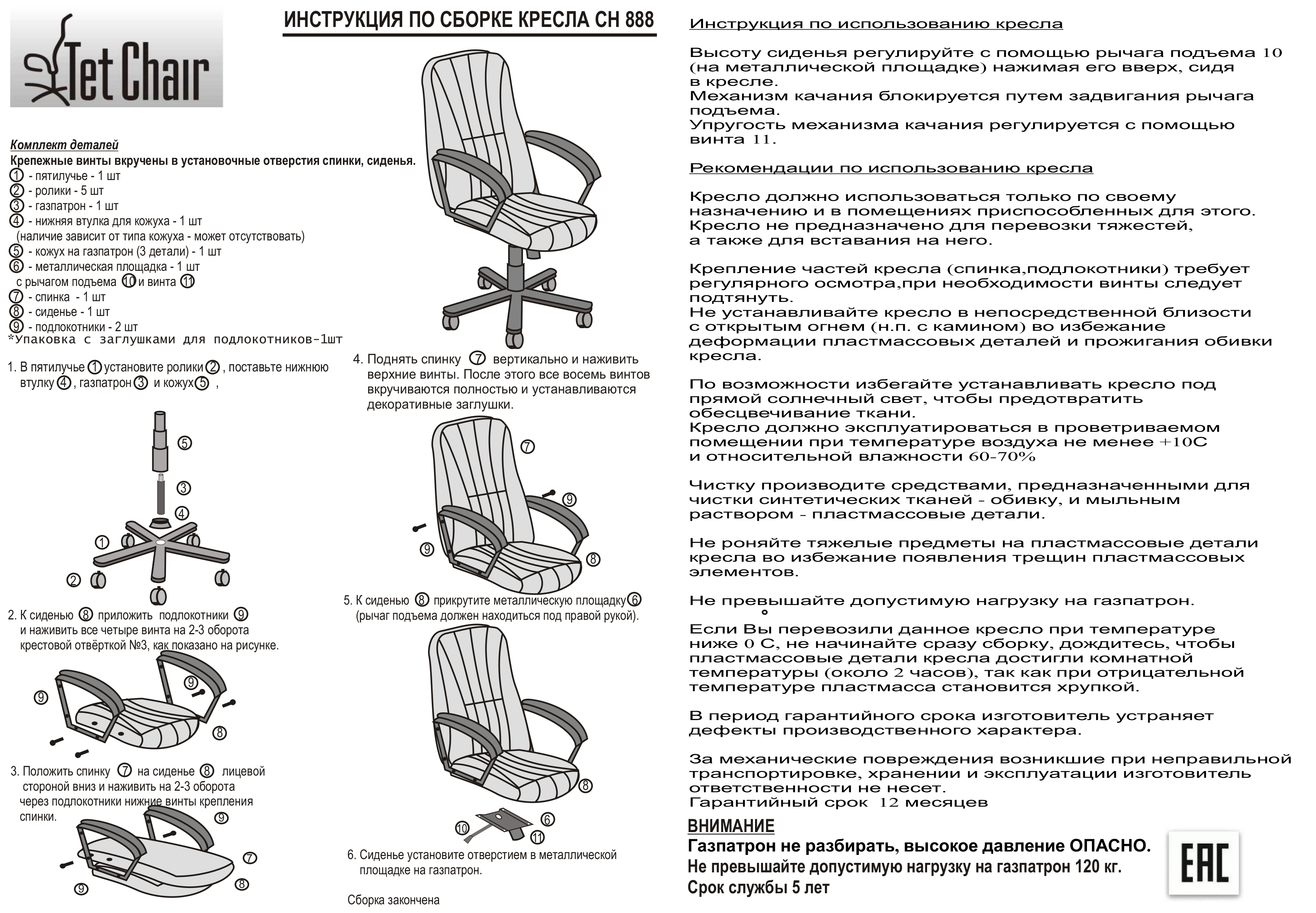

Basic structural elements

The primary task in assembling the chair is to select the correct shape.

It is important to determine how a person spends time at the computer, since different types of activities require different furniture. You should also focus on height, weight, physique features of the future owner of the seat

A homemade computer chair is furniture assembled according to exclusive drawings that fulfills a specific role. Such designs have a unique design, meet exclusively the needs of the owner and usually last longer than serial counterparts. Among other advantages, it is also possible to single out the fact that by making your own chair, it becomes possible to make a product that corresponds to a non-standard height or weight of a person.

Assembling an armchair according to your own sketches also implies the creation of a unique drawing in which you can use any components, including unusual elements. But if you need to make a simple chair, then you can use a standard set of accessories. The following details are usually applied:

- Armrests - to keep the body within the chair, comfortable arm position.

- Seat - for a pleasant pastime, you need to make it comfortable, not very soft.

- The backrest is an important element to help control the wearer's posture.

- Regulating mechanism - to control the structure, create a certain shape.

