Final work

After the glue has dried, and the density of the resulting seam is checked, it is necessary to remove traces of work. To do this, proceed to the final stage of restoring the damaged body part.

It consists of the following steps:

- Remove the foil from the outside of the bumper.

- Using a grinding wheel or emery paper, polish the seam to the level of the rest of the bumper surface.

- If necessary, cover unevenness with putty. To do this, use a wide and narrow spatula.

- A layer of primer is applied to the treated surfaces.

Painting the treated area

It is important to ensure that the painted area does not stand out on the surface of the body kit

Damage to the bumper spoils the appearance of the car. The restoration of a broken body kit can be done in the service. On average, for 5,000 rubles, you can seal the crack there and remove the traces of repair. To save money, the operation is performed at home. The car enthusiast will need to show patience and accuracy, which will lead to an acceptable result.

Gluing process - preparation

Before gluing the bumper with fiberglass, we recommend that you carry out a test compatibility test on a small area of damage. To determine how to glue the body bumper, carefully read the manufacturer's instructions. The adhesive material must match the type of surface of the part.

If there are body kits at the place of damage, they must first be fastened, and only then removed. At the same stage, precisely set the material of the spare part to select the desired adhesive base.

This information is stamped on the inside of the product. When the mixture is selected, it remains to use it correctly in order to correctly restore the spare part after damage.

In order for the repair to last as long as possible, the bumper will have to be pre-treated. The part is detached in advance.

Conduct the required preparation:

- thoroughly clean the vehicle buffer from dirt accumulations;

- remove residual oil, dust;

- let the parts dry;

- wipe it with a chemical to degrease;

- sand the broken surface with an abrasive or grinder;

- if the cracks are too deep, we recommend drilling them, protecting the part from increasing damage.

With the listed procedures, you will achieve a stronger adhesion of the adhesive to the surface, which will guarantee the quality and long service life of the part.

How to glue a bumper: getting started

Once the surface has been pretreated, it's time to do the main part of the restoration process. Cover the damaged area of the spare part with a primer and wait until the substance has completely dried.

The second option: glue the crack on the bumper from the outside so that no glue flows out of it. To do this, use foil. Once the adhesive is dry, the material must be removed.

Primary gluing from the inner surface of the buffer is carried out with a composition with reinforcing properties. To do this, we recommend taking a composition based on epoxy resin with a high degree of adhesion.

If before that you decided to abandon the priming work, then carefully move the damaged areas towards each other

Sometimes cracked parts are held together with metal staples. However, fixing the two pieces from the outside is done with standard paper tape. It will carefully bond the edges of the surface to the same level before painting. After gluing the hole on the inside, the tape is removed more easily than the staples.

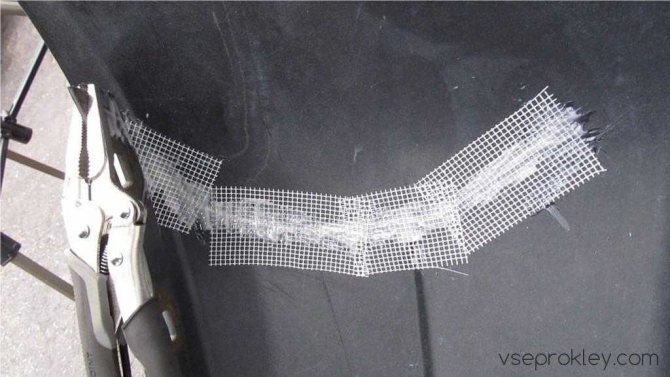

When both parts of the car are securely in place, apply adhesive mixture to both parts of the damaged part. While it is still wet, stick on a metal or synthetic mesh to reinforce the seam.

This can be a masking net, which also needs to be treated with adhesive on top. It is impossible to predict the drying time, since each chemical composition dries in its own way for a long time.

Final stage

When the crack is glued and the adhesive is completely dry, the vehicle buffer remains visually unattractive. Do not sound the alarm - this is natural, because there is still finishing work ahead.

Let's get to work:

- Remove excess compound residues on the plastic, carefully cut or sand them.

- Prepare the surface of the spare part for further painting. To do this, use a primer, putty or other materials for this purpose.

