Types of glue for the installation of expanded polystyrene plates

Adhesives for the installation of insulation plates of this type are of two types: specialized and universal. The first type is intended for the installation of only a certain insulation. All-purpose adhesives are preferable because they not only qualitatively fix the insulation to the wall surface, but also create a reinforcing layer. Adhesives can be made on the basis of bitumen or cement-polymer substances.

Mastic-based solutions are capable of creating a waterproofing layer due to the high content of bitumen in their composition. However, the application of such an adhesive must be carried out continuously, without visible breaks. Among other things, such an adhesive does not require thermal action before installation, and the adhesive mass is always highly plastic.

Adhesives based on cement-polymer materials are used for all types of work. They perfectly cope with the installation of polystyrene foam on concrete, brick foam concrete surfaces, as well as on drywall. Before carrying out work, it is necessary to thoroughly prime the surface.

Tips and instructions for gluing Styrofoam

First of all, you need to remember a number of general rules for gluing foam, which must be taken into account, regardless of the selected adhesive composition:

- The adhesive must be applied in at least 5 places.

- The panels must not be manipulated until the glue is completely dry.

- In the case of external pasting, it is necessary to select a composition that would correspond to the temperature and weather conditions of the region of your residence.

Before gluing the sheets, you need to prepare the surface. First of all, it is cleaned of old paint, dirt, rust, etc., and then degreased.

Silicone, liquid nails and similar mixtures are applied pointwise or in stripes with a step of 5-7 cm.

It is this distance that makes it possible to ensure the most reliable adhesion of the foam to the metal surface. If dry mixes are used, then the sheet will need to be additionally pressed over the entire area with plywood.

For work, you will need the following materials:

- Degreasing agent. The metal surface can be treated with industrial alcohol, gasoline, white spirit, kerosene and specially designed compounds for this.

- Means for gluing sheets. Choose from: foam, silicone sealant, aerosol glue, PVA, liquid nails.

- Burlap if possible.

- If foam or aerosol adhesive is used, a special flushing solvent must be prepared.

During the work, you will need the following tools:

Tools required for gluing the foam: degreasing agent, sheet adhesive, knife for cutting foam plates, spatulas, gun, measuring tape.

- Wooden board or sheet plywood in case of using dry adhesive mixtures.

- Unnecessary clean rags.

- Protective gloves.

- Knife for cutting foam plates.

- Spatulas.

- Gun in case of using polyurethane spray adhesive.

- Yardstick.

Glueing is very simple, everything is done in the following sequence:

- The metal surface is cleaned and degreased.

- The selected adhesive is applied to the foam sheet.

- The sheet is leaning against the surface with slight pressure. When using a dry mix, it is additionally pressed with plywood or a wooden board until the glue dries.

Thus, working with foam is simple, easy and profitable. The set of tools and materials is minimal.Before buying the composition, be sure to make sure that it is suitable for use in your climatic zone, does not contain gasoline, acetone and other solvents. Happy work!

Adhesive for fixing polystyrene foam

Speaking about how to glue foam to wood, you should know that you can do this with the help of various ready-made adhesives.

Polyfoam is characterized by low adhesion to many materials: wood, concrete slabs, bricks. However, the foam can be easily adhered to these materials using any of the formulations: cement and dry adhesives, frost-resistant adhesives, sealants for external surfaces, etc. You will need to make a secure adhesive bond that will keep mold and mildew out. In addition, the connection should not impair the useful properties of wood and expanded polystyrene boards.

Cement based dry foam adhesive is a durable and cheap option.

One of the most durable and budget mixtures is dry foam adhesive, which is made on the basis of cement. It must be diluted with water before use. This mixture has high adhesion to almost any material. There is a fairly large assortment of polymer-cement-based mortars on sale, which are designed to glue polystyrene foam boards on all types of substrates. To fix the external thermal insulation, you can use an effective polymer-cement composition with mineral fillers. Some manufacturers' formulations can be used to protect the polystyrene foam on the front side. The only drawback of such mixtures is that they will harden in about 3 days.