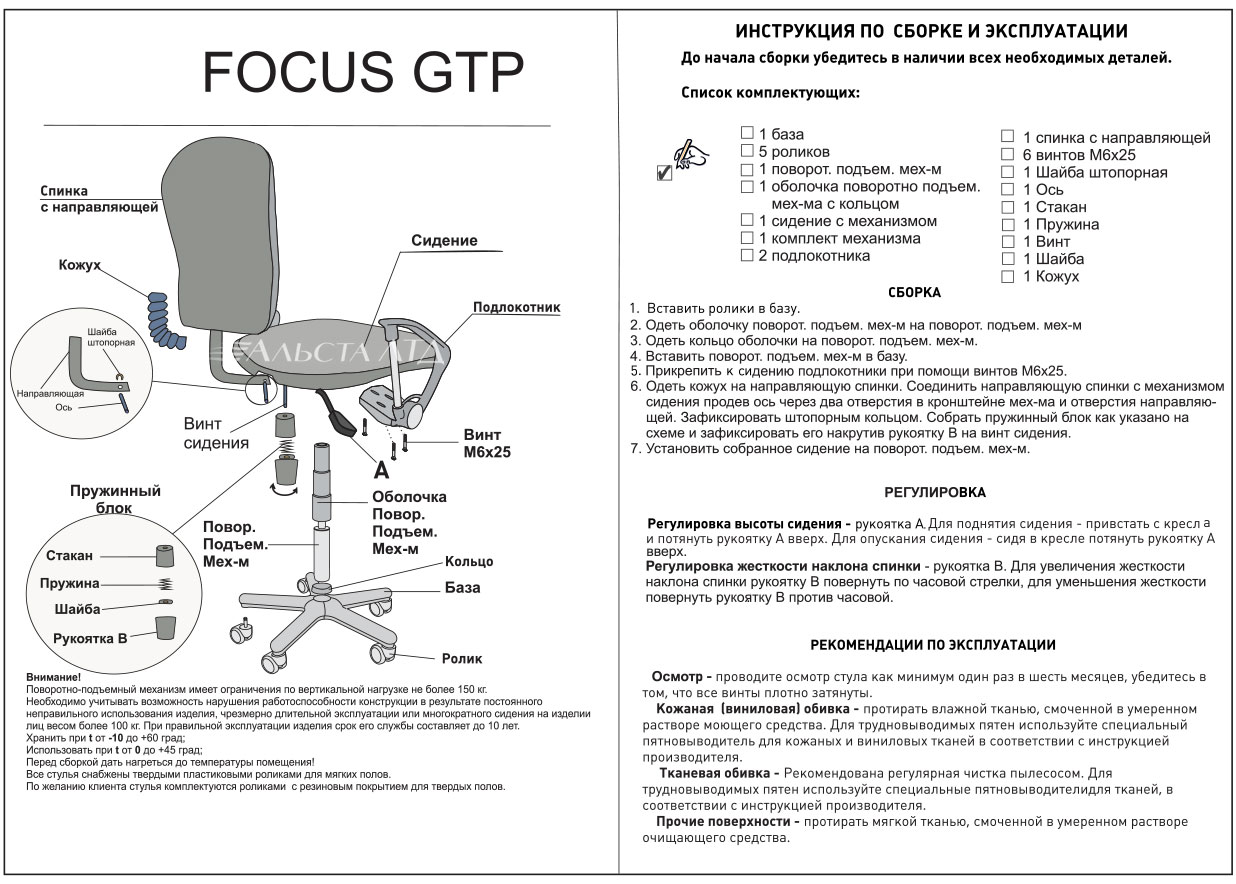

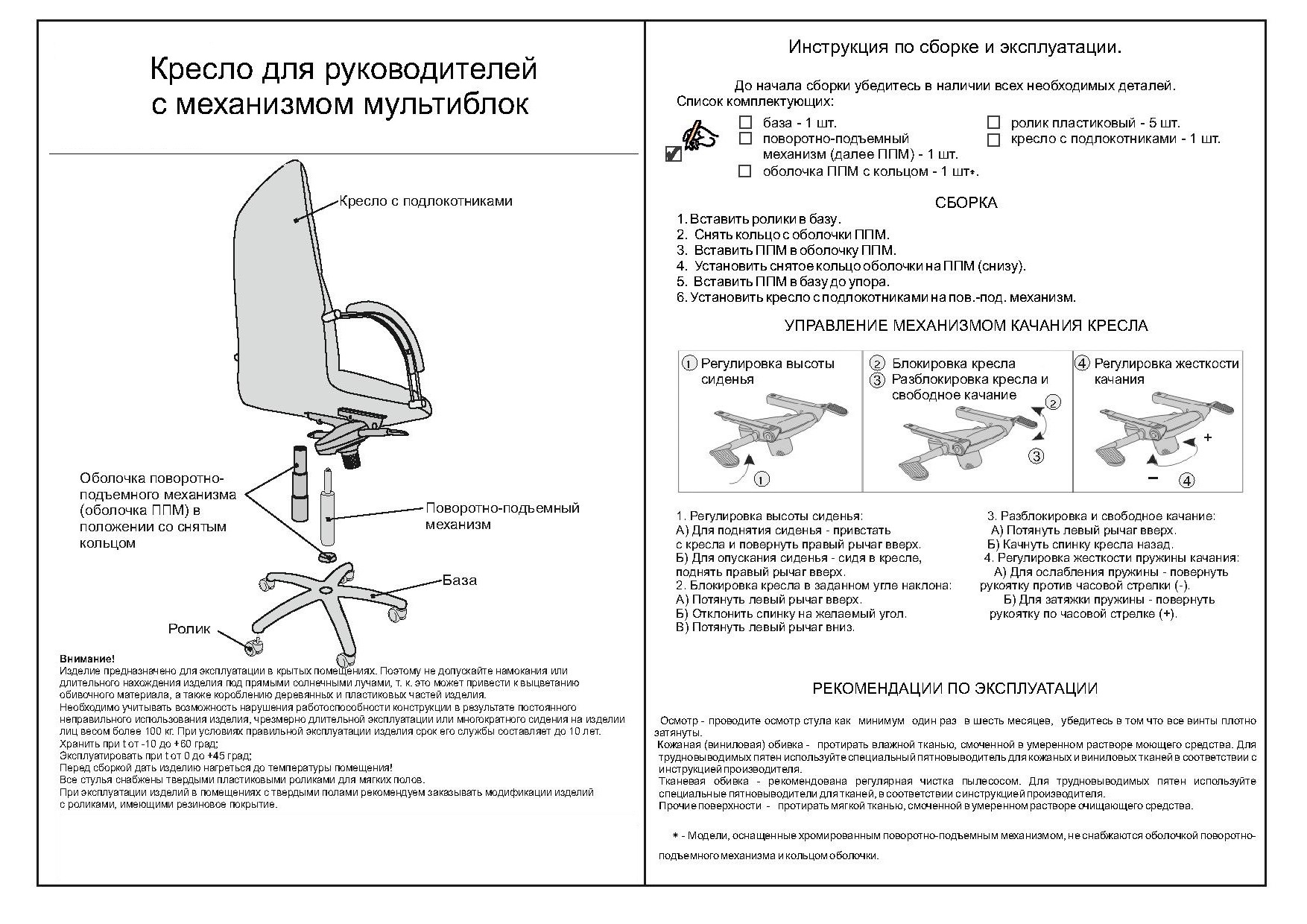

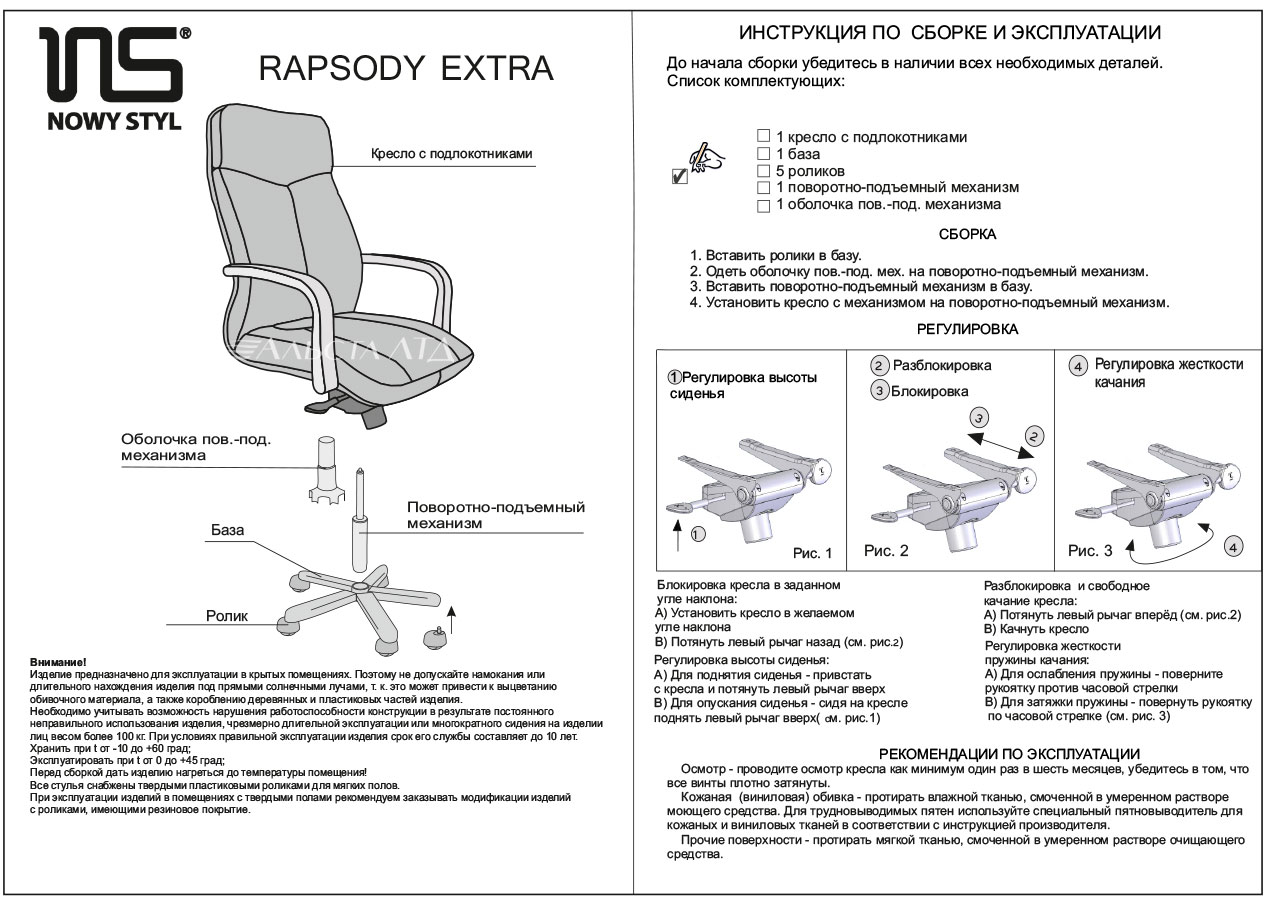

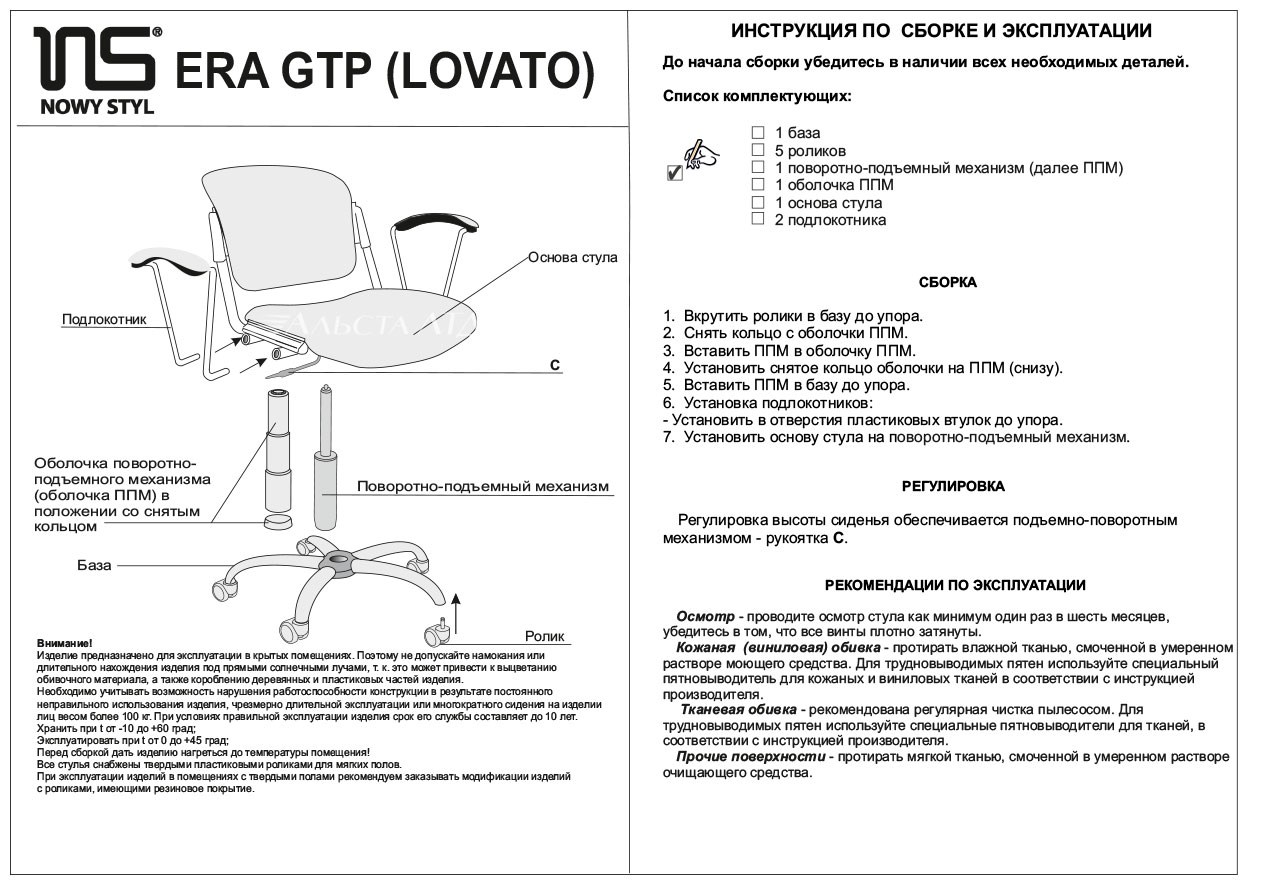

Mechanisms

Mechanisms

Seat

Seat

Back

Back

Armrests

Armrests

Spring mechanism

Spring mechanism

Possible difficulties

It happens that during disassembly of office furniture it is inconvenient to unscrew the short rear fastening screw. In this case, it is recommended to replace the screwdriver with a screwdriver.

If the gas lift moves away from the piastra with great difficulty, the use of a bronze or wooden drift will help solve the problem. It should be remembered that strong blows can break the plastic crosspiece.

It happens that when replacing or repairing the rollers, the metal rod gets stuck in the cross. This often happens if the office furniture has never been disassembled, because over time, all fixtures are compacted. In this case, the use of technical lubricant will help to eliminate the problem.