- The auto buffer must be painted according to the technology. Such paints are available in car dealerships.

Detailed work on painting the bumper with your own hands in the video:

Outcomes

Repairing a buffer at home is not a difficult task. Therefore, if you have minimal experience in this matter and follow all the instructions, you can quickly restore the part. And you will not have to spend money on paying for the work of an auto mechanic.

Adhesive for car parts has significant advantages. It is cheap, its purchase will not hit the family budget. The method of sealing a cracked buffer with an adhesive mixture is in no way inferior to a sealing.

We advise you to watch the video instructions on how to glue the bumper with your own hands with glue:

Mechanical impact on the car bumper as a result of an accident or collision with a high curb leads to the need for repair. In order not to spend money on car service services, many car owners prefer to do the repair themselves. Detailed instructions on how to properly glue the bumper with your own hands at home will help prevent mistakes.

Choosing an adhesive for gluing a bumper

A high-quality adhesive composition should: be well sanded, fill and restore large damaged spaces, not spread during application, have fast adhesion, withstand temperature fluctuations after curing, have high rigidity and mechanical stability.

NOVOL professional PLUS 710 repair box / repair kit

The material allows you to work with surfaces made of polyester laminate / plastic and metal; application is possible on old lacquered surfaces or two-component acrylic primer.

After the adhesive mass has hardened, it remains to polish the glued area, putty and paint the bumper.

TEROSON PU 9225 SF ME, two-component polyurethane based adhesive

The composition is suitable for bonding various plastic parts in a car, including interior decoration.

The bumper repair adhesive interacts with the main plastics suitable for bonding: PP / EPDM, SMC, PC, PA, ABS, PUR.

To increase the strength, the manufacturer recommends to additionally reinforce the bonded parts with fiberglass. A special glue gun is required for application.

3M 05900 (2 tubes of 150 ml) or 05901 (2 tubes of 25 ml) Compound for Repair of Plastic Parts

A two-component epoxy compound designed to repair damage to most common plastics. Bumper adhesive

Once cured, this bumper adhesive is matched to the automotive plastic industry.

Reinforced mesh or fiberglass for the machine can be used to increase durability on a large bonding area.

3M Automix 55045 Plastic Rebuilding Compound

Bumper adhesive with the properties of a full-fledged autoplastic after hardening, allows you to work with most of the plastics produced for auto parts.

It is characterized by a particularly fast solidification after which the workpieces can be sanded and putty, as well as trimmed and drilled when restoring the lost part of the element.

How to glue a bumper: instructions

If the bumper is cracked, it is better to make repairs without delay, so that the place of the defect is not clogged with dirt. First, the part must be removed, after removing the plugs, disconnecting the fasteners. Heavily broken body kits do not need to be removed immediately, they should first be fastened, then disconnected from the car

Before starting work, it is important to make sure once again what material the bumper is made of in order to choose a really suitable glue for it.

Novice craftsmen are interested in whether it is possible not to remove the bumper before repairing and painting? If the product is not properly disassembled, it may burst during manipulation. Only removal of the part will eliminate unnecessary stress in the area of cracks and their further increase.

Preparatory work

In the beginning it is important to carefully prepare the substrate to be adhered. This will directly affect the service life of the glued joint.

The first step is to wash the bumper, cleaning it from dirt, oil, and dry it well. Next, do the following:

- remove the coating (varnish, paint) using a grinding machine or a bar with sandpaper;

- remove all rust, if any (its appearance on the plastic bumper is excluded);

- the edges of the crack are drilled with grooves in the form of a Latin V so that it does not continue to expand, as well as for the purpose of more reliable adhesion of the glue;

- degrease the bumper with acetone, alcohol or other solvent;

- sand the product and primer it or coat it with a special adhesion improver;

- leave to dry completely.

Bonding cracks on the bumper

First, the primary bonding is carried out on the inside of the bumper, using the selected adhesive with powerful bonding properties. Next, the composition is applied to the front of the part, acting carefully and accurately. If necessary, the areas around the crack can be covered with foil, which will exclude the contact of the adhesive with undamaged areas. From the "wrong side" in the presence of large chips, you can apply a mixture of adhesive with soda, since these components, upon contact, turn into a durable acrylic-like plastic.