You can also use special aerosol mixtures based on polyurethane. They can be suitable both for gluing insulation and for filling seams and voids between plates. Similar solutions based on polyurethane can be used to fix polystyrene foam on the inner and outer foundations of the walls, roofs, floor bases, and facade elements. The relatively high cost of such adhesive mixtures is offset by the ease of use and reduced setting time. You should be aware that foam boards can be fixed within 2 hours after applying the glue. Additionally, the slabs must be secured with front anchor bolts.

Polyurethane-based adhesives are fire resistant, maintain their performance over a wide temperature range and do not emit harmful vapors. All this has been achieved thanks to special techniques for the manufacture of compositions.

In some cases, it may be necessary to glue foam boards together. To do this, you can use any adhesive mixture, wet or dry, which does not contain solvents.

Each of the adhesive mixtures has its own advantages and disadvantages. You need to choose based on your needs.

Is it advisable to use foam?

With the help of foam, you can several times simplify and speed up the work with foam. It is great when you need to do everything quickly and efficiently. Differs in high technical characteristics and low consumption. It is sold in cylinders, which makes it easy to transport and use. Compared to simple dry mixes, it is more expensive, but it pays off. 1 cylinder is enough for an average of 20-25 square meters.

The main advantage over aerosol adhesives is that you do not need to use water, electricity or any special equipment to work with foam. In the process of warming, it is possible to save up to 50% of time compared to other popular formulations.

There is no need to make technical breaks, there is no need to install a reinforcement layer, plug in dowels, you can work even in cold weather.The foam has excellent adhesion to the foam. Resistant to fire and high humidity. Does not support combustion, does not emit substances harmful to human health.

What is most commonly used for bonding styrofoam?

When figuring out how to glue the foam to a metal surface, it is necessary to build on a number of key points, taking into account which it will be possible to choose the most suitable composition. First of all, it is necessary to take into account the type of surface to which the material will be glued.

Be sure to pay attention to the type of foam as such. For the rest, the choice of the composition with which it would be possible to glue the foam to the metal surface is reduced to determining the most economically advantageous option

Before choosing a suitable adhesive, you should take into account the type of foam, pay attention to the surface to which the material will be attached. Styrofoam can be glued to metal using various dry mixes, aerosol adhesives, silicone sealants, polyurethane foam and any other materials that would not react with the foam

It is important that the glue contains no gasoline, acetone and other solvents. They will simply "burn" the material

When choosing a composition, pay attention to its components and price.

Styrofoam can be glued to metal using various dry mixes, aerosol adhesives, silicone sealants, polyurethane foam and any other materials that would not react with the foam

It is important that the glue contains no gasoline, acetone and other solvents. They will simply "burn" the material

When choosing a composition, pay attention to its components and price.

Currently, one of the most widely used materials for bonding foam is polyurethane foam. It is able to adhere to any materials and has many positive properties, namely:

- You can work with her without even having such experience.

- Foam allows high-quality, easy and quick adhesion of polystyrene to any surface, including metal.

- The composition is quite cheap, sold in cylinders, which makes its use as convenient as possible. In addition, with the help of foam, you can not only glue the foam, but also seal the seams between the individual plates.

The only drawback of this material is that it dries up very quickly, as a result of which the tube can simply clog before the entire composition is used up. This problem is solved by flushing the tube with a special solvent. If you will be using foam, it is better to buy this solvent immediately.

The polyurethane foam will not only allow you to quickly and cheaply glue the foam to the metal surface, but also help to seal the seams between the plates.

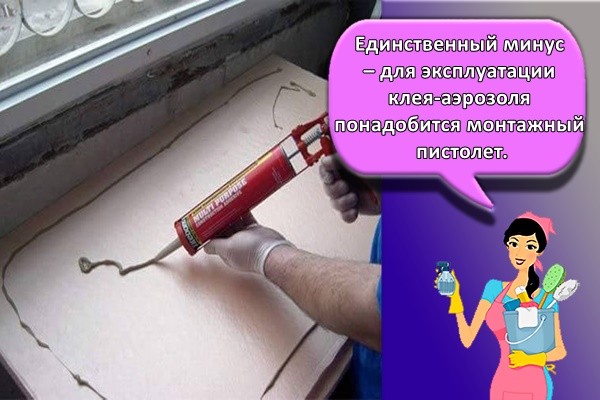

One-component polyurethane adhesive is also quite often used. It is also sold in cylinders, but requires additional costs for the purchase of a special pistol.

