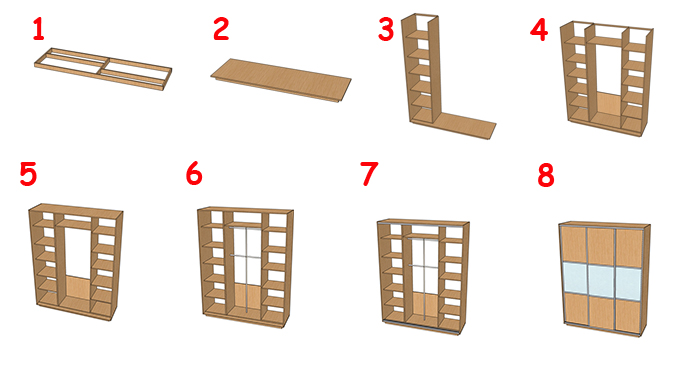

DIY wardrobe installation

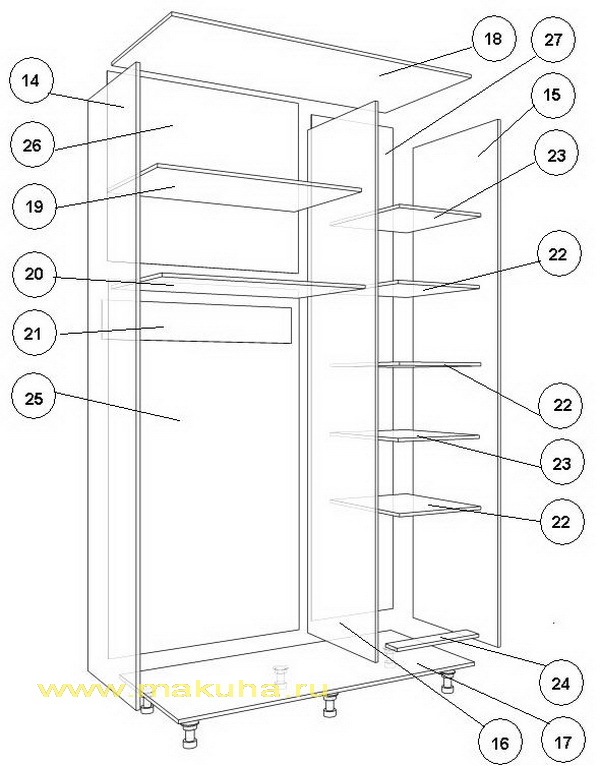

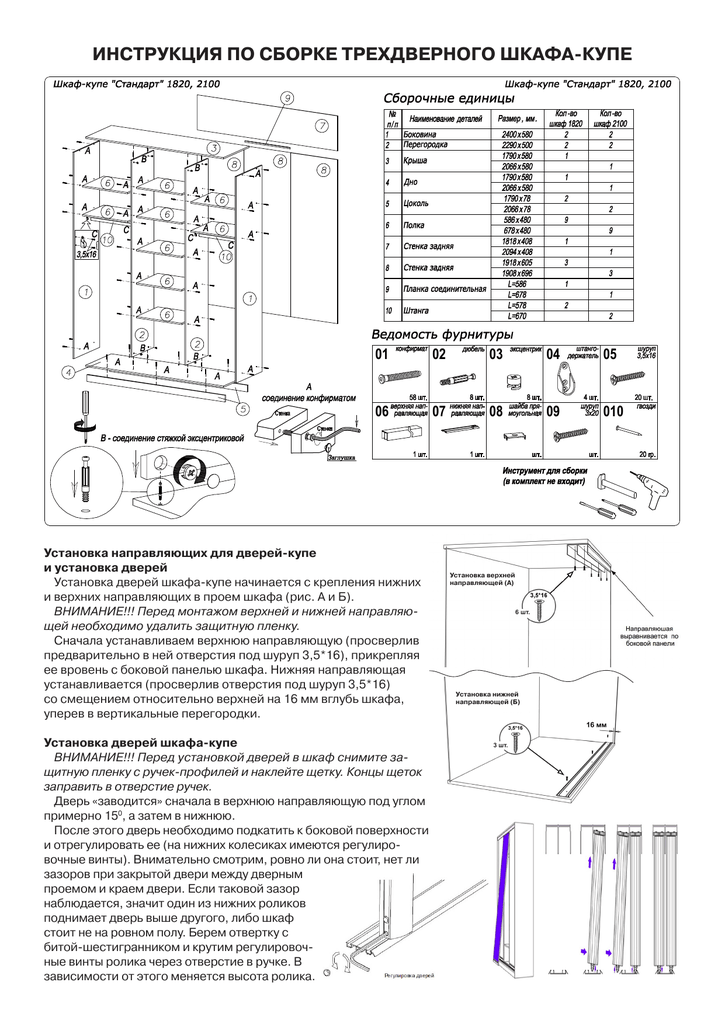

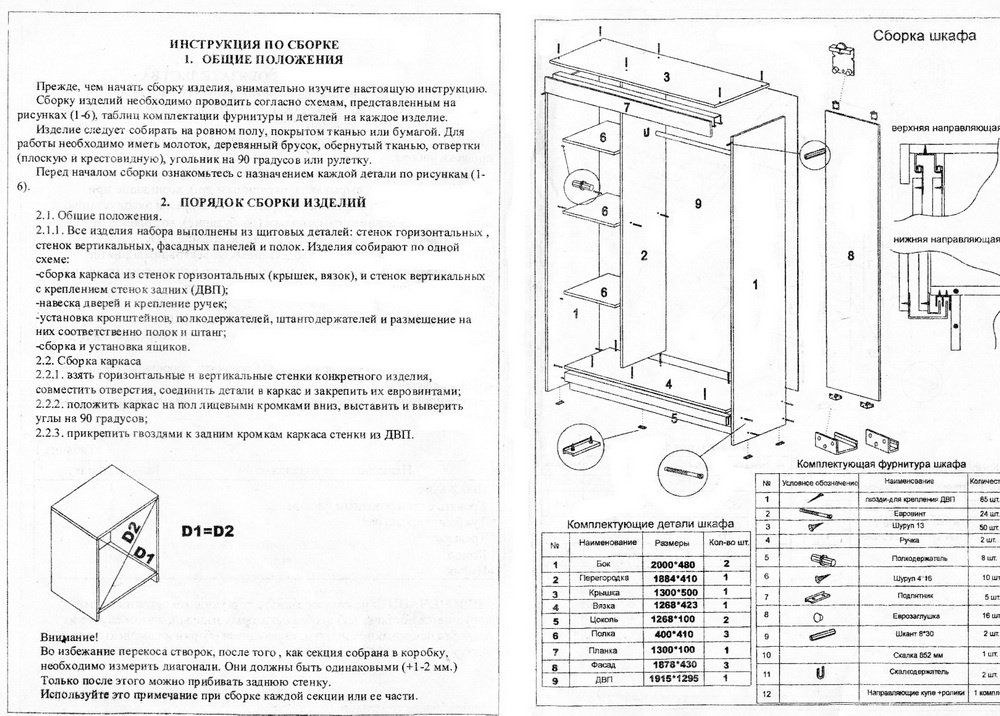

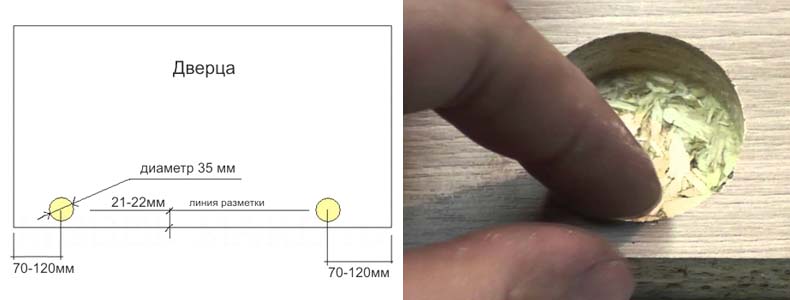

To prepare all the elements of the cabinet, we proceed to its installation. It is assumed that you constantly use a level and a corner to accurately install the details of the wardrobe. Very often, cabinet parts are connected using confirmations (pictured) and closed with plastic plugs.

But, sometimes fasteners are used on furniture corners. Assembling at confirmations is a somewhat more complicated process, but when mounted on corners, they will interfere with the further operation of the wardrobe.

