Operating instructions

The method of leveling walls and ceilings with plasterboard depends on the linear differences in height and width. If the difference does not exceed 3 centimeters, then the sheets are glued to special glue or foam. In other cases, markings are made and profiles for drywall are installed.

When installing sheets on a metal profile, an inter-wall gap is formed. The air space can be filled with polyurethane foam, which will create additional sound and heat insulation. For this, 9-12 holes are drilled in each sheet, the diameter coinciding with the size of the assembly gun barrel.

A small amount of the composition is introduced through the holes under the sheet. To prevent deformation of the covering material, it is additionally reinforced from the outside with a sheet of plywood, holding for 10-15 minutes until the foam completely expands. On smooth walls, the sheets are glued directly onto the mounting foam. Getting the job done requires skill and careful preparation. Glue-foam is applied in zigzag lines over the entire sheet area and immediately applied to the wall. It is pressed with effort and held in this position for 10-15 minutes.

Types, composition and characteristics

In accordance with accepted standards, all putties are divided into starting, finishing and universal. They differ in characteristics and properties, fillers and particle sizes. But in the composition of any product there are gypsum and polymer additives, due to which the putty dries quickly, the treated surface is durable and smooth. Often such substances are called gypsum polymers, they give the coating:

- plastic;

- elasticity;

- bending strength;

- resistance to cracking.

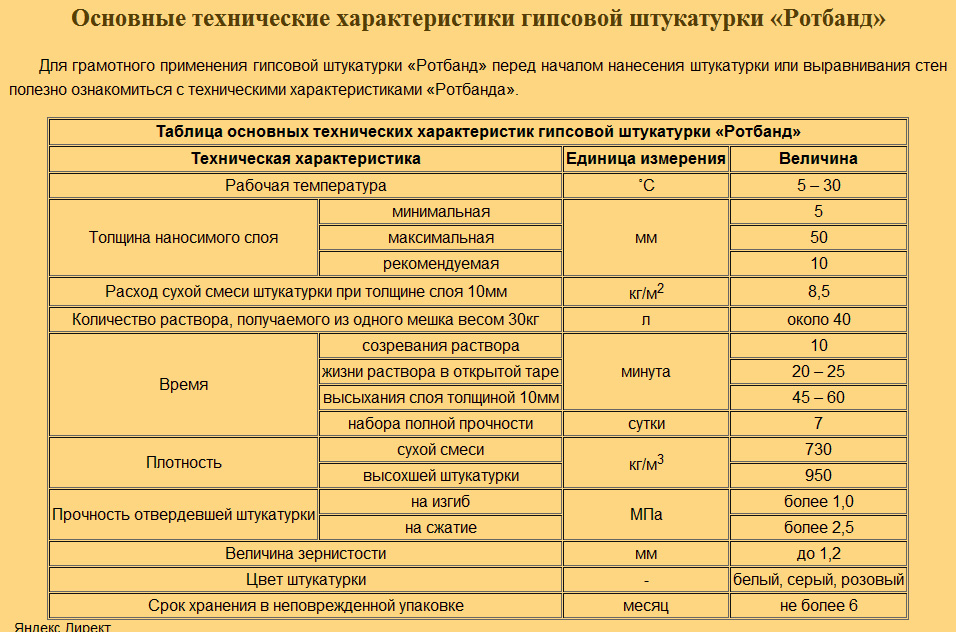

Usually, putties are produced in packages of 5-50 kg, less often you can find cans and buckets with a ready-made mass (diluted with water) of 5, 10, 20 liters. Most putties are white, but there are also grayish ones, the most expensive are snow-white. The characteristics of the funds differ depending on their type and manufacturer. The average technical indicators of materials are as follows:

- operating temperature range - from +5 to +30 degrees;

- total layer thickness without the use of reinforcing mesh, tape - 10 mm;

- correct dilution: for 1 part of dry powder - 0.5 part of water;

- setting time - 1 hour;

- complete drying time - 5 hours or more;

- final strength gain time - 7 days;

- consumption - 1-1.4 kg / 1 m2.

How long the solution dries, its consumption and other technical information should be specified on the package.

Starter putty

Such material is often referred to as plaster mixes. Its main purpose is leveling walls and ceilings, sealing large defects, eliminating serious level drops, fixing devices for socket outlets. Usually, the plaster is leveled and smoothed with starting putty, and in new houses it is used as the first layer or after the primer.

