Features of polymer material for the floor

Linoleum is a popular polymer roll floor covering in a private house, apartment or office. Such material is also in great demand for laying floors in industrial, warehouse and workshops.

Positive traits

The popularity of the use of polymer flooring is due to a number of its advantages:

- sufficient density;

- good flexibility;

- waterproofness;

- a large selection of structures and colors;

- affordable price;

- ease of handling the material.

Coating characteristics

Variety of coating texture

The polymer roll floor covering is produced in rolls, which have a width from half a meter to 5.0 meters and a length from 6.0 to 45.0 meters. The thickness of such a coating is 1.50 - 5.0 mm, and for laying floors in industrial, sports facilities, the thickness increases to 9.0 mm.

Laying on the floor

The industry produces a coating that has a heat and sound insulating base, so it can be laid directly on a concrete screed without special surface preparation. The substrate must be flat and dry. Laying of the coating is carried out using a special glue or polymer mastic.

Repair and restoration of linoleum

Restoration of linoleum The article describes the reasons for the appearance of defects in linoleum coating and how to eliminate them in various cases.

- Causes of damage

- Removing stains

- Repair of joints

- Removing holes

- How to remove bumps

- Sealing punctures and dents

- Restoration of torn linoleum

- Burn update

Linoleum is a polymer floor covering. It belongs to roll finishing materials, looks very presentable, provides thermal and sound insulation of the ceiling and perfectly imitates natural materials, having a rich variety of patterns. However, during operation or as a result of improper installation, damage to the coating can occur that violates its aesthetics. You will learn how to update linoleum after renovating a room and fix defects in this material by reading this article.

Sealing punctures and dents in linoleum

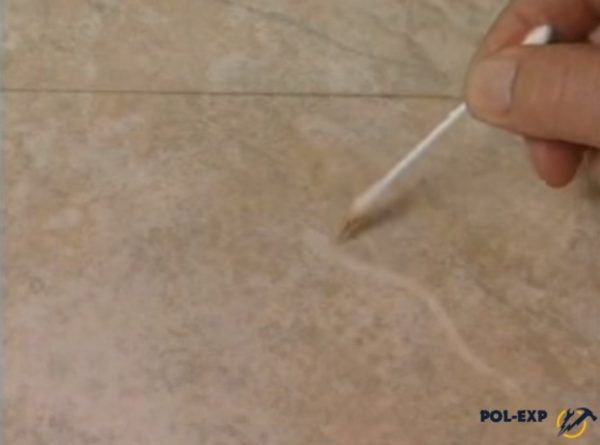

If punctures are found in linoleum, they must be eliminated, since during wet cleaning, water can enter through the holes under the floor covering, which ultimately will lead to its swelling. Small punctures less than 1.5 mm in diameter can be removed with PVC adhesive.

You need to stick an adhesive tape on the puncture site of the coating, and then make a thin hole in it just above the defect. In this case, the tape should not cover the edges of the linoleum puncture. Then, through this hole, it is worth pouring some glue into the puncture. When it hardens, the adhesive tape must be removed, and the excess adhesive mixture must be carefully cut off to the level of the linoleum surface.

If punctures larger than 1.5 mm in diameter are detected, a thicker glue should be used. In this case, no tape is needed. C-type "cold welding" is suitable as a binder.

Dents on the surface of linoleum can be sealed with putty, which can be prepared in two ways:

Dissolve twenty parts of rosin in five parts of alcohol, add dry paint that matches the color of the coating and four parts of castor oil. Then all this must be mixed thoroughly.

Dissolve one part of rosin in four parts of thick turpentine and add a pigment that matches the color, then mix the composition.

After sealing the dent, the mastic should be smoothed out with a spatula, and after drying, its surface should be sanded with sandpaper.

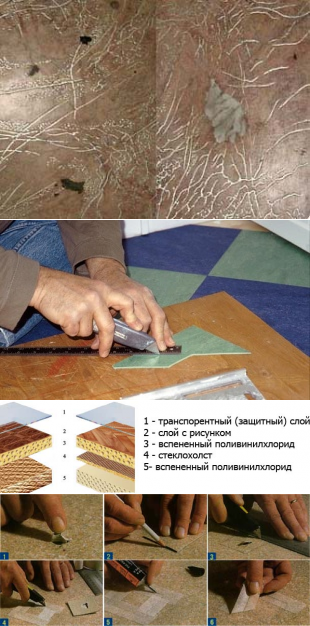

Refreshing linoleum when burning

Probably, most often it has to be done by hookah lovers, and not only by them.The approach to solving the problem with a burnt coating depends on the depth of its damage. Small coals, as a rule, are capable of disturbing only the first two layers of linoleum - protective and decorative. Less often, the upper layer of the PVC base is also damaged, very rarely - when the coating burns through.

If only one transparent protective layer of linoleum is damaged by fire, when its pattern is not touched, the resulting defect after cleaning the burnt edges is practically invisible. And so that it does not stand out in the light as a dark spot, the border of damage can be slightly shaded with the edge of the coin. After that, the "burn" must be putty with a thin layer of linoleum mastic.

In the event of damage to the coating pattern and its base after removal of the burnt place, the burnt spot is very noticeable: this spot has dark edges and yellowness in the middle. Such a defect greatly spoils the appearance of the coating, especially when there are several such spots. In this case, it is possible to repair the linoleum, as in the case of its rupture, with the help of "cold welding" type-C glue.

In addition to it, you will need a pigment that matches the color from the store. Although you can make it yourself. To do this, you need to find a piece of the same linoleum, which is currently burnt on the floor. If this is difficult, try cutting it off from the floor covering somewhere inconspicuous - under a skirting board, for example.

