resistance to vibration, mechanical damage and exposure to chemicals.

Liquid Nails

Liquid nails are a polymer adhesive solution that is suitable for gluing plastic, ceramics, glass, iron surfaces, as well as drywall boards. The composition of liquid nails contains synthetic rubber, due to which the agent sets faster. The mortar is very reliable, as only a small spot application is sufficient for fixing the materials.

Cold welding

It is the least common adhesive used only for bonding wood, plastic, glass and clay surfaces. Most often, cold welding is used when it is necessary to glue a damaged or broken product.

Review of popular brands

There are eleven popular manufacturers of rubber mixtures, whose products are most often used.

Rubber cement

It is a high quality compound made from natural rubber mixed with solvents. Rubber Cement is most commonly used to bond elastic products. After drying, the glue layer resembles rubber in its consistency.

4508

People who are interested in waterproofing products should pay attention to 4508. It is used in the manufacture of products made of rubber

4508 does not lose its properties on contact with water and therefore can be used when repairing wetsuits or rubber boats for fishing. Among the disadvantages of the funds are the fact that it quickly ignites if it is near a fire.

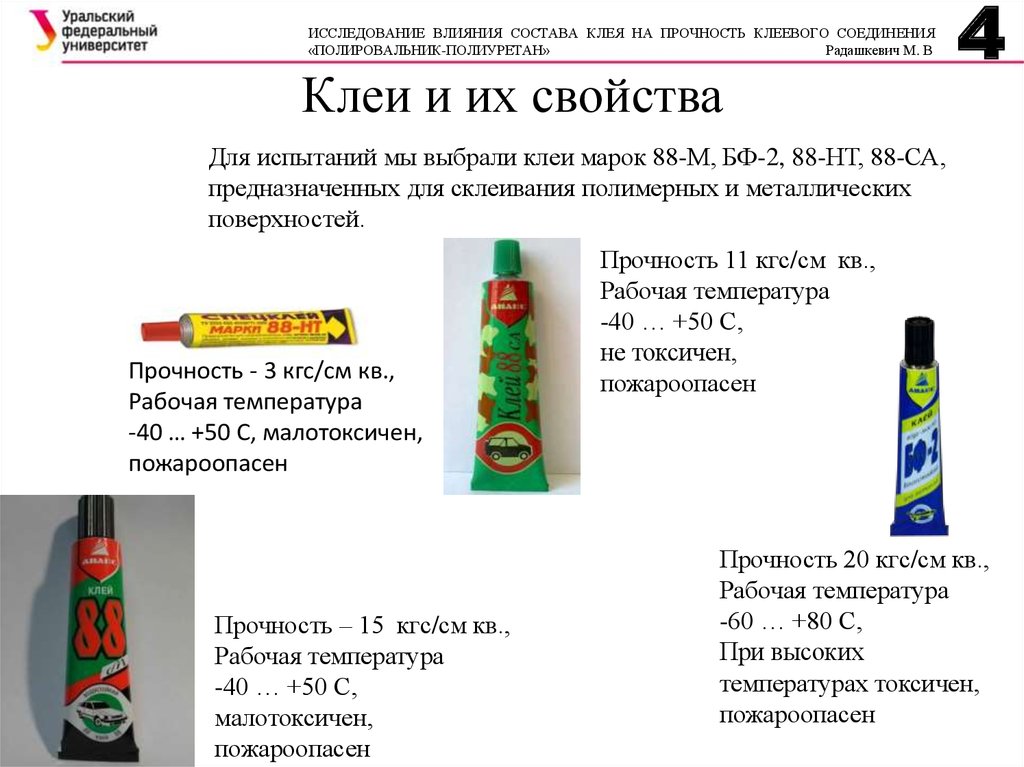

88 CA

It is a versatile adhesive that is used for bonding metal, wood, glass, concrete, fabric and plastic surfaces. 88 CA is resistant to temperature changes, so it can be used at temperatures ranging from minus fifty to plus sixty degrees. Store 88 CA in dark rooms, protected from children.

Loctite

It is a one-component adhesive mixture that only begins to cure at room temperature. Therefore, experts recommend using Loctite only indoors. Suitable for gluing wood, metal, plastic and rubber surfaces. The advantage of Loctite is that it hardens in 10-15 seconds after use.

"Gum"

Fans of elastic products should turn their attention to "Gummi". It is used in the repair and manufacture of products from durable fabric or rubber.