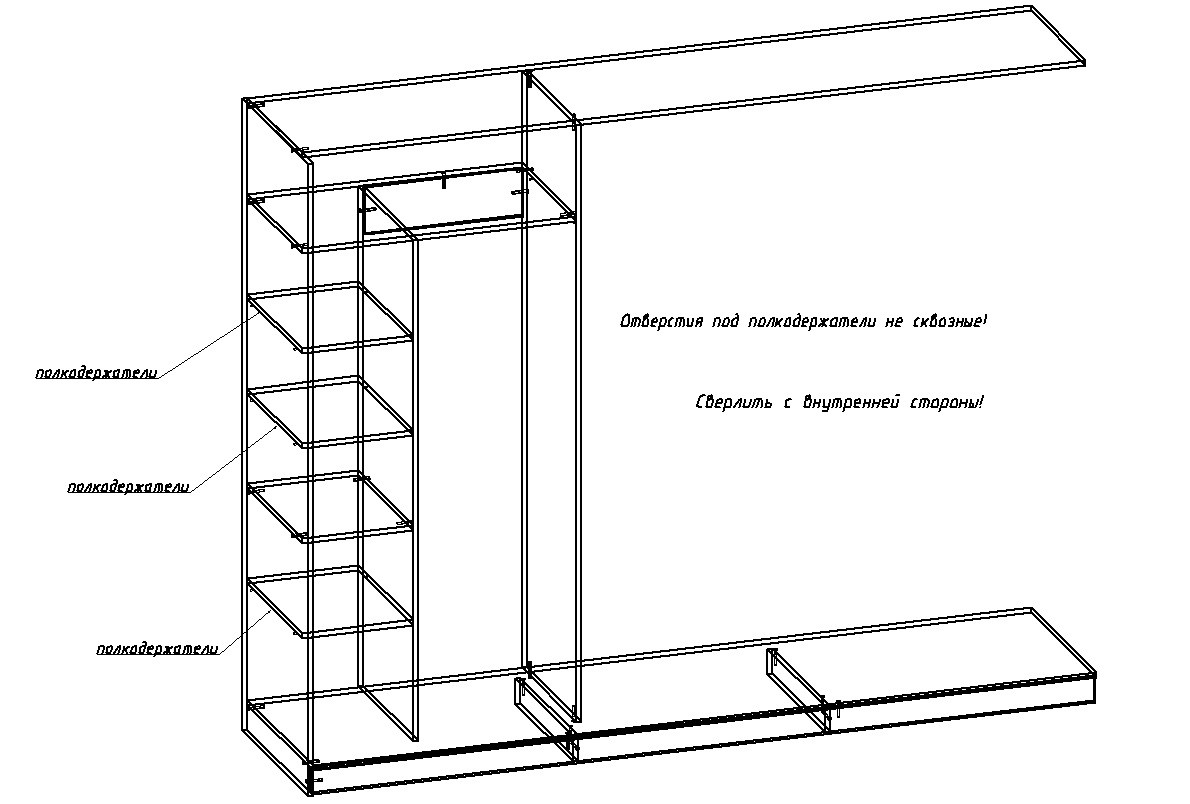

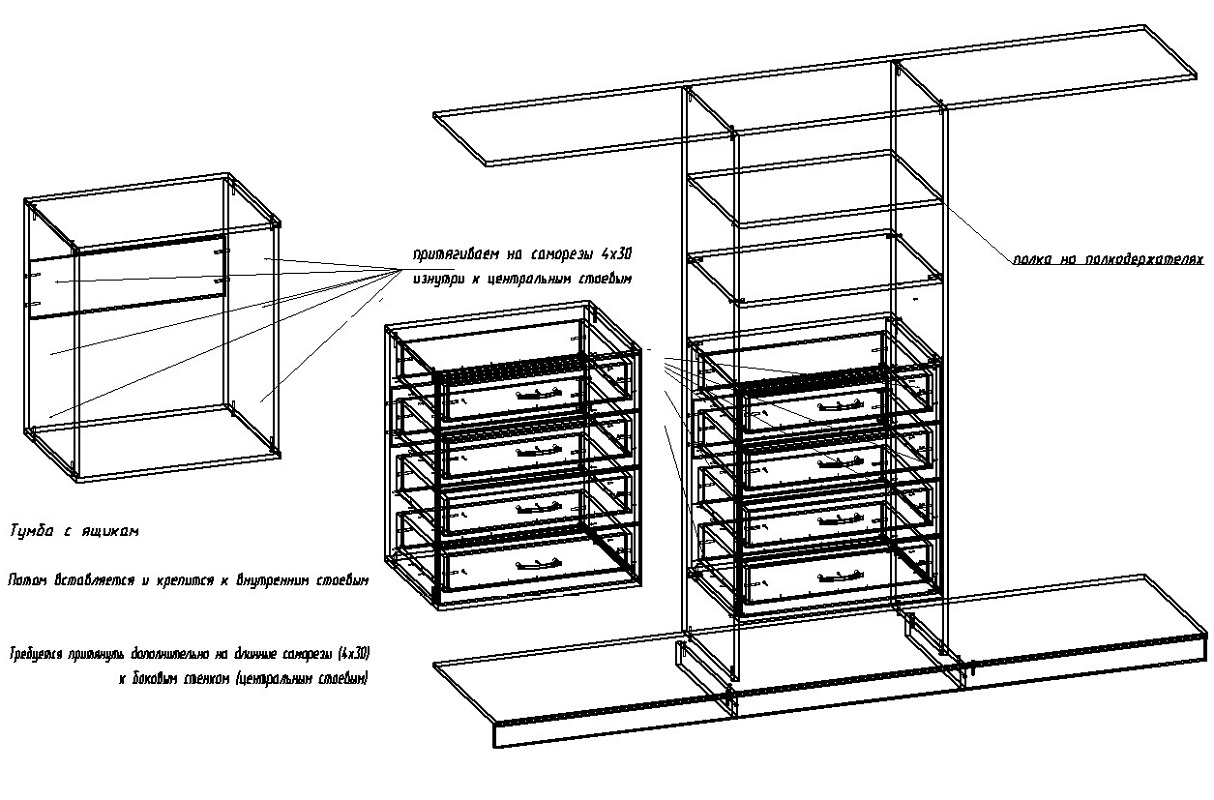

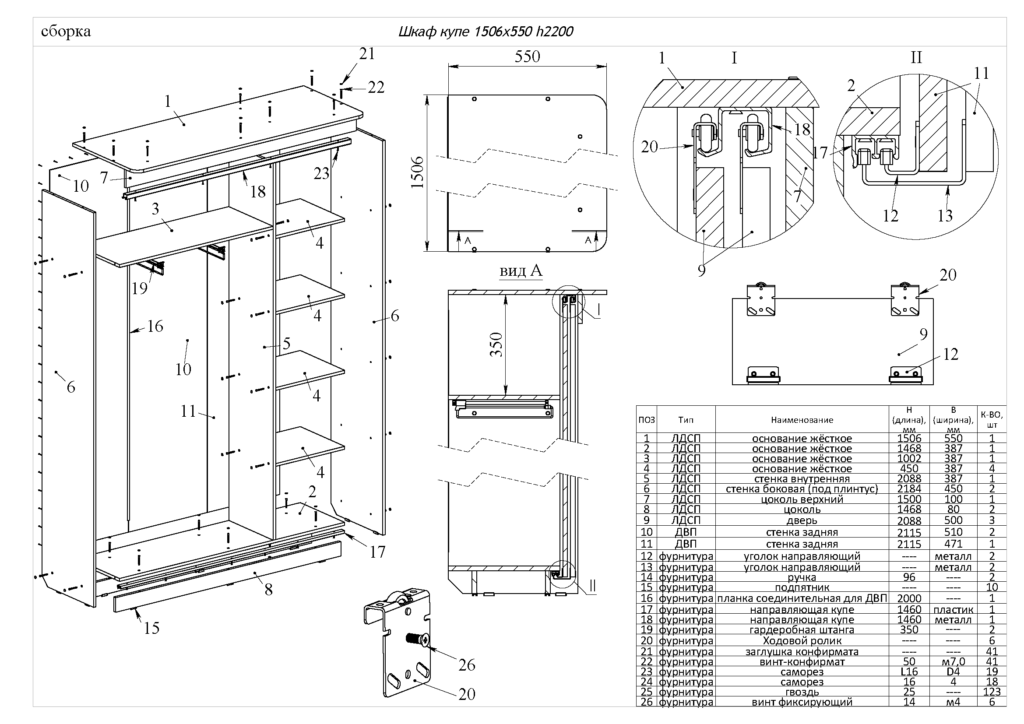

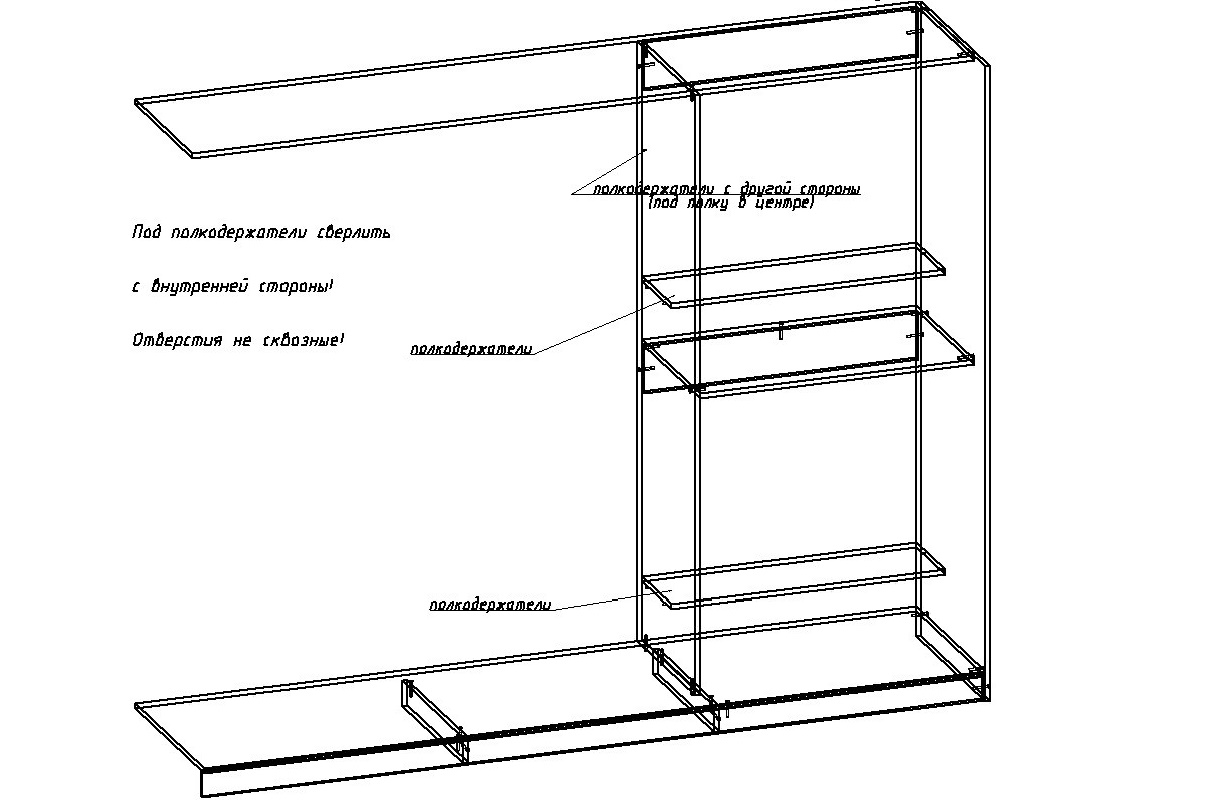

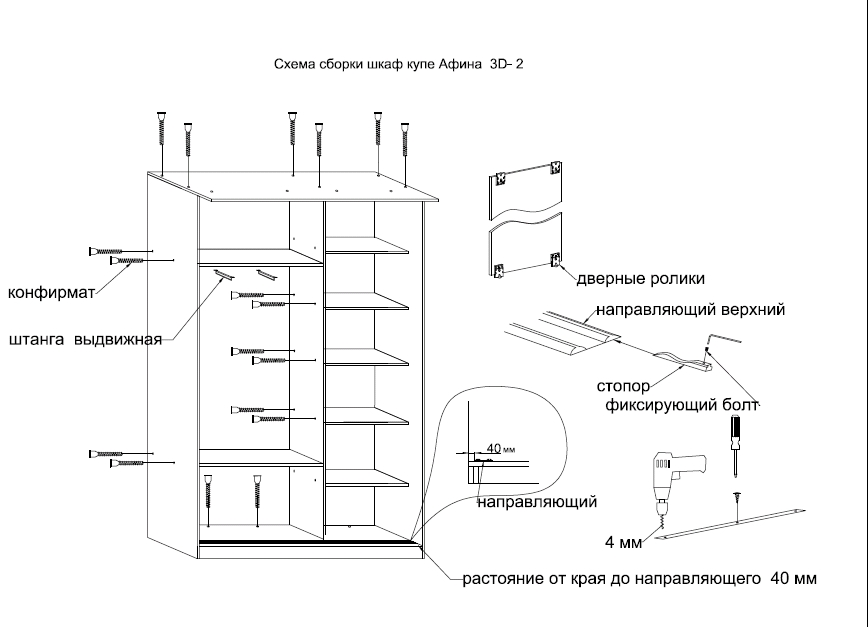

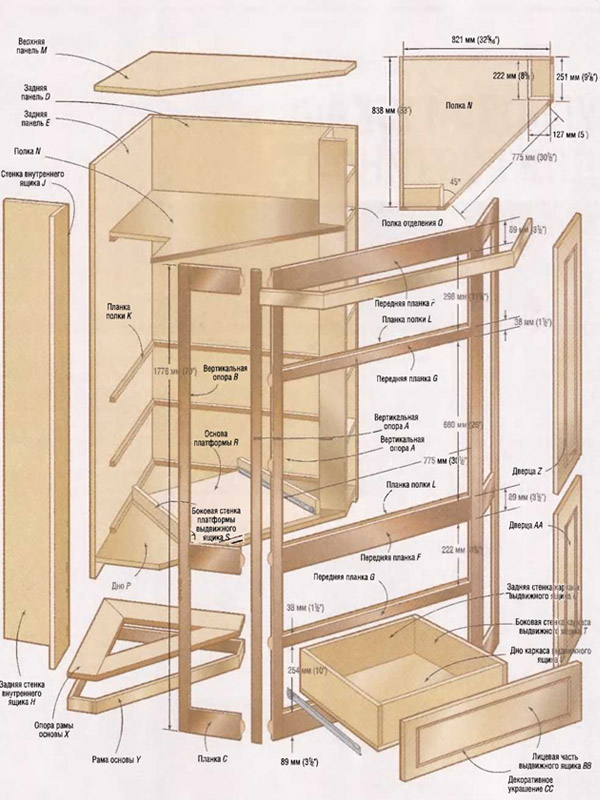

Then the installation process itself begins. Carefully, with a pencil, mark the location of the shelves on the side and center racks, drill the mounting holes, both in the racks and in the shelves (from the end). We fix the fiberboard with a stapler or nails, and do not forget about the corner, especially when fixing the fiberboard sheet. Sliding wardrobes can be installed on legs. We then take their height into account when calculating the height of the cabinet. The legs are fastened from the inside of the cabinet and adjusted with a hexagon. Then the legs are closed with a chipboard false panel.

