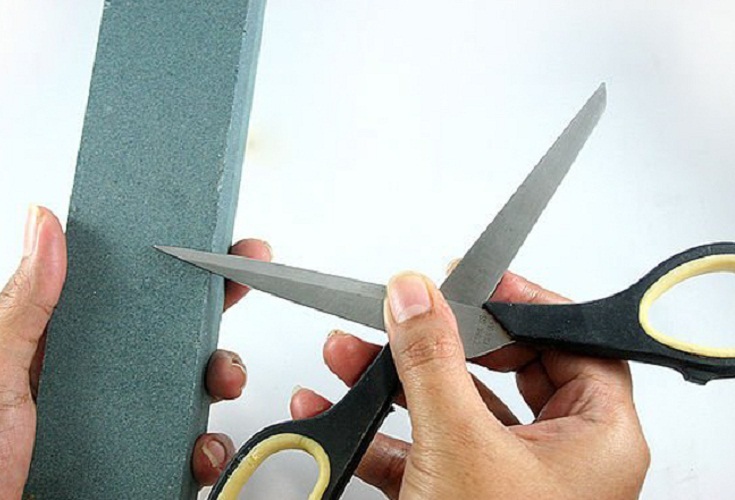

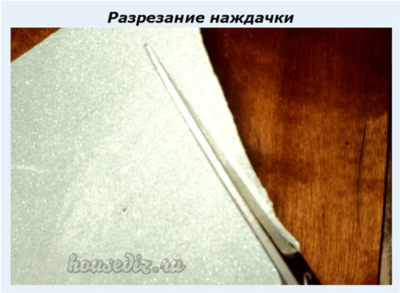

Method two: how to sharpen scissors using sandpaper

The technology for carrying out the work will be similar to the tips described above. To do this, take a small piece of emery cloth and dissect it with scissors in different directions. You can also rub the blades with the specified material, applying light pressure from above. In this case, it is necessary to use coarse-grained material, which is easier to process. Be sure to take into account when working that the sharpening area is the outer edges of the scissors. The inner surface must not be rubbed, otherwise it is possible not to "cure" the instrument, but to spoil it. These two options for sharpening scissors are quite simple and affordable. But for the result to be of better quality, you can use other methods.

How to sharpen nail scissors?

The manicure tool has a curved cutting edge. Manicure scissors and nippers are sharpened by many craftsmen by hand.

It is important not only to repeat the sharpening angle, but also to process the entire bend evenly. The diminutiveness of the blades complicates the task

A thin whetstone will come to the rescue here. How to sharpen a nail scissors with it is shown in the video:

If you decide to use a machine, it is important to set the minimum speed and select a fine abrasive grinding wheel. The metal on the nail scissors is thin, easy to bend and deform

Which scissors can and cannot be sharpened at home?

It is not recommended to sharpen any professional tool yourself: hairdressing, tailor's, nail scissors.

How long does a home sharpener last?

If you use "folk" methods, the sharpness of the scissors will be enough for 5-10 applications. When sharpened on a machine or a touchstone (according to all the rules), they become as good as new - the tool will work properly for 3–12 months. The exact time depends on the loads and the quality of the steel.

Sharpening scissors has many subtleties. This is a whole science that needs to be learned from a master. Hairdressers and tailors know that even in workshops, tools are often spoiled. A good grinder for people of these professions is worth its weight in gold. We advise you to use home methods exclusively for sharpening ordinary inexpensive scissors, which there is simply no reason to carry to the workshop (it is cheaper to buy new ones).

Nail scissors

A characteristic feature of this tool is the curved, curved blades. It is better not to start processing them without good locksmith skills and round fine-grained diamond-coated files.

If the nail scissors don't work well, then try first:

- tighten the screw fastening of the axis of rotation;

- inspect the gap between the cutting edges of the feeds;

- polish with a needle.

I recommend editing bends only as a last resort, using a specialized tool.

To consolidate the material, I recommend watching the video Serg578 "Finishing the blade of the scissors in 2 touches."

Useful goods

- Wood Carving Blades

- Artificial Fishing Lures

- Laser level for 3 operating modes

Checking the sharpness of the cutting tool

After sharpening the scissors, you need to evaluate their cutting ability. Exactly the same measures are required to check whether it is necessary to sharpen the blades at all. As practice shows, not in all cases the absence of sharpening negatively affects the sharpness of the instrument.

After sharpening the scissors, you need to evaluate their cutting ability. Exactly the same measures are required to check whether it is necessary to sharpen the blades at all. As practice shows, not in all cases the absence of sharpening negatively affects the sharpness of the instrument.

Sometimes the reason for the poor cutting performance lies in the strong loosening of the fastening screw. Blades that do not fit well together will crush and chew the material. The troubleshooting method is quite simple. You just need to tighten the screw and try to cut something.

A possible problem that can be encountered during cutting is the small gap between the sharp ends. The presence of such a space will not allow high-quality cutting of the material. If there is no convergence of the cutting edges at a certain point, then the material begins to wrinkle. Having found that the edges are diverging, you need to use a file to process a special stop on each cutting blade. They are located next to the rings and are small metal or plastic solders.

Stitch them carefully, periodically checking that the distance is reduced to the required mark. It will take endurance, the work is monotonous, but not difficult

If the manipulations done did not bring results, then you cannot do without sharpening. To check its feasibility, take a small piece of tissue. Hang so that its edges hang freely. Then the incisions are made. A curved cut indicates that it is time to sharpen the tool.