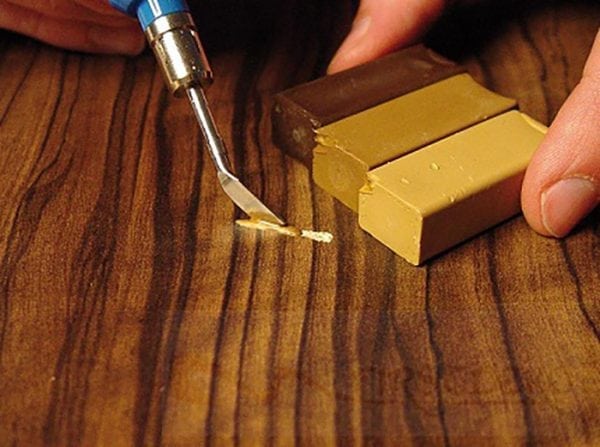

Colored chips should be scraped off the outer surface of the found sample with a knife, collected and mixed with the repair mixture. With the finished composition, it is necessary to fill the burnt area of linoleum, and when the mixture hardens, you need to cut off its excess flush with the coating plane. As an additional measure, it is recommended to then treat the entire surface with a special wax.

If the linoleum burn through is through, you will have to put a patch on it. But in any case, it will be noticeable. Do not leave a hole in the coating. When water gets through it under the linoleum, a damp environment is formed, which promotes the multiplication of spores of fungus and mold. Therefore, when burning, linoleum repair is required.

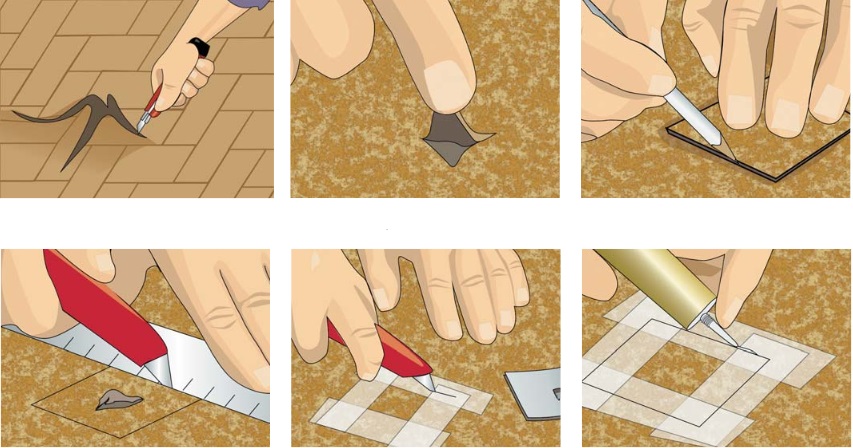

The work is carried out in the following order:

- You need to pick up a suitable piece of linoleum and lay it on the burnt hole.

Then, using a sharp knife, cut through the patch material and floor covering so that the defective surface is located inside the closed cut line. As a result, you should get a hole that is identical in shape to the cut out patch.

After that, lifting the linoleum, you need to carefully glue the edge of the hole to the base, and then connect the joints of the patch and the holes with "cold welding".

After the adhesive has polymerized, its excess at the seam must be cut off flush with the floor covering.

In addition to all the above repair methods, small defects in linoleum can be masked with applications, that is, contrasting patches in the form of roses, butterflies and other things can be glued onto the coating, creating a certain pattern. Then these places are usually covered with a special linoleum varnish. Everything turns out to be quite touching and original.

How to restore linoleum - watch the video:

That's all. We wish you more creative ideas and less trouble. And even if spoiled linoleum does not create any special problems now, especially since you already know how to get rid of them. Good luck!

Option number 1: glue over the entire area

How can you fill a hole in linoleum? You need to prepare the following:

- a piece of linoleum of the same color;

- sharp assembly knife;

- metal ruler;

- construction tape;

- linoleum mastic and cold welding glue;

- notched trowel;

- hard roller.