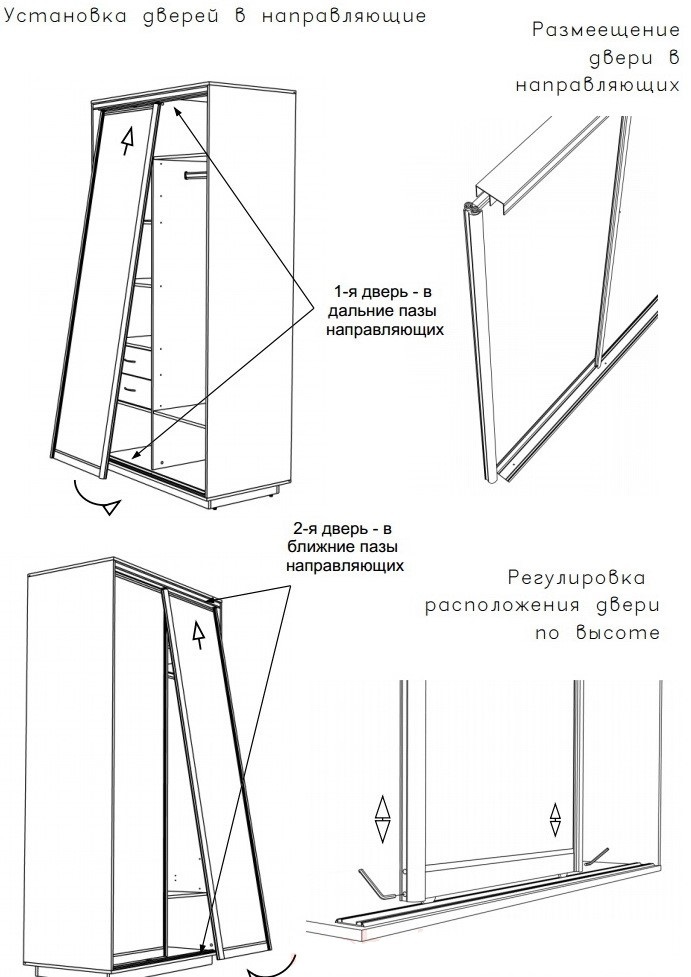

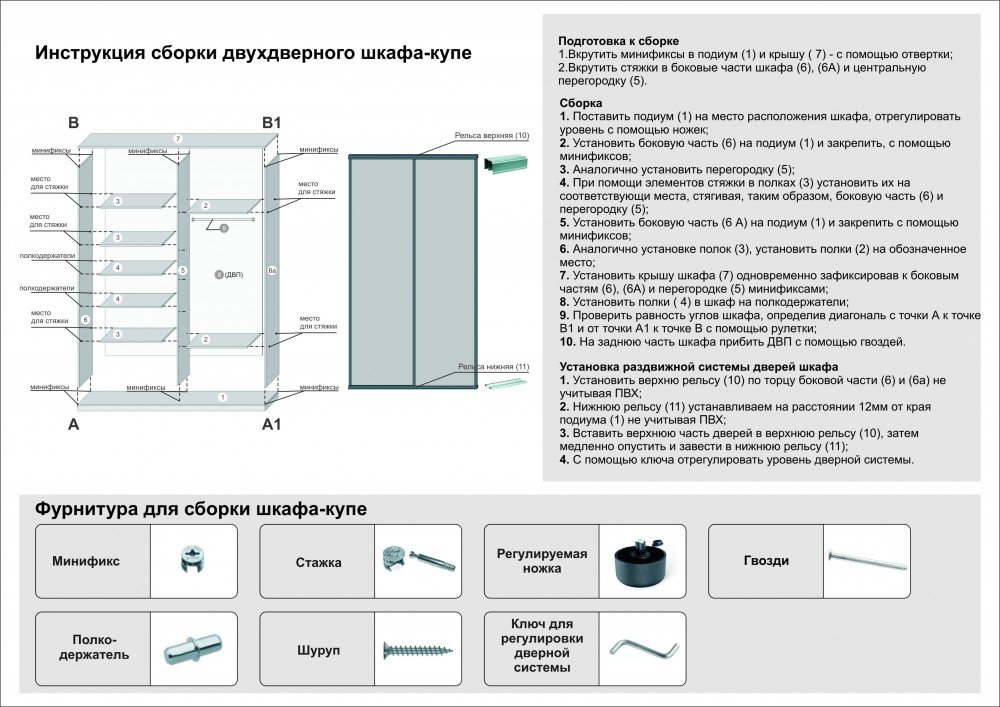

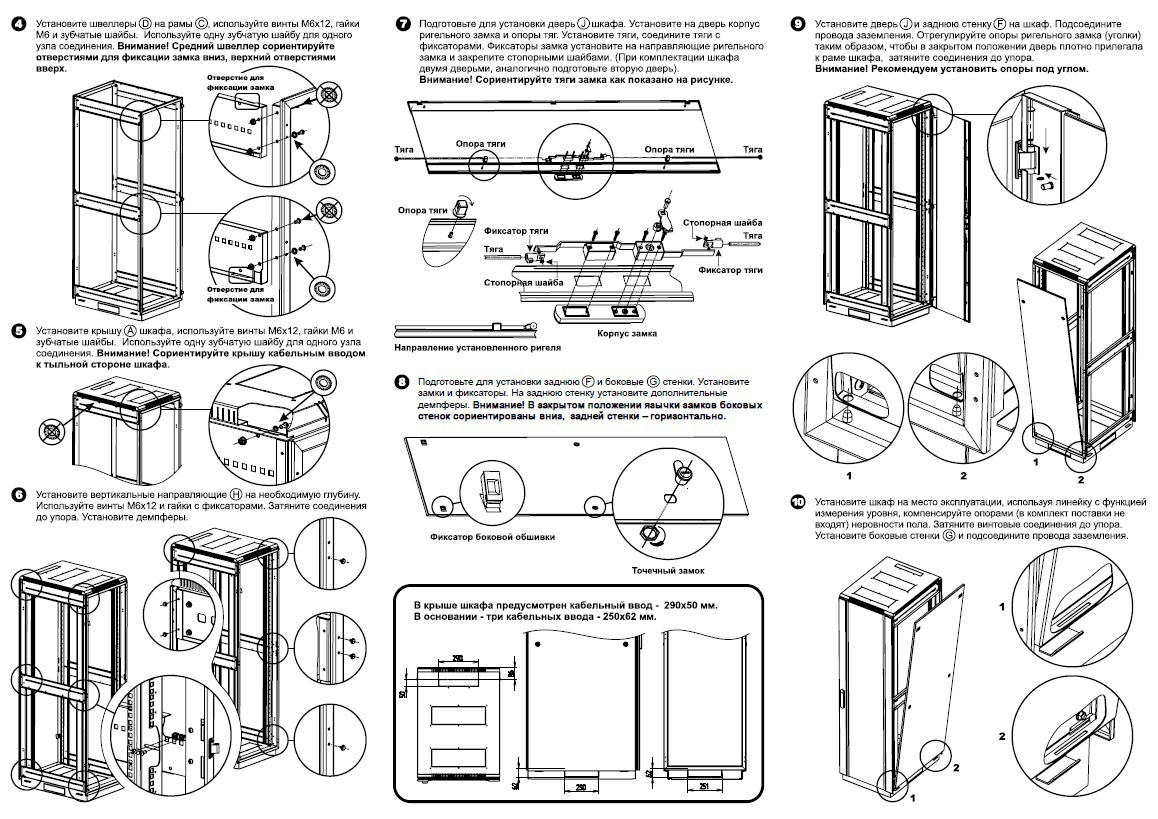

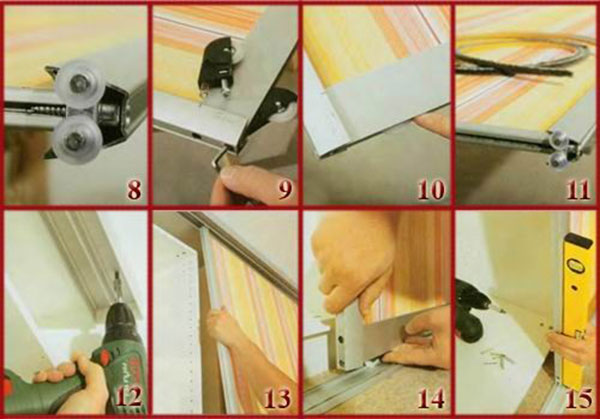

Installing a sliding door system

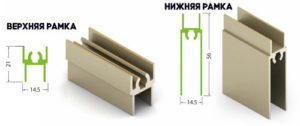

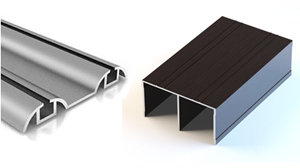

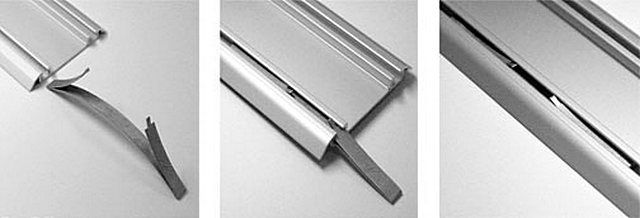

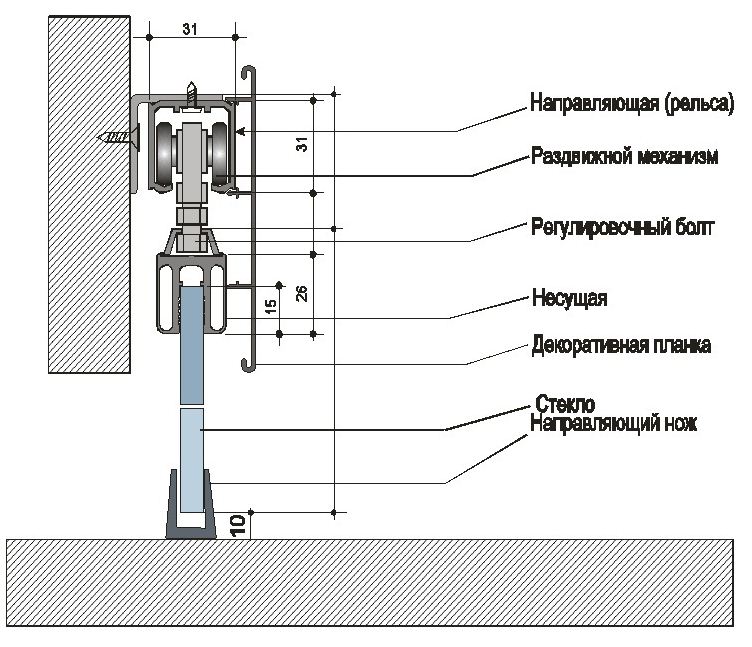

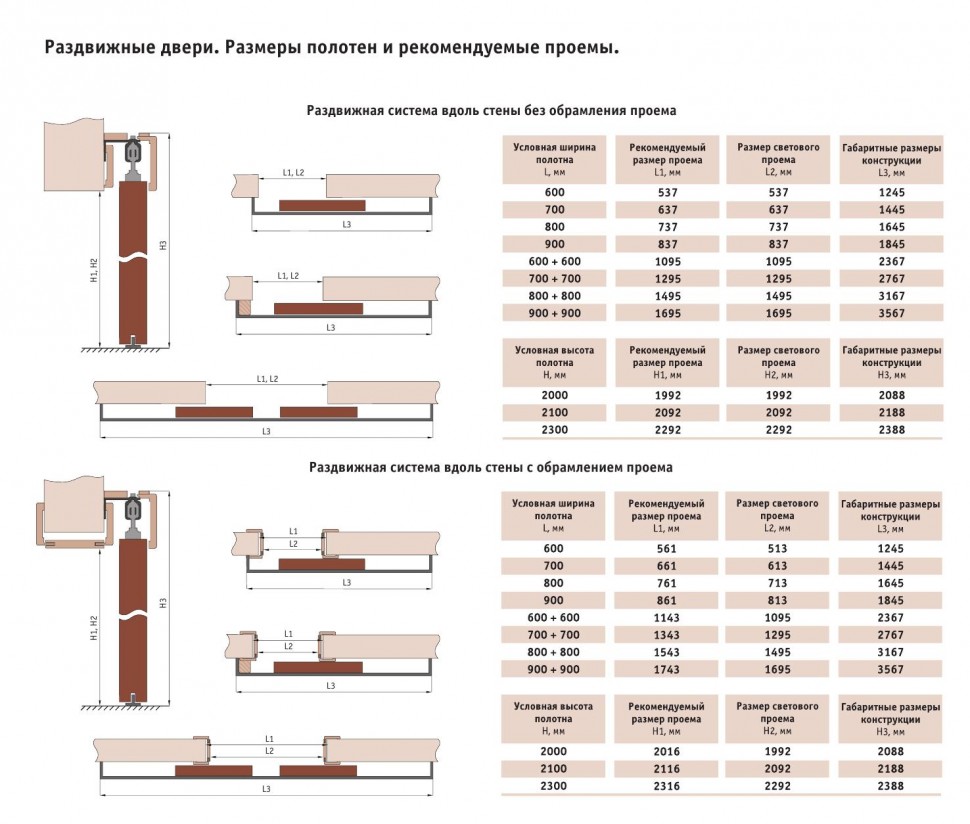

The top guide rails fit flush with the column (top).