To save money, you can buy a basic gray mixture, it is much cheaper. It is necessary to apply the product in a not very thick layer, and in case of significant differences, apply reinforcing coatings. Without the latter, the layer of dried material will simply fall off. The most serious pits, defects, it is better to completely seal up with cement plasters.

Finishing putty

Such a composition helps to form a smooth surface for a fine finish. Typically, finishing putties are applied in 1 layer, creating a smooth white finish. It can be pasted over with wallpaper, painted, and even in light colors. In appearance, the finish coat differs from the starting one in greater smoothness (due to the absence of large particles) and whiteness.

Universal putty

There are also universal putties (start-finish) with unique properties. They can be applied in thick layers with a minimum particle size.The scope of application is wide - sealing joints on drywall, eliminating cracks and deformations, leveling any foundations. Such products have a snow-white shade and do not require the application of a finishing putty.

Features of GKLV installation

Moisture-resistant drywall is mounted in two ways: on a frame or glue solution. The first method involves the construction of a lathing from metal profiles on the rough surface.

The use of adhesive solution also has certain limitations. Do not use water-based formulations. In addition, the rough surface for mounting drywall sheets must be flat and clean.

Drywall, which is also called dry plaster, has become incredibly widespread for interior decoration. They align walls, slopes and ceilings, and soundproof partitions, arches, niches are built from it.

Therefore, it will not be superfluous to talk about the pros and cons of drywall and find out if there are any restrictions on its use.

Plasterboard constructions

It is clear that even the highest quality materials have not only advantages, but also some disadvantages. And in order to understand whether they are suitable for the implementation of a particular design idea, you need to know which ones.

Features and purpose of gypsum putty

Gypsum plaster (putty) is understood as a dry or ready-made (pasty) mixture based on gypsum. Usually, snow-white gypsum is used to develop more expensive products, and yellowish for those that are cheaper. The materials also include modifying additives of various water-soluble polymers, mineral fillers. As the latter, white quartz sand or mineral flour and other components are used. Polymers provide protection against premature drying, cracking and shedding of the material.

The size of the additive fraction determines the properties of the putty and the type of use. The smaller the fraction, the thinner the finished layer will be when applied to the base. Usually the lightest, weightless putties are made on the basis of very fine marble flour (particle size - tenths of a millimeter). A good putty allows you to wipe the surface to a shine, make it very smooth, while using less material.

Scope of application

Most products can only be applied to walls and ceilings indoors. Only mixed materials (with acrylic, latex) are able to withstand the action of aggressive environmental factors, therefore they are used outside houses. Usually, the walls are leveled with gypsum putties for subsequent finishing - for painting and wallpapering. Due to its excellent adhesion, the putty can be used for:

- sealing ceiling, wall joints;

- grouting of various defects and errors;

- filling holes and cracks;

- sealing joints between drywall sheets;

- elimination of chips.

After using the gypsum putty, any surface will become even, smooth to the touch and look. You can also make panels, stucco moldings, interior decorations from this mixture. But we must remember that it is incompatible with chipboard, stone and brick. OSB board (OSB) can be processed with this putty, but only after preliminary preparation and thorough priming. Also, you cannot use a gypsum-based building mixture in a bathroom, sauna, pool - the finish will absorb moisture and quickly lose strength.

Advantages and disadvantages

What material is better to use for leveling and how the gypsum mixture stands out favorably among analogues - we will consider further.

Comparing polymer acrylic putty with gypsum putty, you can find a lot in common. Both are:

- designed for sealing cracks, seams, effectively leveling even difficult surfaces;

- easy to apply, perfectly leveled;

- have elastic texture, white color.

And yet there is a difference. Gypsum material, unlike polymer material, is vapor-permeable.It does not disturb the microclimate in the room, does not provoke the appearance of fungus. Acrylic and latex are less air-permeable, more resistant to moisture, therefore they are often recommended for outdoor use, facade work. Some polymer putties contain artificial ingredients, while gypsum is almost 100% natural.