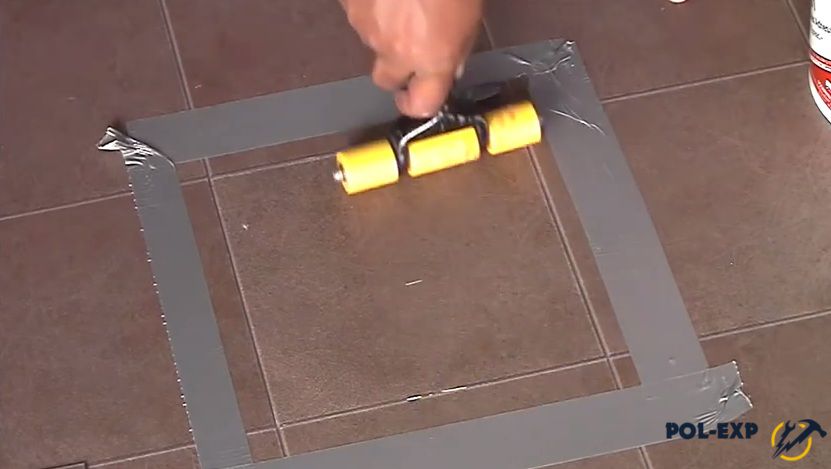

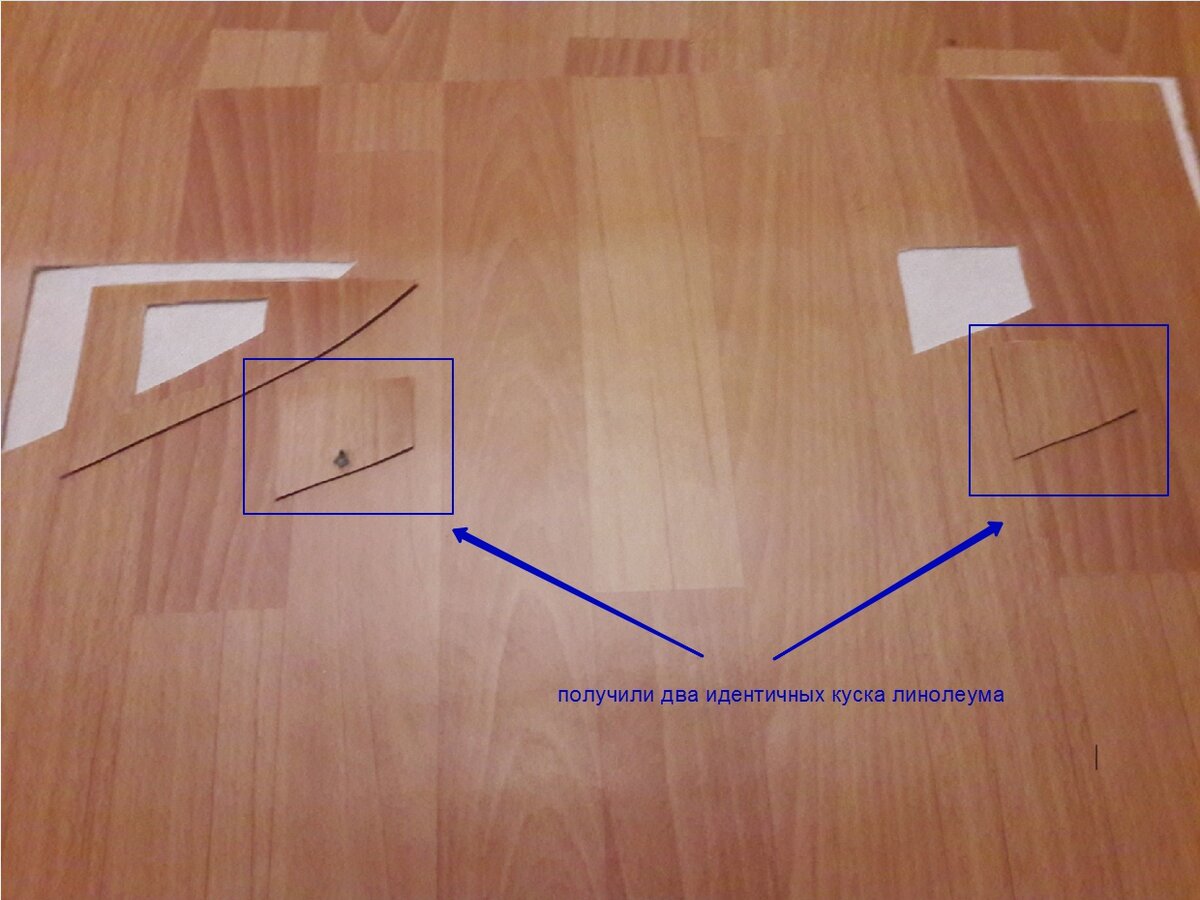

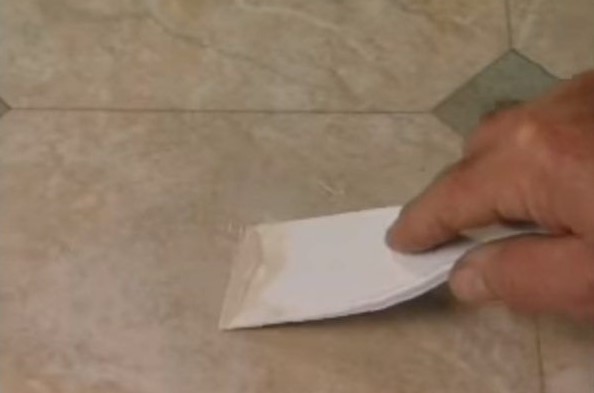

Linoleum must be cleaned of dirt and dust. A patch is placed on the prepared area over the defect, aligning the lines of the pattern. Then the correct position is selected, the linoleum is fixed with tape around the perimeter.

Then a ruler is applied to the coating and both layers are cut through to the base of the floor.It is necessary to remove the top piece, put it aside.

It is necessary to try on the patch to the cut-out area in the coating, check the tightness of the joints and the compatibility of the pattern. Apply the mastic in a thin layer to the substrate with a fine-toothed spatula. To securely fasten the edge of the coating around the perimeter, it is necessary to lift it with your fingers and smear it with mastic under it.

The patch is laid on the site, while it is necessary to monitor the location of the pattern. The material is smoothed with hands, pressing along the edges, and then rolled out with a roller in all directions. Then you need a type A "cold welding" glue, the tip is inserted into the seam and lead along the perimeter

It is important that the adhesive is evenly distributed in the joints.

Until it dries, do not touch the patch, step on it, otherwise there is a risk of displacement and deformation. It is advisable to lay a piece of plywood on it, press down with a load and leave it for several days.

Ways to solve basic problems with your own hands

There are many problems with linoleum, each of which has its own way of solving.

Went in waves

If a defect appears near the wall, you can suspect the absence of a technical clearance during installation. To cope with the problem, it is recommended to remove the skirting board along 3 walls and trim the canvas. It should lie down for several hours - it all depends on the thickness of the material and the temperature regime. When the linoleum straightens out, the skirting boards can be put back.

If a bubble appears in the center of the room, it is worth carefully making cuts on 2 sides along the bulging. Then it is recommended to release the air and glue it with masking tape. This avoids the contact of glue residues on the adjacent areas.

Glue is injected into the holes with a syringe and the edges of the coating are joined. Then masking tape is glued and a load is applied. Stretching of the coating sometimes leads to swelling. In such a situation, it is recommended to cut the canvas and remove the excess. It is necessary to fix linoleum in the same way as in other situations.

Joining seams

When fixing linoleum in large rooms and on thresholds, it is fixed by cold welding. When using, there is a risk of seam divergence. Anyone can glue such a coating on their own. It is recommended to stretch the canvases with an overlap of 5 millimeters. In the center of the bump, it is worth making a cut and grabbing 2 edges. The procedure must be carried out with a flat bar. Then remove the trimmed excess and degrease the edges. The surrounding areas are cleaned with masking tape.