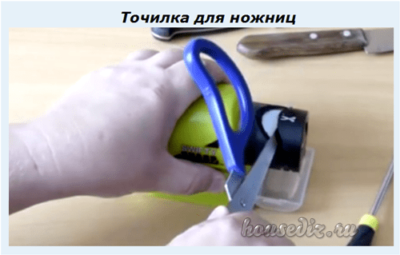

Method four: how to sharpen scissors using special tools and devices

There are several types of processing devices. First of all, these are, of course, special machines. By lightly pressing the blade against the rotating disc, sharpening occurs. Of course, this requires a certain skill and skill. There is also a risk of injury to your fingers, therefore, under no circumstances should children be allowed to operate these devices. A simpler and very convenient device, especially for direct use by women, is a knife and scissor sharpener sold in supermarkets and hardware stores. Just one movement - and the blades will be sharp without any additional processing. Therefore, it will be very useful for the hostess to have such an item at hand.

Sharpening methods

The professional approach angle is formed on special machines in the factory. It must be preserved and maintained. The article does not consider the factory technology, but publishes simplified methods available to the home craftsman to bring household models into working order.

Scissor straightening tools

Sharpener

The scissor blades are bred and alternately dragged through the slot prepared in the tool. The metal of the inlet is ground with abrasive materials. Rotating discs can be used for this. All jags and irregularities are removed to a single level.

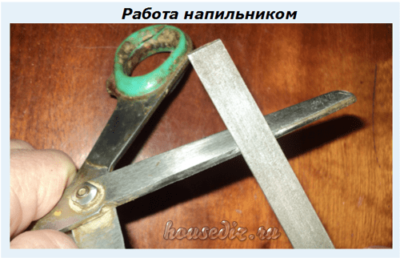

Diamond file or file

When sharpening, the scissors should be well fixed or firmly held in your hand, resting it on some stationary object, for example, a table surface.

The cutting surface of the file must be located only in one plane. This technique ensures the same sharpening angle along the entire length of the blade. Its factory size must not be violated.

If there is a large cut on the surface of the file, then additional polishing of the approach with another tool may be required.

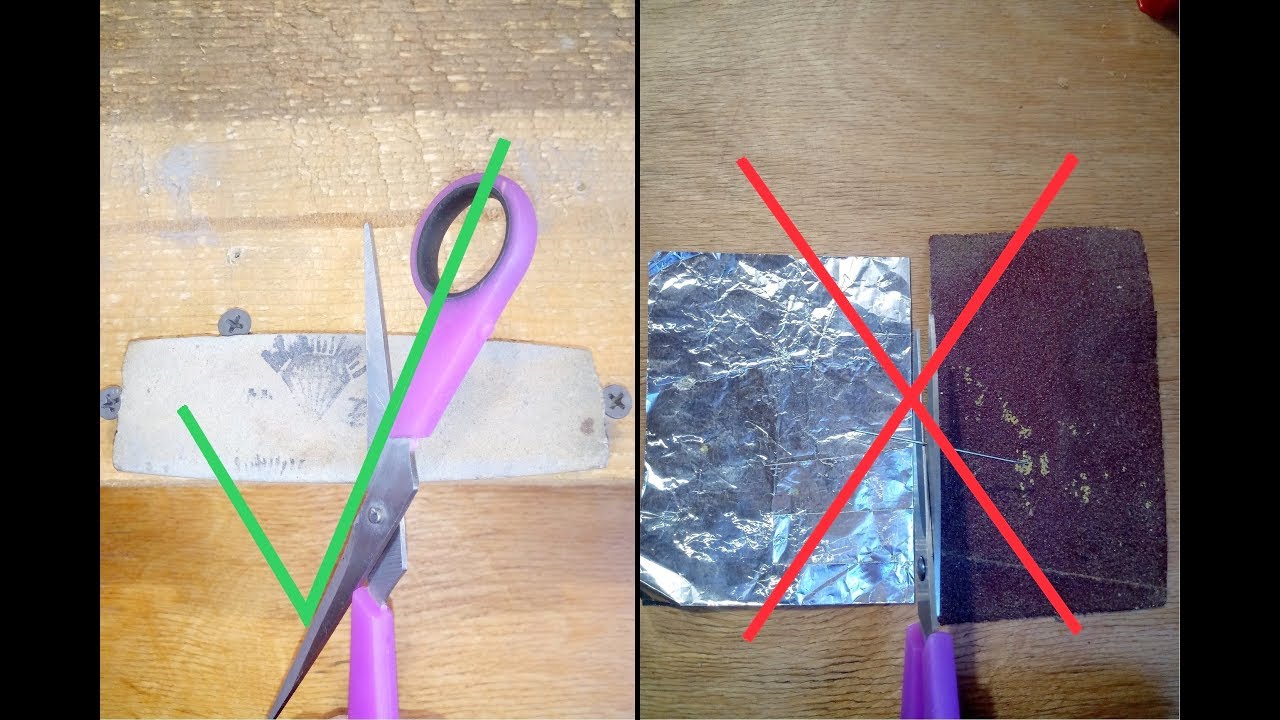

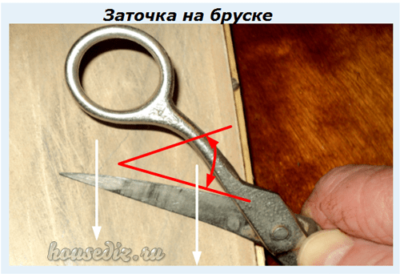

Whetstone, whetstone, whetstone

It is advisable to disassemble the scissors, but you can also work assembled. The technology is the same as when sharpening a knife on these devices. The supply is placed on the surface of the grindstone, the blade is led in one direction, all the time they maintain strictly one angle of inclination. The abrasive material is periodically moistened with water, removing particles of cut metal.