If the bumper is cracked so that it fell into two parts, separate pieces are combined with each other with an accurate fit and fastened with metal tape. If necessary, after gluing, clamps are used to clamp the debris. For reliability, a reinforcing mesh made of metal or synthetics is glued to large cracks from the inside, impregnated with glue. Wait until the product is completely dry according to the instructions in the instructions. After the clamps are removed, the glue seam is grinded to the level of the surface of the part.

Puttying and painting

The sealed bumper needs to be painted with high quality so that its appearance does not cause any complaints. Sometimes, first, puttying is carried out with a special plastic agent, which will allow to level out minimal defects. The putty layer must be very thin, otherwise it will not stick.

After the putty has dried, the surface is sanded with P1000 sandpaper and primed in 2 layers, the drying period of the first is at least 15 minutes. After that, the bumper is painted with decorative auto enamel in the body color. Apply the paint in 3-4 layers with maintaining intermediate drying cycles from 15-20 minutes. The last step is the varnishing of the bumper to give the repaired part a flawless look. Strict implementation of the entire sequence of actions will help save on the work of professionals and learn how to fix minor problems with a car with your own hands.

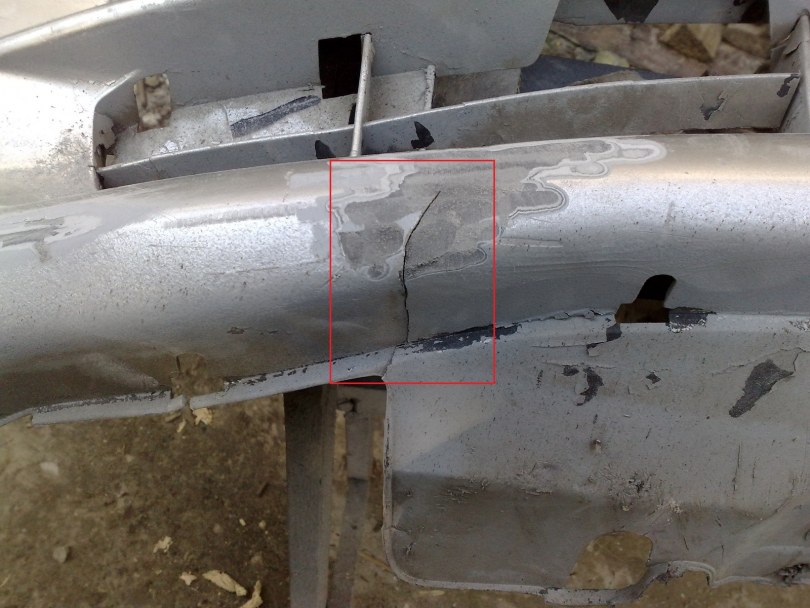

Bumper crack

The process of gluing itself implies - the creation of an inseparable connection, by means of adhesion of the adhesive mixture used between the pieces to be glued.

Modern adhesive mixtures are quite extensive in use and allow gluing thermoplastics, as well as thermosets. All current adhesive mixtures (compositions) designed to restore the integrity of the plastic base in many cases are high-molecular types of compounds, which in the process of hardening are modified and become a full-fledged polymer material.

A sufficiently necessary and important factor for performing high-quality do-it-yourself gluing is the choice of an adhesive base.A correctly selected adhesive mixture guarantees the best adhesion to the required type of plastic, as well as the most similar physical characteristics of the materials used in the production of the bumper and the seam itself after it has finally hardened. Especially for checking the adhesive, it is necessary to carry out a test, control gluing in order to determine whether the mixture is suitable for your bumper or not.

If, after completing the work, you plan to dry the finished bumper using hot drying, it is worth using special thermosetting types of glue, or thermoplastic adhesive mixtures, in order not to provoke the process of destruction or change the properties of the seam itself. It is for this reason that it is worth doing repair work with your own hands in the same workshop.