For the work, it is recommended to take type C PVC glue. For this, it is worth processing the edges, glueing and leaving under the load

After the glue hardens, the excess must be carefully trimmed with a knife, remove the adhesive and treat the welding area with wax

Elimination of burn-throughs

A patch will help to cope with such damage. To do this, it is recommended to cut out the damaged area in the coating. It is best to give the hole the correct shape - round, square, or rectangular. If after fixing the linoleum there is a scrap left, this is considered an ideal option. Otherwise, it is worth choosing a cover of a suitable texture and color.

It is recommended to cut out a patch from it, which is the same size as the hole. You need to try it on

It is important that the pattern and size match. It is recommended to cover the edges of the hole with masking tape.

Clean the floor of debris and prime with a primer. Apply glue to the patch and glue it into the hole. To do this, it is permissible to use PVC or PVA glue. At the place of repair, they put oppression for 2 days.

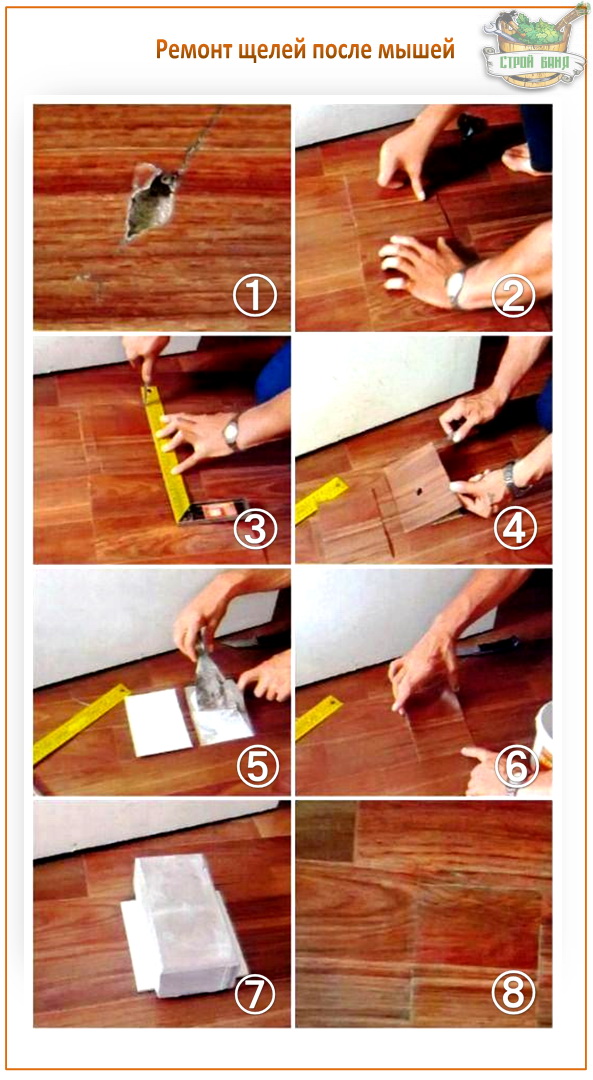

Pasting torn holes

If the linoleum is torn, it can be repaired with a patch. It is also permissible to glue the torn off surface in place if the damage has smooth edges.

Bonding with mastic

Mastic is one of the most popular adhesives. It allows you to easily glue linoleum at home.The method is reliable, it connects "tightly", but if you need to remove the coating for a while, then in the place where the mastic was used, the linoleum will break. In this way, it is also easy to attach a raised piece.

Work order:

- Before gluing the joints, the base is primed.

- Degrease the edges of the coating with any alcohol-containing agent. Acetone or solvents should not be used, as they can corrode linoleum.

- Once the base is dry, apply a small amount of mastic with a spatula.

- Then the edges of linoleum are applied to the surface, pressed tightly. The joint must be carefully rolled with a hard roller.

The mastic dries for about a day, so at this time the place of treatment of the coating must be firmly pressed with something heavy. A board is laid on the joined edges, and a load is placed on it.

What to do if linoleum is burnt?

Today, the range of hardware stores has a large number of high-quality linoleum. It meets all standards and norms, but there are several reasons why it is not very popular and widespread. One of them is cost.

If you bought a high-quality commercial linoleum, then this article is perhaps not for you: it is almost impossible to accidentally burn such linoleum or seriously damage it. But when purchasing linoleum for an apartment, we usually choose the household class of linoleum.

It is such linoleum that is easy to burn through by accidentally dropping hot curling irons, a cigarette or a soldering iron. If you have household linoleum in your house, then a fallen cigarette butt or a soldering iron will most likely cause damage to the floor covering. If the linoleum is commercial or semi-commercial, then there will be no damage left on it.

Now it remains to answer the main question, what to do if you burned the linoleum

First, it is important to immediately remove the hot object from the linoleum to prevent fire

If we talk about the fallen butt, then, of course, it cannot inflict serious damage to the linoleum coating, since during the fall it manages to cool down. However, even such a small thing as ash can leave noticeable marks on the material. Another common situation when linoleum will be damaged can arise if your flooring is laid near sources of open fire, for example, near a stove or fireplace. In such cases, a red-hot spark that has flown out can not only burn through the linoleum, but also start a fire.

If, nevertheless, a misfortune happened and the linoleum in the apartment is still burned out, and you do not want to spend money on its complete replacement, then you can fix it using some simple tips for repairing linoleum. To begin with, you can make a patch that would fit in size and pattern in the burnt area.

Repair of linoleum joints by welding

It consists in restoring the tightness of the seams between the coating sheets. At home, such a do-it-yourself linoleum repair can be done in two ways: "cold" and "hot".