The bottom rail is attached to the bottom of the cabinet, stepping back from the edge by 10-15 mm.

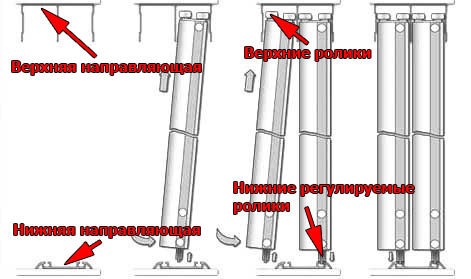

Having strengthened the guides, it proceeds to install the doors. Typically with support roller in the lower part doors and a groove for its movement in the guide.

Doors are inserted by feeding them upwards, and by installing the lower roller and the groove of the guide.

The smooth movement of the doors is regulated by adjusting screws and a hexagon. Doors are installed in guides. In our case, there are two doors. One overlap the other. The total width of each door is 1200 mm. The sliding wardrobe is mounted, you can use it. It was just a special case of one of the wardrobe options, on which we showed you possible options for installing individual parts. And now I would like to give a specific example.

Fastening doors

Today the consumer market offers various systems for fastening furniture doors. Each element has its own specific purpose, which depends on how the cabinet is opened.

Swinging

Swing doors are the most common type of furniture construction. It includes a wooden blade and hardware for fasteners. The number of wardrobe blades depends on the number of inner sections. Typically, if the cabinet has one common section, two doors will be required. If the furniture will consist of one narrow and one wide section, respectively, three sashes will be required. The production of door fastening is carried out on the side walls of the cabinet using the following hinges:

- detachable - such a mount is installed on the inside of the cabinet wall;

- universal - these products can be installed independently of the sides of the cabinet. Hinges are attached simultaneously to the body and doors of the furniture.

After the hinges are fixed on the box of the product, doors are hung on them.

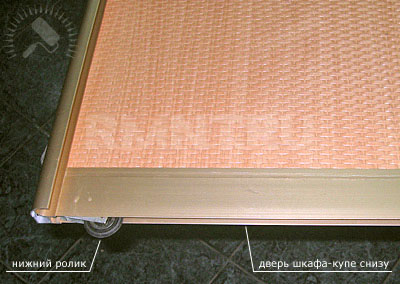

Hole preparation

Hole preparation

Aligning and installing hinges

Aligning and installing hinges

Coupe

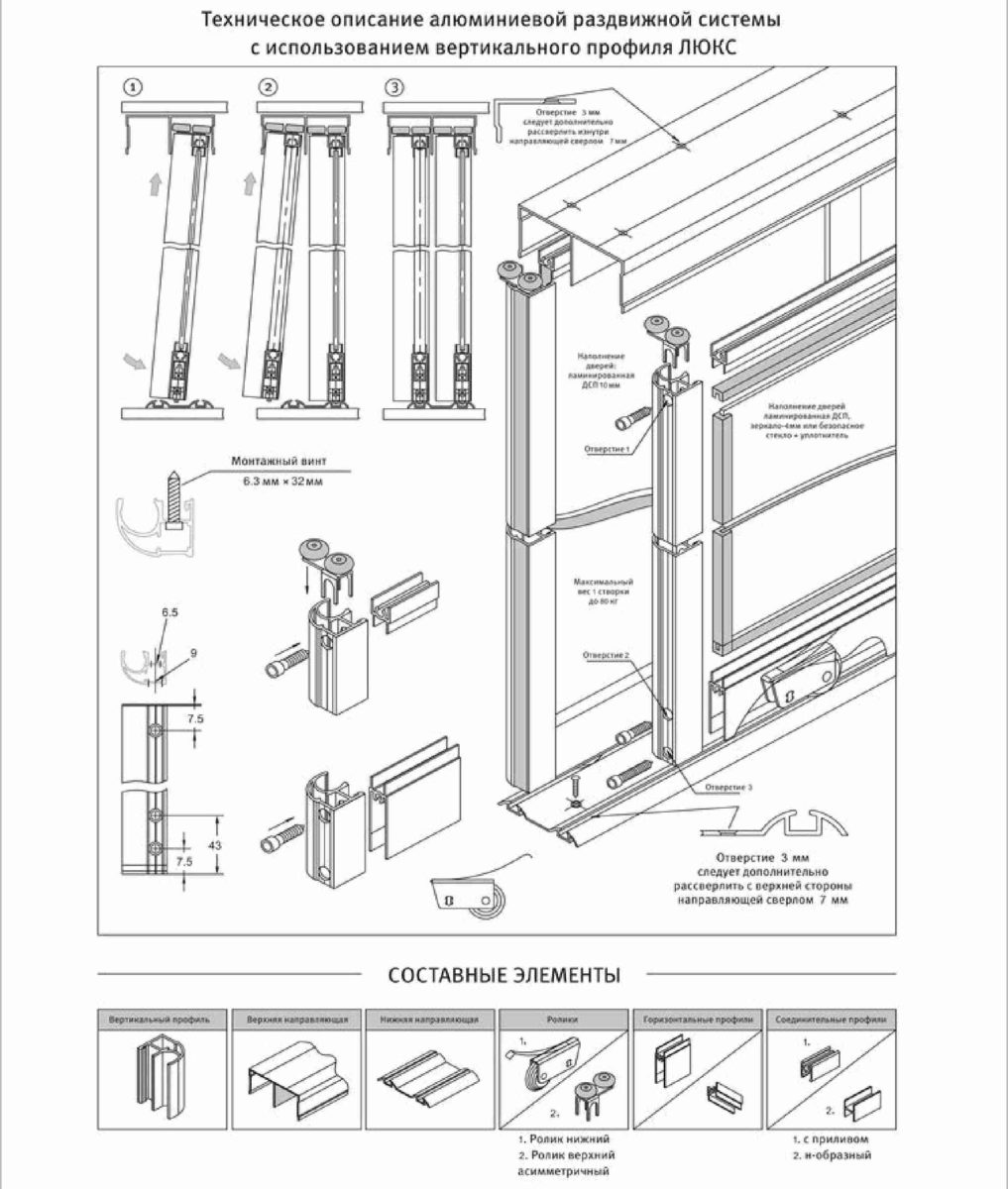

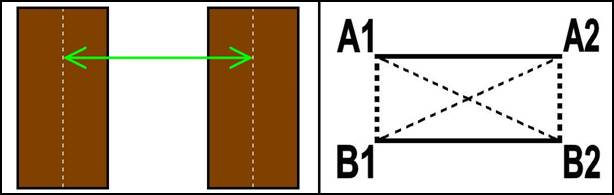

Sliding doors are a sliding system where, when the cabinet is opened, one door goes over the other. Installation of such a structure requires certain knowledge and skills, therefore, before you mount a sliding plywood cabinet with your own hands, you first need to familiarize yourself with the name of the components and their location.

The set of fittings includes:

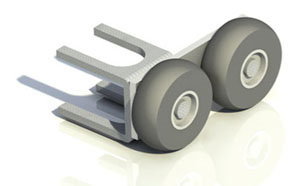

- special wheels for moving doors, installed in the upper and lower parts of them;

- top suspended structure for guiding the canvases;

- the lower guide structure along which the door wheels will move in the grooves;

- cassettes for installing a wooden canvas;

- locks and door closer for easy door opening.

This design is intended for cabinet furniture with a threshold. If a built-in wardrobe is to be mounted, it will be possible not to install the lower guides on the floor.

Assembly

Assembling the structure

Assembling the structure

To assemble the cabinet you will need:

- Pencil and rectangle.

- Drill and drills 5 and 8 mm.

- Roulette.

Instruments

Instruments

Instructions:

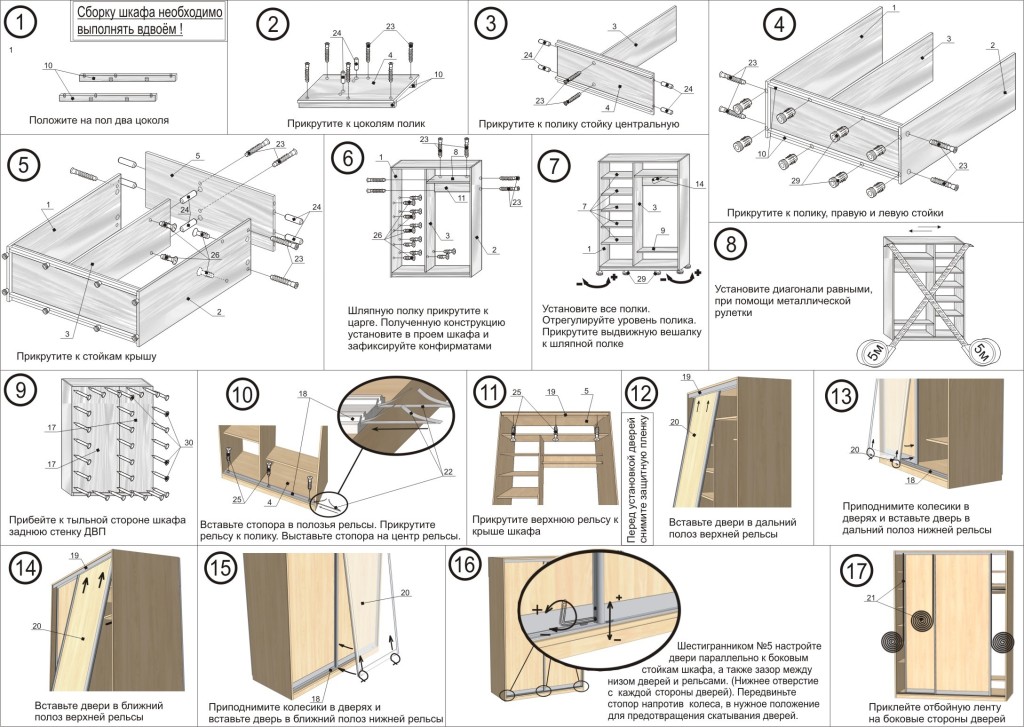

- Purchased confirmations are used to assemble parts into one whole structure. First, we look at our project and mark the attachment points.

- When all the details are marked with markings, we proceed to the drilling process. For holes in the plane, use a drill with a diameter of 8 mm. The hole must be through. The hole depth at the ends is not more than 60 mm, and the diameter is 5 mm. In the places where the shelf supports are installed, we make holes at several levels. When the cabinet is ready, you can safely move your shelves to the desired level.

- To assemble the structure, you will need the help of one person. The work will go faster and the build quality will be better. We connect all the details of the cabinet and install it in place. We expose the cabinet exactly using a level.