Other advantages of gypsum material are as follows:

- favorable price, economical consumption (1 m2);

- environmental friendliness, does not emit toxins;

- the ability to apply on different surfaces, excellent compatibility with other putties in the second layer (even based on cement);

- high adhesion rates;

- lack of delamination, cracking, shedding, shrinkage after drying for a long period;

- ease of puttying and subsequent sanding;

- the strength of the finished layer;

- aesthetic appearance.

The material has few minuses, but they are. The product must be diluted correctly, otherwise there is a high risk of lumps and damage to the entire mass. The finished solution does not cost a long time - it must be applied quickly, until it hardens, it will not be possible to dilute the product again. The storage period of dry mix usually does not exceed 6-12 months, while polymer putties are stored for several years.

Also a big disadvantage is its high hygroscopicity. It is impossible to use the material in humid rooms, with regular temperature drops. It is better to use plaster on plaster in the living room, bedroom, study, office and other rooms with normal and low humidity.

Pros and cons of glue mounting

Application of glue to drywall is done pointwise on all surfaces of drywall sheets

When laying with your own hands in this way, you can achieve savings, since you do not have to spend money on metal or wooden profiles, fasteners. Also, there is no need for preliminary assembly of the frame, setting verticality. It is enough to mark the wall, cut the sheets and mix the glue. There is one more, decisive plus: such a wall is more reliable due to the fact that there are no cavities in it, cracking at the joints is quite rare.

The use of the adhesive method for laying drywall has not only advantages, but also disadvantages. The frameless method is good to use if the surface is relatively flat, but what to do when the ceiling is completely crooked, which is not uncommon in apartment buildings?

In this case, all that remains is the use of beacons or preliminary alignment, and this is a large consumption of materials and a rather laborious work, not everyone can do it with their own hands. The frameless glue method is good for relatively flat walls and ceilings. Of the minuses, it should be noted that carrying out communications under the surface and additional insulation is much more difficult. For cables, you will have to groove the walls, and the insulation will take up a certain place, and it is best to use polystyrene, which not everyone prefers.

Hand kneading technology

You can get a high-quality plaster cast only if you follow the mixing sequence:

- Distilled water is poured into a special bowl, the amount of which is determined by the class of powder.

- Gypsum powder is slowly poured into the liquid. According to standards, it should take about 10 seconds from the beginning of contact of the first particles with water until the end of falling asleep.

- After that, you should wait until the particles are completely submerged in the water and only then start mixing with a metal or plastic spatula.

- Movements should be as vigorous as possible. The consistency of a full-fledged mixture is creamy, homogeneous.

If too much water is added, the gypsum will only absorb the amount it needs. Residual water will quickly loosen the structure of the material and reduce the accuracy of the impression. Adding less liquid than required by the technology for producing the mixture would be not the best solution.Thick gypsum does not make it possible to obtain an accurate imprint due to the formation of air bubbles, which simply do not have time to come to the surface due to too fast solidification.

Taking an impression of the upper jaw on video:

PVA glue: decoding and composition

PVA glue is a product of the chemical industry with excellent adhesive properties. The decoding of the abbreviation is simple: the letters denote the active substance - polyvinyl acetate, its composition is about 95%. The remaining glue formula looks different depending on the specific type of product. The composition may include:

- DOS (stands for dioctyl sebacate);

- dibutyl phthalate;

- other plasticizers;

- tricresyl phosphate;

- acetone;

- esters;

- stabilizing additives;

- preservatives;

- water.

Some people try to make PVA with their own hands, using recipes based on flour, starch. In fact, these substances have nothing to do with the real glue base. Polyvinyl acetate is obtained by polymerizing vinyl acetate monomer. The finished substance cannot be dissolved in water - it only swells, it behaves similarly in oil solutions. PVA is resistant to temperature extremes, inert to the action of the air environment, non-toxic, not harmful to humans.

According to GOST, glue based on polyvinyl acetate must meet the following requirements:

- the absence of a pronounced or unpleasant odor (this indicates a fake or expired glue);

- type - a homogeneous milky-white mixture, sometimes beige or slightly yellowish;

- the glue line becomes a viscous translucent film after drying;

- the strength and elasticity of the seam are at a high level.

Depending on the needs of the user, the properties of the glue can be changed by adding other substances to its formula. For example, some construction PVA consists not only of polyvinyl acetate and plasticizers - kaolin, talc, chalk help to thicken the solution. To increase the water resistance, gasoline is introduced into the composition; to increase the elasticity, PVA is made with the addition of oils, glycerin, but this reduces the strength characteristics. Other possible additives to the glue composition:

- defoamers;

- cellulose;

- metal chips;

- glass chips;

- nitro compounds;

- styrene;

- polysilicates of sodium, lithium, potassium.

Manufacturers of solid PVA adhesives in the form of pencils have to replace polyvinyl acetate with PVP (it can be deciphered as polyvinylpyrrolidone) or two components are combined. The specified substance is thicker and has high adhesive properties.

How to work with him

Starting to work with "Perlfix", it is necessary to determine the amount of work, the area of the working surface and how much material will be consumed for a given area. The unevenness of the walls of the room and the thickness of the application of the material will determine the consumption of Perlfix drywall glue.

Installation of drywall on "Perlfix" takes place in several steps:

- The first step in the upcoming work will be to clean the walls of dirt, old coating, loose plaster and other contaminants that can impair the adhesion of surfaces. If the surface is very dirty, then it is worth washing it;

- The next step is to paint the walls. The primer is carried out with special means that prevent the appearance of water, condensation, mold, mildew and the destruction of the coating by harmful microorganisms. Surfaces that strongly absorb moisture must be primed with a specially designed product. After the primer has been applied, let it dry. It is worth making sure that dust does not accumulate on the dried surface;

-

Next, you should prepare a solution of Knauf Perlfix assembly glue in accordance with the instructions on the package. The glue should be mixed in small portions in order to avoid unnecessary consumption and premature solidification of the ready-made mixture. Dry glue is gradually added to water and thoroughly mixed with a construction mixer or a drill with a special nozzle, at low speed, until the mixture turns into a paste.It is necessary to ensure that no clots form in the mixture, since this will greatly interfere with further work. Do not add or add other substances to the finished mixture. The period of use of the finished material will be significantly reduced if the working tools and containers are dirty;

- You need to glue drywall to the wall as follows. The finished solution is dotted on the prepared sheets so that it is distributed along the midline of the sheet with an interval of 3-5 cm. And for sheets with a thickness of more than 10 mm, "Perlfix" should be applied in two rows and around the entire perimeter at a short distance. One of the basic rules of this stage is not to overdo it, since drywall itself is fragile and can crack. If there are irregularities or small pits on the wall, then they can be corrected using this mixture, namely by applying another layer of glue to the problem area. It is worth remembering that during the use of the mixture, it is prohibited to add dry mixture or water to it. And after the work with the glue is completed, the working tools should be washed with clean water;

- It is necessary to leave the walls without extraneous external influences for 7 days, for the glue to dry. In this case, you can deal with the finishing of other surfaces in the room.

Main manufacturers

Today there are many adhesives that are based on gypsum. It is worth highlighting a number of popular companies that offer quality products.

Knauf

The product of this company is sold in packages of 30 kilograms. The substance is considered to be very reliable and has an optimal price-performance ratio. That is why the adhesives of the German brand have been popular for many years.

Volma

This domestic manufacturer produces gypsum glue in accordance with a unique technology. The composition of the brand is often used by builders, calling it one of the highest quality. In addition to excellent properties, users note the convenient packaging of the product.

Usually such glue is sold in packages of 30 kilograms, while Volma offers 10 kilogram packages. In addition, the price of the products of the Russian brand is significantly lower than the imported counterparts, and the quality is at a high level.

Gypsum polymer

This manufacturer is a partner of the German brand Knauf, which offers ingredients for the manufacture of gypsum substance. The cost of gypsum polymer products is much lower than analogues, but this in no way affects the quality of the product.

Magma

This company was established in 2005. Every year she only gets stronger in her leadership positions. The production of dry mixes is carried out using German equipment. At the same time, foreign technologies and recipes are used. The cost of glue remains fairly affordable.

Manufacturers

Many sites can produce gypsum assembly glue - almost every region has its own local manufacturer. In addition to local players, there are, of course, federal leaders.

Knauf

KNAUF PEARLFIX gypsum assembly glue in a weight of 30 kg is the most popular product among gypsum adhesives. A verified formula, German quality of production, wholesale supplies and a presence in almost every large store of building materials - if gypsum glue is used, then most likely it is KNAUF PEARLFIX for installation work.

The disadvantages include two factors:

- High cost - you have to pay for a brand and an advanced formula, and the price of knauf perlfix assembly glue is 300-330 rubles in the regions. for a package of 30 kg;

- Unstable quality - at the moment, KNAUF has 10 production facilities, including gypsum assembly glue, and due to the large mass of goods in each region, bags from the nearest production are sold. Some of them have negative reviews.

KNAUF PEARLFIX remains the leader in gypsum assembly adhesives and is the benchmark for alternatives.

VOLMA

The closest competitor of KNAUF PERLFIX is VOLMA-Montage.Similar to the German competitor, glue from the Volgograd company is used in the technology of laying VOLMA tongue-and-groove plates. The GWP technology and the corresponding glue are the core of the business of the Russian company.

VOLMA has an excellent reputation among builders, many use both boards and mixtures of this company. In addition, VOLMA-Montage gypsum glue is packed in packages of 5 kg and 10 kg. However, such scales are not easy to find in stores - builders do not need them, and private traders rarely buy glue. During the search for glue for myself, I visited three representatives of VOLMA and no one had packages less than 30 kg.

The advantages of VOLM are the quality comparable to Knauf and a slightly lower price - in the region a thirty-kilogram package of glue costs 280-290 rubles.

Gypsum polymer

Perm manufacturer, representative of a number of local players - in every region there is, and more than one, local manufacturer of building mixtures. The Gipsopolimer plant is located in Perm and has been cooperating with Knauf for a long time - for the same Perlgips gypsum assembly glue, the Germans supply plasticizers that make glue from gypsum. By the way, since the beginning of the 2000s, the German corporation has been trying in various ways to include Gipspolimer in the number of its subsidiaries, but so far the Perm people have managed to remain independent.

Actually, "Perlgips" (unobtrusive association with competitors) became my choice for buying gypsum glue - the cheapest on the market, 250-260 rubles. for 30 kg, the local manufacturer has won the competition for the unassuming DIY customer.

Additional tips and tricks

KN-2 rubber mastic is produced as a ready-to-use dark mass. The surface to which the glue is applied is first thoroughly cleaned of dirt and leveled. True, minor defects can not be eliminated. The elastic mass will penetrate into any crevices and level the base on its own. To save glue, it is better to treat the surface with a primer before applying the substance.

This adhesive is based on a high rubber content. Due to this feature, KN-2 can be used for gluing rubber products. Typically, this mastic is used to securely fix linoleum or rubber-based carpet to the floor. You should always remember that the KN-2 glue contains a solvent. It is advisable to wait 15 minutes after applying the mass to the surface. During this time, the toxic vapors of the solvent will have time to evaporate. After application to the surface, the glue hardens after 7 hours. True, for the mass to dry completely, you need to wait 24-72 hours.

A rubber-based product of the KN-2 brand is used simultaneously for gluing materials and providing waterproofing. When hardened, this substance becomes similar to rubber. The adhesive can be used as a cushioning material.

All cracks and places where the adhesive penetrates are protected from moisture penetration. The viscous mass penetrates into any pores. After drying, it hardens and does not change its properties either under the influence of moisture or as a result of a sharp increase or decrease in temperature.

It is a universal product for gluing various materials and protecting the premises from water penetration. The mastic can be used at any stage of construction and repair work. Toxic substances evaporate a few hours after the application of KN-2. True, this glue is undesirable to use in the kitchen or for gluing kitchen items.

Share link:

Scope of use

The tool is most widely used in children's art. PVA is very popular in schools, kindergartens, circles, developing studios. The child does not need special clothing to work with it. You can remove stains in a regular washing machine. The glue will easily hold together paper, cardboard, threads, fabric, etc. When mixed with gouache, glue is painted on canvas, because such paint will be resistant, will not fade.

PVA is used in construction work: from gluing wallpaper to installing parquet, laminate, tiles. The adhesive is suitable for impregnating wood to make it water-repellent. When 5-10% PVA is added to a conventional cement mortar, the ability of the latter to waterproof significantly increases, as does plasticity, adhesion to the base. Add 70 g of PVA per 10 liters of the bulk to the plaster. This helps to dry the coating quickly and also allows the mortar to adhere better to the wall.