The photo shows work on a homemade grindstone made from ceramic tiles with your own hands.

If the shape of the blade differs from a straight line, having a convexity or concavity, then the direction of the sharpening movement is changed by 90 degrees.

Improvised means

Consider the most affordable sharpening tool:

- sandpaper;

- foil;

- steel wool;

- neck of a glass bottle;

- steel wire.

Sandpaper

They choose varieties with the smallest grains - zero. Cut it along the entire length of the blade. The abrasive material of sandpaper, passing under the cutting edges, sharpens them.

The material is folded in several layers, the cuts are made along the entire length of the blade.

This method works according to the technology of the previous one. The scissors should work the entire length of the blade.

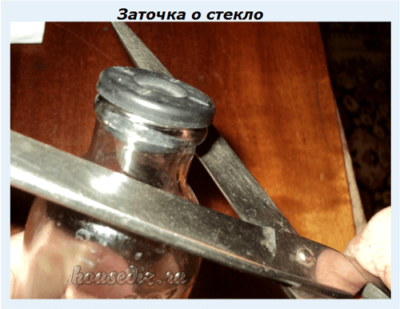

Glass bottle

Grasping the neck with both blades, they make cutting movements along their entire length in both directions. The surfaces are polished. Therefore, the plane of the inlets is positioned in the optimal direction to align them.

Facelift

Any scissors, for example, for paper, when they are in order, should cut the fabric, and the cutter's tool should cope even with the thinnest, for example, silk or chiffon, and not only the entire surface, but also the tips. If the blades individually seem to be sharp, but in fact do not cut the matter, but chew it, then the reason may lie in the fact that the blade mount is loose. When the distance between the cutting surfaces becomes greater, thin material is not cut, but clamped. So, before grabbing the sharpener, you should try tightening the fastener and then try again to cut the fabric. Perhaps it turns out that this is the only problem.

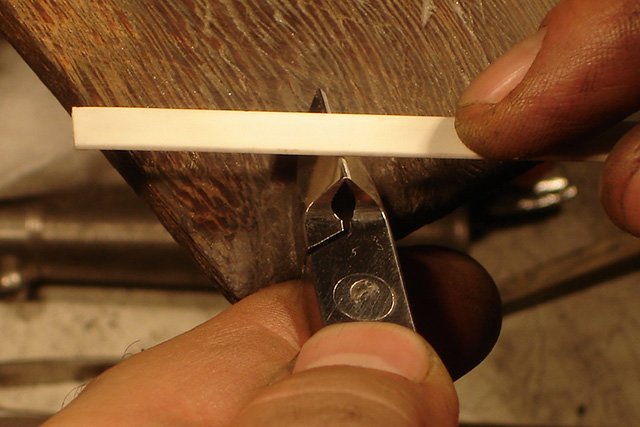

The axis of the scissors flaps is either a screw screwed into one of the halves, or a bolt with a nut, or a rivet. In the first and second cases, you should use a screwdriver with a screwdriver (in the second version, pliers can also help, depending on the shape of the fastener), tighten the mount more tightly, having previously opened the tool, if this is not done, then after tightening too hard there is a risk of not being able to open the scissors in general, or the knives will go very tight. In any case, you need to twist it gently, smoothly. It is permissible to turn the screw by a maximum of 0.5 mm, then check how the blades close, otherwise you can jam the tool so that it will no longer be repaired.

In the case of scissors with non-separable fasteners, the situation is more complicated. The latch consists of a rivet, a head, on one side and a small stopper, a plug made of soldered metal or plastic, on the other side. The tool should be opened, placed with the head down on an anvil or other strong flat metal object and secured. Then, using a hammer, you need to slightly flatten the retainer stop. After checking the cutting ability, repeat the operation if necessary.

If the movement of the scissors becomes difficult, they should be lubricated. For this purpose, a light sewing machine lubricant or any oil is suitable. You need to drop a little on the axle and the canvases will move more easily.

How to sharpen scissors at home: preparation

Paralleling the skates, the blades of the scissors should be similarly sharp. The main principle is that uniformity and linearity must be strictly observed during processing. The angle for sharpening is selected taking into account the hardness of the material from which the cutting device is made. The lower the indicator of this mechanical characteristic, the smaller the angle should be.

If the scissors cannot cope even with cutting plain paper or thin fabric, it is necessary to diagnose the cutting edge and other elements of the tool:

- Checking the hinge assembly. Poor cutting edge retention practically negates the correct function of the tool. If the scissors are screw, then tighten the screw connection. If riveted, they squeeze the rivet. In scissors connected in the classical way, it is necessary from time to time to check for backlash.

- Geometry evaluation. Looking at the blades from top to bottom, a negative bend angle can be observed on serviceable scissors. There must be tight contact at the junction point of the cutting edges. Divided blades, even with a slight play between them, will never fully cut the material, even if their edges are perfectly sharp. If you need to bend the blades a little, you can do this yourself, observing safety precautions.