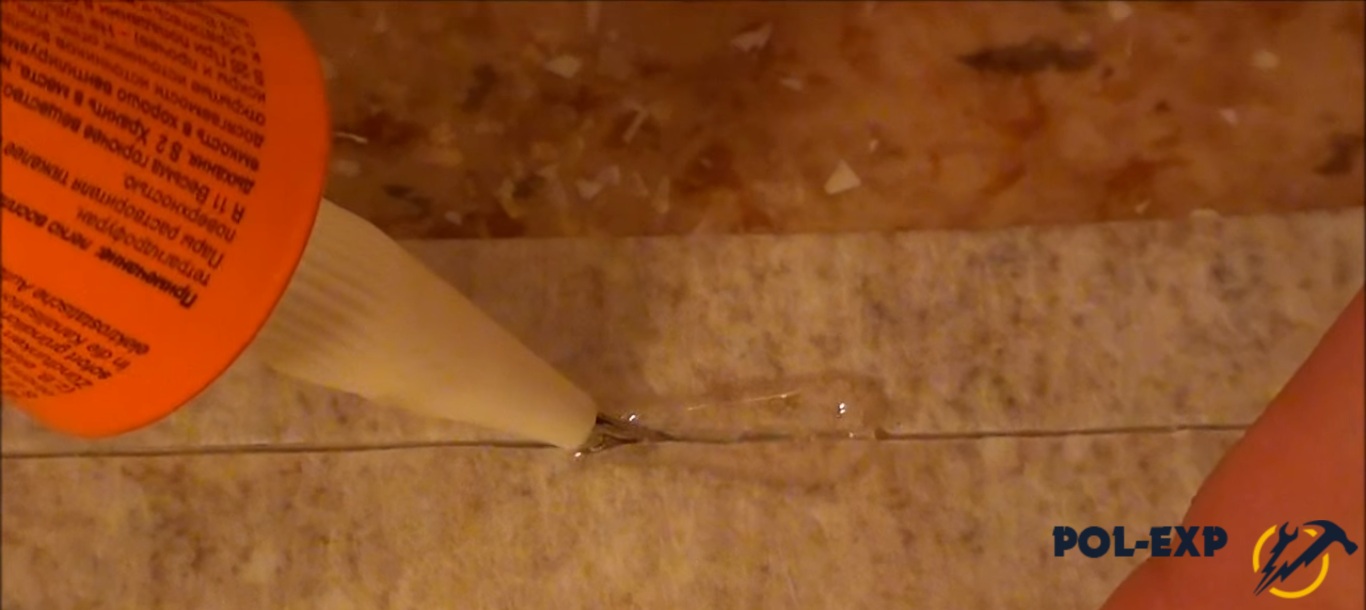

"Cold welding" is a conventional name for the procedure for gluing sheets, in which their contacting edges dissolve with the help of chemically active components of a special glue and are monolithically connected, mutually penetrating each other by 0.1-0.5 mm. After the glue dries, the edges of the sheets remain interconnected by their own structure particles. The "cold" welding method is considered the most reliable and especially relevant for joining elastic materials.

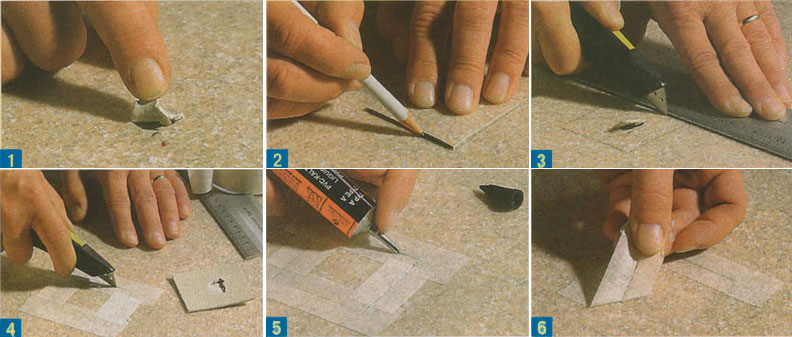

The procedure is as follows:

- It is necessary to combine two canvases of linoleum with an overlap of 50-60 mm.

In the middle of this thickened area, you need to draw a longitudinal cutting line with a pencil.

Place a soft pad under both sheets.

With the help of a sharp knife and a metal ruler, it is necessary to cut both sheets of linoleum at the same time along the marked line.

Then remove the trim and lining, stick masking tape on the resulting seam and cut it along the same line.

After that, a special tip should be installed on the tube with glue and the seam between the coating sheets should be carefully filled with the help of its needle by "cold welding".

After 15 minutes, the tape must be removed, and after three hours the seam will acquire its final strength.

This method of repairing linoleum floors is very popular, but there are often problems with the choice of glue. It is usually labeled as "linoleum glue" or "cold weld". It is produced by Bostik Linocol (France), RICO Grace (Poland), Werner Muller Type C, FORBO 671 Noviweld (Germany), Homakoll S 401, CYCLONE H 44 (Russia) and others less well-known. The cost of packing glue, depending on its volume, is $ 8-15.

Hot welding of linoleum seams is performed using a polymer cord and a hair dryer with a special nozzle. When heated, the cord becomes plastic, it is placed in a seam 3-5 mm wide, where, upon further heating, the material is vulcanized together with the edges of the linoleum canvases. After cooling, the molten cord forms a monolithic structure with the edges of the seams.

How to close a hole in linoleum without a patch

You can get rid of dents and small holes with the help of special adhesives for linoleum:

A-type PVC adhesive. The consistency of the composition is quite liquid, suitable for sealing deep scratches, holes with a diameter of up to 1.5 mm. In order not to stain the adjacent surface, masking tape is glued to the place of the defect. A neat cut is made in it over the hole in the floor covering. The adhesive is pumped in with a syringe. Preferably flush with the surface. After hardening, remove the tape. If the glue sticks out above the surface, then it is carefully cut with a knife. For the best effect, the place is rubbed with wax.

PVC C-type adhesive is suitable for larger holes. Has a thicker composition. The best option is to use it in conjunction with a color scheme to match the color of the coating. Both compositions are mixed, poured into the hole.

Features of sealing holes

The restoration of the floor covering has a number of subtleties:

- Defect location. If this is the center of the room, you will have to work hard to disguise the place of repair. In the corners, under the furniture, damage to the linoleum will be less noticeable.

- The scale of the defect. Repairing large areas is more difficult, you cannot do without a patch.

- The presence of a drawing. With such a linoleum for small defects, you will have to select several colors, if there is no piece left from the installation of the floor covering.

If the hole that appears immediately is not repaired, then gradually it will creep away under mechanical stress. Dirt will accumulate in it, which over time will lead to swelling of the coating, the appearance of unpleasant odors.

Linoleum went in waves

If the defect occurs next to the wall, it is most likely that the technical clearance was not observed during installation. Unscrew the plinth along three walls, cut the canvas, leave it to lie down for several hours, days, depending on the thickness of the material and the ambient temperature. The flooring is flattened, the skirting boards are installed back.

If the linoleum is swollen with a bubble in the middle of the room, then along the swelling, neat cuts are made on both sides, air is released, glued with masking tape so that excess glue does not stain the adjacent area. Glue is injected into the holes formed with a syringe, the edges are joined, fixed with masking tape, and left under the load.

Blistering of the coating often occurs due to stretching of the web. It will be necessary not only to cut the canvas, but also to remove its excess. Gluing is carried out in the same way as in the previous methods.

Joining seams

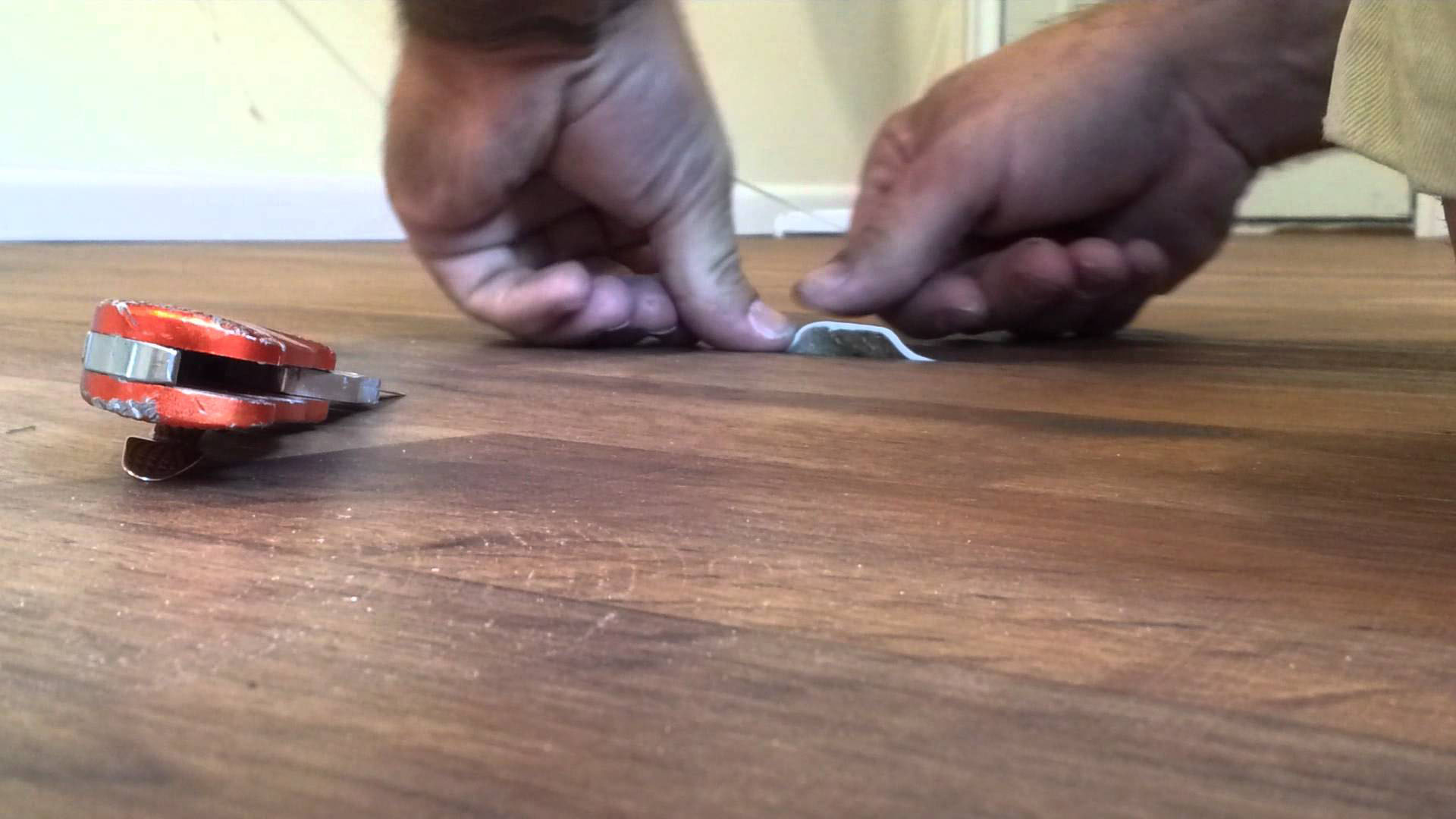

When installing in large rooms and on thresholds, the linoleum connection is often performed using cold welding. During operation, such seams sometimes diverge. Anyone can glue linoleum on their own. The canvases should be stretched with an overlap of 5 mm. In the middle of the resulting bump, make a cut, capturing two edges.Perform the operation with a flat bar. Remove the cut off excess. Degrease the edges, protect the adjacent surface with masking tape. For work, you need PVC C-type glue. The edges are processed, glued, left under oppression. The glue is frozen, the excess is carefully trimmed with a knife, the adhesive tape is removed, the welding site can be waxed.

Close up the charcoal hole

Eliminated by installing a patch. A damaged place is cut on the floor. It is better if the hole is prepared in the form of a regular shape: square, circle, rectangle. If there is a scrap left after installing the floor covering, this is ideal, otherwise you will have to go to the store, select the material that matches the color and pattern (if any). After that, a patch for the resulting hole is cut out, tried on. The pattern, the size (the patch enters the cut-out space on the floor, fits snugly to the edges), the direction of the texture should converge.

The edges around the hole are protected with molar tape. The floor in the area of the hole is cleaned of debris, treated with a primer. Glue is applied to the patch, glued into the prepared hole. Used PVA, PVC glue. At the place of repair, oppression is installed for 2 days. You can restore a burnt hole by showing design skills. For example, make an applique using canvases of different colors.

Torn holes

It is solved with the help of a patch or gluing the torn off surface in place, if the edges at the place of the defect are even.

Even large holes that have arisen during operation can be repaired thanks to modern adhesives and ingenuity.

Repairing minor defects

Small cuts and cracks are the easiest to repair, but many choose not to. Indeed, they are almost invisible on the surface, do not stand out, do not interfere. But over time, dirt and dust will start to clog in them, the edges will fray, the hole will expand. Therefore, you must immediately choose the appropriate method and seal the hole.

How to fix a minor defect in the coating? Here is a list of suitable remedies:

- Mastic. It is realized in the form of a paste, pencil, various colors.

- Cold welding. Reaction adhesive allows you to quickly and reliably eliminate any defect. Melts PVC coating, creating a smooth, inconspicuous seam.

- Sealant. It is advisable to purchase a tool for woodworking, choosing the desired color, it will eliminate minor defects.

Scuffs can be removed with linoleum wax. Shallow damage is well rubbed with such a composition. This should be done with the edge of a coin, then treated with a cloth until a glossy surface is obtained. You can also cover up scuffs with mastic, polish. Before repairing, it is imperative to clean the floor covering from dirt, debris, and dry it well. If necessary, you need to degrease the area.

How to glue a small through hole? It is best to carry out repairs by cold welding, this method is suitable for gluing gaps up to 3-4 mm, but there are compounds on sale for larger cracks. Masking tape is glued to the area around the defect for protection, then glue is applied using a thin spout. After the surface melts, the hole will disappear. As the tape hardens completely, the adhesive tape is removed, and the excess glue is cut off with a sharp knife.

It is necessary to work with cold welding carefully, such means are toxic. It is imperative to use a respirator, gloves, ventilate the room well

Also, small cuts and tears can be glued together with a homemade remedy:

- melt half a kilogram of rosin in powder in a water bath;

- cool the mass to 50 degrees, add 150 ml of alcohol, 100 g of castor oil;

- tint the mixture with pigment;

- using a syringe with a needle, inject the glue into the area of the defect, wait until it hardens completely.

Fixing a large hole without a patch

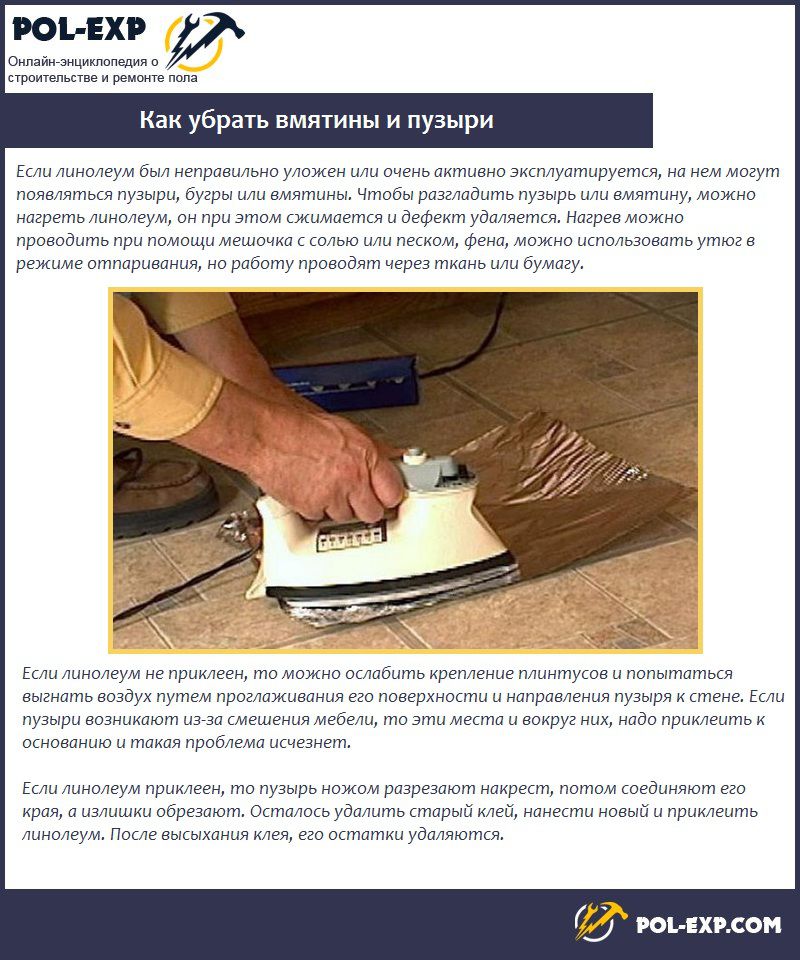

It is advisable to use this option for repairing the coating in the case when a piece of linoleum is not completely torn out.Such a hole can be repaired with sufficient quality, but for this it is necessary to strictly follow the repair instructions. The first stage in eliminating a flaw without a patch is to level the torn off part of the linoleum.

To straighten the flap, you can use one of two common methods. The first of them is to press down on the linoleum with something massive. This will align it, however, it will take quite a long time (about 24 hours). The second way is more efficient. To implement it, you will need to iron the linoleum with an iron through gauze soaked in water.

Note! Be careful when using the iron, as there is a possibility that the coating will melt when exposed to high temperatures. To exclude this possibility, you need to fold the gauze cloth in 10-15 layers.

An effective way to close a large hole in linoleum requires the use of liquid nails. The base located under the break must be cleaned of dirt and dust. Then liquid nails are applied to it. In order to distribute them evenly, it is best to use a construction gun. Next, the torn off part of the linoleum is pressed against the base and rolled out with a roller. In the end, it remains only to remove the excess glue that has emerged with a wet rag and wait a day until the composition is completely dry.