Some DIYers glue the styrofoam using a combination of glue and liquid nails. The latter set quite quickly, making the work much faster and more convenient than with simple glue. However, liquid nails are less reliable than glue, so it is not recommended to use them alone, especially if the foam is glued to an inclined metal surface or to the ceiling, for example, in a garage. In most cases, approximately 65-70% of the panel surface is treated with glue, and the rest with liquid nails. This allows you to work without the use of plywood supports, as required by working with glue alone.

If you need to paste over a small metal surface with foam, you can do with simple double-sided tape.However, in monetary terms, it is much more expensive than other adhesives, so it is advisable to use it only for very modest repairs.

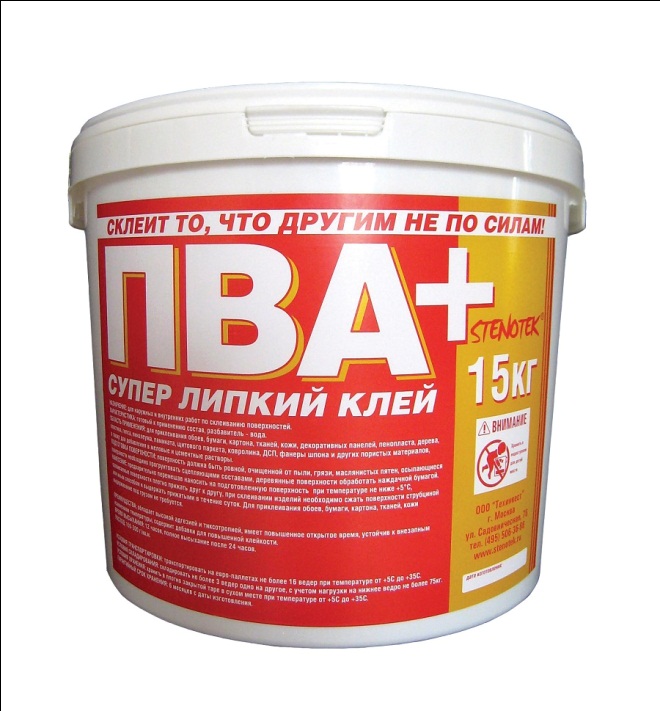

If you can attach the burlap to the metal surface before gluing the styrofoam, this will make the work even easier. It will be possible to use ordinary construction PVA. This formulation is relatively inexpensive and easy to use.

Feasibility of using foam

The use of foam as an adhesive makes handling foam quicker and easier. Its use is advisable if all actions need to be carried out efficiently and quickly. The tool is characterized by low consumption and excellent technical characteristics.

Benefits of using foam:

- ease of use;

- there is no need for technical breaks - the work time is halved;

- no need to hammer dowels, install a layer of reinforcement;

- installation work can be carried out even in the cold season;

- has increased resistance to fire.

Foam is more expensive than simple dry mixes, but justifies the cost. 1 cylinder is enough for 20-25 m2. Carrying out installation work on gluing foam to metal, subject to certain rules, is within the power of even a beginner. Performing the connection on their own, a novice wizard will be able to save financial resources, as well as be confident in the quality of the work performed.

The nuances of proper gluing and reinforcement of polystyrene

If you plan to glue products from extruded polystyrene foam and ordinary foam, the following technology nuances should be taken into account:

- polystyrene is processed using a needle roller for better adhesion;

- It is recommended to cover the foam with long-fiber paper.

If you have to solve the problem of how to increase the strength of a structure based on foamed polymers after gluing, you should use the following recommendations:

- in the case of interior decor or foam crafts, the solution is to create an external reinforcing frame made of paper;

- if it is necessary to reinforce structural elements, it is advisable to use fiberglass.

