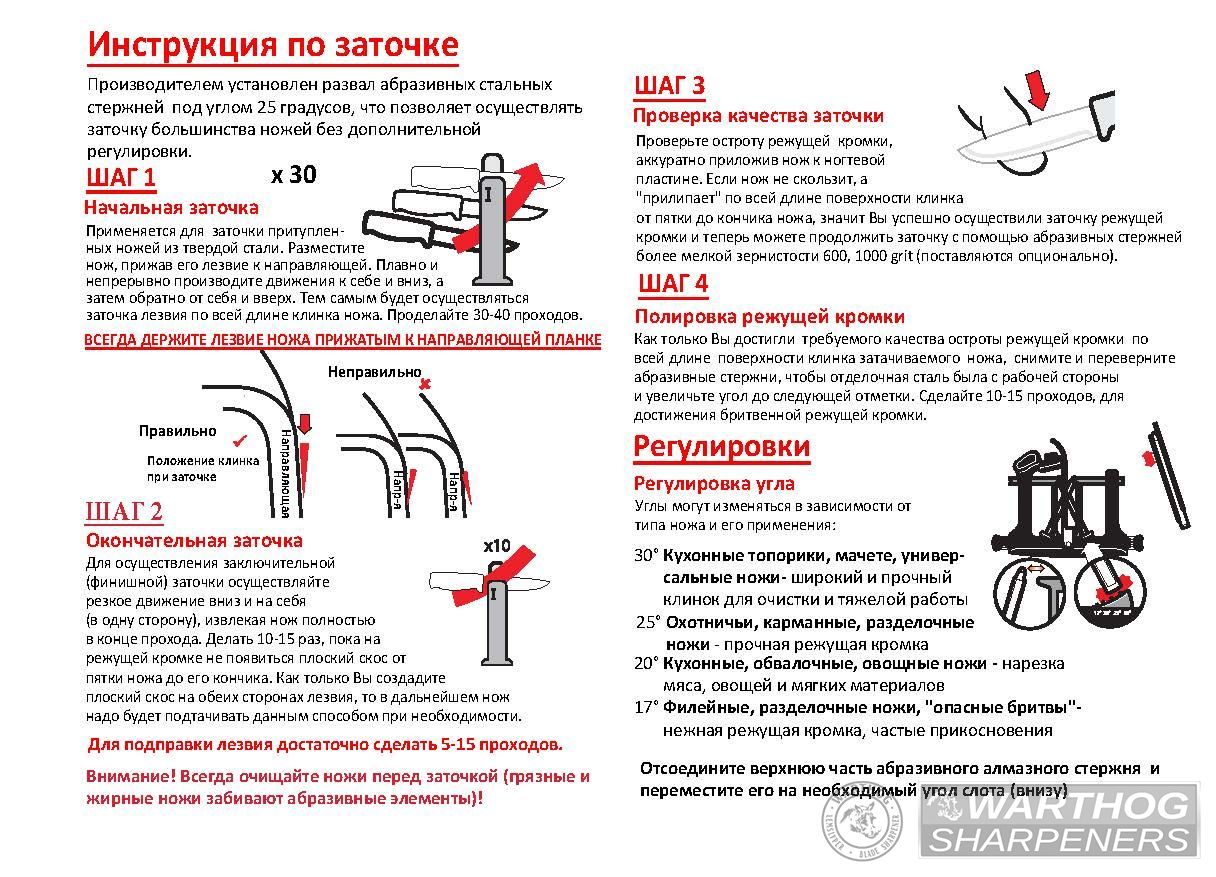

Sharpening knives on the machine

Things to Consider When Sharpening Knives

The guidelines below will help you find the right helper for sharpening your kitchen cutting tools. Knowing what to look for, you half-solve the question: how to sharpen the knife correctly?

When purchasing a bar, you must make sure that it is free of chips and flat.

At first, it is worth buying a medium-hard stone for sharpening, a universal type. However, if you wish, pick up a block with 2 uneven-grain sides or two stones with a small and a large grain at once.

Work rules

- first, use a coarse-grained abrasive, the end of the work should be the use of a fine-grained one;