The preparation of the surface for gluing also has its effect on the quality of the joint. The surface must be prepared as much as possible for the best adhesion of the plastic surface. To obtain a similar result, you must perform the following actions on the back of the product:

- Cleaning the surface from dirt as thoroughly as possible;

- Special machining of two edges in the place of the resulting deformation, using a milling cutter or an abrasive wheel, in order to make a section of the future seam in the shape of the letter "V". This shape will increase the plane of the plastic in contact with the adhesive, which will ultimately increase the strength of the entire joint;

- It is necessary to degrease the surface, or carry out a chemical treatment.

Often, at the time of production of the bumper, to simplify the formation, special lubricating additives are added to the base of the plastic, due to which it is possible to reduce the adhesion of the adhesive. In order to remove such additives, it is necessary to perform more thorough and repeated processing of the bumper plane with special chemical compounds.

In order to make sure that the surface is properly processed and ready for gluing, it is necessary to check its wettability, for example, apply a drop of 60% alcohol solution, while the diameter of the spot itself must be at least 35 mm. Aluminum foil can be applied before bonding the front of the bumper to fix the parts and prevent the adhesive from leaking out, which can be removed once it is completely dry.

Bumper Bonding Material

Bumper Bonding Material

The crack sealing process consists of:

- Application of an optimal adhesive layer. Due to the lack of lamination volume of the adhesive mass, a decrease in the strength of the seam itself is guaranteed. Excessive application of glue can lead to the opposite problems, possibly the formation of differences in the characteristic properties of the bumper material and the bonding joint itself. For example, a different stiffness can easily lead to a violation of the paintwork in the gluing zone, or the seam itself having received even slight deformations, such cases are quite possible even when the finished bumper is mounted in place;

- The adhesive composition must be applied in an even layer to all adjacent surfaces of the parts to be joined;

- In order to seal the seam, it is necessary to stick a synthetic or metal mesh impregnated with the same composition on the inside of the bumper;

- The glue hardening procedure can take from ten minutes to several hours. Nevertheless, it is necessary to ensure that the parts are stationary in order to ensure reliable sealing.

Is it possible to glue the bumper yourself

If the damage is serious, requiring qualified repair, up to replacing the bumper, then it is best to contact a car workshop. However, in case of minor breakdowns and cracks, you can glue the bumper yourself.

You need to choose the right glue, prepare the necessary equipment and clothing, get acquainted with the gluing technique, which allows you to carry out the restoration without removing the bumper.

Choosing the right adhesive

Before you repair the plastic bumper yourself, you need to start choosing an adhesive. It must have the same properties as the restored part of the car. The glue is usually chosen according to the following parameters:

- Heat resistance. Without high temperature resistance, when painting the part, the adhesion will liquefy during heating.

- Good grip. Adhesive substrates must have high adhesion to the plastic.

When choosing a thermoactive or thermoplastic composition, you need to take into account the upcoming painting of the part in advance. Of different kinds, car bumper adhesive

pick the one that best suits your situation. Check out the most popular adhesives in existence today:

- PowerPlast. The solution adheres perfectly to automotive and household plastic parts. It is used mainly when other methods do not bring the desired result. It is easy to operate, dries quickly, tightly connects the processed parts of the car bumper. They can not only repair plastic of various shapes, but also restore missing elements.

- Weicon Construction. Differs in elasticity and durability. It tolerates temperature drops, high humidity and other negative factors.

- AKFIX. It is characterized by high-strength bonding. The structure of the solution allows it to be applied vertically, without drips after use. Does not need additional primer when used. Often used for point connections. The solution contains cyanoacrylate which provides viscosity. It is possible to repair parts with a porous structure or roughness. To speed up the gluing of the bumper, it is desirable to use an activator aerosol.

- 3M. It is a two-component composition. You can fix the fiberglass bumper and other plastic car parts. It is well sanded and painted after application.

- Moment. It is a universal superglue of a domestic manufacturer, which is perfect for connecting damaged plastic car bumpers. Differs in thermal and moisture resistance, strong connecting qualities, low toxicity and relatively low cost. Serious preparation of the working area is required before use.

- TEROSON PU 9225 SF ME. Polyurethane adhesive, two-component. The composition allows you to seal the crack on the bumper without any problems. Interacts with various types of plastics. For strength, the surfaces to be glued are reinforced with fiberglass.