- Checking the condition of the cutting edges.Before you start sharpening scissors, you need to carefully examine them. The metal frame may have chipping or rust on it. It often happens that perfectly sharpened blades begin to cut poorly due to some kind of small chip that does not provide complete mating of the edges. It is enough to remove it, and the scissors will be suitable for cutting.

- Cleaning the surface of the cutting edges. Office scissors are often used to cut the adhesive tape. The adhesive adheres to the sharp halves, and then dust and dirt particles. The remaining pieces of tape block the cutting edges and adhere to the material being processed. You can use rubbing alcohol or thinner to remove foreign objects and glue.

How to sharpen nail clippers and nail clippers

Sharpening tweezers and manicure scissors is more difficult than utility and stationery, haircut or sewing scissors. This is due to the uneven blades of manicure appliances. If sharpened incorrectly, it is very easy to spoil such products. A suitable method in this case would be to use a cone-shaped diamond rod.

Before sharpening the nail scissors, it is better to disassemble the small device. This will make the job easier.

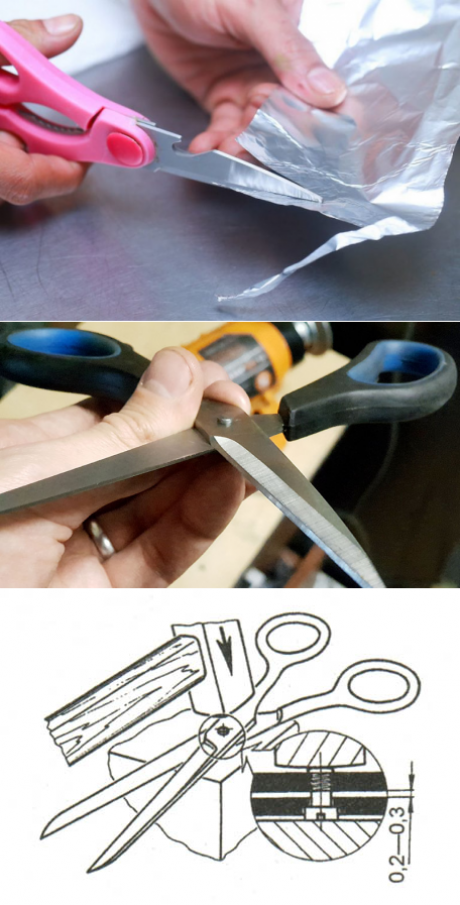

Then, with smooth and accurate movements, move the diamond rod in one direction only! Carefully peel off the metal from the surface until you reduce the shiny stripes to 0.2-0.3 mm. Such stripes appear in places where the blades rub against each other.

Work each blade in turn, moving the diamond rod to one side only. Then collect the scissors and snap in with light pressure. Lightly sand the cutting edges again. For nail scissors, use a sharpening angle of 45-69 degrees.

For tweezers, take a small, narrow diamond block and sharpen the blades from the inside until the cutting edges line up. After the inside treatment, the tweezers' blades are slightly sharpened from the outside to touch up the tips. At the end of the procedure, the blades must be polished with leather material or a special polishing paste.

DIY scissors sharpening methods

If there was no good master nearby, and there is no way to buy new scissors, then you can temporarily reanimate them using available tools for sharpening.

Foil

Fold in 6-7 layers a sheet of foil for baking about 25 cm long.You should get a thick strip. Cut the foil with scissors until the entire thickness is cut. You need to cut the entire length of the blades, starting from the base to the tips. The sharpening quality depends on the width of the foil strips. The scissors will sharpen better if you cut many thin strips. At the end, wipe the scissors with a damp cloth, remove the remaining foil.

Sandpaper (sandpaper)

It is desirable that it has a fabric base and a grain size of 150 or more. Fold the skin in half with the abrasive facing out. Start cutting the sandpaper. The abrasive will touch the blades, sharpen them. You need to make 10-20 strips. You need to cut to the full length of the blades.

On a note! You can also use sandpaper to remove the scissors nicks. This sharpening method is not suitable for a very dull instrument. You can only sharpen it a little with a sandpaper. Finally, wipe the scissors with a damp towel. An alternative to sandpaper is a metal kitchen sponge.

Glass jar

Take an unnecessary can, which you will not mind throwing away. Insert it between the scissor blades open to the full width. The bank must be brought closer to the center of the instrument as closely as possible. Hold the jar in one hand, scissors in the other. Close the scissors by sliding the blades along the surface of the container. It will slide out. It is necessary to exert maximum effort so that the glass sharpens the cutting edges as best as possible. After the procedure, wipe the blades with a damp cloth.