Experts do not recommend repairing a worn out pneumatic chuck. This part is for replacement only. The inside of the device contains high pressure compressed air pumped into the chamber and accidentally escaping could cause serious injury to a person.

The rocking mechanism is also rarely repairable. Usually they change it right away, but the main difficulty is that it is very difficult to find this spare part. In this case, the best solution may be to purchase a new office chair.

Before disassembling office chairs, experts immediately assess the condition of the crosspiece. Inexperienced users often change a shaky base. However, it can last for several more years. In order to secure the chair support in a stable position, it is necessary to insert a metal pin into its rod and seal the connections.

You can also repair minor damage to the upholstery yourself. To do this, you need to use a furniture stapler. Decontamination should be carried out before disassembling and repairing the product. Also, before disassembling computer chairs, they are usually vacuumed.

In order not to waste time on frequent repairs of rollers, instead of them, you can install special plugs - gliders. However, it will be more difficult to move furniture on the floor with them than with casters. The plugs are attached to the slots in the same way as the rollers. The use of gliders allows the seat height to be reduced.

In order to avoid frequent breakdowns, it is recommended to choose high-quality furniture from well-known manufacturers with a warranty period of at least one and a half years. If the malfunction is serious, it is better not to risk it by disassembling the office chair at home, but to resort to the help of a qualified specialist.