Also, expanded polystyrene can be "armored" with gypsum or acrylic plaster.

Installation technology

Before starting work, you need to check the availability of all the necessary tools that may be needed throughout the entire process of installing the foam.

Below is a minimal list of things that can come in handy when working:

- Gloves and rags; it is better to have rubber or cloth gloves, the use of cellophane gloves is unacceptable.

- An industrial knife that will be used to cut the foam sheets.

- Tape measure for precise area measurement.

- Several spatulas.

- A piece of wood or plywood to support the foam boards.

- A sander that will thoroughly clean the metal.

- Degreasing agent surfaces: white spirit, gasoline or any other detergent.

- A solution of glue that has been selected according to the operating conditions.

- The right amount of foam sheets.

First, you need to especially thoroughly clean the metal surface from any dirt, rust or paint residues on it, and then completely degrease the entire area of the metal surface with any available means. The modern construction industry offers a huge number of adhesives, the use of which mainly depends on the personal desire of the installer. They all have both positive and negative sides.

Use of polyurethane foam

Polyurethane foam is quite convenient and easy to use and does not require any special skills to use it. Its gluing occurs with absolutely any surface, however, it dries quickly enough, so delay is unacceptable when working with it.

Foam is produced in small cylinders that have a convenient outlet tube. This helps to apply it quickly and ensures a high quality installation. Polyurethane foam is the simplest material to work with foam and metal.

Application of polyurethane glue

This type of glue has become the second most popular for home use in small quantities. The form of release of polyurethane glue is identical to the form of release of polyurethane foam - small cylinders with a guiding outlet tube, however, to work with polyurethane glue, you need a special gun that squeezes the mixture onto the desired surface.

The polyurethane adhesive is usually applied in dots or in stripes over the entire surface of the foam sheet.

Liquid nails for gluing foam to metal

Liquid nails have a lower surface bond strength than the previous version, but after the first contact between the surfaces, it is not necessary to support the foam sheet.

Using PVA glue

If you want to use PVA glue for installation, then this method will provide a fairly good degree of foam adhesion, but you will need to create an additional layer between the surfaces with burlap. To facilitate the work, you can first stick the burlap on the foam, wait until it dries, and then continue working.

For finishing small areas with foam, it is possible to use double-sided construction tape. This type of connection is of a very high quality as well as a high price. If you are not afraid of excessive financial costs, then this method is for you.

So, as you can see, there are no particular difficulties when installing various types of insulation. Of course, if you are doing this for the first time, then you will need some time to develop the necessary skills, but, as practice shows, almost everyone is able to do this work on their own. In this case, you will not only be sure of the high quality of installation, but you will also be able to save a fairly large amount of financial resources that can be spent on more important things in your home.

How to glue styrofoam to other materials?

Some types of glue designed to hold insulation sheets together are not suitable for other materials. Therefore, when choosing a composition, it is necessary to take into account the features of the surfaces to which the insulation sheets will be attached.

- Concrete. When insulating the walls of the house under siding, the foam is attached directly to the concrete. The most versatile glue for such insulation is polyurethane foam or PVA.

- Metal. Liquid nails, polyurethane glue, PVA are suitable for attaching polystyrene foam to metal. Also, a good result will be when using double-sided tape, if the area to be pasted is small.

PVA glue

PVA glue

- Textile. For pasting fabric surfaces, aerosol or all-purpose glue and liquid nails are usually used.

- Glass. The best option for bonding polystyrene foam to glass is epoxy, all-purpose, or spray adhesive.

Adhesive spray

Adhesive spray

Paper. To increase the thermal insulation of the room, the walls of the house are often insulated from the inside, after which cosmetic repairs are carried out

It is important to remember that you cannot glue the wallpaper over the foam. It is necessary to close the insulation with plasterboard

Ordinary wallpaper glue is suitable for wallpaper.

Wood. Instant or polyurethane glue and liquid nails are used to glue the insulation to wooden surfaces or plywood.