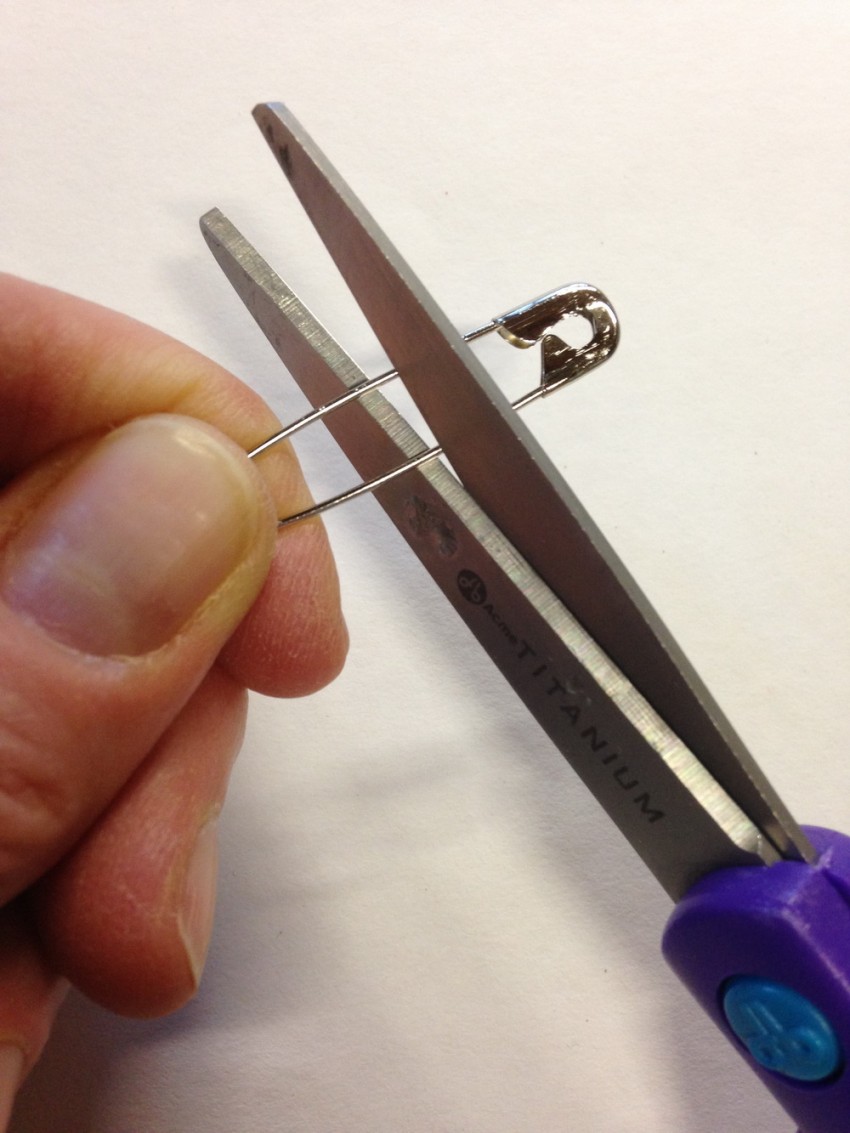

Safety pins

They are used in the same way as in the previous methods. Insert a sewing pin between the blades.Close them, bringing the pin out from the middle along the cutting surfaces. Sharpen until the scissors are sharp enough.

Touchstone (whetstone)

It can be purchased at any hardware store and can be used to sharpen many cutting devices. As a rule, the touchstone is two-sided - with fine-grained and rough sides. It is better to start sharpening with blunt scissors with a rough surface and finish with a fine-grained surface.

Put the whetstone on a towel, cover it with a special honing oil (you can use water or any other oil). In the scissors, unscrew the screw holding the halves together. It is better to sharpen the blades individually.

The inner surface of the blade is sharpened first. Place it with the inner side (the one that is adjacent to the second blade) on the touchstone. Set the correct angle between the inner blade and the cutting edge. You need to sharpen the line of contact of the two faces. Take the blade by the handle and slowly slide it over the touchstone. The edge of the blade must not be torn off from the surface. You need to keep it horizontally away from you. Repeat the action 10-20 times. Repeat the same procedure with the second half of the scissors.

When working with a sharpening stone, you must first practice how to sharpen correctly on old scissors until you develop certain skills.

Five ways to sharpen scissors quickly

- Take aluminum foil and fold six layers lengthwise. Then start cutting the resulting thick foil strip with scissors until the blades are sharp. Cut along the entire length of the blade from base to tip. When finished, wipe the item with a damp paper towel and pat dry. This method is not suitable for manicure tools;

- By analogy with foil, you can use sandpaper. It is best to use a fabric-backed material with a grit value greater than 150. Fold the sheet so that the rough side is on the outside. Start cutting the sandpaper in the same way you cut the foil until you get the desired result. After processing, wipe the blades with a dry cloth. This method is also not suitable for small nail scissors with curved blades;

- Take a metal kitchen sponge for harsh dishwashing and use in the same way as foil or sandpaper. Use scissors to cut the sponge, but be careful as it leaves a lot of debris. Therefore, it is better to perform the procedure over a previously spread newspaper or trash can. Wipe the treated blades with a damp cloth and wipe dry;

- Use a glass jar that you don't need. Squeeze the piece between the blades of the tool and start cutting until the latter is sharp and smooth. Position the can so that it is as close as possible to where the blades are attached. Wipe the sharpened object with a damp and then dry cloth;

- You will need a sewing pin or gypsy needle. In this case, a needle or pin is clamped between the blades of the scissors, as in the glass jar method. Start cutting and continue cutting until the blades are sharp. Then wipe the surface with a damp and dry cloth.

The nuances of sharpening special-purpose scissors

As mentioned at the very beginning, there are many variations of scissors for professional use. Editing of such a tool in most cases has its own technological features.