Disassembly inconveniences

Disassembly inconveniences

Cross state

Cross state

Office Chair Gliders

Office Chair Gliders

Materials and tools for the assembly of the structure

There are many diagrams and drawings in the public domain, with which the assembly of a sofa with an accordion transformation mechanism will become much easier. You only need to substitute your dimensions, which are determined depending on the area of the room and the allotted space for the product. In addition, the dimensions of the berth are taken into account. Before choosing a scheme, it is recommended to decide on the design of the product.

The support for the mattress can be a frame made of metal or fiberboard and timber equipped with lamellas. It is difficult to create a sofa accordion with your own hands with a metal frame without certain skills. Therefore, most often home craftsmen choose the option from wood. The product, made with a wooden frame, has the following details:

- soft mattress, consisting of 3 elements: front and back of the back, seat;

- 2 armrests;

- stiffening ribs that connect the sidewalls at the back;

- storage box for bed linen, pillows, blankets;

- wheels;

- guides that allow you to push the structure.

When creating a scheme for future furniture, the master must take into account a number of points:

Armrest shape: straight or complex

It is also important to decide whether the element will be soft or hard.

Backrest height when unfolded.

The presence or absence of a box for linen on wheels .. Based on the diagram, a drawing is created

It indicates the dimensions of each part. Also at this stage, the characteristics of the material and its quantity are determined.

Based on the diagram, a drawing is created. It indicates the dimensions of each part. Also at this stage, the characteristics of the material and its quantity are determined.

For standard size furniture you will need:

- armrests - chipboard (2.5 cm) or plywood (1 cm) for the frame, timber with a section of 2.5 x 5 cm, hardboard;

- plywood for the facade;

- frame for a berth - fiberboard or timber;

- boards for the frame of the linen box and fiberboard for the bottom;

- foam rubber;

- stiffeners - fiberboard or plywood;

- self-tapping screws;

- boards for guides;

- transformation mechanism, the size of which should correspond to the height of the mattress;

- nuts and bolts;

- upholstery material;

- universal or furniture glue;

- supports for wheels and hinges.

You will also need a flat screwdriver, keys for 10, 12, 13, 14, a screwdriver, drill, ruler, pencil, tape measure, hammer, scissors and staples. You will need a sewing machine to create the covers.

Fasteners

Fasteners

Accessories and materials

Accessories and materials

Transformation mechanism

Transformation mechanism

Components

Components

Features of models from plastic pipes

A rocking chair made of plastic pipes is a great way to "attach" leftovers to the case after making a drinking or irrigation water supply system. From the tools for creating the frame, you will need scissors for PVC pipes, a special soldering iron (welder).

For the side surfaces, you will need a pipe with a diameter of 32 or 25 mm, for jumpers - 20 mm. By the number of joints, tees are purchased. It is better to provide for a purchase with a margin in order to practice soldering on individual parts. The price of tees starts at 5 rubles, so a stock of 4-5 parts will not be expensive.

A template is prepared in advance, according to which pipe sections are cut, providing a margin for each part of 3-4 cm: when soldering, the tube is inserted into the tee by 1.5-2 cm.

If you work carefully, the runners can be rounded without heating. If this cannot be done, then clean sand heated in the oven to 90–100⁰C is poured into the tube. To prevent the sand filler from spilling out, a plug is welded to one side.It will remain on the part even after the end of work, so that moisture does not get inside. The same plugs are welded to all open ends of the pipes.

At the end of the assembly of the frame, a foam mattress, sheathed with a raincoat fabric, is fixed on it, if the chair will be used outdoors. For fastening, strips of fabric (ties) sewn to the mattress are used.

PVC pipe scissors

PVC pipe scissors

Plastic pipe welder

Plastic pipe welder

Side element diagram

Side element diagram

Reinforcement scraps are inserted inside the pipes.

Reinforcement scraps are inserted inside the pipes.

We weld attachment points with a welding machine

We weld attachment points with a welding machine

Rocking chair made of plastic pipes

Rocking chair made of plastic pipes

Types of breakdowns

Due to the fact that a computer chair is a complex mechanism, mechanical breakdowns often occur during its operation. Experts identify several of the most common types of defects.

Cross breakage is a common problem only if the part is made of plastic. The metal crosspiece very rarely breaks down, has a long period of operation. The most common place of deformation is the intersection of the beams of the cross.

To determine the type of malfunction, novice craftsmen should focus on the signs of breakdowns and what is broken:

- inability to raise or lower the seat - breakage of the tip of the gas lift lever;

- Difficulty moving the chair - breakage of the wheel sleeve, absence of a retaining ring;

- skewing of the structure to one side - weak fixation of fasteners, manufacturer's defects, deterioration of the back mechanism;

- excessive mobility of the back - wear of the permanent contact;

- instability of the structure - breakdown of the gas lift or the swing mechanism.

We should not forget about less significant malfunctions, which also require attention:

- mechanical damage to the upholstery material;

- subsidence of foam rubber;

- breakage of wheels;

- deformation of piastra.

Possible problems and errors during repair

Before proceeding with the reassembly of office furniture, it is necessary to check whether the chosen gas cartridge matches the dimensions of the cross. If not, then this part cannot be installed in the chair. In this case, the seat adjustment mechanism will not work.

If the gas cartridge has been in a cool room or on a frosty street for several hours, it is recommended to leave the part in a warm room for a day before starting repair work. It is forbidden to replace the mechanism before the mechanism warms up.