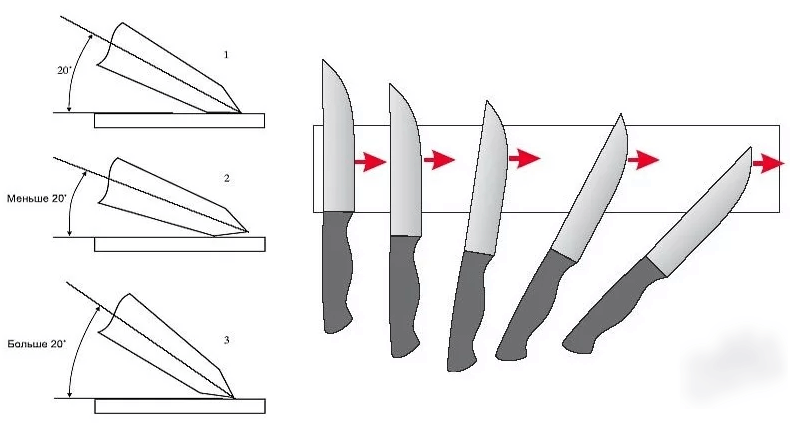

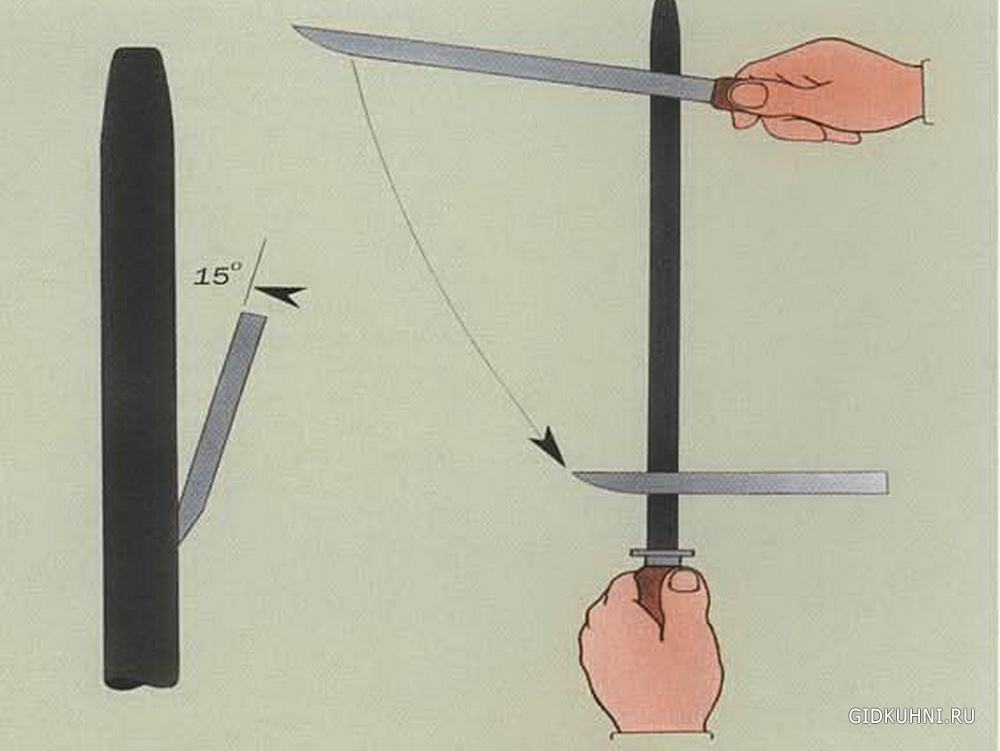

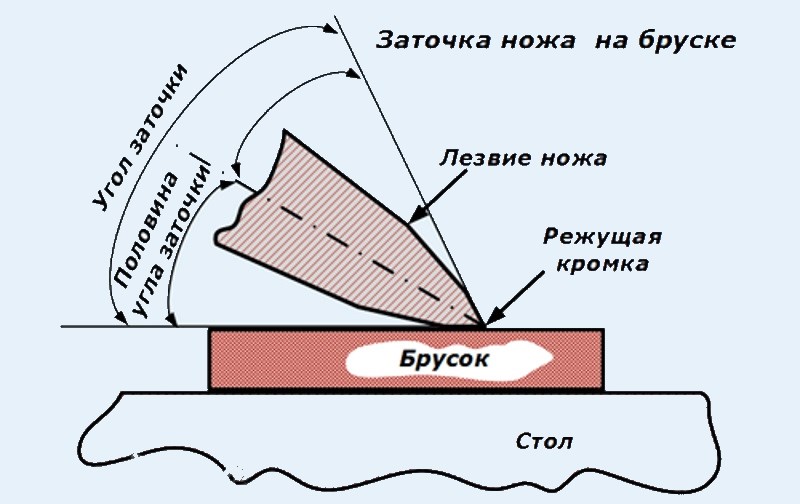

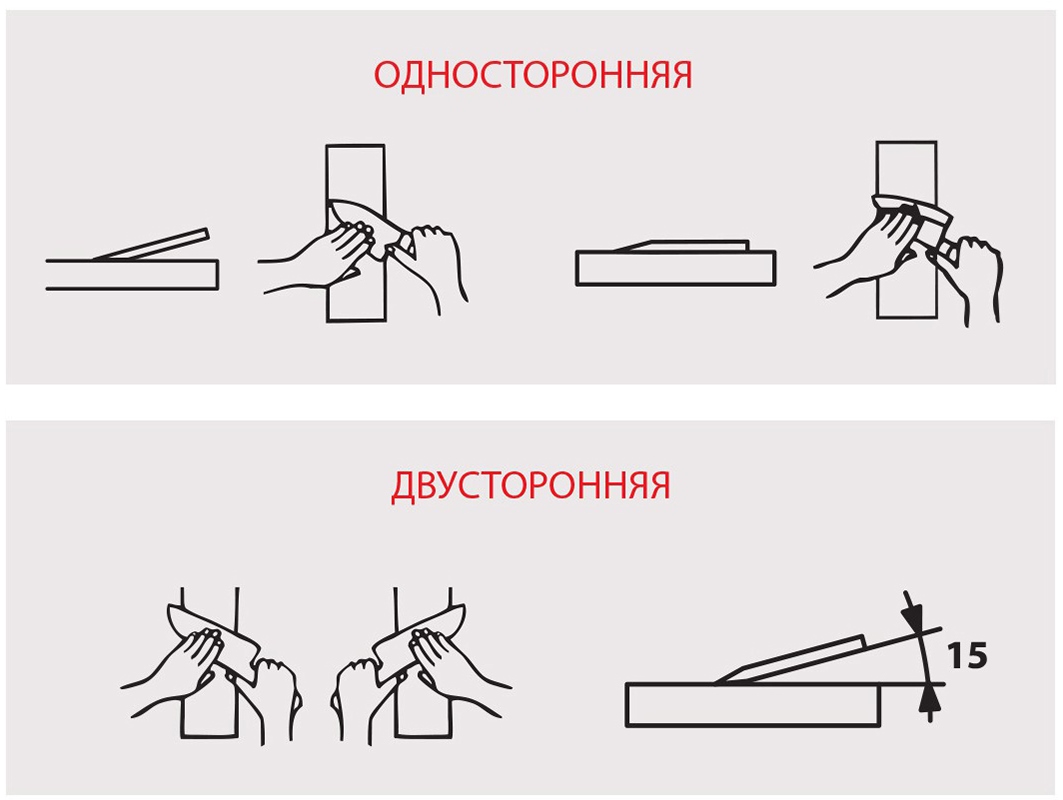

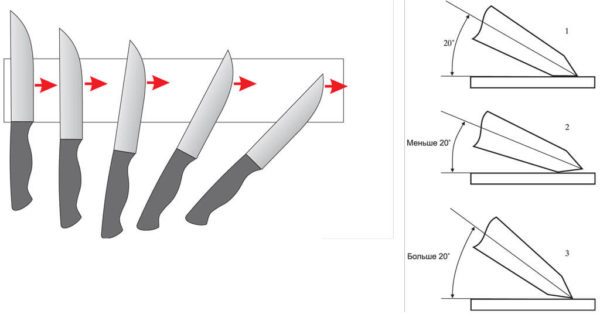

- remember that the most important thing is the correct selection of the sharpening angle: it must be optimal and held along the entire cutting edge while sliding on the sharpening stone;

- when sharpening knives, avoid sudden movements, they should be smooth. Pressure is excluded;

- the blade is carried out alternately or with an identical number of passes on each side;

- Be sure to wet the bars with water (ideally, do it with soapy water): before sharpening (this way the blade will slide better, and the dust from the metal will not clog the pores), directly during work (this way the suspension is removed) and in the end - to clean the bar.

Sharpening knives

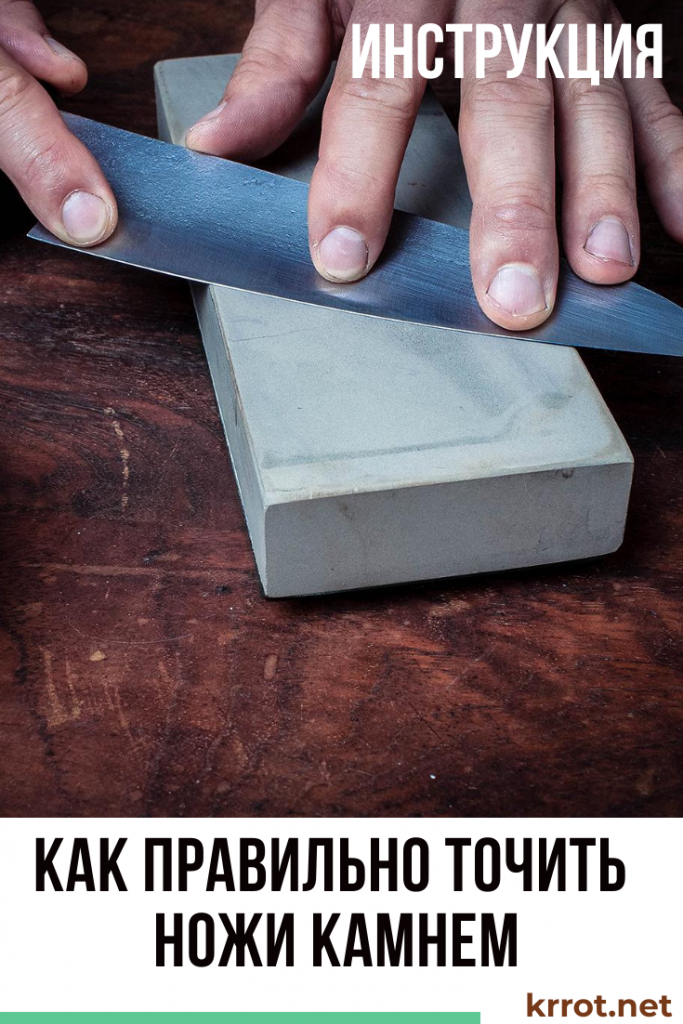

To know how to sharpen knives with a bar, the instruction will help:

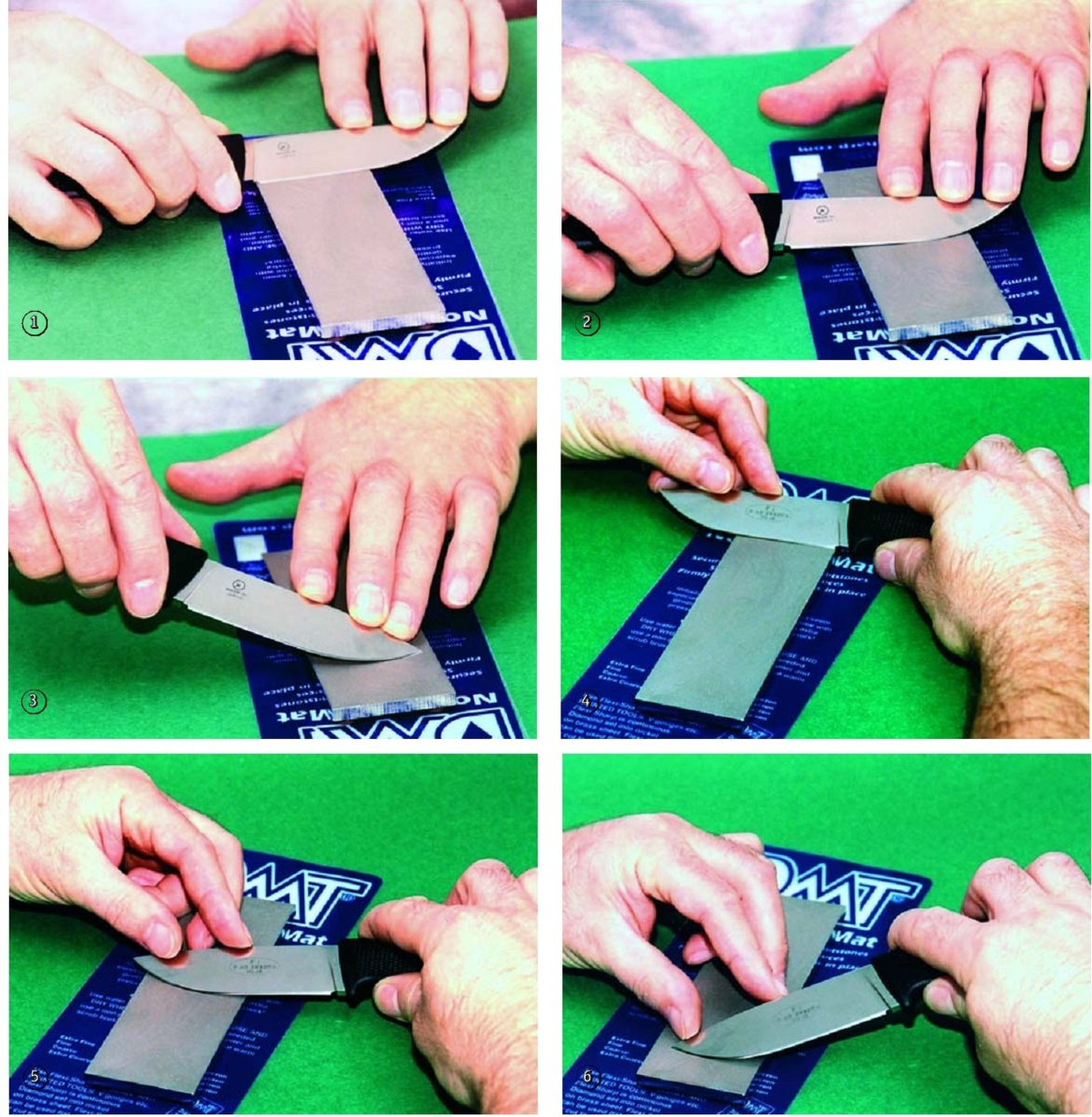

- a stone moistened with water is installed on a flat surface;

- the cutting tool is applied at the required angle to the surface of the bar;

- use a folded sheet of paper to set this angle; attach the paper with the obtained angle to the stone, as well as the knife itself and remember what the slope is;

- set the knife at the beginning and across the sharpening stone, and slide without pressure along the bar with the blade, do it in an arc in the direction of cutting. To fix the sharpening angle more stable, you can support the blade with your other hand. After about 50 movements, change side and direction;

- if an edge with burrs appears along the length of the blade, sharpening on the coarse-grained side of the stone is stopped and switched to fine-grained. The operation is repeated, at the end of the work, reduce the pressure on the blade;

- after finishing sharpening, be sure to rinse the bars with water.