Manicure

In order to bring the nail scissors into perfect condition, it is required to sharpen the edges at a strictly defined angle specified by the manufacturer. This is very difficult to accomplish, even if you know the magnitude of the angle. In addition, you must have some skill in adjusting the coincidence of the cutting edges. Therefore, if you do not want to spoil the scissors, it is better to immediately contact the master.

Hairdressing tool

The blades of a hair clipper must be very sharp and perfectly aligned. Otherwise, they will not cut their hair, but mince and tear them, creating discomfort for a person. You can check the quality of sharpening of such a tool by cutting a thin plastic wrap. You will immediately see a blunt edge or a loose blade.

Experienced craftsmen use templates for precise scissors. With their help, you can simultaneously check the quality of sharpening, the angle of inclination of the edge and the evenness of the surface of the blades. Therefore, not a single professional hairdresser will sharpen his scissors on his own, but will immediately turn to a familiar master. The best processing is done with laser equipment.

Garden pruners

This tool can be easily sharpened at home. High precision is not required for this, as the garden shears are used to coarsely cut branches and thick stems. You can use a sharpening stone or file for sharpening.

Sewing or tailoring

The tool for cutting fabrics must be very sharp, but it is quite possible to sharpen it yourself. However, usually this sharpening is not enough for long and the procedure will have to be repeated often. For work, it is best to use foil or fine sandpaper, as described above for clerical scissors.

Sharpening tools

You can sharpen the knives with various devices. To select the right tool, it is recommended that you familiarize yourself with the characteristics of the options available.

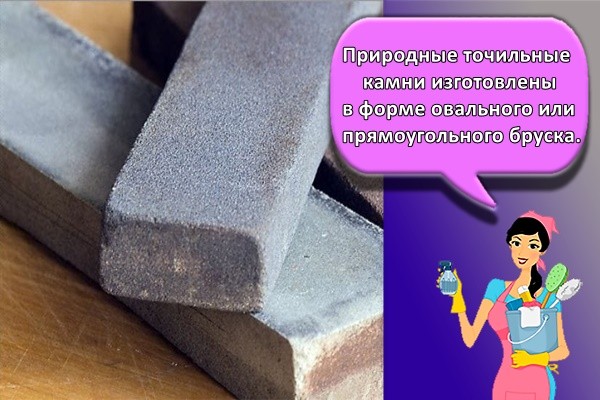

Touchstone (whetstone)

Sharpening stones are made with different abrasive grain contents. To restore maximum sharpness and final grinding, whetstones with a maximum and low abrasive content, respectively, are used.

Natural origin

Natural whetstones are made in the form of an oval or rectangular bar. A piece of quartz or crystalline silica is usually used as a natural stone.

Ceramic

Ceramic stones combine high workmanship and high wear resistance. The disadvantage is the lengthy sharpening process.

Diamond

Diamond stones differ from other varieties by their sharper edges. With long-term use, diamond stones retain their original shape.

Japanese water stone

Japanese stones are designed for finishing with water. This type of stone is suitable for processing daggers.

Mechanical sharpener

Mechanical sharpeners are often used to process kitchen knives. Using this equipment, it is possible to quickly sharpen various blades.

Electronic sharpener

Modern electric sharpeners automatically calculate the angle of inclination, which contributes to a good quality of processing. The electric sharpener is suitable for home and industrial use.

Musat

Musat is used to keep knives sharp. Externally, the tool looks like a rounded file with a small handle.

Lansky

The Lansky sharpener sharpens compact and mid-sized knives. The design allows processing at different angles.

Sharpening and grinding machines

Special machines are usually used for production purposes. The equipment provides high-precision sharpening.

Roller knife

The roller sharpener is equipped with abrasive burrs. As the knife moves, the built-in ceramic or diamond-coated rollers rotate and grind the blade.

Sandpaper is a flexible material with a rough finish. To sharpen different knives, you need to choose paper with the right amount of abrasive grains.

Grindstone

The fastest and most effective method that even a housewife will have to do, but this procedure needs to be carried out using a special technique.In order not to spoil the tools, especially if you are new to this business, practice on other knives before carrying out the procedure.

There are two sides to a whetstone: low and coarse abrasive. You need to start the procedure with a coarse abrasive. Sharpening instruction:

- Place the stone on a fabric surface so that it does not slip.

- Open the scissors as wide as possible. The knife should slide tightly over the sharpener.

- The blade must be sharpened in one direction (away from you). Do not miss the moment and make sure that the canvas completely passes over the stone.

- Then repeat the procedure on the other side of the sharpener.

- The degree of sharpening of the tool is up to 70-75.

Of course, there are not many ways to effectively resuscitate suddenly dull knives with scissors. Someone will prefer not to bother and go to buy a new knife in the store, but someone will still try to sharpen it himself. Not all methods are as effective as you imagine, however, thanks to the correct sharpening technique, you are guaranteed to get good, sharp tools.