Also "Gummi" is suitable for gluing cardboard, paper, wood and natural leather. Among the advantages of the glue are resistance to low temperatures and high humidity.

"Radical"

People who are going to repair a wetsuit should use Radical.It is ideal for restoring water supplies as it is highly resistant to moisture.

"Mark A"

Such a tool is used during the manufacture of rubber or leather shoes, bicycle tubes and tires. "Grade A" contains components that exhibit increased adhesion to glass, leather, wood, rubber, paper and foam rubber. Resistant to low temperature and high humidity values. Thanks to this, it is used both indoors and outdoors.

88n

It is a yellowish homogeneous mass in which there are no foreign inclusions or lumps. 88n is recommended for bonding materials such as plastic, leather, rubber, wood, ceramics, glass, porcelain and paper. The mixture hardens within ten hours after application. During long-term storage, a little sediment may appear in the liquid, but it does not affect the properties of the glue in any way.

GOST 2199-78

According to GOST, adhesives made from natural or synthetic rubber can be used in several areas of activity. They are used in the manufacture of leather furniture or footwear. Also, glue is often used to make rubber products that are often in contact with water.

Plasti Dip

Such a product is made on the basis of an aqueous emulsion containing bitumen-type polymers. Plasti Dip is used for bonding thin rubber materials, paper or wood. The composition is durable and shock-absorbing.

Rubber cement

Rubber cement is often used to restore rubber products. It is often used to repair punctured inflatable boats, bicycle tubes or mattresses. The advantages of Rubber cement include fast solidification, reliability and resistance to moisture.

Composition and properties

The ratio of epoxy and polyamide resins in the composition of VK-9 is 1: 2, in mass units - 60:40. Visually - a gray, viscous mass. Additional components - organosilicon compounds and mineral inclusions:

- asbestos;

- boron nitride;

- titanium dioxide.

The compositional composition hardens at a temperature of +20 degrees. Heating the components during mixing until they boil leads to crystallization and loss of adhesive properties. The mixture retains the property of gluing surfaces for 2.5 hours. The seam obtained after hardening is highly resistant, does not allow water to pass through, does not react to acids, alkalis, heating, and does not shrink.

The maximum tensile strength after hardening at +20 degrees is achieved during the day:

- setting after 2 hours;

- strength at a pressure of 10-12 technical atmospheres (atm) - after 5-7 hours;

- in 150-160 technical atmospheres (atm) - after 18-20 hours.

The in-plane shear strength varies from 140 atm at +20 degrees, to 45 atm at +125 degrees. The adhesive bond retains its working qualities at temperatures up to +125 degrees. At +200 degrees, functionality - 500 hours, at +250 degrees - 5 hours. Each of the components of the glue has advantages, the combination of which gives, in general, the desired properties.

Epoxy resin

Epoxy resin in VK 9 is a brown, transparent, viscous liquid.

Characteristics of the substance:

- gives a strong bond with metal surfaces;

- resistant to aggressive chemical influences;

- uniform solidification, without shells and cracks;

- does not collapse under the influence of temperature;

- does not let water through;

- during the hardening reaction, phenols, formaldehydes evaporate.

In its pure form, the epoxy joint is not flexible enough: it cannot withstand vibration.

Polyamide resin

Polyamide and epoxy resins mix well.

Polyamide polymer:

- elastic;

- slightly absorbs water;

- does not emit toxic fumes;

- possesses high density after solidification;

- resistance to compression.

The synthetic compound belongs to surfactants, superior in adhesion property to epoxy resin.

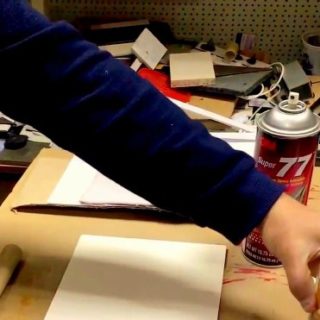

How to use aerosol adhesive

To obtain the most effective result when using aerosol glue, a number of conditions must be met:

- prepare the surfaces to be glued (they must be cleaned, dried and degreased);

- heat or cool the container with glue in natural conditions (it is optimal to use glue at room temperature);

- immediately before use, the container must be shaken vigorously;

- adjust the width of the glue stream by turning the spray head (the width depends on the characteristics of the material on which the glue is applied - the more porous and heavier the material, the wider the layer should be);

- Apply glue to one of the surfaces to be bonded for light objects, or on both surfaces to be bonded if the materials are heavy or porous. The glue is sprayed onto the surfaces to be glued from a distance of 15-20 centimeters from the surface. When spraying, the glue container must be held parallel to the surface to which it is applied, and the spray gun must be pressed to the end, applying the glue evenly and slowly, but without stopping;

- let the glue dry for 5-10 minutes and apply a second layer if necessary;

- keep the time until the glue is completely dry (up to thirty minutes).