In conclusion of our material on how to sharpen knives, for clarity of the described process, we suggest watching a training video where you can find out:

- how to sharpen knives correctly

- how to sharpen knives with a bar by hand

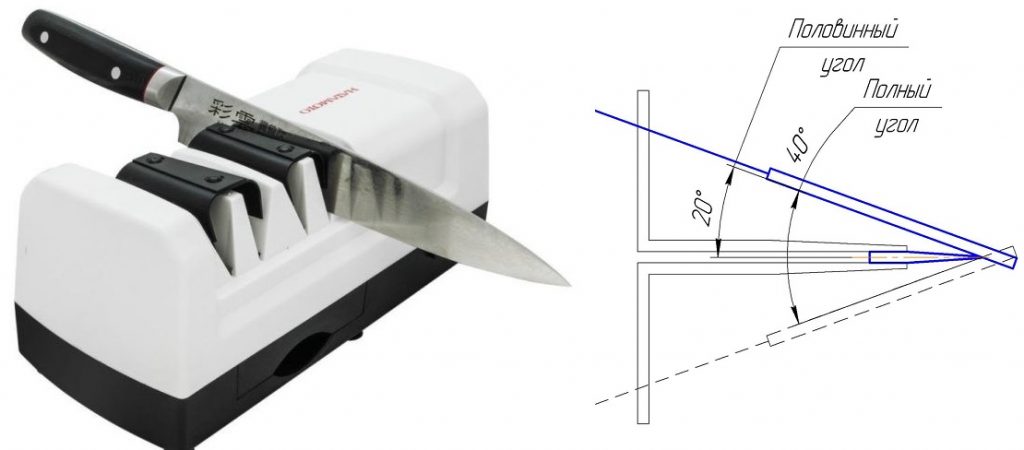

- how to sharpen knives correctly on a mechanical sharpener

- how to sharpen knives on a grinder and so on.

Did this article help you?

Poll Options are limited because JavaScript is disabled in your browser.

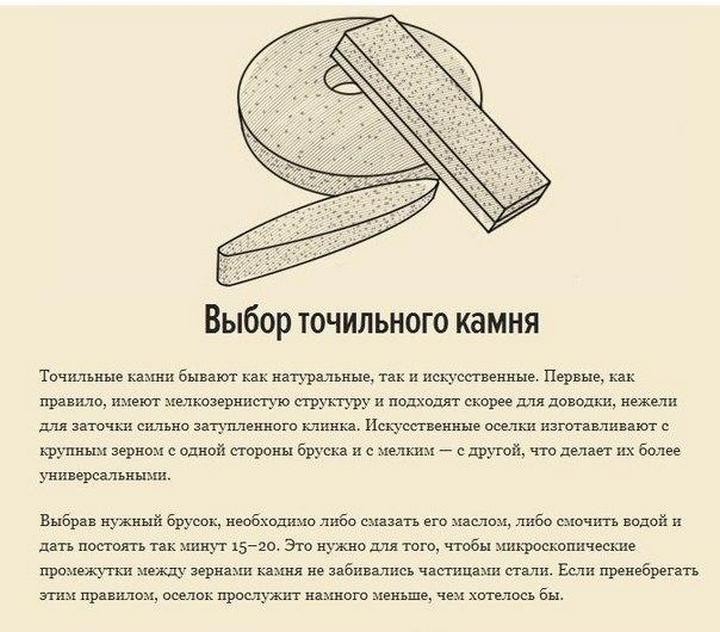

Choosing a sharpening tool

To bring the blade to the required sharpness, you need to choose the right materials and tools for sharpening it. Among them are:

- whetstones;

- musats;

- electric sharpening machines;

- abrasive machines;

- grinding machines;

- mechanical sharpeners;

- electric sharpeners.

To understand the features of each of them, you should consider them in turn. Sharpening stones are the oldest tools that can really make a knife as sharp as a razor. Experienced craftsmen are aware of the existence of various types of grindstone, which have different grain sizes (the smallest abrasive particles that make up such bars), different hardness and density.

If you need to sharpen the knife as efficiently as possible and grind the blade, then you will need to use at least two sharpening stones.The first one should have large grains, the second - small ones. You can find out according to their labeling or less accurately determine the difference by eye.

Musats, like mechanical sharpeners, belong to the kitchen. By means of them, not so much sharpening of knives is carried out, as their amendment, to remove micro-chips and give a minimum razor sharpness for a short period of time. It is enough to work with the device a couple of times and the blade will start to become dull again, since the sharpeners and sharpeners do not have the desired effect on the steel surface of the product.

Electric sharpeners save a person from the use of significant physical effort when sharpening blades, but they also do not provide full sharpness to them. Special sharpening and grinding machines will help in the shortest possible time to give the knives their cutting property, but the disadvantage of such equipment is the overhead and unsafe storage and use of them at home. Such machines catch up dust, are quite noisy and energy-consuming. But thanks to them, any knife can be provided with the necessary sharpness quickly enough, efficiently and with minimal effort.

Experts are advised not to engage in such work on their own on machine sharpening equipment if there is no proper experience in the field of sharpening tools. There is a possibility not only of the final deterioration of the blade on the knife due to overheating or non-observance of the correct sharpening angles, but also the risk of dangerous injury due to inept handling of the equipment.

Sharpening tips with improvised tools

In the absence of special equipment, you can use available tools for sharpening. These methods are suitable for use in atypical conditions.

Stone

On a picnic or on a hike, sharpen the blade with a possibly hard stone. Enough about 10 times to hold the blade along the plane of the cobblestone.

Glass objects

The blades can be sharpened against the edge of the glass product. In particular, an old glass jar with a not too smooth surface will do.

A leather belt is more suitable for finishing sanding. It is necessary to tighten the belt and move the blade over it.

About the angle of the concrete step

Concrete treads are suitable for coarse sharpening. It is enough to hold the knife along the edge of the ledge, applying force. It will take about 10 minutes of processing to restore the sharpness of the instrument.