Instruments

Active plastic is used for the manufacture of this part of the car, and, as a rule, it sticks well. What do you need to repair a bumper? Before restoring a stubborn element of a car at home, you must carefully prepare the necessary tools and materials. Following the step-by-step instructions that will be given below, you will be able to carry out the restoration without any problems. You need to prepare:

- abrasive or grinding machine;

- foil;

- mesh (metal / synthetic).

- sharp knife;

- napkins;

- dye brushes.

You also need to stock up on epoxy glue to put on the mesh, which will serve as the basis for a better screed. Don't forget glasses and gloves.

Adhesive selection

Several types of glue are suitable for the restoration of silicone products. To select the desired composition, it is recommended that you familiarize yourself with the characteristics of the available options and focus on the appropriate one, taking into account the characteristics of the product. As a rule, silicone sealant or cyanoacrylate glue is used to connect the parts. Such solutions reliably eliminate defects and firmly dock surfaces.

A good adhesion result is ensured by an adhesive that meets the following requirements:

- elasticity and strength - the composition forms a seam that is not damaged by external influences and vibration load;

- optimal consistency - the density of the mixture to penetrate into hard-to-reach areas and fill small gaps;

- the ability to withstand high temperatures - just like the silicone itself, the glue must withstand heat without loss of properties;

- ease of use - convenience is affected by the packaging of the substance and the method of application;

- fast polymerization - a high-quality solution can harden in a couple of hours.

Silicone sealant adhesives

Elastic silicone sealant is made from silicon, which occurs in the form of quartz or sand. First, polymers are created from the material, which act as the base for the sealant. The starting material determines the key parameters of the sealant. The main characteristic is a high tensile capacity, which allows the use of a sealant for working with movable joints. The material compensates for deformation at the joints and does not collapse under external influences.

Special types of sealants with increased heat resistance are allowed to be heated up to 300 degrees. Also, the possibility of widespread use is associated with the resistance of the sealant to the negative effects of ultraviolet rays, cleaning agents and moisture.

Cyanoacrylate adhesives

Cyanoacrylate solutions are based on alpha-cyanoacrylic acid esters. As additional components, plasticizers are used to adjust the viscosity and stabilizers to improve adhesion. Depending on the brand of cyanoacrylate solution, modifying components may be present in it, which are responsible for the resistance of the formed seam to moisture and heat.

Cyanoacrylate formulations exhibit resistance to organic solvents and electrical insulating properties. To dissolve the applied glue after hardening, processing with specialized substances will be required.

Is it necessary: when is it advisable to repair a plastic bumper

One such case is an incorrectly painted product. The paintwork on the bumper must be plastic. Only in this case, the varnish and paint will not crack from an elementary bend or a small dent, easily straightened by heat. To find out if your part is well painted, inspect the crack for the following item: whether the layers are peeling from each other.

Clear separation of paint and primer indicates that unsuitable components have been used to paint the bumper. We talked about how to paint plastic at home in a series of summer articles.

We repeat that in this matter it is important to acquire a special primer and paint with plasticizers.

How to glue a damaged bumper

Naturally, the quality of fasteners directly depends on the composition of the selected brand of glue for work. To eliminate the breakage of plastic surfaces, the building materials market offers a sufficient selection of specialized glue for car repair, namely for the bumper. As an example:

- glue moment;

- AKFIX;

- Weicon;

- Power Plast.

Types of adhesives: "Moment" and "88" (click to enlarge)

Types of adhesives: "Moment" and "88" (click to enlarge)

They are versatile and suitable for gluing any kind of plastic, and after hardening, they are transformed into a full-fledged monolithic layer. After the preparation has been carried out, for hot drying the glued part, it is worth using special types of hot melt glue, so as not to provoke further deterioration of the seam condition, or its repeated breakdown. Also, thermoplastic adhesives are used on the condition that in the future the bumper is to be painted, therefore it is reasonable to carry out repairs and painting at the same time.

To check the adhesive ability of the mixture individually for a given item, you must first check it, carry out a test gluing.

Soldering large damage to the bumper

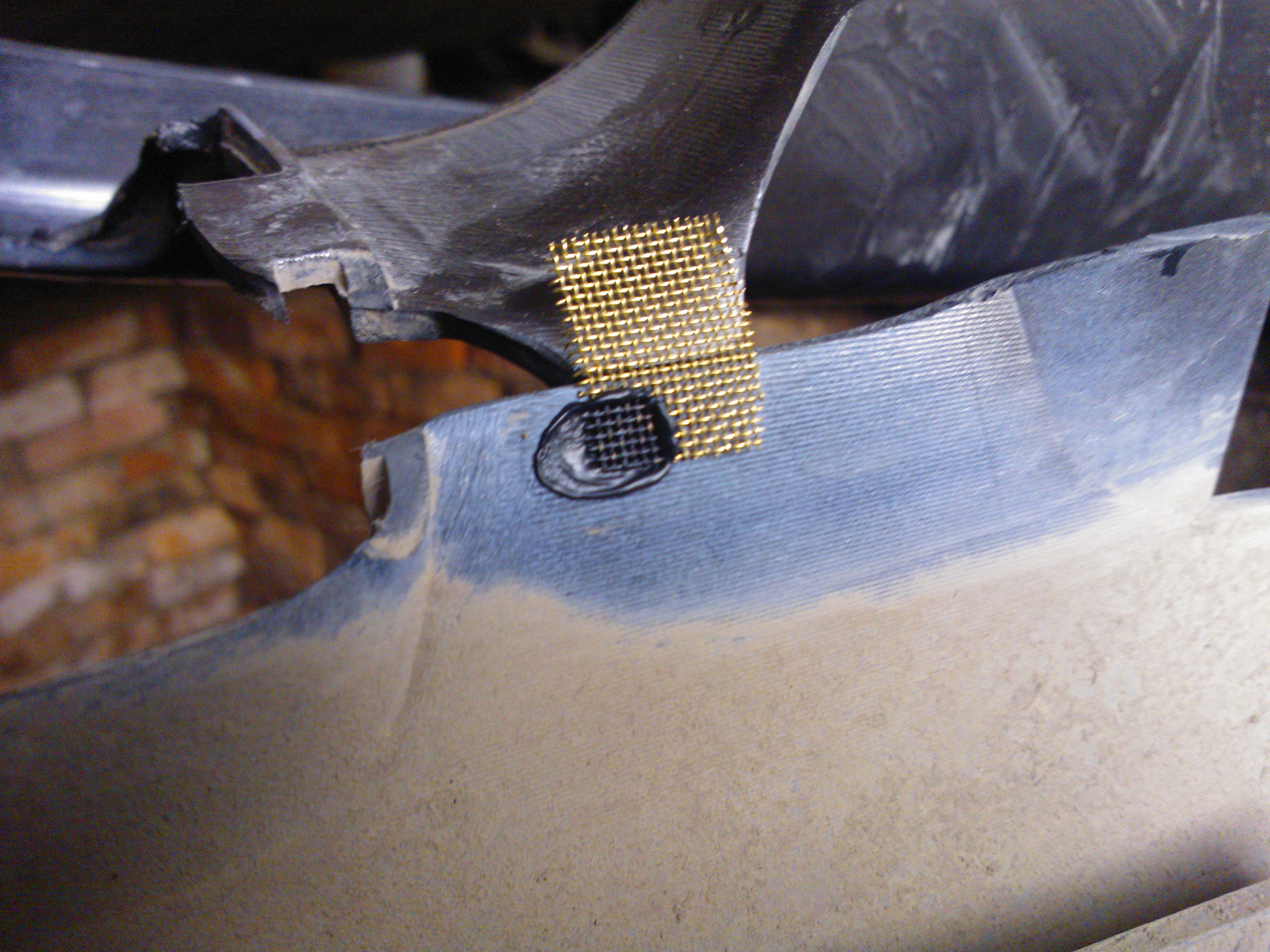

Numerous cracks, breaks and torn bumper elements are repaired using thermal methods, in particular, soldering. This painstaking work requires a small set of tools and materials:

- a soldering iron with a power of at least 100 W with a wide sting and a wooden handle;

- thin metal mesh specially designed for thermal bonding of plastic parts;

- knife, nippers for processing broken off segments;

- screw clamp;

- fine and coarse sandpaper for cleaning seams.

Powerful wide-tip soldering iron

Powerful wide-tip soldering iron

In the process of preparing for soldering, the paint must be removed to the base not only from cracks, but also from torn pieces of the bumper. Moreover, in this case, the body kit is not removed from the car until all the gaps are fastened and fixed by soldering, otherwise the element will lose its exact shape.

Soldering technology is implemented in the following sequence:

- After stripping, wipe the area with a degreaser and let it evaporate.

- Align the edges of the cracks and, if necessary, fix them in this position with clamps.

- Using a heated soldering iron, make tacks along the length of all cracks. For high-quality heating, the sting must be immersed in plastic to a depth equal to half the thickness of the material, and then level the surface of the molten plastic. The distance between the tacks is 1.5-2 cm.

- When the potholders are made on all the cracks, the broken piece must be replaced. Try it on to the hole and trim if necessary so that it fits into the hole flush with the surface.

- Solder the torn-off segment on the tacks, then repeat the operation from the inside. After that, the bumper can be carefully removed from the car and continue to work in more comfortable conditions, although this is not necessary, as it is convenient for anyone.

- Solder all joints on both sides of the body kit. So that the adjacent tacks do not diverge from heating, the seam must be soldered with gaps. That is, first the first section between the tacks is welded, then the third, fifth, seventh and so on. When finished, go back and solder any remaining sections.

- Cut the mesh into pieces 2-4 cm long. They need to be soldered across the seam in the most stressful places - along the edges of the cracks, in the middle, at the junction and near the stiffeners. The technology is simple: a steel mesh is placed on the seam and, heated by a soldering iron, is immersed in the polymer base of the bumper. Finally, smoothen the softened plastic over the mesh.

Bumper stripped and ready to paint

Bumper stripped and ready to paint

At the end of the soldering procedure, sand the surface of the element, then degrease and paint in the desired color. During further operation, be more careful, because from a strong impact, the bumper can fly to pieces, breaking in the same places. To hold it together more firmly, it is worth using another method - welding with donor plastic.

What affects the reliability of gluing

A number of conditions affect the reliability of the seam. All of them are important, and non-observance of any one can lead to the fact that the glued at home will fall off, despite the observance of all the others. So:

Compliance of product material and adhesive.

Correspondence of the type of adhesive to the amount of forces that the connection will experience

The direction of action of these efforts is no less important. So, compounds that give rigid seams are not suitable for repairs, for example, shoes - after all, the sole during operation will bend and twist, despite the fact that the tensile force will be small

At the same time, with this composition, you can successfully glue, say, a hook to the glass, and hang tens of kilograms on it.

Compliance with application technology. Everything is important here - and how many seconds or minutes the surfaces need to be squeezed, and how to degrease them, and how much to keep the parts pressed against each other.All this depends on the properties of a particular pair of "plastic-glue", is described in detail in the instructions and must be followed verbatim. A second deviation in the holding time or premature use of the product may result in secondary damage.

The mechanical part of the process. It is important to thoroughly remove dust from the surface and roughen it. In addition, the direction of pressing the parts against each other should be perpendicular to the surfaces to be glued. It is impossible to allow mutual displacement of parts after pressing - this will also lead to failure.

Gluing plastic tightly is not so easy. Careful adherence to simple rules by a home craftsman will allow you to get strong and durable connections. The main thing is not to forget about safety precautions: do not inhale the vapors of the adhesive and do not allow it to get into food, on the skin or mucous membranes. If accidentally swallowed, you should immediately consult a doctor, be sure to take a tube with you.

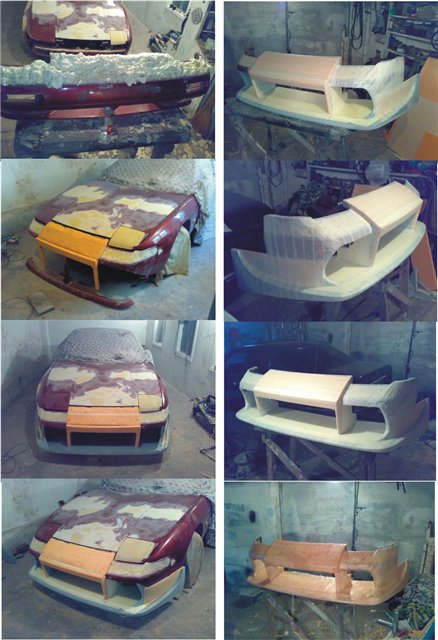

How to make a power bumper

power bumper "width =" 660 "height =" 440 "/>

power bumper "width =" 660 "height =" 440 "/>

The part is mainly installed on SUVs. Thanks to it, the vehicle, when driving off-road, will be able to overcome serious obstacles without compromising integrity. The passive safety of the driver and passengers will also significantly increase. The power bumper is made of iron. Home-made elements, in addition to safety, "give" the SUV an aggressive appearance. With a homemade power kit, you can ride. To obtain this permission, changes in the design of the vehicle must be registered with the traffic police.

Before starting work on creating a power element, you need to draw up a plan for how to make a bumper, and only after that, start working. To complete it, you will need the following tools and materials:

- Roulette, scotch tape, marker, scissors.

- Sheet metal (up to 3 mm thick) and cardboard.

- Grinder, cutting and grinding wheels, welding machine.

The process of work is slightly different, depending on which method will be used to create the bumper:

- Constructed from a single piece of metal.

- Multi-piece construction.

Despite the differences, the process has some similar operations:

- Creation of templates from cardboard.

- Cutting out the necessary elements from metal, or creating the desired shape from a single piece.

- Joining several parts into one piece using a welding machine, or forming a structure by bending sheet metal (practically impracticable at home, since powerful equipment is required).

- Priming and painting.

- Vehicle mounting.

How to achieve maximum effect when gluing plastic parts

For gluing plastic at home to give the maximum effect, you should:

- accurately determine the material and select the appropriate adhesive for it;

- carefully follow the requirements of the instructions for use;

- wait for the allotted time for the seam to gain strength and do not try to use the product ahead of time;

- for outdoor use or for items used in high humidity conditions, you need to choose a waterproof brand;

- despite the declared heat resistance of the adhesive, the parts themselves may not survive this temperature;

- if there is no marking on the product, then you can try to drop a drop of adhesive in an inconspicuous place and see if the material dissolves.

Epoxy resin

Epoxy adhesive provides one of the strongest bonds and is compatible with many types of plastics.

Additional tuning elements

Motorists, trying to give the vehicle a unique design, tune the bumper. Basically, these alterations relate to the installation of the following elements:

Motorists, trying to give the vehicle a unique design, tune the bumper. Basically, these alterations relate to the installation of the following elements:

- Lip. It is a kind of protrusion that is located at the bottom of the protective structure.It is made of fiberglass and polyurethane foam, as a result of which the lip is primed and painted in the color of the car.

- Diffuser. Decorative strip for the lower part of the rear bumper. Foamed PVC is used to create it. Marking is created on the material, after that, the sheet is heated with a construction hairdryer and the details are shaped. They are primed and painted, and then they are attached to the car with the help of a sealant.

- Fangs. A decorative element that can be installed on both metal and plastic bodywork. For mounting on "plastic", use fiberglass. To install the fangs on iron parts, metal and a welding machine are used.

Also, to give the car an individual look, stickers are placed on the bumpers, or parts are pasted over with carbon.

What damage to the bumper can be glued at home

Without the help of car service specialists, it is possible to eliminate different types of bumper defects. The easiest way to restore restoration is scratches, which can be almost imperceptible superficial or deep, reaching the inner layer of the part. Repair in the second situation will be more difficult, since deep scratches often turn into cracks. In case of through cracking of the bumper, it is not recommended to use the car until the problem is completely eliminated, since while the car is moving, a vibration load is applied to the front of the body, which can cause the crack to expand. This will affect the condition of the entire case and its performance.

In addition to scratches and cracks, dents, punctures and chips can form on parts. Dents appear as a result of strong external influences and must be corrected. Breakouts and chips are often caused by a collision with an oblique obstacle.