We connect the power supply to the water heater

The storage boiler belongs to household electrical appliances of increased power. The device must be powered from a separate cable line from a common distribution board. How to properly connect the water heater to the electrical network of an apartment or a private house:

The table shows the maximum power, so the cable must be taken with a margin. For most heaters, a 2.5 mm square wire will work.

- To supply voltage from the panel to the boiler, use a three-core copper cable of the VVG type. Select the cross-section of the wires according to the power of the unit, using the table above.

- To protect the supply line, install a differential two-pole circuit breaker with a trip current of 30 mA as shown in the diagram below.

- The connection of the grounding conductor is a mandatory requirement of safety regulations.

- To connect the wires to the contacts of the heating element, remove the protective plastic cover (usually held by 2-3 self-tapping screws).

- It is not necessary to install an outlet for the water heater. However, if the appliance is supplied with a factory plug, the socket can be neatly positioned to the side of the tank.

Do not mount the socket directly under the water heater, where it could be flooded with water in case of an accident.

Required tools and materials

The type of tool used to mount the water heater is selected depending on the features of the walls. In this case, a construction gun is necessary in each of the cases.

Perforator

A hammer drill is required if the heater is hung on concrete walls to form holes for dowels to be inserted into.

Electric drill

An electric drill is used in cases where holes are drilled in walls made of a softer material than concrete (drywall, brick, etc.).

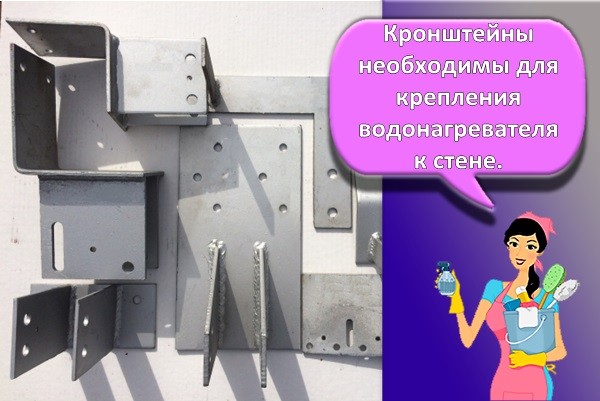

Brackets are required for fixing the water heater to the wall. The length of these hooks depends on the volume of the boiler.

Dowels

Dowels hold the brackets in the wall. That is, these fasteners take up some of the load that the boiler creates.

High quality hoses

To connect the boiler, you will need at least two copper (not metal) hoses, one of which supplies cold water, and the second returns hot water.

Instructions and wiring diagram of the device

Without instructions and a diagram, it is impossible to connect the boiler to the general network, since the installation algorithm of the device directly depends on the design of the heater.

Filter

A coarse filter is required if the heating device is installed in places where contaminated water (with large particles) is supplied.

Installation work

Choose the place of installation of the storage heater as close as possible to the water taps and the electrical panel. The water heater must not occupy the usable space. After checking the strength, markings are drawn along the wall, holes are drilled, plastic dowels are driven in, or a homemade shield is mounted.