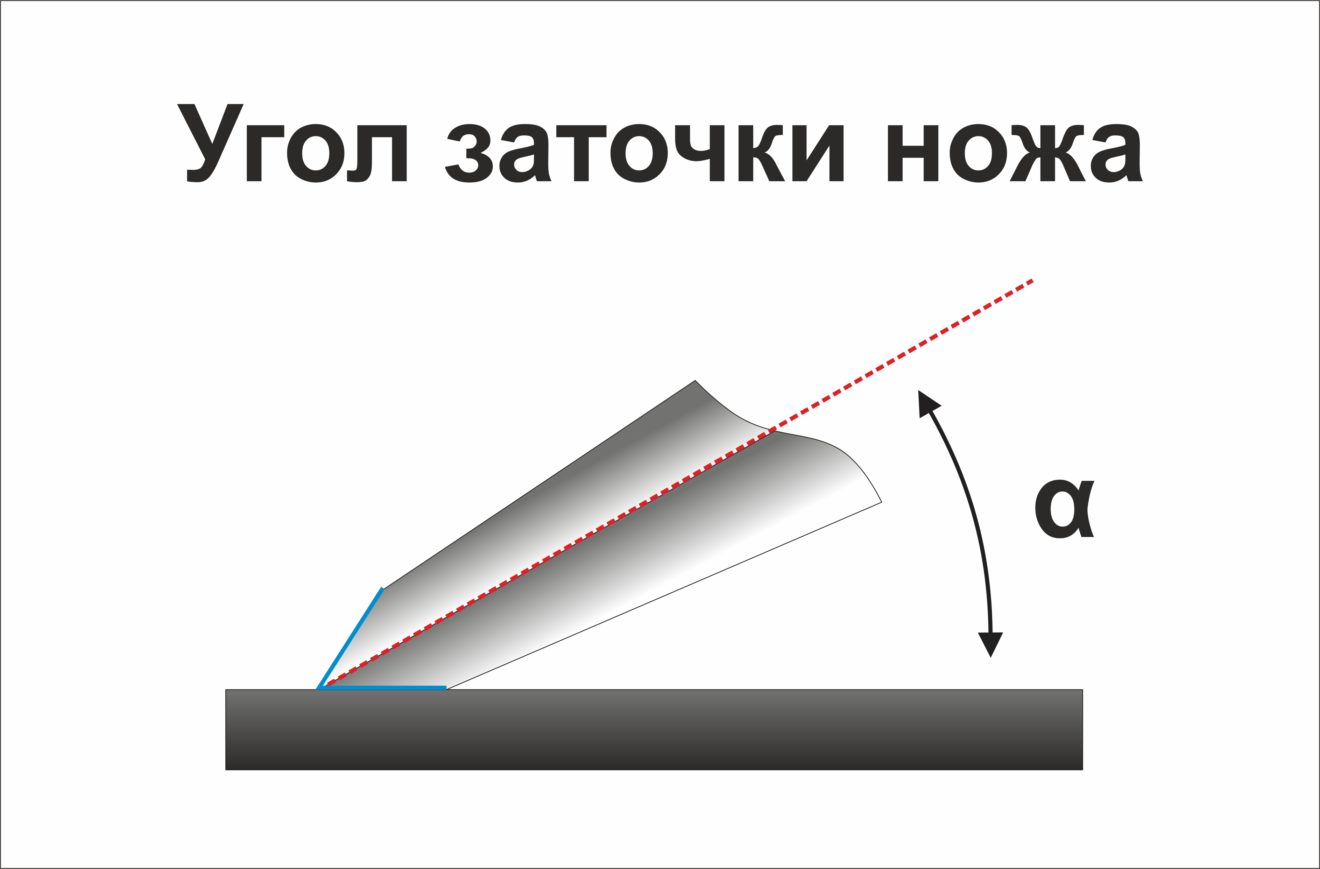

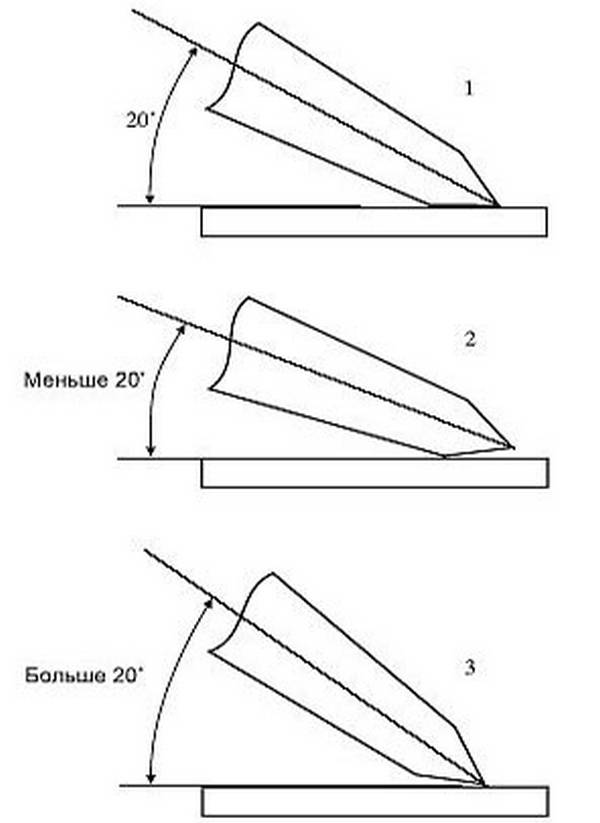

How to determine the angle of sharpening of a knife

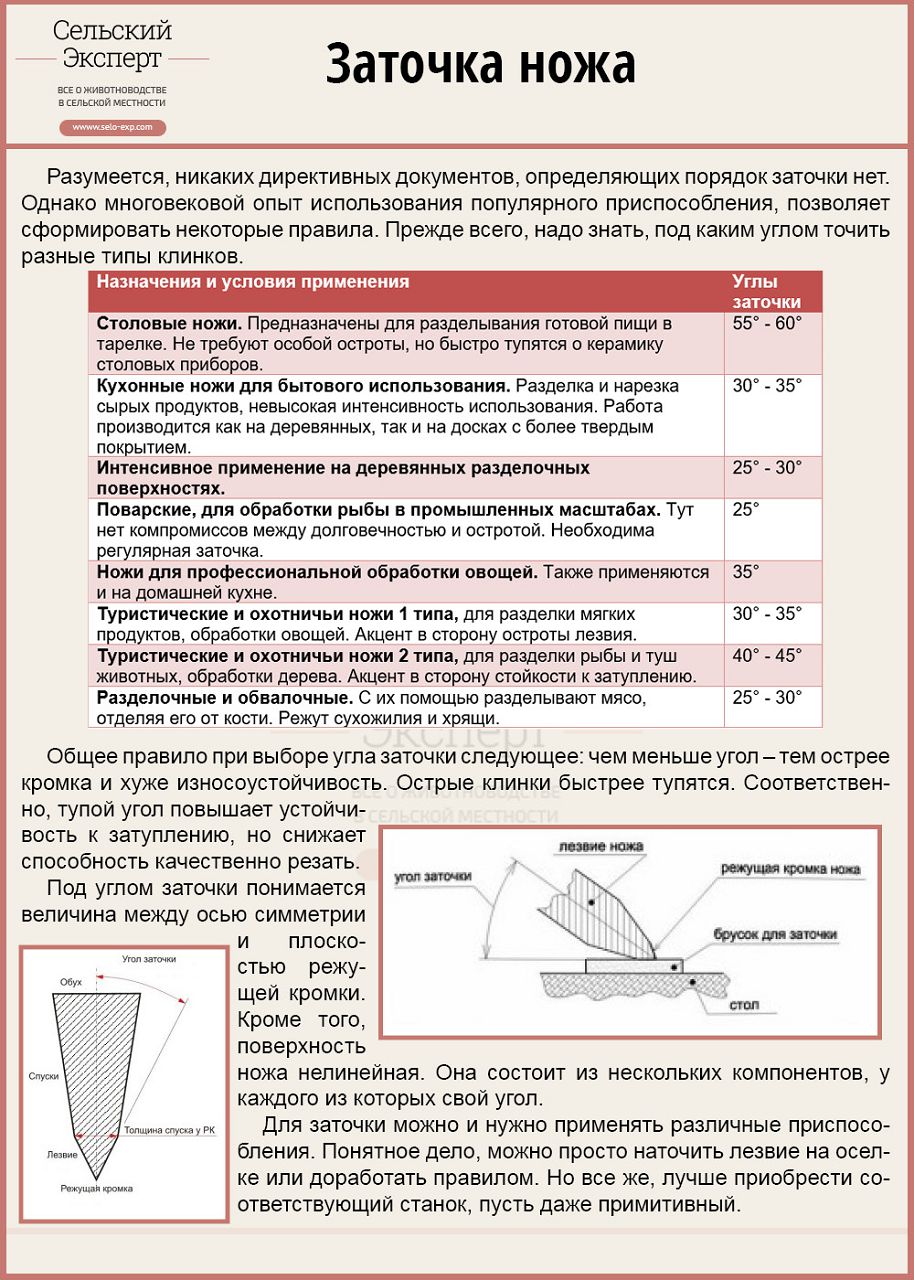

The size of the sharpening angle depends on the purpose of the blade. There is a table by which it can be determined. It was developed by the world company CATRA, which controls quality and advises on sharpening all types of knives.

On it, depending on the purpose of the blade, the following sharpening angles are recommended:

- Thinning and sirloin - 5-10 degrees

- Fruit - 10-15 degrees

- Chopping - 15-20 degrees

- Boning for meat and large fish - 20-25 degrees

- Cleavers, hatchets and vegetable knives - 30-35 degrees

- Chopping axes - 40-45 degrees

- Table knives - 55-60 degrees

- Hairdressing scissors - 45-55 degrees

- Household scissors - 50-60 degrees

- Metal scissors - 75-85 degrees

- Straight razor - 10-15 degrees

In the table you can find the angles and the proportion of more rare tools that can be used at home.

Also, do not wash knives, razors, scissors and other metal blades with hot water, put in dishwashers to avoid dulling too quickly.

It should be borne in mind that stones and sharpening stones are also designed for different types of blades - these properties are indicated on them, and the stone must be chosen so that it fits the available sharpening blades. Often, the stone comes with a set of knives and must be suitable for a specific set or blades with a similar characteristic.

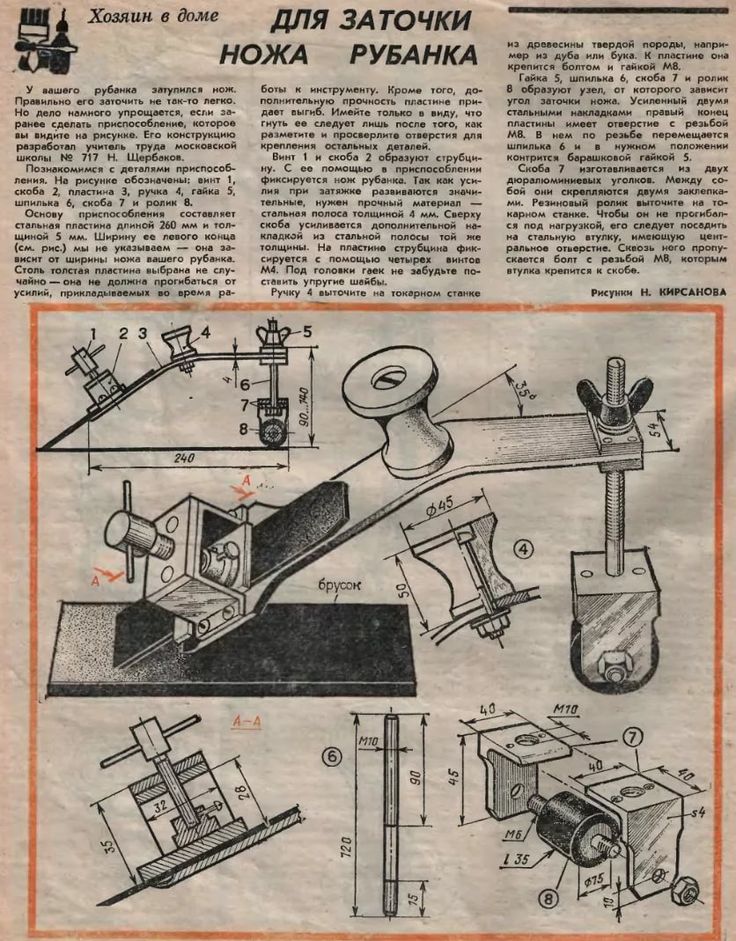

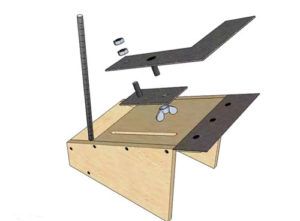

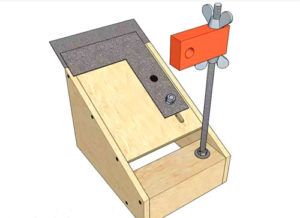

Making a machine for sharpening knives with your own hands

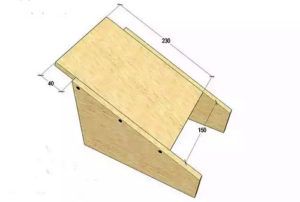

Although it is now possible to easily buy the necessary tools and equipment for sharpening knives and other cutting tools, nevertheless, handicraft citizens continue to make knife-cutters with their own hands in their free time. When making a knife sharpener with your own hands, you need to decide on its type (manual or electric) and the type of abrasive materials used (bar, circle, sanding belt), as well as the materials available that will go to make the body of the assembled device, its frame. Consider the option of a manual sharpener using an abrasive bar and plywood as the frame of the structure. The appearance of the assembled device is shown in the following figure.

Manual sharpening machine made from scrap materials

For the manufacture of such a machine, you will need the following materials and tools:

- sheet plywood with a thickness of 10-12 mm or chipboard, it is possible from old cabinet furniture;

- metal hairpin with a diameter of 10–12 mm;

- sheet steel 1 mm thick;

- fastening screws or nuts with washers, corresponding to the diameter of the stud used;

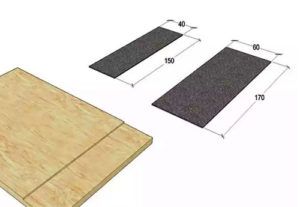

- bar 25–30 mm thick - for the manufacture of abrasive bar stops;

- profile metal pipe with a section corresponding to the dimensions of the bar;

- abrasive bar;

- hacksaw for metal and wood or their electrical counterparts (jigsaw, grinder);

- electric drill or screwdriver.

Manufacturing work is carried out as follows.

| Illustration | Description of action |

|---|---|

| Making the base of the machine and handcuffs | |

|

The base of the machine is made of plywood or chipboard. |

|

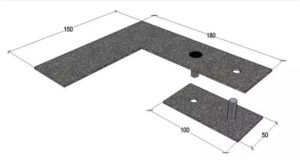

Holes are drilled in the base for attaching the adjusting pin. |

|

Handcuffs are made of sheet steel. |

|

The adjustment pin and handcuffs are installed on the base of the machine. |

| Manufacturing of fixing and tilt angle control devices. | |

|

A fixing device is being manufactured. |

|

The fixing device is installed on the prepared base. |

|

A device that regulates the angle of inclination is manufactured and installed. |

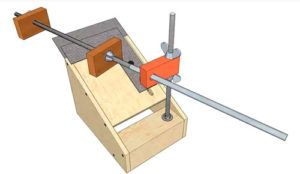

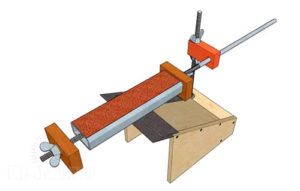

| Manufacturing of carriages and bases for removable bars. | |

|

A carriage for abrasive bars is made from another metal rod and wooden blocks. |

|

A base is cut out of a profile metal pipe for placing the bars, and the final assembly of the machine is performed. |

On the market of goods intended for sharpening knives and other cutting tools, there is a wide selection of models that differ in design and purpose, type of use and equipment, which allows you to choose a device in accordance with the selection criteria and financial capabilities of the user. When choosing a specific device or model of grinding equipment, sales consultants in trade organizations will provide assistance, and how to use it correctly can be found on the Internet.

You can learn how to sharpen knives with a bar correctly by watching the video below.

How to sharpen knives on a grinder

The use of a machine is considered an effective way of sharpening, however, the mechanism is cumbersome, and for this reason it is not available in every home. But if you have the opportunity to use it to sharpen dull kitchen appliances, you should know some of the intricacies of this work:

sharpening on the machine is carried out at high temperatures, therefore, it is necessary to set the minimum number of revolutions so as not to damage the blade;

the blade must be firmly pressed against the sharpening surface, and the movements during sharpening must be smooth;

when achieving a sharp cutting surface, it is important to keep the sharpened part at an angle of 25-30 degrees in relation to the grinding wheel.

Please note that you will need a lot of time to work. In addition, those who do not have sufficient experience in this matter should not take on sharpening on the machine.

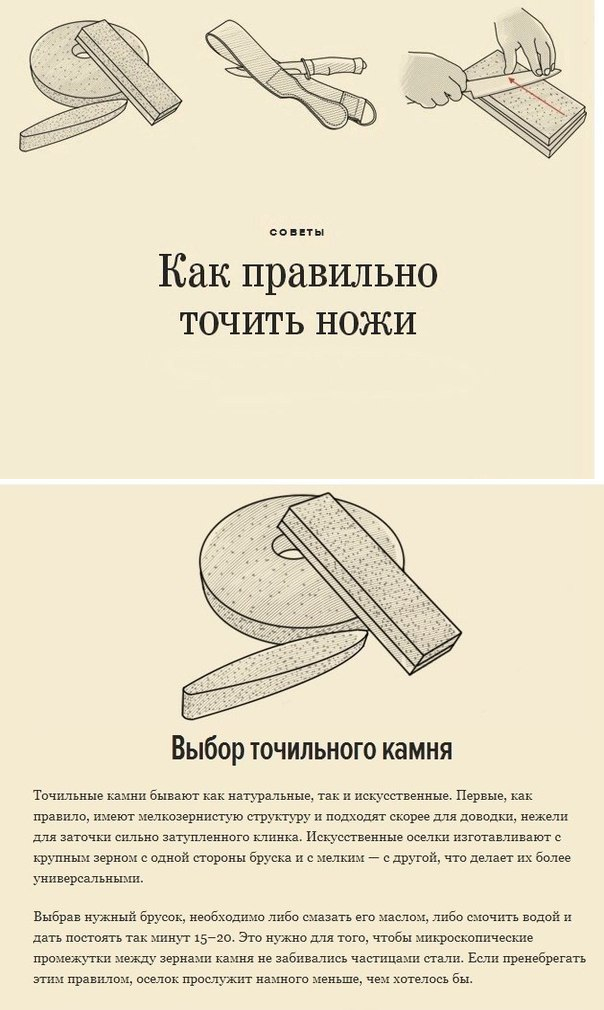

Sharpening stones

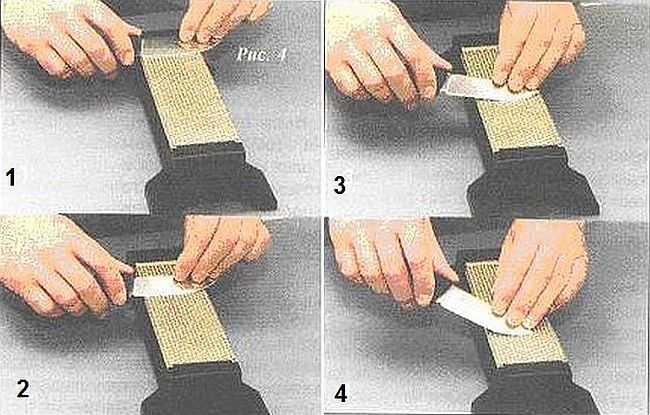

Sharpening knives with a bar is within the power of each of you. This is a well-known method for complete sharpening.

Sharpening stones are made from artificial and natural materials. The surface of each of them has a different grain size. Coarse sharpeners are suitable for grinding large pieces of metal, while fine-grained sharpening stones are more useful for grinding and sharpening.

The bars are also divided according to the method of processing - water or oil. Depending on it, the surface of the sharpening stones should be soaked in water or smeared with a special oil (machine oil or vegetable oil are prohibited!). This will prevent metal filings from clogging the abrasive surface and reduce the quality of the sharpener.

For high-quality sharpening in the house, you should have several types of bars. Now let's move on to the process:

- Place a coarse block on the table. During operation, it should not move.

- Place the blade on the stone near the handle, choosing the desired angle.

- Make a smooth motion with the knife blade over the stone, moving the point to the side.

- At the bend of the blade, slightly raise the knife handle so that the edge of the blade is sharpened evenly.

- Repeat several times, swiping the knife in the same direction.

- Now turn the knife over and sharpen it from the back.

- Install another stone - medium grit. It will remove the "burrs" on the metal and make the blade sharp.

- Grind a kitchen knife on a fine-grained stone.

- At the end of the process, rinse the stone with water to rinse out the remains of chips that are clogged in the pores.

The sharpening stone can be replaced with sandpaper with varying grain sizes. It is firmly fixed and the same manipulations are carried out as when working with a bar.

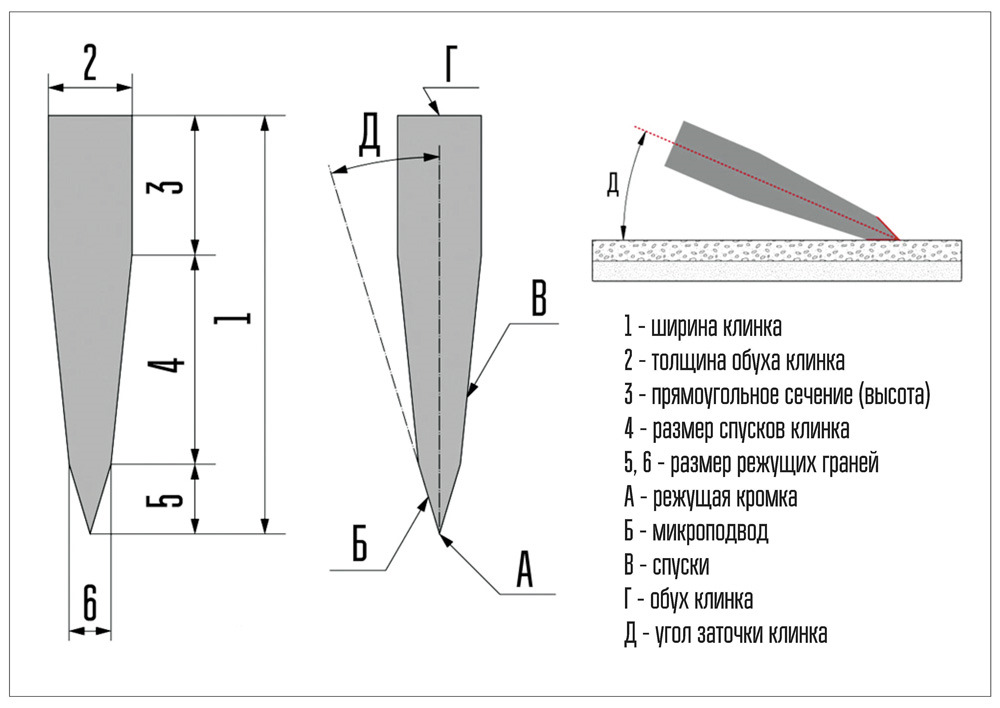

Correct knife sharpening angle

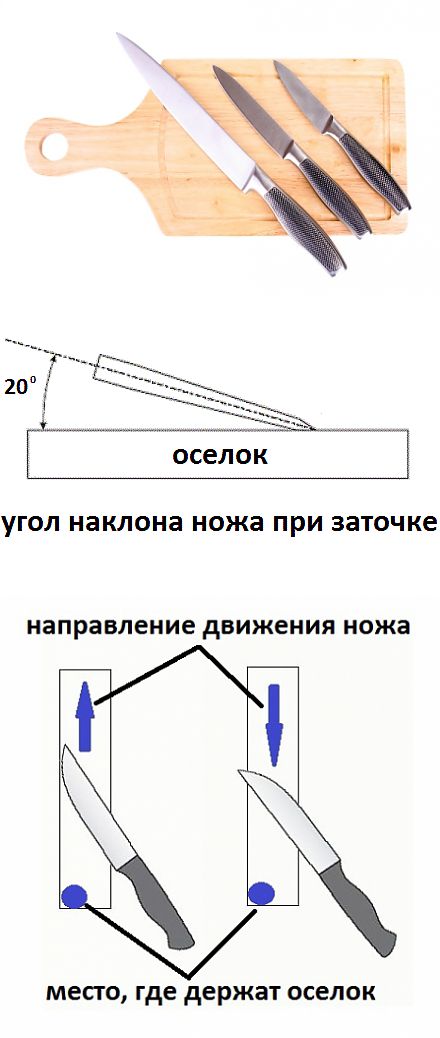

When sharpening kitchen knives, it is important that the objects are in a certain position in relation to the work surface. To do this, you need to choose the correct sharpening angle.

This parameter depends on many factors, for example, the type and level of strength of the metal from which the blade is made, as well as the purpose for which this tool is used. So, the degree of sharpening for different types of knives:

- scalpel and razor blade - from 10 to 15 degrees;

- vegetable, meat and fish knives - from 15 to 20 degrees;

- other cooking utensils - from 20 to 25 degrees;

- hunting blades - 25-30 degrees.

It is important to choose the correct sharpening angle, this is necessary to achieve the desired sharpness of the kitchen appliance

Types of knives and their purpose

The modern classification divides knives into the following categories:

- Combat. They are melee weapons, are in service in the army, as an addition to firearms. They are not intended for free sale and use.

- Tourist. Available commercially, not prohibited from wearing, the handle and scabbard are usually made of synthetic materials.

- Hunting. They have a varied form and direction of use: work on butchering the caught game, skinning, arrangement of a hunting area. Certain species require a purchase and wearing permit.

- Foldable or foldable. A very common species, loved by all age groups of people. From the name it is clear that the blade is folded and the cutting edge is placed in the handle. Some types are supplied with clips for fixing on a belt or pocket.

- Multitool. Folding multifunctional knife with a set of tools - indispensable for travel and repair. The standard sample includes: small and large blade, pliers, screwdrivers, wrenches, ruler, hook, scissors.

- Special purpose. A tool used in certain areas of human activity: medicine (scalpel), diving, Emergencies Ministry, gardening.

- Campers or campers. They are quite large in size and weight.Designed for setting up a tourist camp, cleaning the territory of the resting place from bushes and small trees. An example is a machete or kukri. In practice, they can easily replace an ax, but at the same time, they remain knives.

- Tag or sports throwing knife. It is all-metal, without a cutting edge, designed to hit a target with a hand throw.

- Kitchen. Used for cooking, produced in various shapes, sizes, thicknesses and blade configurations.

- Canteens. They have a specific shape with a rounded blade tip, the main purpose is to facilitate food intake.

- For survival. Positioned as assistants in extreme conditions. They have a number of features: the presence of a compass, a hollow handle containing a survival kit (a lighter, fishing line with a sinker and a hook, a thread with a needle, antiseptic, antibiotic).

How to sharpen a ceramic knife

The right choice for sharpening a ceramic knife is an electric sharpener. The material used for the manufacture of blades for such knives has high hardness, resistance to oxidation, abrasion, and therefore keeps the factory sharpening for a very long time. During operation, careful handling and storage is the key to the sharpness of the cutting edge of the ceramic blade. It is not recommended to use bars, sharpening machines, pastes, sandpaper for sharpening, as there is a chance of harming more than fixing it. Therefore, in the absence of the opportunity to use your own electric sharpener, it is better to contact a specialized workshop that provides such a service (always with a guarantee).

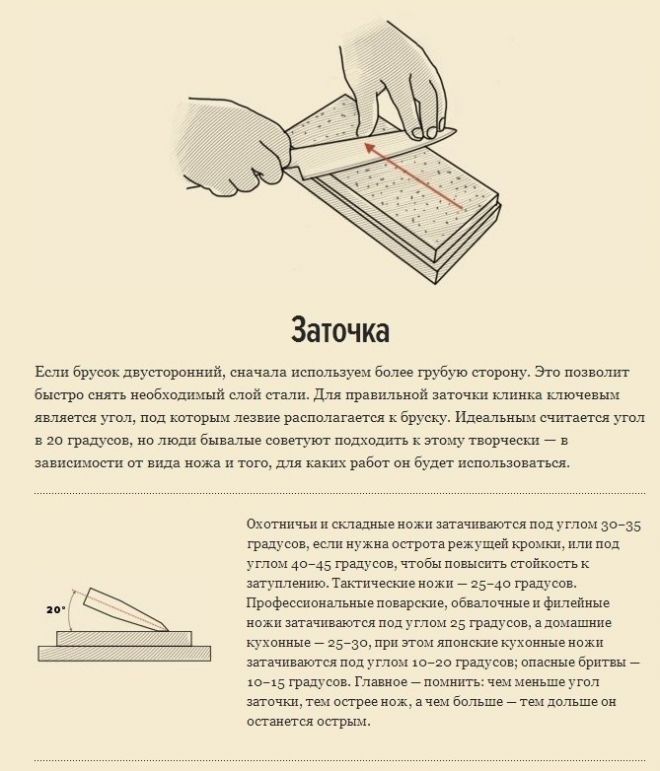

How to sharpen a knife at home. Instructions

So, what needs to be done in order for the knife blade to become sharp. If we talk about the mechanics of the action itself, then we can describe the sharpening process as follows: the sharpness of a knife blade is achieved by removing a certain amount of metal from the edge. This can be done by rubbing a metal blade against the surface of a whetstone. It is recommended to start sharpening with a coarse grit and then use a fine grit.

Important principles for sharpening knives:

- The most important thing to know in order to sharpen a knife blade correctly is choosing a suitable sharpening angle to hold it throughout the entire time the blade slides over the sharpening stone;

- Do not press too hard on the knife blade, the movements should be smooth;

- It is recommended not to forget about wetting the sharpener with water or soapy water. This should be done in three cases: before sharpening, so that the blade glides better over the bar; in the process of sharpening to remove the suspension accumulated on the surface of the stone; after sharpening to clean the bar.

By the way, it is recommended that you first take the knife that you will not mind ruining if something happens. Better to practice with a knife of little value. Especially if the main knife is expensive and you really don't want to ruin it.

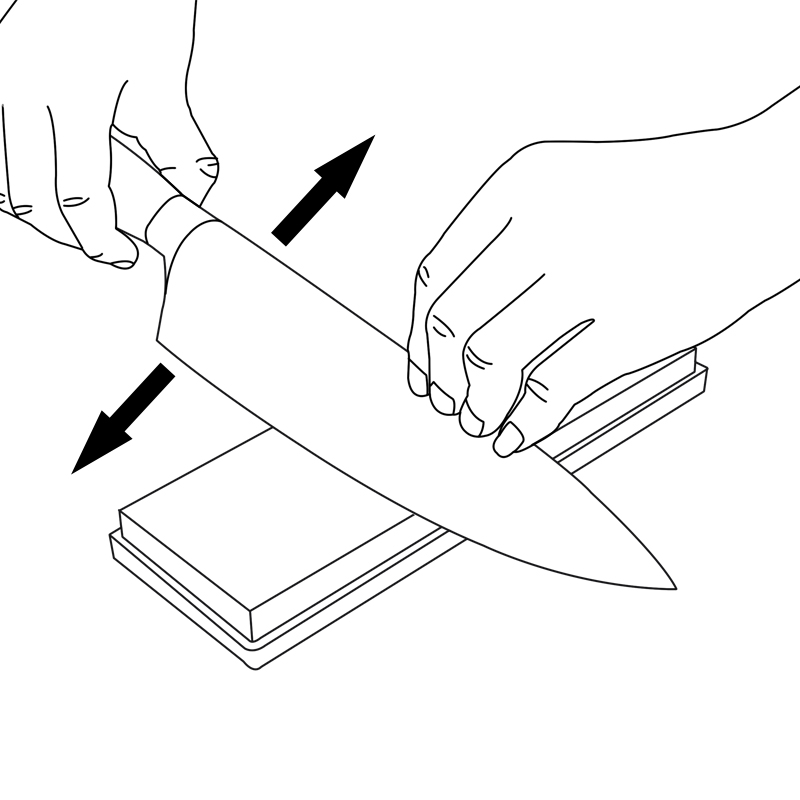

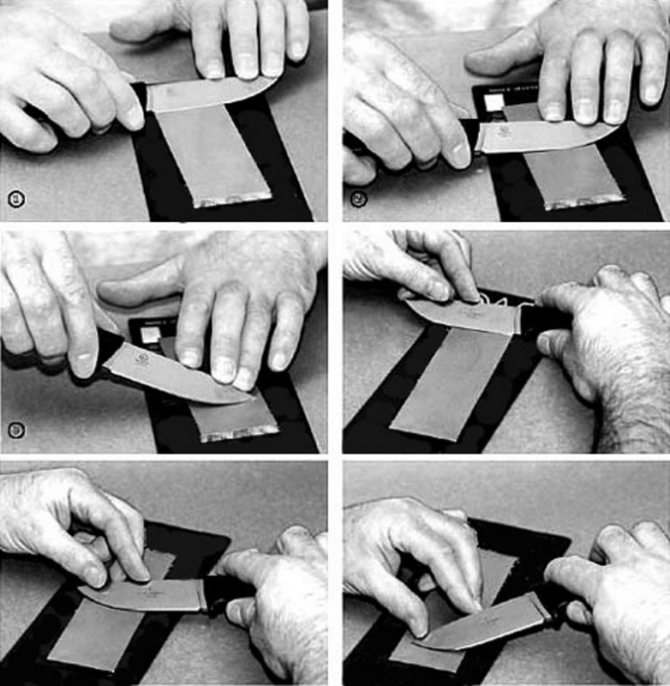

Instructions - how to properly sharpen a knife at home using a sharpening bar:

- First, rinse the whetstone with water, and then run it over it with a wet sponge soaked in soapy water;

- Then you need to sit down at the table and place the whetstone on a wooden board. A cutting board is also suitable for this. You can also put a towel under the stone. You can also choose and need an angle for work. You can put the bar perpendicularly, or you can put it at an angle of 45 degrees. The user himself must choose how it will be more convenient for him;

- After preliminary preparations, you need to choose an angle for sharpening the knife. Here one general principle should be remembered: the smaller the angle of sharpening of the knife, the sharper the blade will be, and the more - the longer the sharpness of the blade will hold after sharpening. It must be remembered that the chosen angle will need to be adhered to throughout the entire knife sharpening procedure;

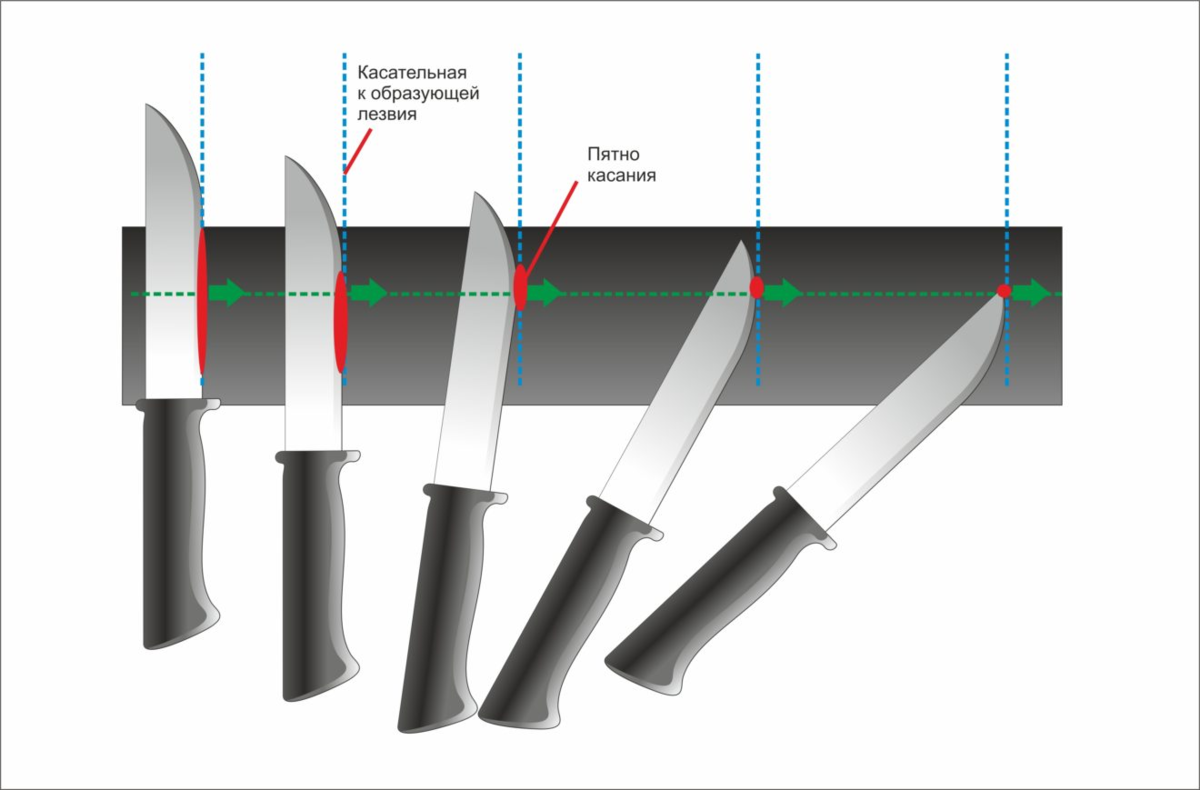

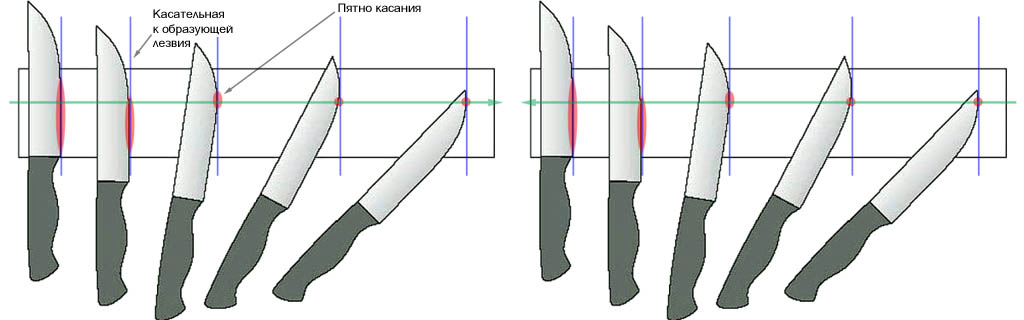

- So what do you need to do to sharpen a knife? Position the knife across the bar so that the top edge of the knife handle is above the bottom edge of the sharpening bar. You need to hold the handle with one hand and the blade with the other. Holding the knife in this way, you will need to guide the knife blade along the sharpening bar, sliding along an arcuate path away from you. There are some things to consider that are very important when sharpening knives:

- the cutting edge that slides along the surface of the grindstone must be perpendicular to the direction of travel;

- In order to maintain the initially selected sharpening angle, at the bend of the blade, you will need to raise the knife handle;

- Don't press hard on the blade. The sharpening process does not require this. But driving a knife blade over a stone is also not too weak. Sharpening the knife simply will not work;

- Don't forget about the suspension. It accumulates during the sharpening process, so you need to periodically wash it off with water.

We carry out knife grinding

Grinding is the final step in the sharpening process of the knife, after which it will have a sharp edge. To carry out the work, special grinding stones are used, which have a rather fine abrasive grain. It feels like a velvety surface, but in reality, this grinding abrasive can make a knife blade so sharp that it will rival even the best razors.

What is the main purpose of grinding? Thanks to her, the cutting edge acquires not only the desired property, but also firmly fixes it. It has been noticed that polished metal surfaces do not deteriorate as much as normal ones. As a result of this property, the pungency will be preserved for as long as possible.

When grinding, the same principles should be considered as when sharpening a knife. Each movement should be uniform and measured, the position of the blade should be perpendicular to the axes of the bars, the inclined angles of the sharpened steel to the abrasives should have a constant value. And you shouldn't do the job with unnecessary effort. If the alignment of the steel will occur gradually in layers, then in the end a razor sharpness will be achieved.

In conclusion, I would like to note that all this can be mastered, but you definitely need a practical skill, which you can get if you wish. And based on the knowledge acquired from any owner, the knives in the house will always be in a sharp and sharpened state.

How to prepare knives for sharpening

The very first step in turning is preparation. Before proceeding with the procedure for updating the cutting properties of the point, it is necessary to take into account all the nuances, for example, what bar to sharpen the knife with. To determine how to sharpen knives with a bar correctly, you need to know the hardness of the blade, grain size and individual characteristics of the bar, as well as their compatibility with each other. For example, coarse grains are not suitable for a soft blade (Figure 3).

Figure 3. An example of incorrect selection of stone and sharpening

Figure 3. An example of incorrect selection of stone and sharpening

All tools should be washed, dried and completely degreased before turning. If the handle is greasy, it may slip out of the hand during the point and injure the operator. The same goes for the blade, which can not only slip off, but also deform or scratch. Then it is necessary to determine the degree of dullness as follows: the duller the cutting edge, the more prominent it is, and the sharper, the smoother it is.

How to sharpen knives with a bar by hand

For knives, their correct sharpening are used:

ceramic bar - although it is not cheap, it fulfills its "mission" perfectly. The main thing is to make the right choice, and then it will be convenient to sharpen. 2 such bars are required - with a grinding surface and for the main sharpening - with a coarse one. The stone should be as wide as possible: the more comfortable it will be in work. And as long as the longest cutting tool in the kitchen.It is on such bars that you should start practicing how to sharpen a knife. They are distinguished by their durability and wear resistance;

a diamond bar is also not cheap, but the result after its use cannot be compared with an ordinary stone: sharpening is much more comfortable, while it also serves for a long time. The basis for such a stone for sharpening knives is either aluminum or plastic. 2 plates made of diamond-coated metal are attached to it.

- they are not afraid of blows, if they fall, they do not break;

- they are not in danger of clogging with steel particles. After sharpening the knife with a bar, rinse the stone under water and be sure to wipe it;

- works with such a bar quickly, it will last a long time and practically does not grind;

- you do not need to buy 2 bars, since they are made double-sided: one side is sanding, the other is rougher.

There is only one drawback to such bars - the cost. They are not cheap, unless it is a fake, which will become unusable very quickly. Japanese water stones are also bars. They should be used only after being wetted with water.

In the course of sharpening, a suspension is formed, so the surface is also polished at the same time.

Note that the cost of these stones is high and they wear out quickly.

- Roller knife

This option is quite simple to use and not expensive, everyone can afford it. Especially it is not bad for women. A few rolls and your knife will cut great. Although - not for long.

Optimal sharpening angles

To make the blade as sharp as possible and not damage it, you must adhere to the recommended angles of inclination during the procedure. For convenience, you can find a table that shows the optimal angles for different variations of knives.

Table knives

The angle of inclination when processing table varieties is in the range of 55-60 degrees. This is due to the use exclusively for cutting ready-made food.

Home kitchen

Household kitchen knives are sharpened at an angle of 30-35 degrees. The working load on them is relatively low due to the short-term operation.

Professional chefs and kitchens

Knives used in professional cooking are processed at an inclination of 25-30 degrees. The right pungency significantly reduces the stress on the cook.

Chopping and boning

The blades used for cutting and deboning are sharpened at an inclination of 25-30 degrees. Sharp knives help you work with less effort.

For professional fish processing

The fish is cut with blades sharpened at an angle of 25 degrees. Less sharp blades will squeeze rather than cut the fish.

For professional processing of vegetables

Since vegetables have a dense structure, there are no special requirements for the sharpening angle. The optimum tilt angle is 35 degrees.

Folding and hunting

The angle of inclination when sharpening these knife models varies according to the needs of the owner. Sharpening is carried out to maintain sharpness or increase resistance to bluntness.

For spice

If good sharpness is required, the angle is set in the range of 30-35 degrees. At the same time, the resistance of the cutting edge to external influences.

High resistance to bluntness

To increase the stability of the cutting edge, an angle of 40-45 degrees is chosen. Processing at this angle allows you to maintain sharpness for a long time.

Sharpening methods

Before sharpening scissors, you need to understand the features of their use. The methods used for knives are not suitable in this case. This is due to the use of the edge cutting method, which requires filing angles from 30.

Smaller edge angles are bad because the blade dulls faster and the cutting process is easier. An important feature of the tool is the need to preserve the factory angle, since it is precisely for it that the structure is fitted.

You can sharpen the tool blades using the following methods:

- On a special machine. High quality processing, productivity.

- On a grindstone. The method is painstaking, difficult to implement due to the low accuracy of the sharpening angle.

- Sharpening bar. The simplicity and availability of the method. Turning is possible only on a perfectly flat surface, difficult angle control, low sharpening speed.

To quickly sharpen scissors, you can use the following tools and methods:

- foil;

- bottle;

- a pin;

- by sharpening with a needle.

Sharpening scissors on the machine

At what angle should the knives be sharpened, and how to fix the knife when sharpening

The main conditions that determine the sharpening angles of the blade are the purpose and conditions of use of the blade. The smallest sharpening angle assumes the sharpest blade for a thin cut, such as a fillet look. A larger angle of the sharpened blade is preferred when dressing a chopping tool - an ax, a lager knife. Applying knowledge in practice, just to get the desired sharpness and resistance to bluntness with different tools, be sure to take into account the type of steel of the blade.

Having decided on the sharpening angle, the knife is held with one or both hands, pressing it against the abrasive. Gripping with both hands occurs by the handle and the opposite part from the sharpened edge of the blade, thus holding the tool with a long and wide cutting part. Control over the desired fixation and observance of the angle is visually tactile, acquired with experience.

Required angle for each tool used when sharpening the blade:

| No. n \ n | Knife types | Angle (in degrees) |

| 1 | dining room | 55 — 60 |

| 2 | kitchen household | 30 — 35 |

| 3 | professional kitchen | 25 — 30 |

| 4 | professional chef | 20 — 25 |

| 5 | professional for fish | 25 |

| 6 | professional for meat | 30 |

| 7 | vegetable | 35 |

| 8 | for root crops | 22 — 25 |

| 9 | boning for meat | 25 — 30 |

| 10 | sirloin | 10 — 15 |

| 11 | for chopping bones | 30 — 45 |

| 12 | folding - pocket | 20 — 25 |

| 13 | tourist - universal | 30 — 35 |

| 14 | tourist, camp knife | 40 — 45 |

| 15 | special-purpose shoe | 30 — 40 |

| 16 | leather cutting knife | 20 — 25 |

| 17 | joinery | 30 — 45 |

| 18 | camp inmate - machete | 45 — 60 |

How to use the round disc knife sharpener

There are various accessories for sharpening knives, including sharpeners with round discs. The difference is that the grinding material in this case is a special rotating roller that grinds the cutting surface at an angle of 45 degrees.

The main advantage of such devices is that after sharpening there is no burr left on the blade, and the work is done simply. In addition, roller sharpeners stay sharp for much longer than V-shaped sharpeners.

Most often, such sharpeners are adapted not only for knives, but also for scissors.

So make sure to choose a sharpening cavity first.

Take the sharpener in your left hand and the knife in your right.

Place the blade of the knife in the area of the handle between the discs and forcefully slide it to the tip.

Repeat the same thing several times.

Be careful not to cut yourself.

How to sharpen meat grinder knives

Before starting the process of sharpening knives and a mesh for a meat grinder, it is necessary to prepare a workplace. The surface on which the work will be carried out must be perfectly flat, without grooves and depressions. If possible, you can use a plexiglass board. The sharpened knives, mesh, abrasive surface (sandpaper, sharpening stones) are lubricated with sunflower oil to obtain a homogeneous paste when grinding the abrasive. A wooden clamp is used for uniform sharpening. Medium pressure is applied to the center of the sharpened knife or net. The work is done in a circular motion in a clockwise direction.

Myths

There are many myths associated with knife sharpening. Adhering to common myths, many make mistakes when using sharpeners.

Laser sharpening

Modern technologies do not allow making the blade sharp with the help of a laser. Laser systems have no abrasive properties and are intended solely for marking and patterning the surface of the blade. Typically, a laser machine is a marketing ploy of companies that attract customers by misleading them.

Self-sharpening steel

The most common myth is the assertion of a self-sharpening tool that does not dull with prolonged use and, on the contrary, only sharpens in work. The properties of steel do not always allow it to remain sharp, and under any circumstances, the material gradually becomes dull.

What knives you shouldn't sharpen yourself

When planning to sharpen dull blades, you should read the information about which blades are not recommended to be processed by yourself. By studying the recommendations, you will be able to reduce the risk of damage to the instruments.

Favorite and comfortable

Not having enough experience or performing the sharpening procedure for the first time, it is better not to use your favorite and most convenient knives. Deviation from the correct sharpening angle and other errors can cause blade breakage. For this reason, it is better to train the skill on old blades, which, in case of damage, do not mind throwing away.

Ceramic

Due to the nature of the material, ceramic products can only be processed with diamond-coated bars. In the absence of the necessary equipment, you should not try to sharpen with a standard bar, and it is better to entrust the work to professionals. Armed with specialized equipment, you can try sharpening a ceramic blade following standard technology.

Damascus steel and damask steel knife

Unlike ceramic tools, it is not allowed to sharpen knives made of damask and Damascus steel with diamond stones. Devices with diamond chips damage the surface of such products and cause them to begin to crumble. Processing with a standard bar is not difficult, but it takes a lot of time, therefore, it is better to take dull blades made of Damascus steel and damask steel to a special workshop, where their condition will be quickly restored.

Share link:

How do you sharpen knives by hand?

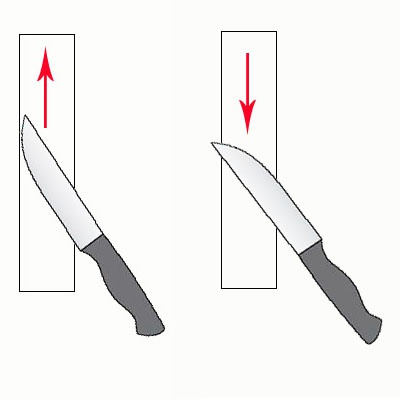

Without mastering the techniques of manual sharpening, the master will not be able to sharpen the knife correctly, since any device for sharpening knives with his own hands will only slightly facilitate his work when aiming the edge of the tool. This process looks like this:

- A bar of medium or coarse grain is laid on the desktop, and then fixed.

- Calculate the sharpening angle. They begin to sharpen the knife away from themselves, keeping the angle constant. Movement - uniform and smooth, strong pressure is not required here.

- In one movement, the tool is carried out to the end of the stone. The edge of the knife to be processed should always be perpendicular to the center line of the bar, therefore, when approaching the rounded part (to the edge), the blade is turned, trying to maintain the required perpendicularity as much as possible.

- At the end of the movement, the tip is not removed from the surface, but a “walk” in the opposite direction is started. The actions are repeated until a thin solid "burr" appears on the reverse side of the blade, which is checked with a finger, it is carried out perpendicular to the edge. If it is even along the entire length of the blade, then this part of the operation is completed. Otherwise, work continues along the entire length until the ideal is reached.

- The bar is exchanged for a second product - with a finer grain. Sharpening is continued from oneself, but without a reverse movement. The second side is processed in the same way.

- They switch to another pair of sharpening stones - small. In the first of them, the process with movement only from oneself is repeated.

- When the burr edge is almost invisible, they switch to the last sharpening stone - the smallest.On it, movement from oneself is done only once on each side, while simultaneously reducing pressure to a minimum.

The remaining mini-defects are fought with a belt glued to a bar, rubbed with GOI paste. Do this by alternating sides, turning the edge back. Many have seen such a simple process in old Soviet films.