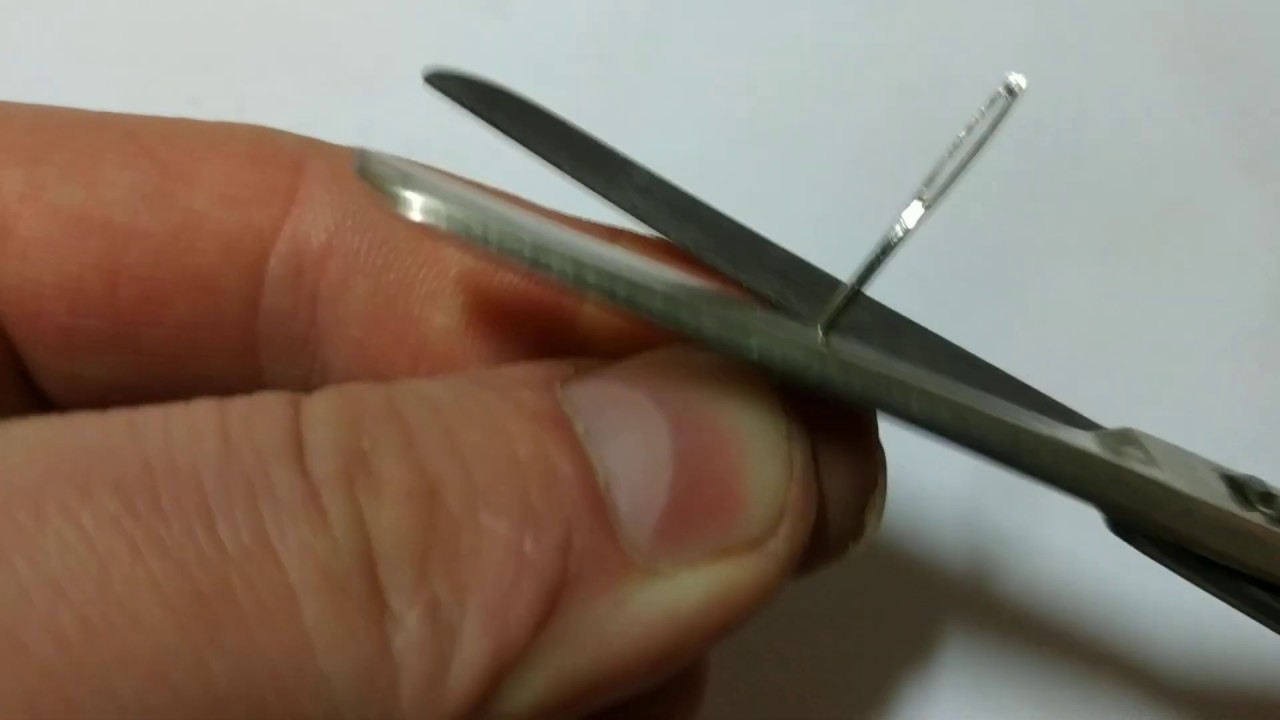

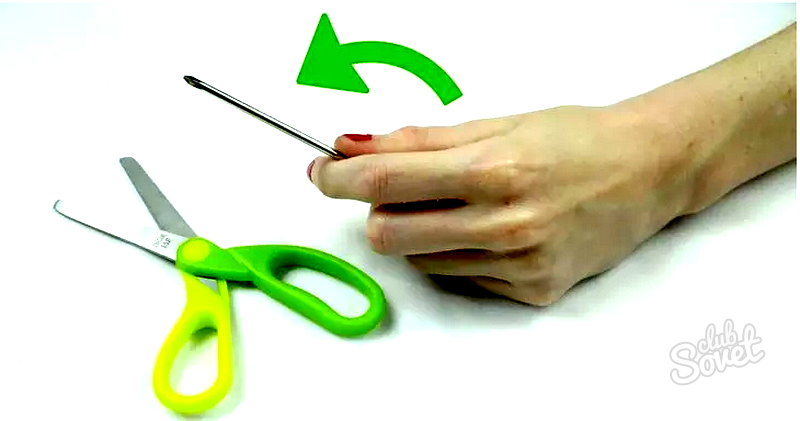

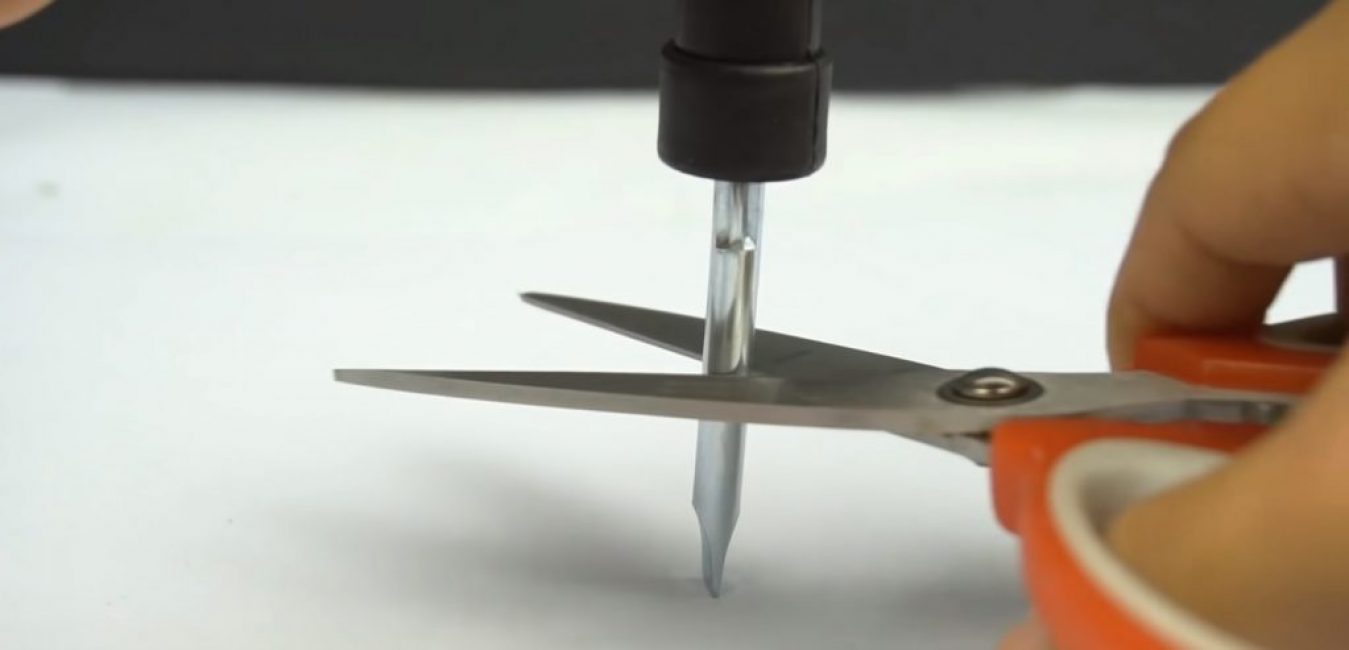

Needle sharpening method

In most cases, it is required to sharpen the scissors, provided that there are no special tools at hand. The way out of this situation is often the use of an ordinary needle.

In most cases, it is required to sharpen the scissors, provided that there are no special tools at hand. The way out of this situation is often the use of an ordinary needle.

This method of sharpening a metal product involves the following work:

- Stretch the two halves as wide as possible.

- The needle is placed near the section.

- The two halves of the scissors gradually come together. Naturally, the needle moves forward.

It is recommended to repeat this procedure 2-3 times. In the manufacture of a needle, as a rule, hard metal is used. Upon contact with the cutting edge, the metal layer is removed from the treated surface. Naturally, the needle is positioned at the desired angle relative to the cutting edge.

Fundamental rules

Experts recommend sharpening scissors once every 6 months. If the instrument began to "deteriorate" earlier, do not postpone this procedure. The main sign that sharpening is necessary is the appearance of dark spots. Just keep in mind that before the process itself, the scissors need to be prepared a little.

How do you know if you need to sharpen scissors? There are several ways to help you understand this. Often, for example, a plastic bag, film, wet wipe, or even latex gloves are used. These materials are used to conduct tests that evaluate the blades. Secure the material so that it lies flat. Place it between the scissor blades and try to cut. If the material starts to cling to the scissors or tear, then it's time to process the tool.

Sharpening in several stages

So, having studied all the options described, still how to sharpen the scissors correctly? If there are no special factory devices in the household, it is recommended to carry out the work in several stages to obtain the best result. To do this, remove accumulated dirt from the blades with a cotton swab or cloth soaked in solvent before machining. Depending on the purpose of the scissors, this can be soil, food residues, paint, fine fabric dust, etc. Removing the foreign layer will provide the best result. Then use a file or a coarse block first. After that, use coarse sandpaper and then fine sandpaper to secure the result. Finally, slightly tighten the bolt holding the blades together. After all, perhaps this was the main reason that the scissors do not want to "obey" the master.