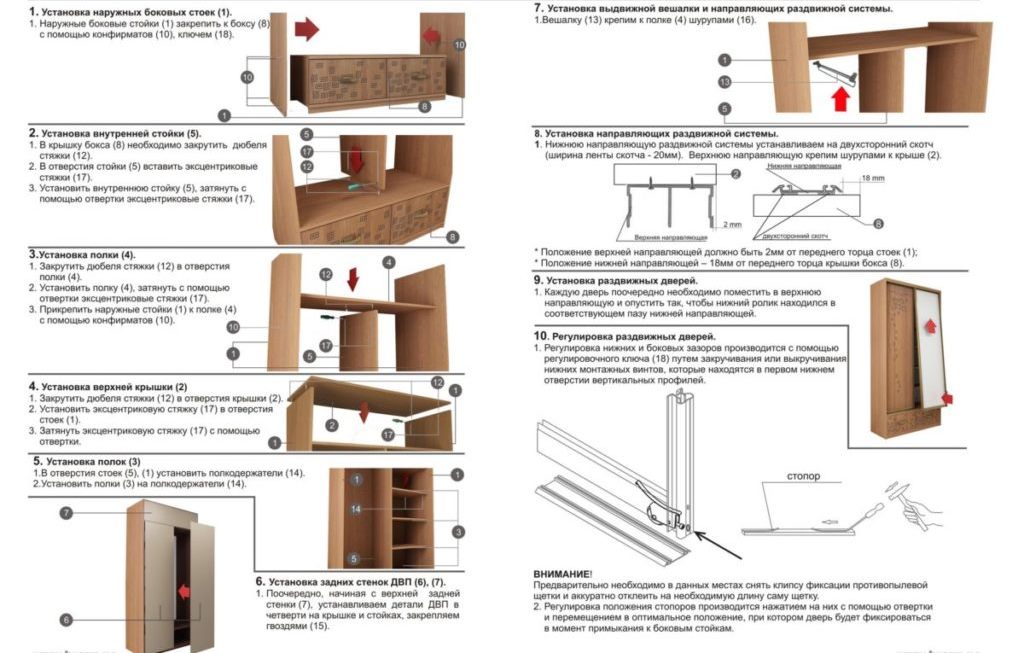

- Now you can start installing the facade. We fasten the upper guides along the edge of the cabinet lid. We retreat from the edge of the cabinet bottom by a maximum of 10 mm and fix the lower guides. Before tightening the screws, insert the stoppers into the roller track.

- Now you can put the facade back in place with two people. One person puts the upper part of the facade into the guide, and the other sets the wheels in the desired track. A hex key is used to adjust the front. The adjusting screws are located at the bottom of the front end. Raising or lowering the lower roller, we set the facade to the desired position.

Completing of the work

Completing of the work

When the wardrobe is loaded with things, the adjustment will need to be repeated. So the work on the installation of the wardrobe was completed. Now you can proudly consider yourself a master and try to assemble a more complex structure. We already have experience, which means that the assembly will be much faster and better.

Do you want to share with us your experience in assembling a wardrobe? Leave comments on the article. Our readers will be interested to know the secrets of your successful cabinet assembly.

What do the doors for a sliding wardrobe consist of?

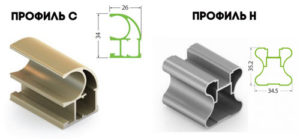

A sliding system usually consists of the following components:

- door frame (side pillars + horizontal strips);

- filling - door leaf;

- lower and upper rollers;

- buffer tape;

- guide tracks.

For a further understanding of the terms and the entire assembly process, in the table you will find a detailed description of each component.

|

Door frame |

|

| Side racks

|

Dural posts have longitudinal grooves into which the canvas is inserted. From the outside, the profile is made in the form of a fold, which serves as a handle. The cross-section of the racks can be different, but they all hide the longitudinal groove with a bend. Some side strips are made solid, and separate handles in the form of figured plates are attached to them in the middle. |

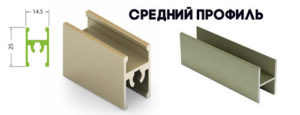

| Cross bars

|

The cross members connect the vertical posts into a single structure - the frame. A pair of vertical rollers are installed inside the lower cross member. The section of the horizontal strip and the height of the sides of the track completely hide the rollers. |

|

If the filling consists of several fragments, then the middle strips are inserted into the frame. They have double-sided grooves, into which sheets of canvases enter from above and below. Find out more information about profiles for wardrobes. The products of the Austrian company "Stern" are worthy of attention. |

| Buffer tape

|

The self-adhesive fleece strip (also called Schlegel) serves two purposes. The soft structure of the tape dampens the sound from the door adjoining the side wall of the cabinet body.The pile cuts off the penetration of dust into the wardrobe. On the racks on the outside of the frame, vertical grooves are made for the buffer tape. |

| You can assemble the door frame according to the principle of a window frame from a wooden bar. In it, as in a metal frame, longitudinal grooves are made with a router along the inner perimeter of the frame. The width of the gap should be equal to the thickness of the filling web. | |

| Guide tracks

|

They have a different section. In section, both planks resemble the letter "Ш". The lower track is made with low longitudinal grooves. This is enough to keep the wheels from moving laterally. The upper profile has high sides (40 mm) in order to keep the upper roller devices, and with them the entire door from tipping over. You can find out more about guides for sliding wardrobes here |

|

Door leaf filling |

|

| Mirror

|

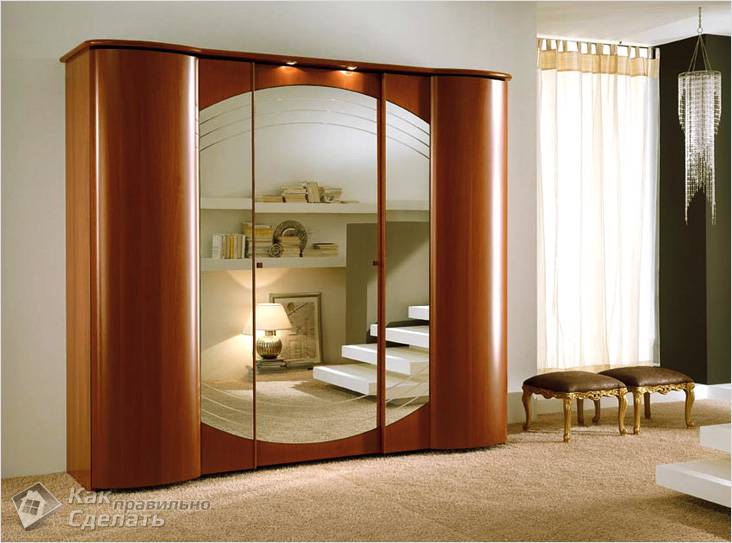

Mirrored doors of the sliding wardrobe create a beautiful facade of furniture, visually expand the space and improve the lighting of the room. You can use colorless and tinted mirrors in silver, bronze, matte and different colors. A film is glued to their back side, which holds the fragments in case of destruction of the door filling.

Three decoration technologies are used to decorate mirrors:

|

| MDF and chipboard

|

You can make a complete filling of sliding systems from MDF. For compartment doors, use plates with a thickness of 6 to 10 mm. On their surface, upon request, you will be made beautiful patterns by laser installation. The material is also pasted over with colored PVC film with pictures.

Laminated chipboard sheets are cheaper than MDF boards. On the building materials market, you can find laminated chipboard with matte and glossy facades, imitating leather and valuable wood species. |

| Laminate

|

Laminated parquet lamellas can fully replace expensive material for sliding doors. There are boards of light and dark colors that imitate valuable wood species. The parquet is 10 mm thick and fits perfectly into the aluminum frame of the doors. |

| Plywood

|

For budget assembly of the facade, use laminated plywood. The material is easily sawn and cut with a hacksaw and jigsaw. The filling is done both homogeneous and combined. You can insert fragments of the correct geometric shape or make curly combinations of parts from MDF or chipboard with a mirror. Aluminum profiles have 10 mm wide grooves. If the filling material is less than this size, then a seal will need to be installed. |

|

Lower and upper rollers |

|

| Bottom rollers

|

Fastened with self-tapping screws on both sides inside the horizontal rail profile of the door frame. The wheels are made of polymer, which ensures silent door movement. The movable units are made in such a way that when the door is installed, they are pressed against the springs inside the lower strip. This allows the top of the frame to be inserted into the guide rail. |

| Upper rollers

|

Installed on the frame racks on both sides of the door. Unlike the lower castors, they rotate horizontally and are completely hidden by the high profile of the cross member. |

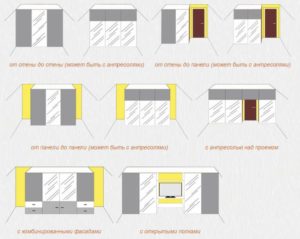

Design options

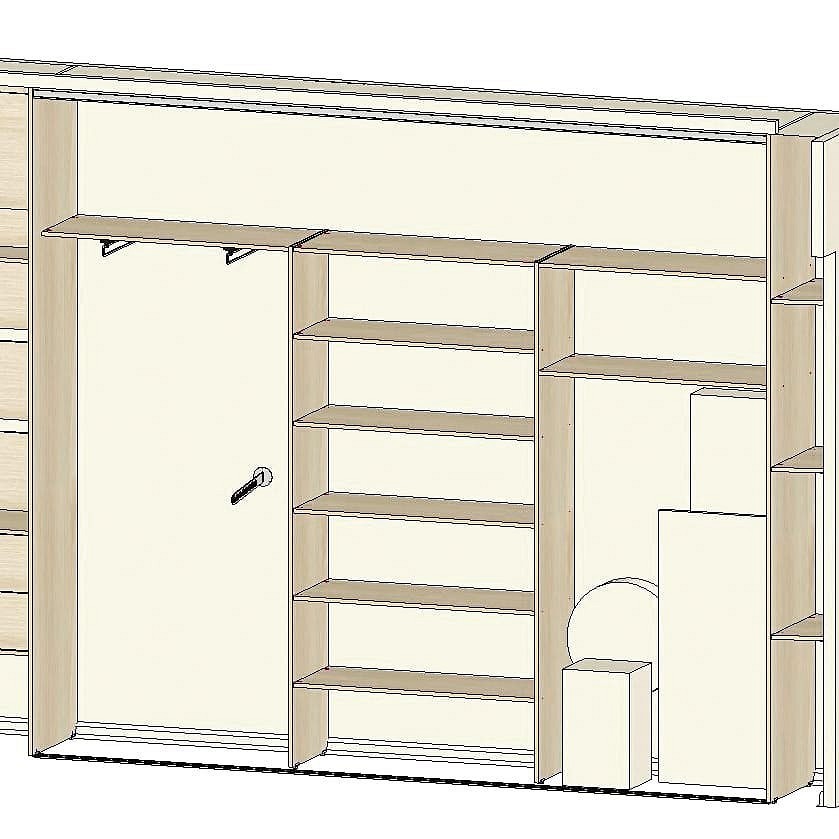

Built-in option

Built-in option

If you want to install a wardrobe in an apartment or house, you need to make accurate measurements of the proposed installation site for a piece of furniture and place an order with a company that manufactures wardrobes. The second option would be to measure the installation site, self-design the structure, order the sawing of parts and install the wardrobe.

Corner cupboard

Corner cupboard

You have a choice - recessed structures, corner cabinets and models of individual walk-throughs. When you decide on the choice, you can start assembling it yourself.

Walk-through cabinet

Walk-through cabinet

In many apartment projects, the hallway was made small in size in the shape of a rectangle. If you put an ordinary wardrobe with a swing door, there is absolutely no room left.A sliding wardrobe with a sliding door has become a real salvation. Its height mainly goes up to the ceiling, which maximizes the use of the area. Mirrored door leaves visually increase the space.

Installing the enclosure

In order to secure the frame the first time, it is recommended to watch the video instruction, clearly demonstrating the nuances of installation. For built-in wardrobes, the functions of the frame are performed by the floor, ceiling, walls and a frame for fastening the sliding parts of the compartment.

To level the surface, laminate or wood-based panels are used. Correct geometry is checked with a level. The frame with auxiliary strips is built into the wall using self-tapping screws.

Assembly nuances

Collect the frame with a height to the ceiling in an upright position. If the elements are combined on the floor, when the cabinet is lifted, the side diagonal will be longer than the floor-to-ceiling distance. The finished structure cannot be lifted and built into a niche.

The sequence of work with a stretch ceiling

The combination of a high wardrobe with a stretch ceiling is carried out in the following ways:

- Stretch ceiling above the cabinet. A wooden beam is screwed to the ceiling to the level of the main body. Next, the door device guide is attached to the mortgage plate. A decorative chipboard panel is mounted on the side, on which a baguette is placed under the stretch canvas. The body is assembled with shelves. Before installing the sashes, the stretch ceiling is fixed.