Features of working with dry mixes

The scheme for applying glue to polystyrene.

The most budgetary option is gluing with a dry mixture, which is diluted with a certain amount of water immediately before use. Such mixtures are made on a cement basis. Before gluing the foam with such a mixture, be sure to study the information on its packaging. It should be stated that it is designed specifically for handling foam.Such mixtures are reliable and durable. Before gluing foam with their help, it is necessary to thoroughly clean the surface of various dirt, remove, if any, remnants of old plaster and any kind of delamination. Manufacturers of such mixtures recommend priming the work surface before gluing the foam.

The mixture can be applied to individual areas or in a continuous layer

It is important that there are at least 5 glue points on each foam sheet.

Required tools

The set of tools and auxiliaries required for bonding the foam depends on the fixing agent used. In any case, you should prepare:

- foam of the selected thickness, its amount should be equal to the area that must be pasted over plus 10% for waste;

- a small spatula and rags to remove excess glue mass, if they are not removed, hard lumps will form;

- a primer for treating the main surface to which the foam will be attached;

- wide brush for priming;

- a knife for cutting styrofoam.

If additional fixing of the plates with dowels is planned, then you need:

- hammer drill with a 10 mm drill;

- hammer;

- special dowels, shaped like umbrellas (fungi).

Installation of foam on the balcony

When using a dry mix, the following are additionally required:

- tap water;

- plastic mixing container;

- construction mixer (drill attachment);

- comb-spatula for applying the composition to the foam.

If aerosol glue is used, then a special assembly gun is required, into which the can is inserted.

Expanded polystyrene - what's what and why?

The correct technical name for the well-known polystyrene is expanded polystyrene. Looking closely at this material from a short distance, you will find that it consists of many small balls that hold each other - these are polystyrene granules that have been foamed under high pressure and temperature and compressed in a press.

Due to this technology, in the structure of the foam there are many microcells invisible to the eye, in which there is air. Thanks to this, the material acquires an airy lightness and the properties of a very good insulation. Consumers loved it for its extremely low cost - in fact, it is the cheapest heat insulator, and builders appreciated its technical characteristics. We will dwell on this in more detail, because along with the popularity of the material, like mushrooms after rain, numerous myths about its shortcomings also grew.

Polyfoam is very durable - polystyrene retains its shape for at least 25 years when used outside and at least half a century when used inside. You will probably be surprised, because many people talk about its fragility. Indeed, ultraviolet light and constant exposure to moisture can shorten the service life. Here are just the same factors that can shorten the life of almost any building material, including all kinds of heaters.

Expanded polystyrene is not afraid of mold and mildew - thanks to this, it can also be used in a humid environment, for example, in a basement. Polystyrene granules practically do not absorb moisture. However, they say that all kinds of rodents easily make holes in the foam. Again, this is only partially true - if rodents have something to eat, they will make holes even in concrete. Deprive them of food or exterminate them with poison, and you do not have to think about their relationship with Styrofoam.

Polyfoam does not support combustion - whatever they say, but this material is many times safer than the same wood. It takes twice as much temperature to ignite as in the case of wood, and when it burns, it emits much less heat. The material is safe for human health and the environment - among the widespread myths, there is also a myth about the alleged harm of the material to human health. But dozens of studies have disproved this myth long ago.Look around, there is a huge amount of much more harmful materials around you.

Of the disadvantages of foam, it should be called a small strength - it breaks easily, and even a small blow can leave a dent on its surface. For this reason, it must be protected from mechanical damage - traditionally, plaster mixtures are used for this. They also protect the material from the effects of ultraviolet radiation.

Review of popular brands

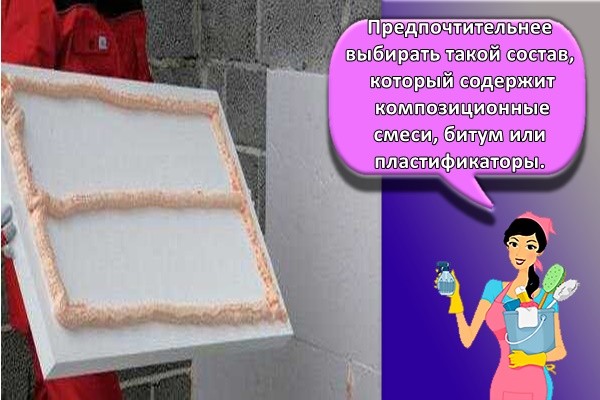

The adhesive composition used for gluing expanded polystyrene sheets with metal must be characterized by:

- endurance to lower temperatures;

- the ability to use for outdoor work;

- the absence of any solvents in the product;

- guaranteed high degree of adhesion of the glued surfaces;

- ease of use.

It is preferable to choose a composition that contains composite mixtures, bitumen or plasticizers.

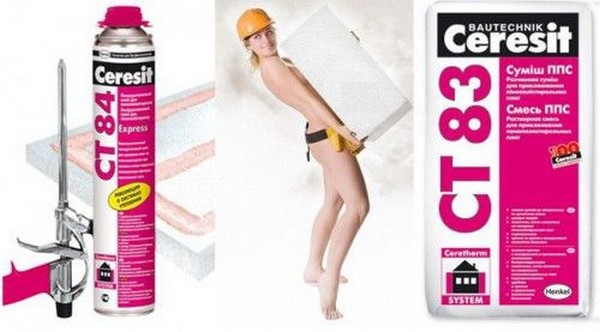

"Ceresit"

Due to the high quality, the brand's products are respected by professional builders. Advantages of the Ceresit adhesive:

- ideally applied to foam blocks;

- good plasticity;

- can be used for indoor and outdoor work, resistant to temperature extremes and various atmospheric phenomena;

- shock-resistant, vapor-permeable composition;

- environmentally friendly;

- long correction period (20-25 min.).

Disadvantage: working solution should be used within 2 hours.

"Moment"

The line of Moment glue is annually expanding. Positive properties of the composition:

- even with prolonged use, the glue seam does not crack;

- has excellent technical characteristics;

- does not shrink during drying, does not deform;

- frost resistance, water resistance, heat resistance;

- the adhesive is available in containers of different sizes;

- short curing period.

The disadvantages include an unpleasant smell of glue (disappears only after complete drying), more often than others it is faked (as a result of which the presence of toxic, harmful components is observed in the composition).

"Master Termol"

The Master Termol combined foam adhesive has the following properties:

- long term for plate adjustment (up to 50 minutes);

- high adhesion and plasticity;

- the composition is environmentally friendly;

- the lowest temperature for using the mixture is -5 ˚С, which allows you to start installation work earlier and finish later;

- the time of technological movement is 12 hours, after which it is possible to dowel the foam.

The use time of the finished composition is 30 minutes, the material consumption per 1 m2 is 6 kg.

"Profline 3K-45"

Adhesive mixture for the installation of foam and mineral wool, which is suitable for interior and exterior decoration. Positive properties of the composition:

- ease of use;

- moisture resistance, elasticity, frost resistance;

- frugality;

- high adhesion;

- shelf life of the finished mixture 2 hours;

- environmentally friendly product.

During the preparation of the composition, preventive safety measures should be observed. The dry mixture is characterized by increased dust formation, therefore, it is necessary to protect the eyes and respiratory tract from it.

"Penoplex Fastfix"

Highly effective compound for the installation of thermal insulation. Advantages of the glue:

- universal - it glues foam plastic equally well to various surfaces, including metal;

- ease of use - the time for preparing the adhesive is reduced;

- heat resistance - not afraid of temperature differences from -50 to +90 ˚С;

- after the glue hardens, thermal conductivity is not disturbed;

- no shrinkage.

Those who used Penoplex Fastfix glue consider the disadvantages of the fact that the amount of work performed on the surface coating does not correspond to the one mentioned on the package, it is much less.