As already noted, care must be taken when disassembling and reassembling to avoid excessive force. Despite the fact that the gas lift fits snugly to the base of the office furniture, this part is held solely by the friction force

And each blow with a hammer gradually pushes down the entire structure

In this case, it is important to apply uniform efforts and hit different parts of the part. If the hammer hits only one side, the gas chuck will get stuck in the crosspiece.

Then you will have to change the entire lower part of the office chair.

After assembling the furniture, it is recommended to check the functionality of the mechanisms. That is, it is necessary to turn the seat in a circle in both directions. And then you need to sit down and press the lever, lowering and raising the chair.

If the mechanism does not work after installing the gas lift, this indicates an incorrectly fixed piastre or a new part. You should also check the condition of the lever that activates the swing mechanism.

The main difficulty of this repair is that it is possible to evaluate the performance of the purchased gas cartridge only after installation. Before that, you cannot press the button located on top of the structure. During reassembly, the swing arm may clamp this element. In this case, the gas lift will not work. But if, after assembly, all the structural elements of the office chair function properly, but the seat does not fall down, it is necessary to pull out a new part and take it to the store.

In order to avoid premature breakdown of the gas cartridge, you must follow the manufacturer's recommendations regarding the operating conditions of the furniture. The service life of office chairs is significantly reduced if these items are constantly exposed to increased stress. Such furniture, in general, can withstand a weight of up to 120 kilograms.

Share link:

Required tools

What will come in handy for you:

- washers;

- 8 pieces of screws;

- 2 springs;

- 2 plugs;

- nuts;

- screwdriver;

- screwdriver.

Step-by-step instructions on how to assemble a chair bed

Stick to the following sequence:

- It is preferable to keep the parts in a warm room for at least two hours.

- Free up space and prepare the items you need.

- Lay packing materials on the floor, unpack products.

- Place the brackets on the sidewalls and fasten with screws through washers.

- Fix the supports and attach the nuts. Do the same with checkboxes.

- Then you can start installing the drawer side. For this you need fasteners.

- The spring and plug should also be secured.

- Fasten the sides to the mechanism with screws.

- Attach the backrest and make sure the structure is secure.

Frequently asked questions for novice furniture makers

Before proceeding with the manufacture of a particular design, you should familiarize yourself with the list of questions that often arise among beginners in this business.

How to saw parts?

When cutting longitudinal parts, it is better to use a circular saw, and for transverse parts, an electric jigsaw.

Jigsaw

Prices for popular models of jigsaws

Jigsaw

How to connect the parts of the structure?

For connections on which the main load is carried out, you will need to use euro screws or self-tapping screws. In other cases, the parts are assembled on wooden chops and glue.

Chopiki

Paint or varnish?

The choice of materials for processing depends on the quality of the wood itself. If there are no defects on the material, then it can be treated with a stain, and then a layer of varnish can be applied. If spots appear on the surface, then the wood must first be putty, covered with a primer, and only then painted.

Wood varnishes come in different shades.

How to reduce the consumption of paints and varnishes?

Quite often, during the final finishing, the paint is quickly absorbed into the surface, which leaves bald spots on it. This is due to the fact that natural wood has a porous structure. That is why professionals recommend pre-treating it with linseed oil.

Drying oil for wood processing

Design features

A high-quality office chair is a complex design, in the development of which various specialists took part - engineers, doctors, designers. The main elements are as follows:

- Back and seat. Provides back support and seating comfort.

- Permanent contact. A component that connects the two previous elements and is responsible for changing the position of the back.

- Five-beam crosspiece. It is the base on which the entire load falls.

- Rollers. Elements at the bottom of the cross, responsible for the possibility of easy movement of the chair without damaging the floor covering.

- Gaslift. A shock absorber that guarantees the elasticity of the structure and allows you to adjust the height of the office chair.

- Armrests. They significantly increase the comfort of the seated person, especially if they are supplemented with soft pads, but this element is variable, not all models are equipped with it.

Despite the external similarity of all office chairs, they differ in types and models. The adjusting mechanisms also have their own differences, which are shown in the table.

| Spring-screw, or Freestyle (FDA) | It is characterized by an elastic spring under the seat, reliability and unpretentiousness. Able to change the position of the backrest and the degree of effort when deflected. The distance between the back and the seat can be adjusted. It is used in budget models together with piastra. |

| Piastre | Directions of work - only up and down. Used in tandem with FDA. |

| Top gun | The mechanism allows you to swing, like a rocking chair. Provides a deviation of monolithic seats in the range of 95-130 °. Ensures stability of the chair even at the maximum tilt angle. |

| Synchronizing mechanism | The device is reliable and very durable, with precise positioning of the chair. The set of functions includes tilt and fixation of the backrest, height adjustment, adjustment of the planting depth. Under the weight of a person's weight, in automatic mode, it changes the angle of inclination of the seat. It is considered the most expensive mechanism. |

Types of chairs

There are many different types of chairs, differing in the level of comfort, cost, ways of placement in space. The design is an "improved chair" with a soft back and seat covered with textiles, leather, leatherette, fur, in some cases - armrests, a footrest, a swing mechanism.

The main classification looks like this:

- by appointment - for recreation (interior), for work (office);

- by design features - with a rigid frame, without a frame;

- at the place of installation - in a living room, in a garden or on a veranda, office (computer), gaming (gaming).