Everything! The implement is ready to go!

Home sharpening methods

If the scissors do not cut well, you need to check the hinge assembly. The halves of the tool must be securely fastened. The loosened fastening makes it impossible to use the scissors correctly.Fasteners can be riveted and screwed. You can tighten the fastening screw with a screwdriver. If the fastening is riveted, then you need to squeeze the rivet.

Then you should check the cutting edges, inspect them for nicks. One notch can spread the blades and interfere with tool performance. There is often dirt on the surface of the blades. Before sharpening, you need to clean them with alcohol or solvent. After preparatory work, if the tool has not recovered, it is necessary to start sharpening. To sharpen scissors with a needle, you need:

- Choose a hard metal needle.

- Open the tool, place the needle close to the hinge and try to cut it.

- The needle should move towards the ends of the blades.

- Repeat these steps several times. As a result, the instrument should become sharp.

A good way to sharpen your scissors at home is to cut the aluminum foil. You need to fold the food foil several times and cut it into small pieces. Fine-grit sandpaper can also be cut. In order to sharpen scissors at home correctly, you can use a glass bottle, trying to cut its neck. You can buy ready-made sharpeners, but they are only suitable for one type of tool.

Prohibited actions

To extend the life of the scissors as long as possible and delay their bluntness, you must adhere to some recommendations:

- Do not boil the device in order to disinfect. This will lead to rust. It is better to treat the instrument with an antiseptic.

- Lubricate the pickup mechanism with oil every six months.

- It is advisable not to disassemble the scissor mechanism unnecessarily. Some items cannot be reassembled.

- Use scissors only for their intended purpose.

- Choose the correct angle for the sharpening of the blade. Otherwise, the scissors will stop cutting.

If the scissors are dull, you don't have to go straight to the store for new ones. You can revive the instrument by sharpening it. This is best done in a special workshop. If the scissors need to be sharpened quickly at home, there are a few simple methods that can be used, but they all have only a temporary effect. It's better to find an opportunity to have the device sharpened by a professional anyway.

After watching the following video, you can find out a few more effective ways to sharpen scissors with your own hands: