What is carbon film?

The carbon film is made on the basis of polyvinyl chloride (PVC) and visually and tactilely imitates the fashionable carbon fiber today. Due to its economy, it is very popular among motorists who are actively styling their iron horse.

Carbon film will make your car stand out on the road

Carbon film will make your car stand out on the road

A quality film is created in a process called calendering. It allows you to create a thin but strong material with uniform thickness along its entire length. Thanks to this, there will be no seams on the car, which will further bring its look closer to the original carbon. In addition to its prestigious appearance, the film has a number of other advantages.

- The coating combines both pleasant and useful properties. The carbon film will not only delight your eyes, but also protect the car from small scratches, dust and stones flying from under the wheels.

- If there have already been shallow damages on the car, the film will hide them and smooth out the relief.

- The likelihood of corrosion will be significantly reduced, as the car is reliably protected from moisture.

- If you have purchased material of decent quality, it can easily survive both severe frosts and unbearable heat.

- The color of a high-quality film does not fade under the influence of direct sunlight and protects the original paintwork from fading.

When self-cleaning a car with a film from dirt, you should use soft sponges and special car shampoos for vinyl covering

The service life of the film, if used correctly, can be from 5 to 10 years. But if during this time carbon goes out of style or your tastes change, you can remove the vinyl without any problems. To do this, it only needs to be heated. In this case, the paint and varnish layer will look exactly the same as before covering. This means that the pasting process does not threaten the original appearance of your car.

Types and features of films

There are two types: vinyl, polyurethane. The protective properties of vinyl are added due to the thickness, and polyurethane due to their abilities.

When buying vinyl material, attention is drawn to:

- adhesive on the surface of the back of the vinyl;

- thickness in microns;

- width;

- strength, elasticity;

- term of possible operation.

The assortment of vinyl by type belongs to several categories:

- Matte. The advantage lies in the adoption of fairly complex forms. The service life is up to 7 years.

- Glossy. They are mainly used for constricting body parts.

- Mirrored. Prevents the formation of body rust. Presented in two colors - gold, silver. The service life depends on the manufacturer.

- Carbon fiber. Availability at different prices, quality depends on it. The term of operation is from 5 years.

- Textured. It is used to simulate various materials: wood, metal. The material is dense, the service life exceeds 10 years.

Durable polyurethane (up to 300 microns), protects the body from scratches, impacts

It is capable of transmitting ultraviolet light, which is important when pasting not the entire car (when removing the material from a part of the body after a few years, the color of the entire car will be uniform). The price is more expensive than vinyl

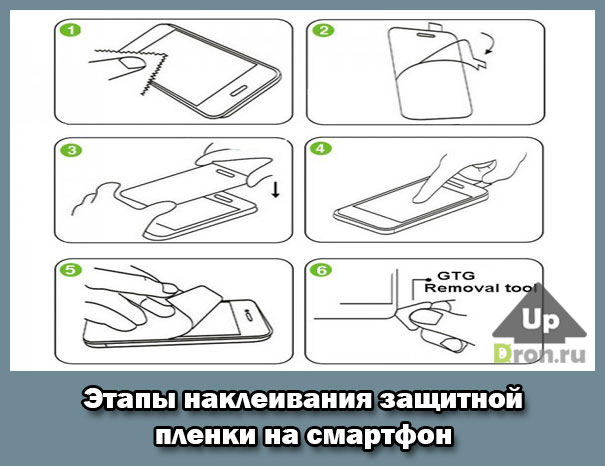

We proceed directly to the very pasting of the car.

There are two ways of wrapping a car: wet and dry.

It is better to leave the application of the film on the hood to the dry method to professionals, we will consider the wet method.

- We dilute a soap solution (about 10%), fairies are perfect.

- We spray the solution onto the part to be pasted (in our case, the hood).

- We take a prepared piece of film and tear off the paper base (it is better to do this together)

- If there is no companion, then lay the film on the parts directly with the backing, press the corners with magnets and gradually peel off the paper layer of the film from below, by moistening the part, the film will still be mobile on the hood for some time.

- The material should lie flat.

- We take a squeegee and from the center of the part we begin to smooth the film, expelling air, if there are irregularities and ribs on the part, you can heat the film with a hairdryer and it will become more pliable and elastic.

- But do not overdo it with a hairdryer, a correctly laid out and positioned film lays down by itself.