Thus, there are several answers to the question of how to fix a hole in linoleum on your own. The choice of a suitable method is carried out depending on the nature of the damage and its dimensions. The quality of work depends on the correct selection of adhesive and other materials used to eliminate the flaw.

What recommendations can you give for eliminating a hole in linoleum at home?

Self-repair technology

Many problems associated with polymer floor defects can be eliminated on site by yourself. The instructions below contain basic recommendations and methods for solving the problems of restoring the integrity and appearance of floors.

Repairing holes and stains

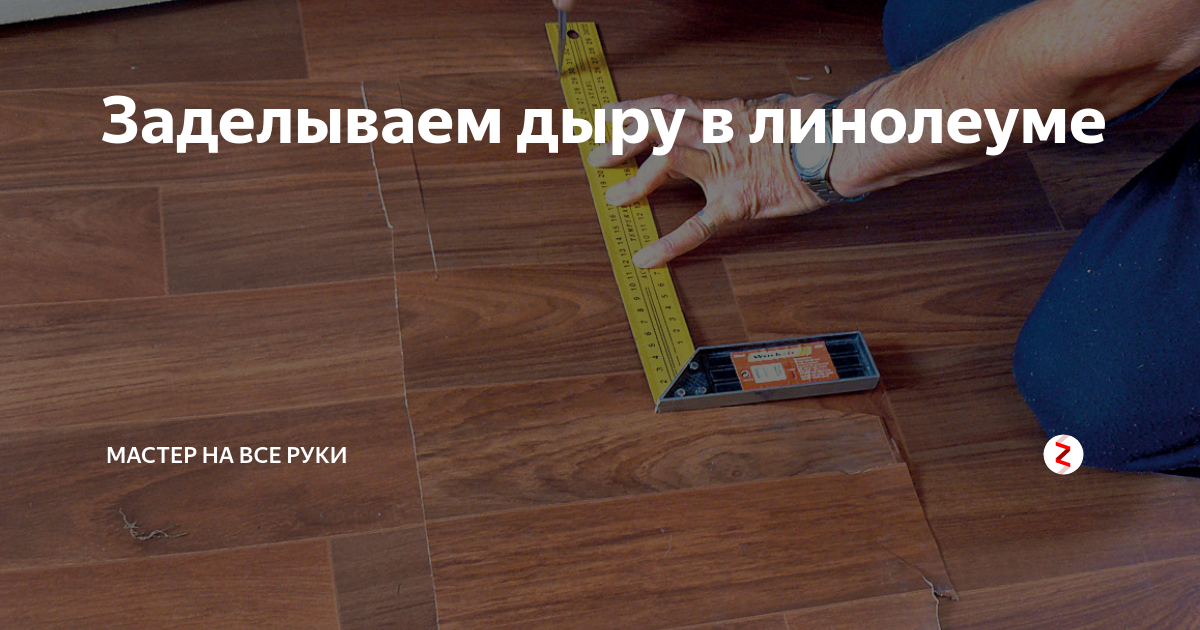

- Repair of linoleum with a hole in many cases, in the presence of material of a similar structure and color, can be carried out by cutting out a damaged fragment of the polymer. For this operation, it is advisable to use a metal ruler and a sharp knife;

Removing the defective part

- Then, using special glue, install a patch carefully selected for the pattern in place.

Advice! If there is a very noticeable difference in color tones between the patch and the main part of the floor, it is necessary to correct the situation with the help of heated colored mastic.

A few tips on how to update linoleum after renovation:

- For removing stains resulting from contact with aggressive chemical substances and which cannot be removed with water and linoleum detergents. it is necessary to lightly process with a fine-grained emery cloth. As a result of stripping, a matte area will be obtained on the linoleum;

- To give the original appearance, it is necessary to wipe the surface with a rag, having previously impregnated it with a small amount of turpentine, followed by polishing with a dry cloth rag.

Repairing cuts and tears

All cuts, tears, punctures and old seams in linoleum are repaired using cold welding (PVC adhesive). Special C-type glue has a dense structure and is similar in composition to a polymer. Thanks to this property, with the help of glue, you can both glue and replace linoleum at the point where the stripes diverge.

Let's take a closer look at how to repair torn linoleum:

Photo of cold welding of linoleum

- As a preparation, it is necessary to rub the ends of the torn coating site with sandpaper to eliminate burrs and irregularities;

- The gluing site is thoroughly cleaned and dried;

Advice! It is advisable to securely fix the edges of the linoleum to the floor with the help of double-sided tape until the cold welding dries.

- The adhesive must be squeezed out along the entire length of the break. Due to the thick structure of the glue, you can not be afraid that it will fall on the front of the linoleum;

- After the final drying of the cold welding, it is necessary to carefully cut off the formed glue bumps. The joints are additionally masked with special linoleum mastic.

Elimination of small punctures

Floor punctures with a diameter of no more than 1.50 mm are simply enough to fill with liquid PVC glue (A-type).

- Masking tape is glued to the coating and a hole is made in it to fit the size of the puncture. In this case, pieces of scotch tape should not go deep into the polymer floor;

- The hole is neatly filled with glue;

- After the end of the crystallization process, the adhesive tape is removed and a bump of glue is cut off.

Advice! Punctures with a diameter of more than 1.50 mm are best filled with thicker C-type glue. With this procedure, tape can be omitted.

Correctly and efficiently carried out repair of linoleum floors will give them a presentable look, ensure long-term operation, and also save you from additional financial waste on a new coating. In the video presented in this article, you will find additional information on this topic.

Advice! Punctures with a diameter of more than 1.50 mm are best filled with thicker C-type glue. With this procedure, tape can be omitted.

Correctly and efficiently carried out repair of linoleum floors will give them a presentable look, ensure long-term operation, and also save you from additional financial waste on a new coating. In the video presented in this article, you will find additional information on this topic.