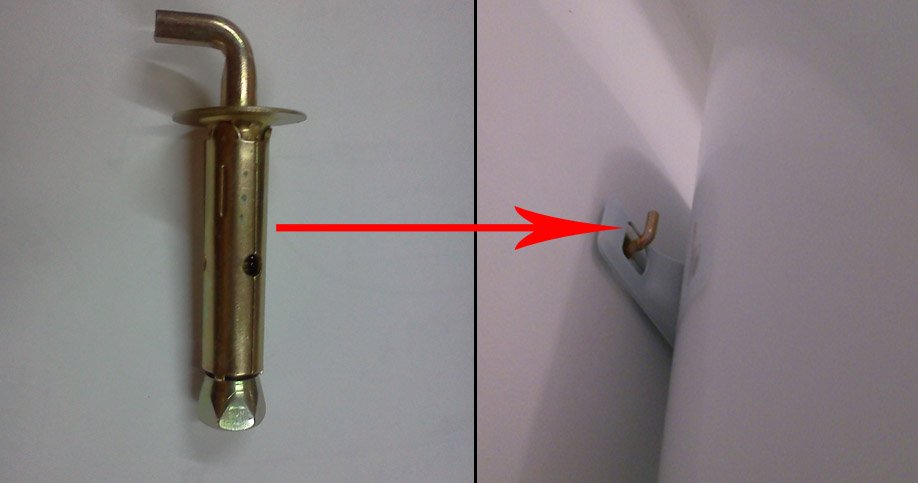

The boiler has a lugged fixing plate at the back. An anchor is inserted into the holes and screwed into a plastic dowel. If hooks were used, then the boiler is simply hung with lugs. When using studs, the fastening plate is pressed with nuts.

At the end of the installation work, connect the outlet pipes to the water supply, try to fill the tank with water and check how securely it is fixed.

Connection to communications

Connection to the general water supply network is carried out according to the following algorithm:

- Tow is wound on the blue boiler branch pipe (designed for connecting a hose with cold water), which is lubricated with a unipack.

- A tee is screwed onto the branch pipe, from the side of which a drain valve is then installed.

- The relief valve is screwed onto the bottom of the tee with an arrow pointing down.

- A shut-off valve and a threaded adapter are installed below.

- The second part of the hose connects to the cold water pipe.

After that, a shut-off valve and an adapter, to which the hose is connected, are screwed onto the red pipe. The latter is then connected to the water supply.

2> Rules for the operation of water heating equipment

It should be noted that the key to the successful operation of water heating equipment for a long time is compliance with the rules for using water heaters. Here are the main ones:

- experts advise at least once a year to remove the heating element and check it for the presence of scale build-up, and this is due to the fact that at the maximum heating temperature of hard tap water, scale forms in the heating element, as a result of which heat transfer decreases, the system overheats and stops functioning; in this case, you have to change the heating element;

- it is forbidden to hang the heating element in the absence of grounding in the room, since drops of water falling on the body can damage the device, as a result of which the possibility of a person's electric shock is not excluded,

- it is forbidden to connect an empty storage boiler to the mains;

- if an excess of pressure over 6 atm is observed in the city water supply network, then it is necessary to install a pressure reducing reducer;

- it is not allowed to connect the heater to the water supply network without installing a safety valve that comes with the water heater;

- it is not allowed to drain water from the storage heater connected to the network;

- the consumption of water from the water heater as drinking water is excluded.

Design features

To figure out how to hang a water heater on the wall, you first need to find out the design feature of the storage device. By type of heating, boilers are:

- Gas water heaters are connected to a mains or a cylinder. Require the outlet of the chimney outside the room.

- Electric boilers are powered by a household electrical connection. The absence of combustion products does not require the conclusion of the chimney, since it is generally absent.

- Indirectly heated water heaters are equipped with a heat exchanger connected to the heating system.

What all these boilers have in common is the storage capacity. The larger the tank, the heavier it will be when filled with water. This design feature determines how to hang the boiler on a wall made of different materials and where to choose a place for it.

Any model of the water heater is sold with fasteners. Floor-standing appliances are easier to install, while overhead boilers require a solid wall. As standard, each boiler body is fitted at the rear with mounting lugs. Includes steel hooks. If not, you will have to buy separately. The thickness of the hook must match the diameter of the hole in the lugs.

Even an inexperienced person can figure out how to use a wall mount for a water heater:

- The first option - the dowels for fixing the device are driven in with a construction gun. However, not every owner has a tool at home.

- It is easier to drill holes in the wall for plastic dowels and screw in steel hooks.

Standard fixing options are suitable for sturdy concrete or masonry substrates. How to mount the boiler to weak walls will depend on the looseness of the material.

How to mount a boiler on walls made of different materials

The fixing of the boiler to the wall is carried out practically according to the same scheme, regardless of the design and dimensions, but there are differences.

- The metal anchor for the boiler is driven into vertical fences using a special pistol - this is a reliable, but time-consuming method. Not every owner has the necessary tool and you need to rent, borrow or purchase a new one for a one-time installation.

- Metal dowels are used, which are fixed in plastic lugs.The reliability is somewhat reduced, but this method is easier. Holes are drilled in the wall monolith, plastic covers are inserted and L-shaped dowels are screwed in to hang the unit.

Foam concrete

For foam concrete, it is necessary to select special fasteners to the wall

For foam concrete, it is necessary to select special fasteners to the wall

Spiral nylon dowels are used to attach lightweight water heaters with a capacity of up to 50 liters to a wall of aerated concrete blocks. Heavy units from 80 - 100 liters are secured with a boiler holder with a metal tip.

A steel plate is used, which is fixed with steel studs threaded through the thickness of the wall. On the reverse side of the partition, tighten the nuts, and the dowels for the boiler are attached to the plate. There is an option of installation using chemical or adhesive anchors that are securely held in the wall.

Adobe

It is not enough to drive steel anchors into partitions made of this material. For the hinge, a special metal shield is used, which transfers the load from the water heater evenly to the entire wall. Hooks are welded to the support for mounting the unit.

The carrier is attached to the partition in several places. Through-the-wall threaded pins are used, nuts and washers are screwed on the reverse side. The studs are welded to the shield or fixed with a bolt connection.

Ceramic tile

If the wall is finished with ceramics, the heater can be hung if there is a fence made of durable material under the cladding. The layer on which the tile lies should be a solid mass without voids and be no thicker than 3-4 cm.Metal anchors of the correct length are used so that they capture the ceramics, mortar and wall body by 10-12 cm.The boiler will break if it is fixed only into the tile with mortar, - the layer will separate from the wall.

Plasterboard partitions

Fasteners for plasterboard walls

Fasteners for plasterboard walls

You can fix the boiler to drywall if you make a frame support when erecting a partition. The embedded element corresponds in area to the dimensions of the heater. The narrow backing will hold the anchors, but the heavy unit will push the plasterboard wall around the perimeter of the frame element.

Wood

The method of installation into the wall of a wooden house depends on the design of the fence. Solid walls of logs or beams are strong and can withstand the boiler on anchors. Over time, the dowel in the tree loosens, so an additional metal plate is placed. It will serve as a support and a non-combustible gasket for the dimensions of the heater.

In wooden panel buildings, the frame is made of timber, between the supports there is a shingle filling with insulation. The support shield is necessarily installed and attached to the frame to which the water heater is mounted.

Lining

The material is used for decorative finishes and is not considered a base for fixing. A non-combustible gasket is required. An asbestos sheet is placed between the boiler and the clapboard if the finish is on a solid foundation. Otherwise, a durable metal shield is needed, which will provide additional support and fire protection. The shield can be replaced with a frame made of a square tube or other profile.

Gypsum

A solid support is installed under the gypsum or adobe in the wall, to which the boiler is attached

A solid support is installed under the gypsum or adobe in the wall, to which the boiler is attached

In such material, the dowels and anchors are pulled out, therefore, the plane of the ceiling and floor is used if the floor is of a solid structure. Vertical racks are fixed on the upper and lower supports, sometimes longitudinal niches are cut out for them in the plaster. For fasteners, steel anchors and dowels are used. The hooks for hanging the heater are welded to the support legs.

Brick and cinder block

The water heater is fixed with an anchor screw into a silicate or red brick wall, if the partition thickness is more than 250 cm. Metal support pads are used if the stones in the wall have a hollow structure with round or rectangular holes.In cinder block partitions, similar gaskets are always used, since the strength of the material is inferior to brick.

Types of water heaters

In a system with a single-circuit boiler, a boiler is used to heat water

In a system with a single-circuit boiler, a boiler is used to heat water

Boilers are classified based on the type of energy used and the principle of operation. The storage unit contains a tank with a heating element inside, in which a given volume of water is heated. The advantages lie in durability and economical operation, and the disadvantages are manifested in the large weight, dimensions and the need to wait for the heating of the liquid.