What varieties are suitable

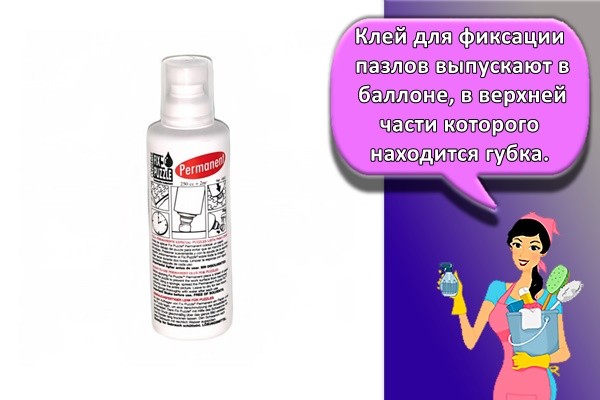

In order to reliably connect the puzzles into a single picture, various gluing means are used. Both special glue and intended for other household purposes are used.

Specialized

Together with a set of puzzles, special glue is often put in the box. It has a liquid consistency, is able to penetrate between elements, firmly connect them. Odorless and colorless glue, it can form a glossy layer on the front side, after which the picture does not need to be varnished.

PVA

The properties of special glue and PVA do not differ much. To reliably connect the assembled puzzles, PVA is applied on the front side with a brush, filling all joints and gaps. After drying, white stains will become transparent and form a matte film on the surface of the glued picture.

Wallpaper for vinyl flooring

The elastic adhesion of the elements can be obtained after applying the vinyl wallpaper adhesive. The advantage of the composition is the ability to prepare glue of different thicknesses.

Rating and review of the best brands

There are several brands of puzzle glue available from specialized stores. They differ in the quality of the coupling and the appearance of the glued elements.

Step puzzle

Step puzzle glue is odorless, dries after 2 hours, 80 ml is enough to glue 1000 puzzle pieces together. It is poured onto the front surface of the painting in two layers with a break of 1.5 hours. A thin transparent film is formed. If the details were slightly torn, thanks to Step puzzle they are neatly connected and become even. It is necessary to strengthen the picture from the back side by applying another layer of glue to it.

Ravensburger Puzzle Conserve

The glue is convenient to use because it comes in a can of 4000 elements. The liquid comes from it through the foam nozzle, which does not dry out and remains in working order for a long time. Ravensburger dries in an hour, forming a shiny film on the surface of the puzzles. After applying to the front side, the painting does not need to be turned over, since the final quality of the joint is high.

KSK-M

Using a bottle of KSK-M synthetic glue, you can assemble a mosaic with an area of at least 0.4 square meters. After application to the front surface in several layers, the drying time is about 2 hours. Until this happens, it can be washed off with soapy water.

Educa

The glue for fixing the puzzles is released in a balloon, in the upper part of which there is a sponge, the composition is squeezed onto it and applied to the outer surface of the picture. The glue dries up in an hour, does not leave marks and streaks. One can is enough to fix 5000 elements.

"Red Cat"

A bottle of Ginger Cat glue has a dispenser through which the composition is squeezed onto a finished picture or onto a small piece of sponge. With light movements, it is distributed over the surface of the assembled puzzles. Two hours after drying, the painting is placed on the base and in the frame.

Fix Puzzle Conserver Permanent

Using this brand of glue, you do not need a brush, since the bottle is equipped with a sponge spout. A picture made of puzzles is wiped and the composition is applied to the front part so that it hits all the gaps and crevices. Shake the bottle first.

Glue cost

The cost of adhesive mixtures is different, the price depends on the properties of the mixtures - on the curing time, on the level of bonding, on the method of application.

Average cost of some mixtures:

Ceresit polyurethane foam - the cost of 750 ml is 650 rubles.

Tytan polyurethane glue - the average price of 750 ml is 400 rubles.

Facade glue T-AVANTGARDE-K - this glue is sold in packages of 25 kg, the cost of the package is 280 rubles.

Dry mix Ceresit - the cost of a 25 kg package is from 400 to 600 rubles.

Liquid nails - the price of 300 ml is about 200 rubles.

Dry glue moment - the cost of a 25 kg bag is 300 rubles.

Aerosol glue - the average price of 500 ml is 900-1200 rubles.