- When smoothing the polyurethane anti-gravel film, hold the squeegee at an acute angle to the surface to be pasted, try to press the film with smooth movements so as not to break the fold (watch the pasting process in the video)

- When the entire film is pressed against the part, we begin to tuck the film.

- Start at the corners, this is the most difficult, it is better to practice on extraneous corners, not on the papered hood.

- Here you cannot do without a hairdryer. We warm, stretch, bend.

- We go along the edge of the part with a hot hairdryer and iron the edge with our finger so that the protective film is firmly pressed. Now we bend it by 1 cm and cut off the excess with a clerical knife.

- An anti-gravel car will serve you on average for 6-10 years. Under the influence of time, the polyurethane film does not become cloudy or yellow.

When choosing films, read our reviews here.

The advantages of the film are very broad:

- Fully protects the covered surface,

- Completely invisible on the car if tucked correctly.

- UV protection

- Can be polished

- Dismantled without leaving damage.

- Possibility to choose a design (matte, glossy,)

How to care for and properly operate a glued car or body part, read the article

The service of applying an anti-gravel film to the body is more often relevant for new cars. Thanks to anti-gravel protection, the car retains its original appearance for a long time.

So, let's summarize.

- Anti-gravel protection will help preserve the original appearance of the car

- The protective film will save from chips, scratches and minor accidents

- Polyurethane film will prevent the effects of reagents on paintwork

- The service life of the polyurethane anti-gravel is 3-10 years.

- The protective film is invisible and does not change the appearance of the vehicle.

- The anti-gravel is glued and dismantled without leaving any traces.

- If a small section of the film is damaged, it can be re-glued

A beginner often does not know how to glue the film on a car with his own hands, he makes mistakes. One awkward movement, and you can damage the paint, part.

For this reason, it is better to contact a car dealer so as not to damage the car.

His choice must be taken seriously. Our specialists have extensive experience and an impeccable reputation.

We guarantee that we use quality films from trusted manufacturers.

Come to IDWRap studio - the result will meet all your expectations.

Surface preparation of the machine before installation

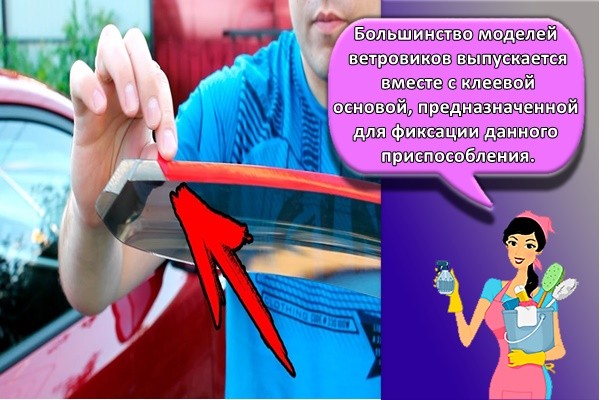

Most of the models of visors are produced with an adhesive base designed to fix this device. Otherwise, it is necessary to purchase specialized tape, which is preheated with a construction hairdryer.

In addition to a hair dryer, you will need a dry rag and technical solvent to fix the plastic overlays. After preparing the specified components, you will need to perform the following steps:

Wash the car body and windows, paying particular attention to the areas where the plastic covers are to be glued.

Treat the body and visor with a technical solvent, removing the fat layer.

Carry out additional processing of the body, covered with wax polish or paraffin wax.

If the car has old deflectors, then to dismantle the worn-out linings, you will need:

Open and lock the side door.

Warm up the connection between the deflector and the car body with a construction hair dryer

This procedure must be carried out with extreme caution. Overheating will cause the paintwork to peel off the surface of the body.

Pry off one end of the old pad and push the line through.

Run the line along the entire deflector, thus detaching the trim from the body

Care should also be taken during this procedure to avoid contact with the body surface.

After dismantling the old visor, treat the surface with a solvent.

If the old visor is plug-in, then dismantling is carried out in two stages. First you need to pry off one edge of the deflector, and then pull the plate towards you. At the end of this procedure, it is also necessary to clean the surface of the body.

It is possible to install new deflectors provided that the ambient temperature is above +10 degrees. It is prohibited to carry out the procedure in winter. In the cold, the adhesive does not set, which is why the deflectors will fall off a few hours after installation.

The gluing process

If you want to properly paste over your vehicle with vinyl film, you need to follow the following algorithm:

Wash and dry the vehicle thoroughly. This must be done even if you are going to paste over only individual body parts. Treat all surfaces on which you are going to glue the vinyl with white spirit degreaser (or any other). Make sure that there are no traces of dirt, dust, rust or sand on the surface.

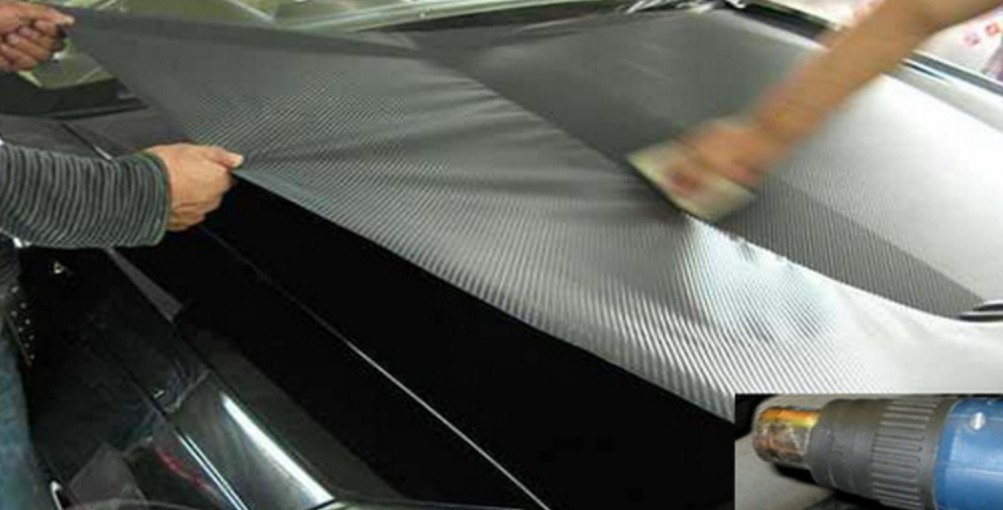

Car wrapping with auto vinyl

Car wrapping with auto vinyl

- Fitting. To do this, you need to attach the film to the place where, according to your plans, it should be glued. In this case, under no circumstances should the substrate or the mounting layer be torn off! After you have chosen the most successful coating location, it is advisable to mark the places where the edges will be located with masking tape. Fitting is a very important stage, and therefore it should not be done "hastily".

- Cut a piece of vinyl to the size you want. In this case, it is better to leave a small margin of space on all sides.

- Place the film on a horizontal surface, and then peel off the white paper that acts as a backing. At the same time, this must be done, constantly observing so that the film does not stick to itself. It is best to tear off the backing at an angle of 30-40 degrees.

- Apply a soapy solution to the part of the car to be pasted - it is better not to spare it and cover the entire surface with a uniform thick layer. This will eliminate bubbles and ensure that the film can move after application.

- Apply the coating to the surface of the vehicle. At the same time, it must be slightly pulled all the time and fixed at the extreme upper corners. From the middle and to the edges, the coating must be rolled with a rubber squeegee and dried in parallel with a hair dryer. It is necessary to roll from the middle so that all residual soap solution and air bubbles are removed in time. If you notice that wrinkling is inevitable in some area, you can lift the cover and stick it on again, heating it in parallel with a hair dryer.

- To fully activate the adhesive, it is necessary to re-blow the hair dryer over the entire surface of the coating after it has already been glued. In parallel, you need to roll it out with a felt squeegee.

Car wrapping with vinyl film

Car wrapping with vinyl film

- Trim the edges of the coating with a margin of 5 millimeters and glue to the surface with ordinary glue with sealing properties.Due to the fact that vinyl flaking always begins at the edges, this step must be carried out with great care.

- Run a rag over the entire surface of the vinyl. After that, the car must be left for about a day at the same temperature. After 24 hours, the vinyl will fully adhere to the surface. You cannot wash the car yourself within 7-10 days after you have covered your car with vinyl with your own hands. Also, of course, you should avoid visiting automatic car washes.

How is gluing with an anti-gravel film with your own hands?

It will be possible to quickly glue the material on the car if you think through everything in advance and purchase the necessary equipment.

You will need:

- anti-gravel film;

- masking tape;

- roulette;

- solvent (white spirit);

- napkin;

- rubber squeegee;

- squeegee with alcantara;

- stationery knife;

- puller;

- construction hair dryer.

- We measure a part of the car with a tape measure, make a 10 cm margin for tightening - adjustment and turning. Let's take a look at the hood as an example.

- We cut the film for the necessary part, about 135 cm by 110 cm, the width of the film in a roll is 152 cm, so we cut off 130 cm, leave the width.

- Before starting work, the car must be washed well, if there are traces of bitumen or glue, you must carefully wipe off the entire part, including the edge from the bottom, for folding.

- If there are irregularities and rust, we skin, putty and polish.

- If we glue a new car with foil, just degrease it.

- Degrease with white spirit or other means (alcohol, solvent).

- Only on a perfectly flat, clean and grease-free surface of the body will the polyurethane protective film adhere firmly.

The process of pasting the car with your own hands

If you do not want to spend extra money on pasting in a special workshop, you can easily do it yourself. For insurance, you can call a couple of reliable friends: at some stages it may take more than two hands.

If you've ever used conventional self-adhesive tape, wrapping your car shouldn't be too difficult either. The material adheres tightly to the surface of the parts, does not slip and does not crumples, and high adhesion will prevent the film from peeling off. You also need not be afraid of the formation of bubbles: the structure of the material is such that it allows air to be removed through special channels in the adhesive layer.

Prepare all the necessary tools before you start pasting.

- Industrial or household hair dryer.

- Squeegee with felt or plastic cover.

- Scissors and a knife (preferably clerical).

- Degreaser (e.g. White Spirit).

- Soapy water solution.

- Spray.

- Soft, lint-free cloth or rags.

- Primer or sealant to secure the edges.

There are two main methods for wrapping a car with carbon film:

- dry;

- wet.

What is the difference between them?

Wet method

If you have never wrapped cars before, or if your film is not of the highest quality, you might want to choose the wet wrapping method. It is much lighter and gives guaranteed results. To cover the car with this method, carefully follow the sequence of steps.

- Measure your car and cut the material to the size you want.

- Make sure there is no dried dirt on the car. If necessary, wash and dry it first.

- Thoroughly degrease the surface to be glued.

- Using a spray bottle, apply the soapy solution evenly to the vehicle.

- Remove the backing paper from the film.

- Apply the solution evenly on the adhesive side of the film.

- Cover the car with foil. This is the most difficult step, so you may need help.

- Use a squeegee to smooth out the coatings. Your movements should go from the center to the edges of the car. In this case, the soapy solution will gradually come out.Never stretch the film! Be patient: the appearance of the car will depend on how well you complete this stage.

- After you have completely flattened the film on the surface, dry it with a hair dryer.

- Smooth out the coating again with a squeegee.

- If there is a lot of excess film left, carefully cut it off with a clerical knife, leaving 1.5–2 cm of reserve.

- Tuck the edges inward and apply a thin coat of primer. This will help prevent flaking of even the cheapest material.

- Leave the car to dry for a day.

For a week after pasting, do not use the services of contactless car washes.

Dry method

The main difference between the dry method and the wet method is the use of a stream of warm air to activate the adhesive layer. It is much more complicated and requires some experience and skill. In addition, this method is not suitable for vehicles with serious damage such as deep dents or corrosion. It is best to apply the pasting in a warm and well-lit room.

The first steps are similar to the previous method: take all the necessary measurements, thoroughly clean and degrease the car. We don't need a soapy solution. Apply the film to the surface and start smoothing with a squeegee and a blower from an industrial hair dryer

Proceed with caution: air bubbles will be very difficult to remove. To do this, you have to separate the material and smooth it again.

Repeating this step will ruin the adhesive layer.

Watch the temperature of the air flow: overheating negatively affects the condition of the film. Finish the process by re-leveling and applying primer.

What you need to know for self-pasting

Many car enthusiasts prefer not to contact the service for applying vinyl covering on the car, preferring to stick it with their own hands. This avoids unnecessary financial costs. In addition, in this case, you can be sure that the gluing was done correctly and in good faith.

When you have decided on the color and type of material, you need to calculate the amount that will be required to complete the work. Just in case, take with a small margin - it will be a shame if the film is not enough.

The coating is applied in a well-ventilated room with a temperature of at least 20 C. If this condition is neglected, the film will soon begin to peel off due to temperature deformations.

Before gluing the vinyl, the vehicle must be properly prepared. You will need to wash and dry it thoroughly. No scratches, chips, or foci of corrosion are allowed on the surface of the car body - otherwise, these places will cause premature peeling of vinyl. In order to properly glue vinyl, the surface must first be thoroughly degreased. For this, white spirit is used.

After all these operations, the car is ready for vinyl stickers - we can start working.

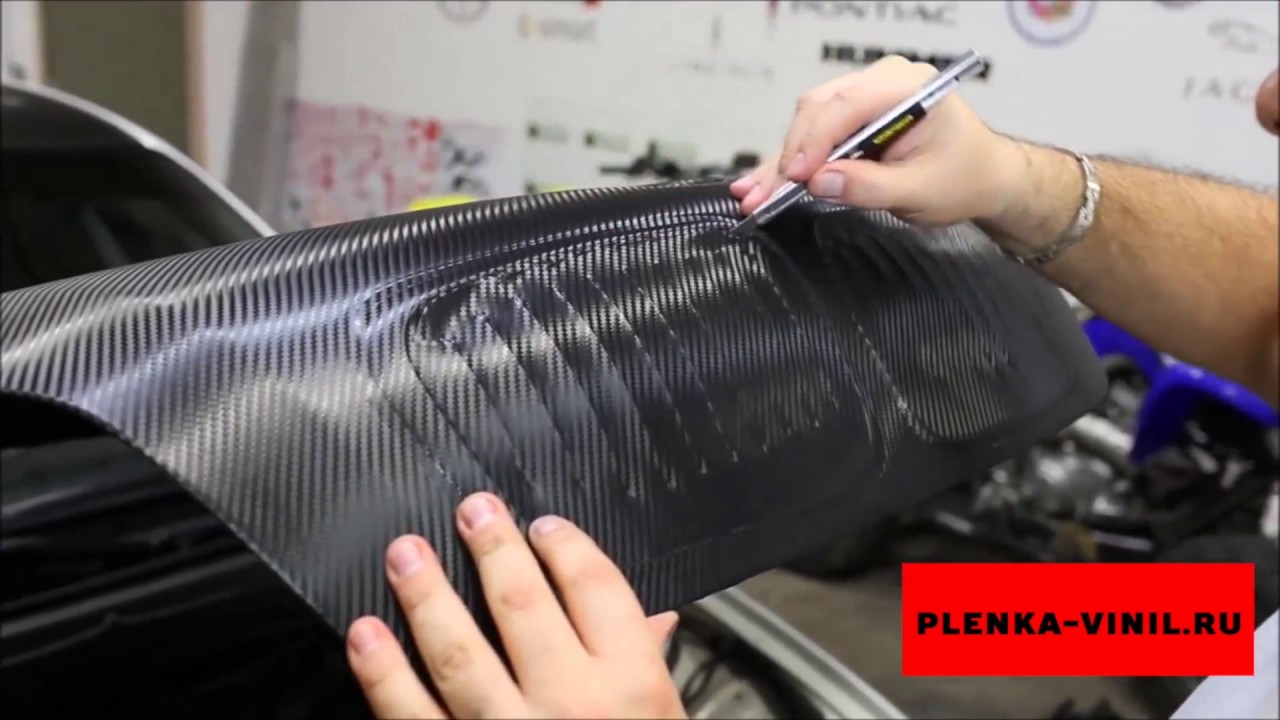

Air removal, correct turns, carbon

To avoid problems and poor-quality film application, it is recommended to wait until the material has cooled down after it has been applied to the surface. Having found air under the film, you need to carefully pierce the bubble with the tip of the blade along the surface and run your finger over the pasted material. The flaw will be invisible. Small bubbles dissolve on their own after a while.

Correct turns must be done while the vinyl is warming up. With the help of a professional hair dryer, the material is heated, stretched in the place of the curl and laid on the corner. The film must be pulled out so that it envelops the corners well. After completing the work, you should warm up the surface, wait until it cools down and only then cut off the excess material.

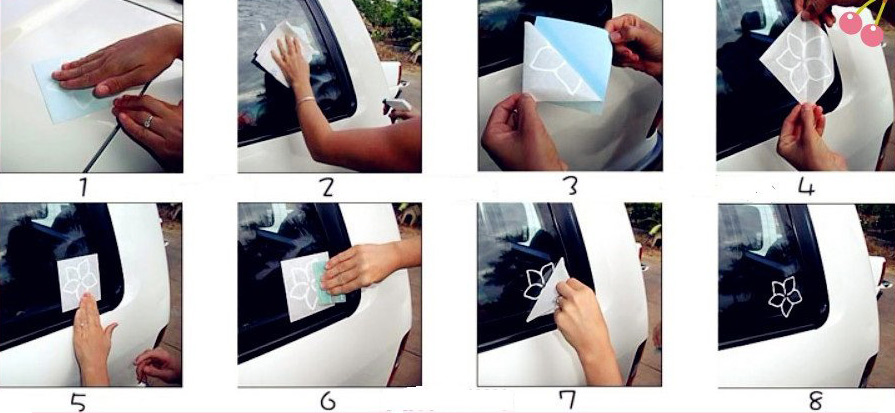

The carbon film is glued to a clean, grease-free surface.The material is attached to the surface with masking tape or magnets, after which a workpiece of the required size is cut out. It is recommended to leave 3-5 cm of stock. When removing the protective covering, it is necessary to slowly and carefully glue the material, starting from the center and moving to the edges. All work is done with a squeegee. Warm air will help fight bubbles and bumps. The edges are folded under the bumper and secured with heat-resistant glue.

We advise you to read our articles

Lada XRay will be equipped with a Jatco CVT

The main problems of the VAZ 1.6 engine

The easy way to increase engine power and reduce consumption

How to get rid of scratches on the plastic of a car?

Sticking vinyl on a car

Now let's take a step-by-step look at how a self-adhesive vinyl sticker is performed on a car:

- First, we try on. Without removing the backing, we try on vinyl on the surface on which we plan to glue. Using construction tape, we put all the necessary marks on the car. We measure the material and carry out cutting. It should be remembered that irregularities and difficult areas will require more material.

- Lay out the vinyl on a flat surface and carefully remove the backing. Care should be taken to ensure that no debris gets on the surface of the sticker or wrinkles form there. It is best to use the services of an assistant - this will greatly simplify the work.

- If you are a beginner and are not entirely sure that the decal will be done correctly the first time, you are better off using the wet method. Using a spray bottle, moisten the adhesive surface with soapy water and apply it to the place of fixation. This method allows you to correct the position of the film during operation. If you are sure that everything will work out right away, you can use the "dry" method - in this case, the surface of the sticker is not wetted.

- We put the vinyl on the surface to be pasted and smooth it by pressing it with a rubber squeegee. At the same time, we warm up and dry the film with a construction hairdryer. A regular household hair dryer will not work - it will not provide the required temperature. The gluing is carried out from the center to the edges. We expel air bubbles and moisture when it comes to the "wet" method. We make sure that the heating is carried out as evenly as possible.

- At the places of bends and corners, the material will have to be stretched more, so we pay special attention to the heating.

- After that, all the air from under the film is removed, we dry the surface with a hairdryer and leave for half an hour.

- Then we process it with a felt squeegee, removing small air bubbles and carefully smoothing it. Warm up the folds with a hairdryer, cut off the excess film with a construction knife and process the edges and joints with a sealant.

- We let it dry for about 12 hours and we can consider our task completed - the car is ready for use. It is not recommended to wash your car for 7 days.

Methods for pasting a car with vinyl film

For professionals, the dry method of pasting is definitely suitable. The work is done on the first try and is done very quickly. The quality of the coating is high, and the material will last for a long time.

Dry way of car wrapping

Technology for wrapping a car with a wet film

So, let's consider the procedure for pasting a car with a wet method in stages:

- Prepare the surface. In order for the material to be applied easily and, as a result, to match the tone of the car, it is necessary to clean the surface of the car by carefully polishing it, removing irregularities and degreasing. Next, the body is dried with a soft dry cloth.

- Lay the cover over the car body. It is recommended to start working in small areas with the smallest surface bend radius. This is necessary so that the film stretches over the surface, and does not shrink. At this stage, notes are made with scotch tape, and the required film size is determined.Before pasting, the surface must be sprayed with soapy water (detergent + water in a ratio of 1:10, respectively).

- Heat the vinyl. The heating temperature should not be more than 60 degrees, otherwise it can provoke damage or complete deformation of the film.

- Begin gluing the pieces. It is recommended to follow the principle of "one piece per body part". If it is not possible to glue the film in one piece, it is better to make a small overlap of one piece of material on another, in order to avoid the ingress of water and air in the future. You need to work with a squeegee from the middle to the edges, as when gluing wallpaper. The end of the hanging cloth must not stick together!

Technology for wrapping a car with a wet film

Air removal, correct turns, carbon

To avoid problems and poor-quality film application, it is recommended to wait until the material has cooled down after it has been applied to the surface. Having found air under the film, you need to carefully pierce the bubble with the tip of the blade along the surface and run your finger over the pasted material. The flaw will be invisible. Small bubbles dissolve on their own after a while.

Correct turns must be done while the vinyl is warming up. With the help of a professional hair dryer, the material is heated, stretched in the place of the curl and laid on the corner. The film must be pulled out so that it envelops the corners well. After completing the work, you should warm up the surface, wait until it cools down and only then cut off the excess material.

The carbon film is glued to a clean, grease-free surface. The material is attached to the surface with masking tape or magnets, after which a workpiece of the required size is cut out. It is recommended to leave 3-5 cm of stock. When removing the protective covering, it is necessary to slowly and carefully glue the material, starting from the center and moving to the edges. All work is done with a squeegee. Warm air will help fight bubbles and bumps. The edges are folded under the bumper and secured with heat-resistant glue.

Car wrapping with carbon film

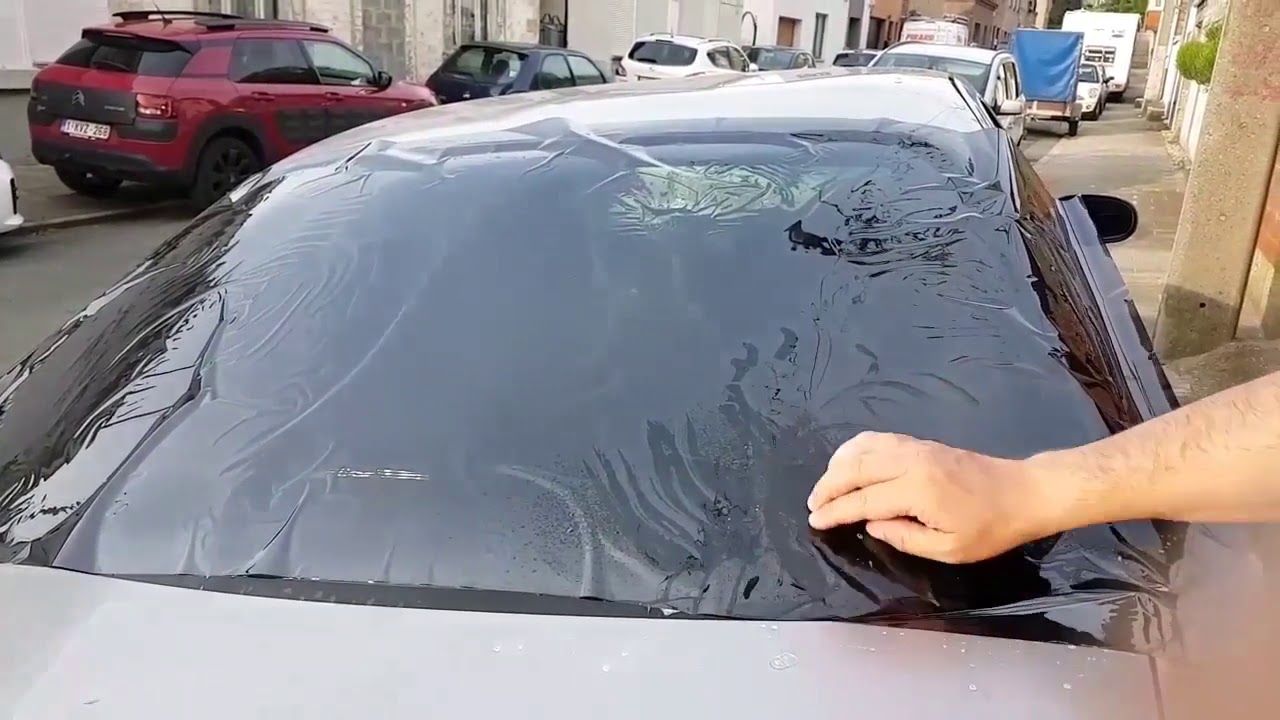

How to remove vinyl from a car

Like everything in our life, vinyl has an expiration date. To remove material from the surface of the car, the following recommendations must be followed:

- The car can be left in the sun or indoors where the temperature is over 20 degrees. Further, using a hair dryer, the surface is heated to 70-80 degrees.

- Coating is removed from edge to center at an acute angle.

- If after completing the procedure, there are still areas with a film on the surface, they are removed with alcohol or solvent.

The film removal procedure is quite simple, but at the same time painstaking and time-consuming. The work must be carried out carefully and without haste.

Expert advice

In order to increase the service life of the film, it is recommended to leave 2–3 cm of material so that it can be tucked over the edge of the element. When treating large areas, it is best to work in a warm place and not use the machine for 24 hours after the procedure. In the first days after processing, you should take care of the car, since the material is more susceptible to various influences. In order not to damage the surface with a squeegee, you can roll the air with your hands.

Pasting a car requires concentration, calmness and self-confidence. The right material will provide excellent coverage for the machine and will last for a long time.

Do-it-yourself car wrapping

To begin with, the car owner can apply the film in two ways: on dry and wet surfaces. The choice is up to the driver, but it is better to rely on your own accuracy and speed.

To achieve a good result, you should work with an assistant. The pasting process involves the implementation of the following rules and recommendations:

- Smooth material from flat surfaces, working towards the edge.

- In order for the film to fit perfectly on bends and grooves, it is made elastic by heating it to a certain temperature.

- Do not stretch the material too much.

- If air is found under the film, try to smooth the material with a squeegee.

Do-it-yourself car wrapping

Tools and materials for car wrapping with film

Car wrapping in a dry or wet way cannot be done without special materials and tools. For successful work, the master will need:

- car film;

- dry, soft, lint-free cloth;

- stationery knife and scissors;

- the hairdryer is professional, but the use of the usual one is also allowed;

- plastic or felt squeegee;

- a spray bottle with soapy water (surface treatment with clean water is difficult);

- masking tape;

- degreaser (white spirit is perfect).

If the film is very large, it is best to work with an assistant.

Felt squeegee

Which films are easier to glue

In the automotive market, the owner of the car can purchase cast or calendered film. It is believed that the first type is most suitable for vehicles, as it is perfectly applied to recesses and bends.

In addition to the type of film, the quality and technology of gluing depends on the method of application - dry or wet. The first method is considered difficult and the work should be done very quickly, since the film instantly adheres to the surface of the car, and errors cannot be eliminated. Despite this, the coating is applied in one go and lasts a long time.

Calculation of the film for pasting a car and its cost

Car wrapping requires careful preparation. Before starting work, you should calculate the amount of material. This must be done taking into account a number of factors, including the car model, the type of film, the level of knowledge and the qualifications of the master.

Car wrapping with foil

For small vehicles, it is recommended to purchase material that is at least 137 cm wide; for the rest of the car, 152 cm will be enough. To paste over the body of the sedan, the master will need about 17-19 m of film; for an SUV you will need at least 23-30 m; for station wagons and crossovers - 18-23 m.

Preparing the car for pasting with vinyl

For successful work, the surface of the car must be carefully prepared, namely: washed, cleaned and degreased. To wash the body, use a special shampoo or any detergent. Rubbing alcohol and thinner will help remove stains, insect marks and grains of sand adhering to the surface. A perfectly clean body can be obtained by polishing the car.

Finally, you can start marking the film. For the procedure, you will need a clerical knife and scissors. Having applied the material to the surface, it is necessary to mark the dimension line and make other necessary marks.

Preparing the car for pasting with vinyl

Primer, soap solution, cut

To prepare the soap solution, you will need detergent and water. Proportion 1:10. The detergent will ensure a comfortable application of the material. Pasting a car with vinyl film in car dealerships is done using a primer. The need to use it arises in hard-to-reach places where you need to stretch the material; along the edges of the part where the film is wrapped and in case the adhesive layer received the master's prints, deteriorating its properties.

Cutting the film begins with the front and rear bumpers. As a rule, bumpers are about three meters long. For accurate measurement of the wings and "skirt", a tape measure is ideal. You need to cut the film sparingly, using every centimeter. When cutting material for the arch, the leftovers can be folded or used on another surface, such as a threshold or mirrors. When cutting doors, it is recommended to make a small margin.

Conclusion

Compared to conventional painting, it gives a lot of advantages: a democratic price, additional body protection, a more effective appearance and the ability to get rid of the coating at any time. The modern market offers various types of materials - the choice depends on the tasks and the taste of the owner of the car.

Bold Gold Vinyl

Bold Gold Vinyl

An additional advantage of vinyl is that any car owner can stick it on their own, without resorting to the services of specialists from a car service. If you competently follow all the necessary requirements and carefully follow the instructions, the vinyl covering will serve you for a long time, and the design of the car has every chance of becoming effective and unique.