Water heaters are:

- electrical;

- gas;

- indirect heating.

Flow models heat water before entering the mixer. Such a model is mounted on a water pipe and works as a heat exchanger that passes liquid in an arbitrary flow. Cold water is heated to boiling water in a few seconds and hot water enters the tap.

Gas

Gas boilers are almost always performed in a flow-through version and contain a heat exchanger made of copper flat elements inside, which give energy to the water tube. The burners are located under the heater and transfer heat to the fins. The waste gas collector is located above the heat exchanger, collects them and directs them to the chimney by means of natural draft or forced ventilation.

Electric

A heat source in the form of a heating element is placed inside or under a built-in water tank. The water heating tank is protected by an insulating foam or polyurethane layer and a casing. At the front there is a control panel for adjusting the temperature.

The heated water in the tank is replaced by cold water when disassembled from the tap. If the supply of warm liquid is running out, you need to wait until the device warms up. The sensor coordinates the temperature and turns on the heating element when the indicator drops below the established norm.

Indirectly heated

The water is heated by the energy produced by the boiler

The water is heated by the energy produced by the boiler

The equipment operates in winter from energy generated by a gas, electricity or coal heating boiler. The unit supplies hot water to several taps due to its high performance. It is a cylindrical metal tank protected by thermal insulation.

Inside the container there is:

- a heat exchanger in the form of a coil (tube), through which antifreeze or water from the heating system flows;

- magnesium anode to protect the insides from corrosion;

- thermostat for temperature coordination and start-up;

- hazardous pressure protection valve.

What is not recommended

How to install the boiler correctly was discussed above. But there are recommendations on what to do during installation and use of the unit, you cannot:

- turn on the installed unit, not filled with water;

- connect a pipe from the water main to the water heater, if the pressure in it is more than 6 atmospheres;

- remove the protective cover of the unit and drain the liquid from it without disconnecting it from the power supply;

- engage in the installation if you do not know how to install a boiler with your own hands;

- the use of "left" components, different from those recommended by the manufacturer;

- when installing the unit, ignore the installation of the safety valve;

- do not follow the installation and safety rules.

Design features

The design of any water heater necessarily includes fasteners. They vary depending on whether the boiler is installed on the wall or on the floor.

With a floor-standing device, everything is relatively simple. But the installation to the wall is carried out using steel fasteners on the back of the case. water heating tank... In this case, dowels will be needed, the dimensions of which must correspond to the fasteners on the boiler. By the way, there are devices that require removal of the back panel. The dowels are fastened with a construction gun. If there is none, then you need to drill holes for the screws for fasteners using a punch or drill.

Usually fasteners - steel hooks - are included with the water heater. Parts should only be used if they are of good quality. Their diameter should be more than one centimeter.

The water equipment market is represented by three main types of boilers. The method of installation work will depend on their type:

- Indirect heating. The peculiarity lies in the absence of heating elements, heating of the liquid is possible from external sources. The design can be both wall-mounted and floor-mounted.

- Gas storage. The liquid is in a special container, it heats up due to the fact that the gas burns out. It is recommended to entrust the installation to specialists.

- Electric accumulative. Heating of the liquid is provided by heating elements at the bottom of the tank, the water temperature is regulated by a thermostat. The most popular due to the ease of installation, connection and operation.

Where to hang the water heater: expert recommendations

As a rule, water heaters are installed in places protected from freezing of water, near water points. If these points are located at a certain distance from each other, then they provide for the installation of several water heaters. When choosing a place, you should consider the possibility of hot and cold water access to plumbing fixtures. It is also necessary to provide free space for the subsequent maintenance of the boiler. When choosing a wall where to hang a boiler, its strength should be taken into account. Often, a water heater is installed in bathrooms on the back wall of the toilet. Before making a final decision, it is recommended to “tap” the wall. If it turns out that it is thin and there is a ventilation mine behind it, you can hang a boiler up to 100 liters in volume on it, it is recommended to hang a water heater up to 200 liters only on load-bearing walls.

Before installing a boiler, it is worth finding out a number of some important points, namely:

Diagram of a storage water heater device.

decide on by analyzing its technical characteristics and design;

find out if there is a possibility of shutting off the water for the installation period and access to communications;

where and at what height can the water heater be hung: vertically or horizontally, in the kitchen, in the toilet or in the bathroom. Before you hang the device in the bathroom, you should know that the water heater, like other household appliances, must be installed in certain areas. According to safety rules, there are four danger zones in the bathroom.

Therefore, it is important to correctly plan the location of each household appliance and choose the safest one for the boiler;

- plan a place for laying the cable, taking into account the characteristics of the room;

- think over how many mixers will function from the boiler: several or one;

- whether additional work will be required: chiselling of capital walls, installation of boxes, chiselling, etc.;

- where to drain water in case of need for constant drainage from the overpressure system;

- think over which option is suitable for your apartment: flexible water supply to preserve aesthetics or reliable pipes;

- where to install the outlet.

DIY tools and installation

The piping of the boiler is carried out after installation on the wall.

The piping of the boiler is carried out after installation on the wall.

Marking of the position of the heater on the fence is done. The distance from the holes on the bracket to the ceiling and the adjacent wall is measured.

Installation is carried out in 3 stages:

- Hitching up the unit.

- Connection to the water main.

- Electricity connection.

The boiler is connected to the water supply with a blue and red branch pipe, through which cold liquid enters and hot liquid is removed. For fastening, connecting fittings are used.

Tools used:

- puncher, construction gun, drill;

- roulette, level;

- welding machine;

- grinder with a circle for metal;

- set of wrenches;

- plumbing welding device.

How to fix the device?

Walls made of bricks or blocks are considered ideal for installing a water heater, but it is extremely undesirable to mount it on a thin wall. However, fastening to other types of materials is also permissible. The most common are:

- drywall,

- tile,

- wood,

- lining,

- foam blocks,

- plaster.

Consider the installation features for each type of wall.

Drywall

Experts consider drywall a capricious material and question its resistance to loads. However, there are two effective ways by which you can install a boiler in a room sheathed with drywall sheets:

- installation for reinforcement, which is laid under the wall cladding material;

- mounting on holes drilled in the wall.

Tile

Sometimes during the repair, the question arises: when is it better to mount the heating tank - before or after laying the tiles. It's good to have options. What if the tiles are already installed? Qualified specialists believe that in this case, three conditions must be met:

- glue evenly applied to the tile;

- the tiles must be laid without voids;

- the wall should be made of solid materials that prevent the tiles from sagging or wobbling.

If all the requirements are met, then any water heater can be mounted on top of the tile.

Wood

The information on fixing the tank to a wooden surface is full of controversy. According to some sources, installation on a tree is extremely undesirable, since the wall will not be able to withstand the colossal load, which will become even greater after filling the boiler with water.

According to other sources, the installation is permissible. True, with a proviso

Before fixing the water heater, it is important to choose a non-combustible base for the unit in accordance with fire safety rules

Lining

This material in this case is considered capricious. Therefore, you cannot do without special conditions for the installation process. You will need two vertical beams, which must be carefully processed and painted to match the color of the lining or tank. They are permanently attached, and a water heater is already hung on them. By itself, the lining is not able to withstand the weight of the boiler.

Foam concrete

Special fasteners such as nylon spiral dowels are required. If the volume of the device exceeds 100 liters, it makes sense to use metal fasteners. Two mounting options are available - using metal dowels or using special or chemical anchors for foam concrete. The option using a chemical (or adhesive) anchor is considered the most reliable and modern, as well as environmentally friendly.

Gypsum

There are two mounting options:

- Cutting holes in the slabs for the frame (metal profile pipes) with subsequent fixation to solid surfaces such as the ceiling, floor or walls.

- Using two 40x4 metal tires bent at right angles. They will be used as anchorage. One end of each rail goes to the anchor to the concrete ceilings, and the other for additional fixation - to the dowels to the wall.