- Extension of the stretch cover inside the wardrobe. A timber or chipboard insert is screwed onto the floor surface. The bottom edge of the embedment must be carefully cleaned from chips to prevent damage to the film. The place of contact of the ceiling with the timber is closed with a PVC plate, the film is stretched. The sliding system bar is fixed to the embedded beam and is hidden behind the ceiling plinth. After completing the work with lighting inside the wardrobe, the door blocks are installed.

- Placing the ceiling around the perimeter of the wardrobe. Marking is made along the contour of the structure to fix the wooden planks, segments of the required dimensions are formed. Holes for fixing elements are drilled through the boards in the ceiling. From the rear of the fragments, a baguette is screwed to the ceiling, the joints of the profile are adjusted. The base for the sliding device is screwed to the floor slab. The profiles on the walls under the panel are joined with the workpiece on the beams. Film editing is coming to an end.

- Installation without a foundation bar. If the film has been placed earlier, the top of the wardrobe is closed with a lid. A few centimeters are left between the top edge and the ceiling film. The work is carried out as carefully as possible so as not to damage the panel. The remaining gap is masked with decorative ceiling plinths.

The choice of a particular technology depends on the state of the repair, the skills of the performer.

Cladding

In most cases, the front part is decorated with mirror inserts, drawings, a combination of overlays of different textures.

An interesting option for doors is jalousie. A non-standard facade is made according to individual measurements. For manufacturing, an inexpensive solid pine with a beautiful texture and high strength is used. Surface treatment is simple, suitable for painting.

The finished wardrobe must be inspected for defects, protruding chips, open self-tapping screws. It is necessary to eliminate all the shortcomings that can damage the things stored inside.

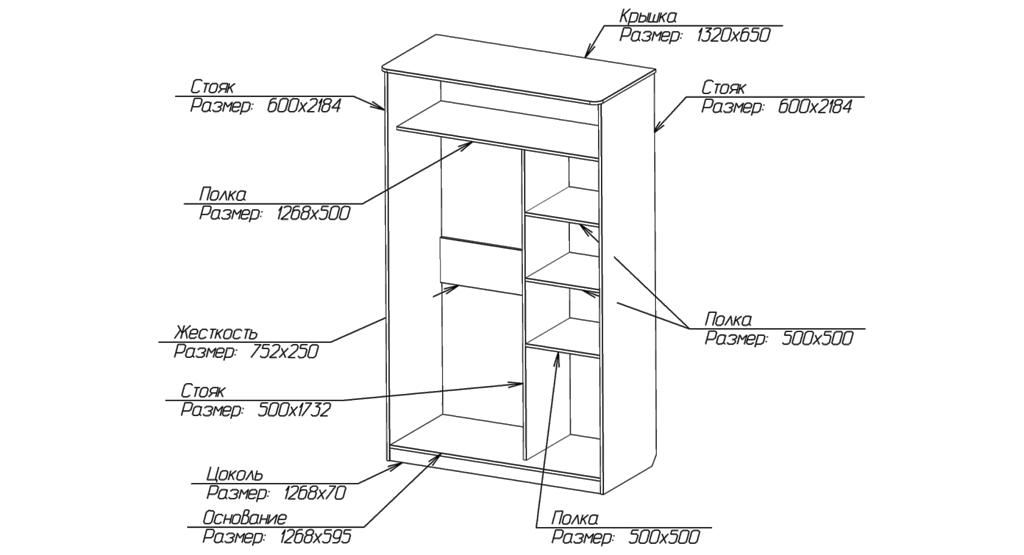

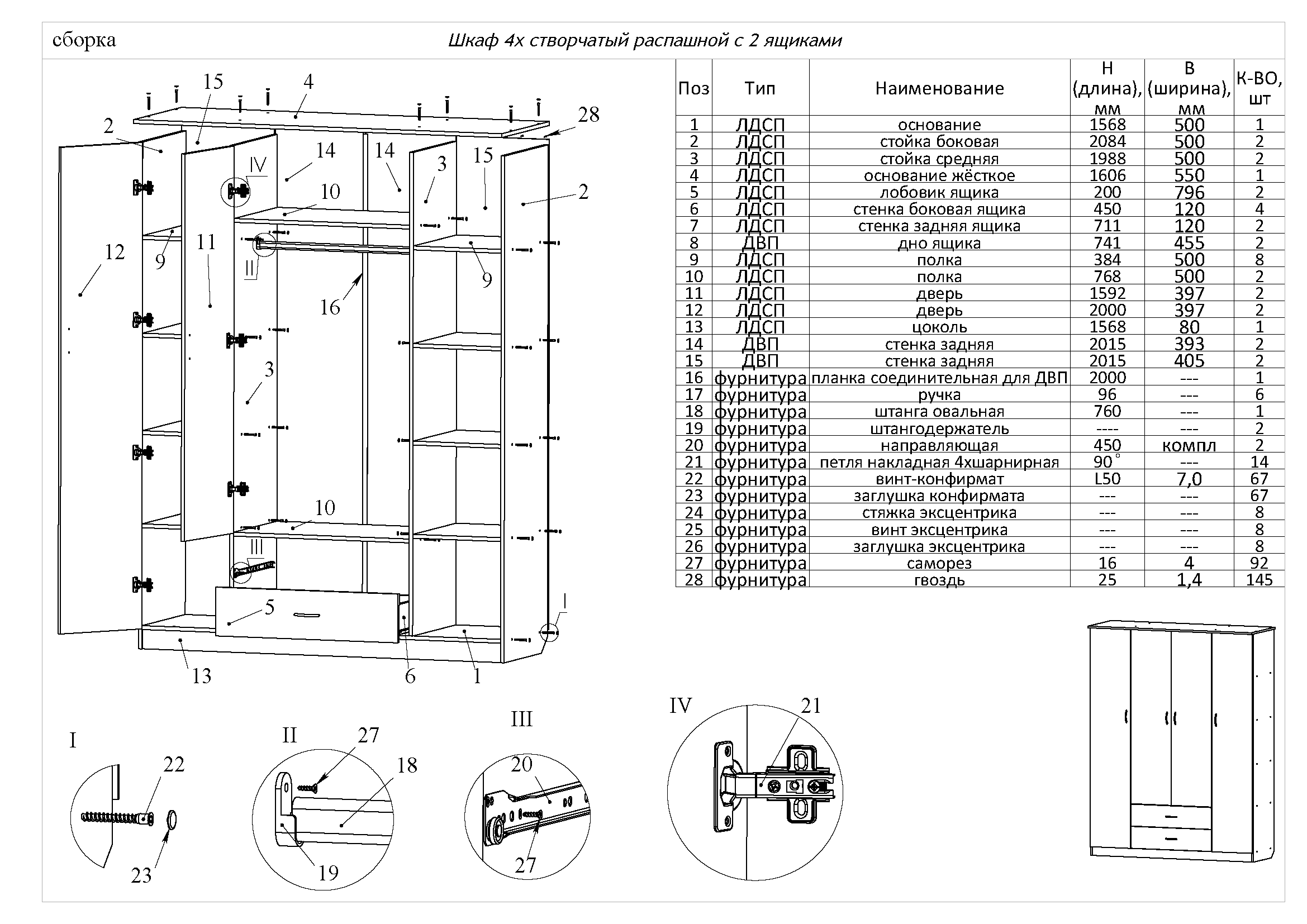

Assembly order

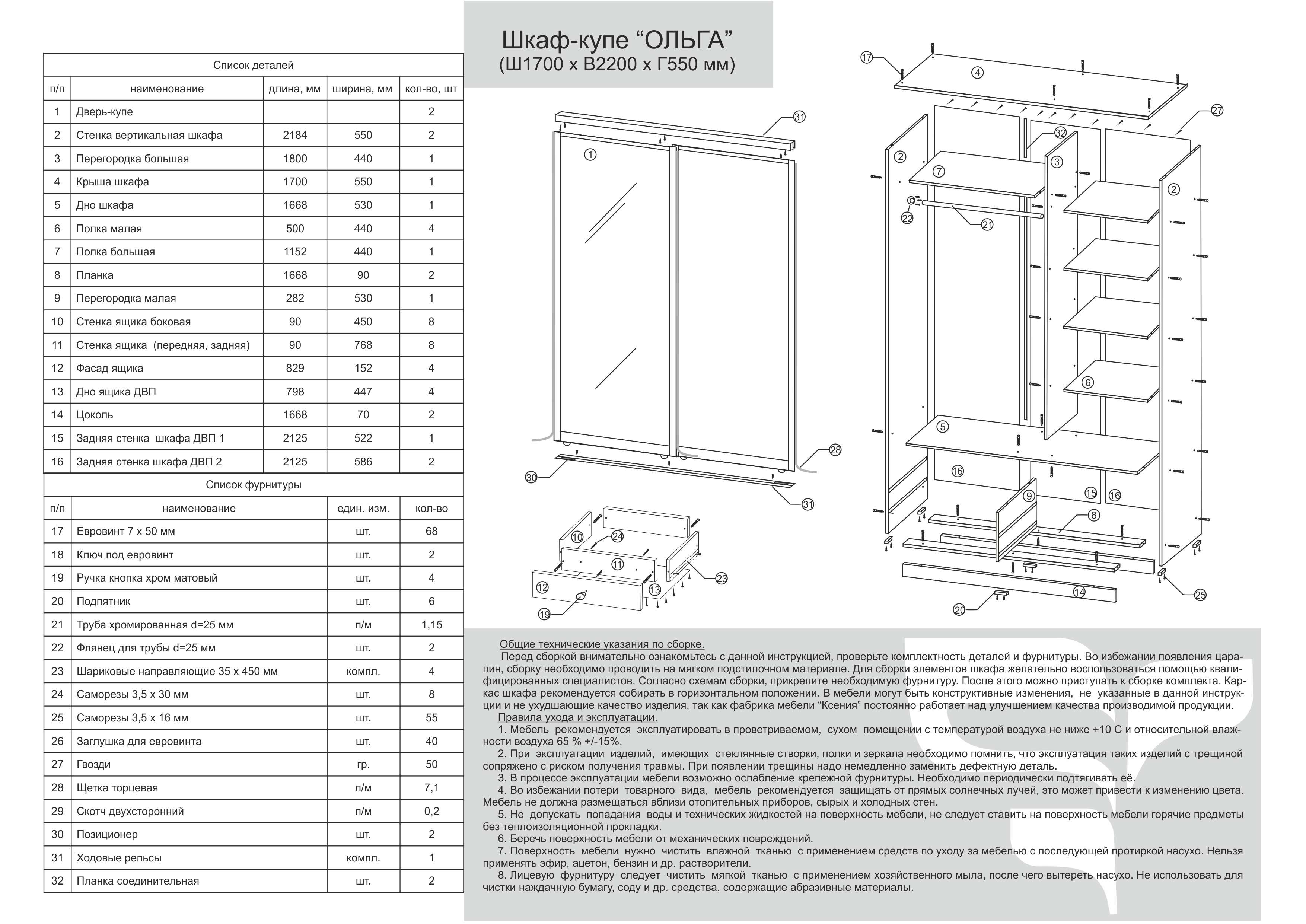

The base (bottom sheet of chipboard) is screwed with euro screws (confirmations) to two longitudinal legs of chipboard. The support part should be with an edge so that the material does not swell from moisture while standing on the floor. You can immediately nail down the thrust bearings - 3 pieces per strip.

The work takes place on the floor and therefore the box is collected face down

.

To the base of Basya's cabinet, you need to attach the middle rack and then the side ones, and in order not to return to the bottom anymore, put the plugs into the holes of the euro screws. Do not forget to install the heel pads on the side racks of the cabinet.

The next step is to pull the top cover of the cabinet, and put the plugs. To give rigidity to the box, install shelves that are pulled together with euro screws between the sections (in some configurations, such shelves are not available).

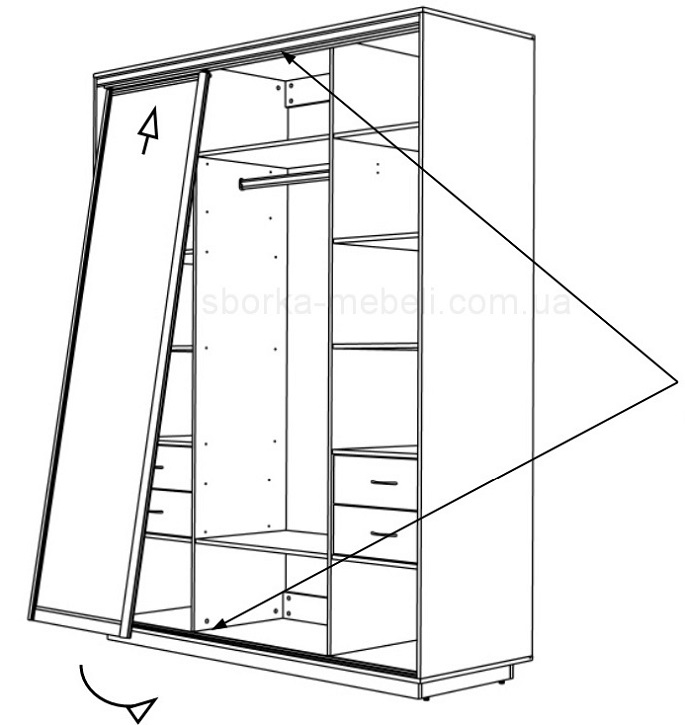

We measure the diagonal and nail the back wall

Before nailing the back wall, make sure the wardrobe is rectangular. This is done with a square, attaching it to the corner of the cabinet or diagonals are measured with a tape measure. You can use two options at once to be more accurate. All angles should be equal to 90º, and the diagonal of the two sides should be the same. In case of unevenness, it is necessary to align the body by shifting to the lower side.

If the box has precise shapes and data, then you can nail the back of the cabinet with nails. The stiffening wall is attached not only along the perimeter, but also to the shelves.

The structure should now be rigid and can be set upright.

Installing and configuring doors

Two rollers are screwed onto the top of each door. It happens that the mirrors are attached to the middle door of Basya's cabinet, but if the manufacturer has not glued it, then you will have to do it. To do this, you need to attach a mirror and outline it in a circle. Then put on liquid nails.

Now you need to install the lower guides and upper roller rails. Having retreated from the edge 2 cm, the guide is screwed at the bottom and in the same way the rail at the top.

Then carefully insert the doors into the grooves of the profile. The rollers must move smoothly, and the doors must fit well, not touch or catch on anything. In case of poor running, the track rollers can be adjusted. After that, we screw the rollers with a fixing screw. We fasten the guides to the lower parts of the doors. Now we install the upper front plank and install the shelves and the bar for the dresses. Basia's cabinet is ready for use.

Self-assembly of furniture can save you a lot of money. It is good if a person has simple skills in assembling objects. It will be useful for beginners to learn how to assemble a wardrobe on their own. Step-by-step installation of each element of the product will allow for quick installation.

Among all types of products for storing clothes, the leading place today is occupied by a wardrobe. It is multifunctional, spacious, available in different shapes and sizes, and does not require additional space to open doors. That is why most people, when choosing between a wardrobe and a wardrobe, prefer the latter option.

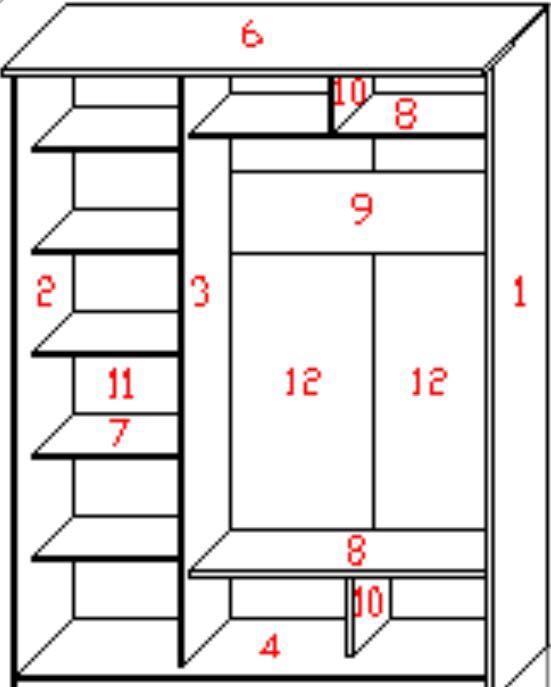

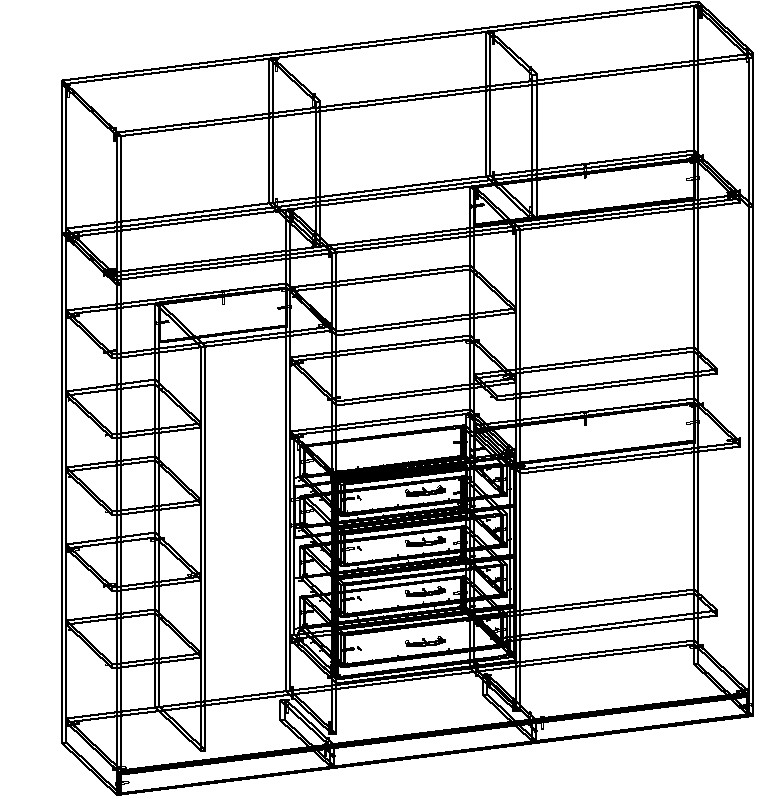

Do-it-yourself assembly of a sliding wardrobe in the video presented is quite simple - for this it is enough to have the necessary tools in the apartment and be familiar with the design of the product. Often, when ordering a cabinet without the services of assemblers, companies send a document containing a drawing of the product. Also, all the constituent parts are listed in this way, which are numbered in order. Looking at the drawing and comparing the elements of the cabinet, you can intuitively assemble the product.

To work according to the wardrobe assembly scheme, you will need the following tools:

- building level - to check the evenness of the installation parallel to the floor;

- corner;

- rubber and regular hammer;

- straight and Phillips screwdriver;

- roulette;

- pencil and ruler;

- screwdriver;

- wood drill - to make holes;

- drill for metal - for installing an aluminum base.

Of the additional tools for assembling furniture, a jigsaw, drill and sandpaper can be useful on your own. It is also necessary to prepare all the details of the cabinet, which means - check the diagram for compliance with the number of items

Pay attention to the fittings and mechanisms: if there are drawers in the cabinet, the complete set should include ball guides

Instruments

What to assemble a wardrobe from

For the manufacture of furniture, you can choose different materials. But this must be done even before designing, since the assembly process may vary somewhat.

Natural wood

It is a traditional material used to make furniture. In this case, not the best choice. Boards for cabinet assembly must be thoroughly dried and impregnated with special solutions: water-based polymer emulsion or hot drying oil. In addition, their surface should be free of any defects: knots, cracks, etc. Considering that the wooden surface is hygroscopic, it is not recommended to use it for the manufacture of built-in furniture. The wood will warp due to changes in humidity inside the niche.

Photo: Instagram almaty.mebel.kz

Lining

Various options can be used: MDF, PVC or wood. It should be noted that the slats that make up the sash are inserted into the wooden frame. The wood from which the frame is assembled is selected only when dry, without defects. The lining is adjusted to size, the boards are glued together. This complicates the assembly process somewhat. In general, this solution is quite appropriate, but only for cabinet doors. It is often used for inline constructs.

Photo: Instagram alyance_naydi_kzn

Wood boards: MDF, chipboard, fiberboard

Perhaps the best choice for self-assembly of the cabinet. The materials have all the advantages of wood, but at the same time are completely insensitive to moisture surges. For work, choose plates of high and medium density, they are best suited for this. The slabs can be simply cut into pieces of the desired size. It is optimal to use cutting services for this.

Photo: Instagram good_wood_shop

Plywood

Standard or laminated sheets can be used. The latter are distinguished by their attractive appearance and are considered more environmentally friendly. The material is produced in the form of slabs of various thicknesses. When working, one should take into account some softness of the sheets; when installing self-tapping screws, plywood may deform. Therefore, it is recommended to use special gaskets.

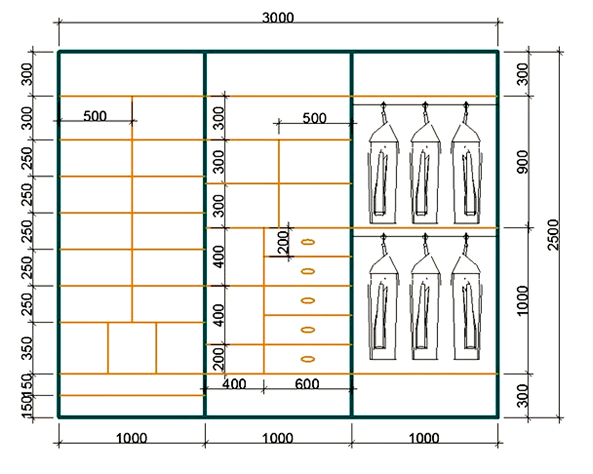

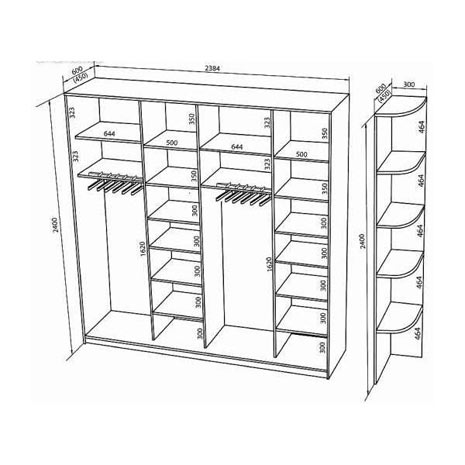

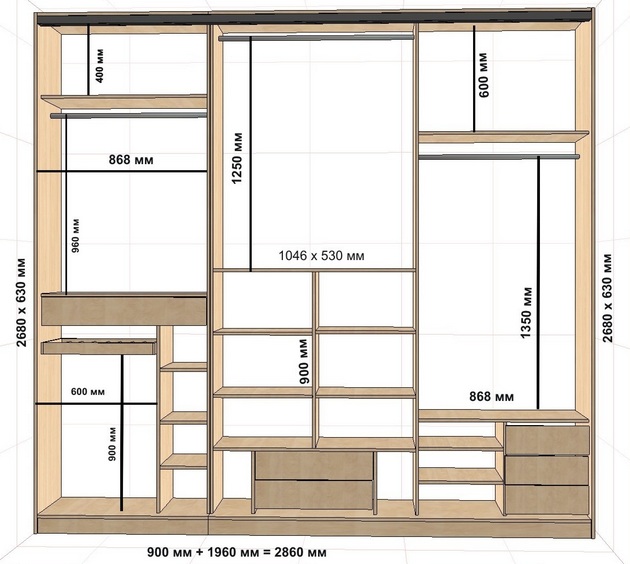

Development of design and drawing

Before taking on the drawings of the cabinet, you need to understand how to make measurements correctly. The niche in which it is planned to install the wardrobe will not always have the correct geometric shape. That is why measurements in a niche must be carried out according to the rules:

- first, measurements are taken along the back wall: at the top, at the middle level, at the bottom;

- then we also measure the "frontal part" with an indent;

- height measurement also takes place in three positions from the "rear" and from the "front".

Installing a built-in wardrobe without such measurements can lead to the fact that a case made without taking into account errors and differences will either not enter, or when trying to assemble the structure, serious gaps will be found. It will be a shame if the cut shelf turns out to be less than the required size and simply fails. Before embedding, carefully calculate all the errors in order to leave an allowance for installation. Sometimes it happens that as a result, the drawing of the shelves resembles a trapezoid, and not the expected rectangle. It all depends on the quality of the walls, the density of the plaster on the inner corners of the niche.

Next, go to the drawing. If you do not have drawing skills, it is better to contact the designer. Based on your data and wishes regarding the material, you will be made a drawing of the future wardrobe in a niche. In such work, one must not forget to take into account the thickness of the material, the edges, if you want to thoroughly close the cutting points, and the margin for the mechanism of the compartment itself, on which it is also necessary to lay about 10 cm.

Having detailed diagrams on hand, you can be sure that the manufacture of cabinet parts will be more accurate. The allowances left when taking into account the errors of the walls will make the embedding more accurate.

Now, with regard to the design of the future cabinet: not having a lot of experience in drawing up drawings and installation, give up complex radial structures of the facade. Here you need not just skills, but good professional experience in order to calculate and then correctly assemble such a structure. Limit yourself to a simpler cabinet option that is guaranteed to be able to control during assembly. Order all decorative elements strictly in accordance with the drawing.

What tool is needed to make a wardrobe

Taking into account the fact that the cutting of laminated chipboard sheets will be ordered from a third-party company, the following tools will be needed for the independent manufacture and assembly of the wardrobe:

- A good electric drill with a set of drills, in which there are necessarily several pieces intended for working on wood (to create seats for confirms) and the material of the selected profile of the sliding system. There should be several identical drills so that the work does not stall if one of them breaks.

- Hex screwdriver for tightening furniture screws.

- Normal quality hammer and medium sized nails.

- Self-tapping screws and a screwdriver with a Phillips tip or a screwdriver with a screwdriver for tightening them suitable for the selected chipboard thickness.

- A tape measure for marking the locations of the euro screws and self-tapping screws, a square for accurate measurements, a simple pencil for putting down marks and a level so that the cabinet does not turn out to be skewed.

- Metal hacksaw for corners.

- Special crown for a drill, designed for cutting large holes on chipboard parts.

It is better to prepare all the tools listed above in advance so that you do not urgently look for a specific screwdriver or drill in the process.

How to work with chipboard - a popular material for cabinet furniture

Currently, laminated chipboard is mainly used in the production of furniture. This is the foundation. Represents coarse wood chips. It is hot pressed into a sheet shape. In the manufacture of plates, formaldehyde resins are used, they are an additional component. The difference from a plain chipboard is to cover it with a foil made of paper and melamine resin. In terms of environmental performance, it is better to use materials of class E1. Chipboard boards have good compaction, due to which furniture made from them is strong and has a long service life.

Fastening the rails to the cabinet door

If you think that this material has the same composition, you are wrong. By coating, they are divided into veneered, rough and laminated. According to the quality composition, they can be divided into three varieties: the first - they use first-class sawdust (usually a tree of the same species). The surface is flawless, not a single chip. The slab is decorated, laminated with foil or veneer. Second grade - you can already see small defects. Veneering may or may not be. Third, there are already tangible defects. Such plates are not covered with anything.

Until the cabinet is completely assembled, make sure that the attached parts do not tilt, as the fasteners may break off.

In addition, laminated chipboard is moisture resistant and fireproof (withstand high temperatures). Basically, they are used to make the body of furniture, but they are also used in the production of partitions or used as interior decoration. It is worth mentioning that chipboard, due to its composition, perfectly holds nails and screws.

In order to stiffen the wardrobe, it is necessary to secure the back wall.

The main "steps" of collecting wardrobes of the "coupe" type with your own hands are indicated in the instructions.

Furniture made from these boards has many advantages over other materials.

- Acceptable price indicators.

- No difficulties in manufacturing.

- Quality factor.

- Significant period of use.

- A variety of colors and decorations. This will help you to perfectly match the furniture in the living room, kitchen or children's room.

- It is in perfect harmony with other materials.

Such furniture looks great in any interior.

Another important feature of laminated chipboard is that these boards have heat and sound insulation. Therefore, they can sheathe the walls of the room.

Make sure the holes for the shelves and the hanger bar attachments match the holes on the opposite rack.

Also, if you have started a redevelopment of an apartment / house, knowing how to assemble a wardrobe on your own will help you easily and quickly resolve the issue of moving this furniture.

Installation of a rod and fittings

At the penultimate stage, the assembled cabinet body is equipped with additional fittings and accessories. Depending on the design, these can be:

- barbells;

- pantographs;

- trombones;

- baskets;

- trousers;

- tie, etc.

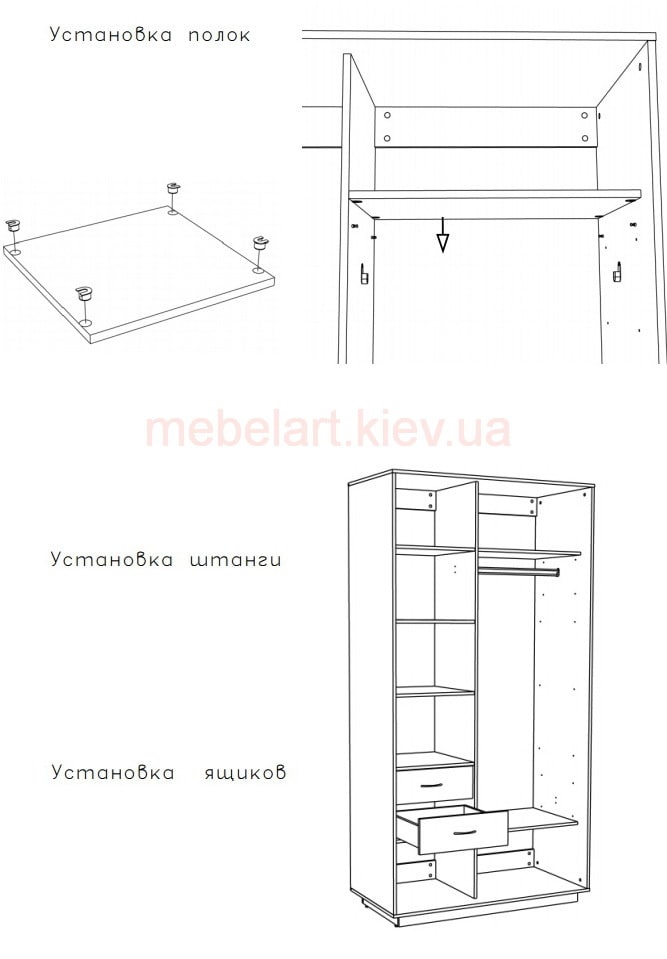

The rods, on which the clothes will be hung, are usually placed in the center of the side walls or internal partitions, at a distance of 120-150 mm from the lower plane of the cabinet roof or upper shelf. The mountings into which the rod is inserted are screwed with screws 3.5 * 15mm. Moreover, its size should be several millimeters less than the internal dimensions of the section (depending on the thickness of the fastening itself).

We attach the upper bar for clothes

We attach the upper bar for clothes The bar is fixed

The bar is fixed Lower bar attachment

Lower bar attachment Lower shaft installed

Lower shaft installed

Other fittings and accessories are installed in accordance with the instructions that come with them.

Varieties

The main types of structures:

- case - for manufacturing, the assembly of the case is required, a large consumption of materials, is often used to delimit individual areas of the room;

- built-in - re-equipment of an unnecessary niche into a usable space in the corridor, bedroom and other rooms;

- radius - all items of the front part are made in a curved shape, the complex geometry of the device requires special skills;

- straight line - a universal design method with simple installation, suitable for classic and high-tech interiors;

- corner - a more complex installation technology of non-standard shape for efficient filling of the corner space.

The type of construction is selected depending on the layout and design of the room. Manufacturing and installation of parts and blanks in some modifications can be difficult for assemblers who do not have the necessary experience, therefore, for a reliable and high-quality assembly, it is better to involve qualified specialists.

How to assemble wardrobe doors?

Before assembly, carry out the preparatory measures:

- drawing up drawings;

- calculation of the size and number of parts;

- purchase of components.

Blueprints

Taking into account the dimensions of the doorway (the distance between the side walls, bottom and ceiling of the cabinet), draw up a diagram of the location of future doors, their number and dimensions

Expert opinion

Alexander Didenko

Furniture assembler at Mabax

The Swiss company "Ikea" sells doors for sliding wardrobes separately. You may not be engaged in manufacturing, but buy a ready-made kit. Measure the wardrobe in the store, or see the dimensions in the catalog on the seller's website. It is better to attend to the design of the cabinet, taking into account the finished doors, so as not to subsequently adjust them to your wardrobe.

Payment

Basic data - the height and width of the opening of the wardrobe cabinet. Take final measurements of the opening after installing the cabinet body in the design position. The distance between the sidewalls is important for determining the number of doors. The generally accepted number of canvases is from 2 to 3 pieces.

Standards and recommended door sizes for sliding wardrobes

Standards and recommended door sizes for sliding wardrobes

Our guide with a calculator will help you to correctly calculate the doors of the wardrobe.

Purchase of components

After the doors have been calculated, make a list of the needs of materials and fittings. Include in the list:

- The number of uprights, top, bottom and middle profiles, their length.

- Material, size and area of filling fragments.

- Number and dimensions of self-tapping screws and set screws.

- The length of the buffer tape.

- Number of top and bottom rollers.

- The thickness and length of the sealing cord.

To enlarge the diagram, click on the picture

To enlarge the diagram, click on the picture

Expert opinion

Alexander Didenko

Furniture assembler at Mabax

Ready-made sets of sliding systems are also sold by Aristo and Versailles. You can easily assemble the components, having a design with high quality parts and good smoothness. These systems are in no way inferior to expensive kits from other companies. The doors can withstand up to 100,000 opening-closing cycles without breakage. The minimum period of trouble-free service is 30 years.

Step-by-step instructions for assembling doors for a wardrobe

| 1 | Check the geometric correctness of the opening of the chiffonier by the equality of the diagonals of the opposite inner corners.

|

| 2 | Control the horizontal of the bottom and top plates and the vertical of the side walls with a plumb line and level. If deviations of the parameters of the opening from the norm are found, eliminate them.

|

| 3 | Drill the mounting holes in the upper and lower guide tracks.

|

| 4 | Using a screwdriver, fasten the guide rails with self-tapping screws to the top plate and the base of the wardrobe.

|

| 5 | Secure the roller assemblies to the upper ends of the door frame posts with set screws.

|

| 6 | Insert the lower support rollers on both sides into the lower frame rail. Fix them with self-tapping screws and screws.

|

| 7 | Screw the upper, middle (if combined filling) and lower bar to one of the posts.

|

| 8 | To correct the thickness of the filling sheets, put the sealant into the grooves of the profile before installing them. If it is glass or a mirror, the sealant is pulled over the canvas.

|

| 9 | Insert sheets of glass, mirror or MDF, chipboard into the slots of the profiles.

|

| 10 | By installing the second frame post, you will have a complete door assembly.

|

| 11 | Glue the buffer tape into the outer grooves of the uprights. Remove the protective film from the back of the self-adhesive tape before mounting.

|

| 12 | Follow this example to collect the rest of the doors.

Begin installation in the cabinet by installing the lower rollers in the grooves of the guide track. While squeezing the spring-loaded lower bearings, insert the upper rollers into the guide rail.

|

| 13 | To prevent accidental door opening, install additional spring stops and closers in the lower rails.

|

For an alternative way of assembling a door with a 3 meter high mirror, see the video.

Preparing for assembly

When the finished parts are delivered, you can start preparing them for assembly. You need an iron to work. Gently attach the acquired edge to the end of the part so that the beautiful side is on top. Carefully walk over it with a heated iron. Make sure the steam is not turned on on the iron.

Press down the heated edge well and wipe it thoroughly. Carefully sand the cut edges with sandpaper. There is no need to rush to prepare the parts. Try to achieve the maximum quality of work so that your wardrobe looks neat and beautiful.

From the base / plinth parts, assemble the base of the podium for the bottom of the cabinet. The base must be required.