The very design of the object is also different, there are:

- ordinary - installed on four legs, have a soft back, armrests, coffee coasters, poufs, and other details that provide maximum comfort;

- chair beds - designed for cramped rooms, significantly saving space. It is not recommended to constantly sleep on such furniture, but it is possible to put an unforeseen guest who remains overnight on it, as well as use it in a summer cottage;

- rocking chairs - performed classic (on skids-skis), with a pendulum mechanism (have a fixed base), spring (rattan rocking chairs "papsan"), as well as "Viennese armchairs" (runners are connected in a closed circle);

- recliners are especially comfortable, expensive models that can fully unfold and have a footrest. Transformed manually or by means of an electric drive. A ventilation system, a mini-bar, vibration massage, etc .; sometimes built in here;

- suspended - it can be a hammock, "egg", ball, "cocoon". Hanging is done on the ceiling, wall, rack, beam.

Frame models are made of natural wood, metal, plywood, chipboard, plastic. Usually several materials are used at the same time. Frameless options are pillow bags filled with foam balls, synthetic fluff. There are also convertible, lightweight inflatable items.

Product requirements

When choosing a model for a future chair, you need to focus on the permissible load that it can withstand. The set of the fisherman must correspond to the dimensions of the product. You can, for example, make a seat from a folding canvas chair, shorten its legs and, if necessary, sew a soft cape. In this case, you should definitely take into account the maximum permissible weight for which the product is designed. Even if you convert a regular chair into a boat seat, don't exceed the load limit. The simplest folding products can withstand only 60 kg, but mostly models are designed for a weight of up to 90-120 kg.

For fishermen who do not fit the first option, it is better to make a chair from scratch. The frame should be made stronger and tougher using chipboard or boards. The method of making such a seat is not complicated, if you first understand the instructions and take into account possible errors.

The set of the fisherman must correspond to the dimensions of the product

The set of the fisherman must correspond to the dimensions of the product

Consider the way the chair is fastened

Consider the way the chair is fastened

How to do it yourself

To make a pendulum rocking chair with your own hands, you will need a drawing, carpentry tools and improvised materials. Working with wood at home is a little easier than working with metal.If the decision is made to make a rocking chair from iron, the finished furniture must be treated with an anti-corrosion coating.

Made of wood

At the preparatory stage, you should decide on the type of furniture. The easiest way is to make a rocking chair, in shape and design, reminiscent of a reduced copy of a garden bench, with a seat and a backrest made of slats. This model is lightweight and easy to use. There is another type of chair - with a monolithic base, but such a product will be more heavyweight.

Next, you need to prepare materials and tools. For work you will need:

- hacksaw;

- plane;

- hammer;

- screwdriver;

- Sander.

Plywood (wood), timber and slats are suitable materials. Hand-made drawings are made on paper in a small cage. An ordinary chair is taken as a basis, only in the lower part runners are attached to it. During operation, the recommended sequence of actions should be strictly observed.

The pendulum mechanism consists of two bars connected by hinges. The components are set on glue or inserted into special grooves. The seat is made on the basis of a frame that repeats the shape of the back, made of beams fastened with transverse slats. To assemble the rocking chair pendulum and support, hinges are attached to the legs, fixed on a fixed base - the swing angle depends on the length of these elements.

Step-by-step instructions for manufacturing and assembly:

- The base is made from the boards.

- The seat and back are cut out, connected with fasteners.

- Legs are cut out, then they need to be put on glue and screws.

- Armrests are formed and polished, attached to the product.

After that, the finished furniture is sanded. Additionally, wooden parts can be primed. The final stage of finishing is varnishing.

Prepare tools

Prepare tools

Cut out the parts of the chair

Cut out the parts of the chair

Connect the pendulum mechanism with hinges

Connect the pendulum mechanism with hinges

Fasten the supports

Fasten the supports

Assemble one side of the mechanism, check

Assemble one side of the mechanism, check

Attach the second side

Attach the second side

Saw out the seat, fasten

Saw out the seat, fasten

Drill to base

Drill to base

Collect the back

Collect the back

Form and sand the armrest parts

Form and sand the armrest parts

Attach the backrest and armrests to the base

Attach the backrest and armrests to the base

Cut soft pillows, paint the chair

Cut soft pillows, paint the chair

Put on the covers and you're done

Put on the covers and you're done

Made of metal

The pendulum mechanism of a rocking chair made of a metal profile is an ideal solution for a summer residence. As materials, iron bars or steel reinforcement, cut to the desired size, are suitable. Of the tools you will need:

- rod bending device (device for unbending reinforcement segments);

- welding machine;

- clamps;

- a circular saw;

- electric drill.

It is recommended to use a tape measure and a metal (wooden) square for measurements. You should also prepare several drills for working on metal, they should be of different calibers. Experts also recommend purchasing high-quality paints and varnishes for furniture finishing in advance.

Work algorithm:

- To make runners - to give the sections of the reinforcement the desired shape using a rod bend.

- Assemble two sidewalls - weld the racks with seat rails to the runners, fix the armrests in the desired position.

- Connect both sides with cross-braces.

- Carry out a primer and then paint the frame.

After that, a bed is formed from wooden beams. You can also stretch a cotton sling on a metal base or assemble an iron rocking chair from individual parts made using the art of forging technique.

If the chair leans forward strongly, you can attach transverse slats behind the backrest, which serve as a decorative function. They will act as a counterweight to maintain the stability of the structure. Bars can be metal or wood. If the pendulum tilts strongly backwards, they are installed in the front.

Types of chairs and general instructions for creating

Regardless of which drawings are applied, there is a certain algorithm for how to make a chair.First, individual parts of a piece of furniture are created, then they are processed - holes for fasteners are made in them, paintwork is applied. Then the product is assembled into one whole. In some cases, painting and opening with varnish is carried out after the manufacture of the chair has come to an end, that is, a whole, assembled product is already processed.

Before making a chair, you need to decide on its type. Furniture items can be roughly divided into:

- Solid. They have no upholstery. In fact, they are chairs with armrests.

- Semi-soft. Padded upholstery fits on the seat, backrest, armrests. This saves materials.

- Soft. The upholstered armchair is fully upholstered with filled material. This is the best solution for your home, which will allow you to rest comfortably.

- Rocking chairs.

Preparation for work

The sofa will be assembled from three folding chairs, therefore, first you need to make them. To make one chair you will need:

- Durable furniture fabric (jacquard, microfiber, flock, chenille, leather) - 3 meters with a width of 150 cm.

- Foam rubber 10x100x200 cm - 2 sheets. Three chairs take 5 sheets. Do not try to replace two thin sheets of paper with one 20 cm piece - thick filler will quickly rinse out. During operation, the foam rubber in the front of the seats usually sags. Then turn the pillows to the other side or, opening the zipper, place the foam inserts.

- Zippers 80 cm long - 7 pcs. Take with a margin of length and quantity so that you do not have to run to the store again.

- Good reinforced threads.

- PVA glue.

- Tailor's tape measure, ruler, chalk, scissors.

- Sewing machine.

The whole sofa consists of such folding chairs, which can be easily transformed into beds.

Diagram of one folding chair

Each chair consists of four blanks. Each piece, in turn, consists of two pieces of foam rubber. We cut the foam rubber as follows:

- Square 80x80 cm - 2 pcs.

- Rectangle 60x80 cm - 2 pcs.

- Rectangle 20x80 cm - 2 pcs.

- Rectangle 30x80 cm (in the photo - pink) - 2 pcs.

Blanks for a frameless chair

Using PVA glue, we glue together two sheets of each part. We get four blanks with a thickness of 20 cm.

How to do with a skeleton?

A traditional soft piece with a frame is the more common option. To make it, you will need to prepare materials, tools and experience in carpentry.

Instruments

Of the tools you will need:

-

drill;

- sandpaper;

- jigsaw;

- pencil and ruler.

Of the materials you will need:

- lumber (most often consumers prefer 20 mm plywood);

- screws;

- thin nails;

- foam rubber and upholstery;

- joiner's glue;

- stain;

- glossy paint.

Manufacturing

The process of making a classic version of an upholstered chair is quite simple:

- Carefully study the drawing, prepare materials and tools, and proceed with the procurement of individual parts. They are cut from plywood with a jigsaw.

To make the parts correctly, it is recommended that you first cut them out on thick cardboard, and then transfer them to lumber.

For the manufacture of side parts, transverse strips are used. Here it is important to decide on the angle of inclination, bend and size of the furniture.

After making wooden parts, carefully clean the surfaces, paying special attention to the ends.

Prepared sidewalls are stained.

The ends of the sidewalls must be reinforced with metal rims.

Then you can start covering the product with fabric. Using a drill, holes are made in the product and the rims are fixed with screws. Prepared foam pillows are laid on the base and fixed with glue. You can also stick the foam rubber on the armrests. From above, the filler is fixed with a furniture stapler.

We have chosen artificial leather as the upholstery material.We trim the back of the furniture piece with it, and then proceed to other fragments of the chair.

Large-headed nails are used to securely attach the fabric.

As for the finishing, this is the treatment of the product with wood stain and paints and varnishes. This will not only give the furniture an attractive appearance, but also extend its service life. Since paint or varnish will reliably protect the product from increased moisture and other negative factors.

Helpful hints

If a person decides not to buy a computer chair, but to assemble it on his own, then he will be able not only to spend time with benefit, but it is guaranteed to provide himself with durable furniture with an exclusive design. You should focus on the interior of your personal account, not only at the stage of creating a drawing, but also when choosing an upholstery fabric. If everything is done correctly, the chair will meet all the needs of the user and will become the envy of friends and acquaintances.

Some people build massive wooden computer chairs. They have a large mass, but are as stable as possible. The disadvantage of such structures is not only immobility, but also the absence of adjusting elements and wheels. The metal profile provides additional freedom at the stage of drawing up and during the final assembly of the product.

Alternatively, you can assemble a chair-table, where a special tabletop will be placed for installing a laptop. This solution is suitable for freelancers, but ineffective for gamers.

Before making an office chair with your own hands, you need to thoroughly prepare and review several master classes. Office work can significantly affect posture, including when using serial furniture, so creating a structure according to individual requirements is the best solution, but it also has difficulties.

It is important to assemble the most comfortable, but at the same time not overly comfortable furniture. The office is a place to work, not to rest

You can assemble computer chairs with your own hands from old furniture, but this will significantly worsen the appearance of the product. It is best not to use used materials, especially when making furniture for a child. By choosing a previously used profile, wood and upholstery, you can significantly reduce the life of the chair.

Of course, making your own furniture is a costly business, but it is several times cheaper than purchasing items in a specialized store. But you can cut costs, for example by using a lift from an old chair, as well as castors, adjusters and fasteners. And in the end, you will still get a unique thing that no one else will have.

From the car seat

From the car seat

From an old chair

From an old chair