After using the glue, the container must be turned over and pressed on the spray. Hold in this position until all the remainder of the glue comes out of the spray tube. Unused glue in an aerosol can is stored at a temperature of 5-30 degrees in a dry, shaded place.

Other articles

December 6

The well-coordinated operation of the car's heating system determines the temperature inside its cabin. The temperature regime affects not only the comfort of its driver and passengers, but also the ability to optimally control the vehicle. The key role in the operation of the heating system is played by the heater tap, which will allow you to start or stop the operation of the corresponding system at the right time.

5th of December

Many adults dislike winter, considering it a cold, depressing season. However, children have a completely different opinion. For them, winter is an opportunity to lie in the snow, ride a roller coaster, i.e. have fun. And one of the best helpers for children in their boring pastime is, for example, all kinds of sledges. The range of the children's sledges market is very extensive. Let's consider some types of them.

15th October

Feeling the breath of winter, all motorists think about replacing seasonal tires. And very many of us when buying winter tires face a difficult choice - "studs" or "Velcro"? Each type of tire has its own advantages and disadvantages, and it can be very difficult to give preference to one particular tire. In this article, we will try to make this difficult choice.

October 14

Pouring low-quality diesel fuel into the tank can harm the engine up to its complete failure. To minimize or eliminate the negative consequences of refueling with a low-quality diesel engine, special auto chemistry helps - additives in diesel fuel, which are described in detail in this article.

13 October

Twice a year, all drivers ask one question - when to replace seasonal tires? In the spring everyone is wondering when to put summer tires, and in the fall they are looking for a moment when to install winter tires, and very often drivers make a mistake. How to choose the optimal time to replace seasonal tires, and how to avoid mistakes in this difficult matter - read in this article.

October 11

Heaters and preheaters of the German company Eberspächer are world-famous devices that increase the comfort and safety of winter operation of equipment. About the products of this brand, its types and main characteristics, as well as the selection of heaters and heaters - read the article.

Reading time:

6 minutes

How often do your clothes, bedding and other textiles tear? No one is immune from such situations, so there are different options for solving them.Of course, you can just sew it up, but this does not always work. The hole may appear in a conspicuous place where the seam will be very visible. This is where aerosol adhesive for fabric and other materials comes to the rescue. There are at least 5 varieties of this glue. Choose the composition based on the material to be glued.

The main difference between aerosol glue and other types is the principle of application. The adhesive components are in an aerosol can. Thanks to the spray gun, it is easy to apply and lays down evenly. The number of layers can be adjusted. Excellent for bonding materials in hard-to-reach places and large surfaces with different textures. This adhesive is hermetically sealed and provides an elastic connection.

Plexiglas gluing

The process of gluing organic glass elements is accompanied by a number of difficulties. The fact is that the material can have a different chemical composition. What is usually meant by plexiglass can be acrylic, polypropylene, polystyrene or polycarbonate. These are materials of different chemical composition, therefore, for some, a certain type of glue is suitable, while for others it is useless.

For gluing plexiglass can be used:

- Specialized reaction adhesives.

- Solvents.

- Contact adhesives.

Reaction glue is the most convenient to work with. It allows you to create a transparent seam that effectively holds the elements together. The toxicity level of the adhesive is the lowest in comparison with solvents or contact compounds.

A cheaper solution is to use solvents. The use of such materials makes it possible to obtain high-quality adhesion, but the process of solidification of the joint takes longer. In a small amount of solvent, plexiglass shavings are added, with which you have to work. As a result, it dissolves, which makes it possible to obtain a sticky mass. The solution is used for bonding. Alternatively, you can simply apply the solvent to the parts to be joined. They shrink together, dissolve at the edges and are welded into a monolithic structure.

The weakest bond is the contact adhesive. It can be "super glues", epoxy resin. The use of such components gives a very poor result. Parts disintegrate even under low mechanical pressure.