Types of sealants: what is the best way to glue the glass on the headlight?

With the help of a sealant, glass is attached to the headlight, and the sealant should not allow moisture or air to pass through, so that condensation does not appear from the inside of the headlight, which will worsen the appearance and quality of light.

A wide range of sealants are now available commercially. In order to seal the headlamp, one-component sealants are usually used. But there are different packaging options: tubes, bottles and even roll tapes. Removable dispensers are installed in liquid sealants.

there are also pasty compositions, as a rule, they must be diluted with a special substance that usually comes in the kit.

Sealants are: anaerobic, silicone, heat resistant and polyurethane.

Main varieties

Understanding which sealant is best for a car engine, you need to know that among all sealing compounds, substances for internal combustion engines occupy a special group. Such specialized tools can maintain the declared characteristics under severe operating conditions, namely, with large temperature drops and high pressure.

Anaerobic sealant

A similar product has received wide

spread relatively recently. This type of sealant differs in that

hardens after contact with metal. Therefore, it is used to provide

high-quality connection of car engine elements.

Anaerobic sealants harden in about half an hour, but only when certain conditions are met. After obtaining the desired shape, the sealant retains its elasticity for a long time, providing a reliable and durable connection of the steel parts of the internal combustion engine.

Example of aerobic sealants

Example of aerobic sealants

The special chemical formula of the considered

means provides softness and pliability of the sealant under the influence

oxygen. Therefore, you can work with it slowly, which allows you to accurately and

precisely apply the compound on the surface of the parts to be joined.

The disadvantages of anaerobic sealants

is their exactingness to the quality of the mating surfaces. They must

be perfectly even, without flaws. In addition, moisture and dust can negatively

affect the quality of the finished seal, and therefore such substances

must be applied to well prepared parts, and only directly

before assembling them.

Silicone sealant

Sealing compounds created on

based on silicone, have been used for the repair of internal combustion engines for a long time. If you compare them with

analogues of other types, they are the most popular and demanded.

Such sealants freely fill small cavities (up to 6 mm), and the finished joint demonstrates the preservation of its original properties and elasticity for a rather long time. Silicone sealants are perfectly adapted for operation at elevated pressures, and therefore are ideal for forced power units.

Example of silicone sealants

Example of silicone sealants

Work with silicone-based formulations

even an unprepared person is capable. Such sealants do not need

specific knowledge and skills of the employee. Other advantages include:

- the ability to solve a variety of tasks;

- no difficulties in application;

- low requirements for the quality of surfaces;

- the ability to fill irregularities and imperfections

planes; - good elasticity and strength of the finished seam.

On contact with water and / or air

the silicone sealant hardens. After applying the composition to the surface,

wait 5-10 minutes before connecting parts.

Repair

internal combustion engine sealants

In addition to anaerobic and silicone sealants, there are synthetic resin-based compounds on the market. They are much less often used in the repair of automobile engines, and are more focused on solving everyday problems.

Example of an engine repair sealant

We also recall the sealants that

are introduced directly into the engine systems (oil, cooling, etc.).

They belong to a separate group, and are applied when specific

malfunctions. For example, such substances can provide effective assistance in

solving the issue of a leak in the oil system of an internal combustion engine or to facilitate the search for a source

leaks. To do this, it is enough to pour the substance into the engine oil.

Advantages and Disadvantages of Anaerobic Compound for Engine Repair

When repairing an engine using automotive sealant, the following advantages are distinguished:

- The flexibility of the seam has a positive effect on the quality and reliability of the joint.

- The presence of oxygen leaves in a soft state, which allows you to slowly carry out assembly and adjustment.

- Provides adhesion when there is a lack of air.

- A reliable homogeneous shell is formed on the motor elements.

- High temperature.

Disadvantages:

- With a thick layer, it is difficult to block the complete access of oxygen, so its thickness does not exceed 0.5 mm.

- Increased pressure on the joint will cause it to collapse.

- A neat, even application is required. Since air will seep onto the uneven part, and the sealant will remain in its original state.

- Complete cleaning of the surface is required before application, otherwise the ingress of debris will lead to partial sealing.

- For the engine sump, the application takes place just before the assembly itself.

Therefore, for the first time, the use of an anaerobic composition is carried out with extreme caution in order to avoid certain difficulties.

Removal methods

There are several common sealant removal methods that you need to familiarize yourself with in advance.

Warming up with a hairdryer

A powerful hair dryer is considered an effective method of removing silicone residues. This tool is used to warm up the applied adhesive to soften it and wipe it off gently with a cloth. It is necessary to use the hairdryer carefully so as not to accidentally damage the coating and not cause mechanical damage to it.

With a knife or screwdriver

Sometimes people do not have a hair dryer on hand and have to remove glue residues by other means. To do this, you can use a screwdriver or a kitchen knife. These tools can scratch the surface to be cleaned and must therefore be used with care. Only thick layers of sealant are removed with screwdrivers and knives.

Solvent use

People who do not want to use a hairdryer, screwdrivers and knives use special solvents to remove traces of sealant. Such formulations are very effective, since after using them, the silicone begins to corrode. Do not use too much solvent as it can damage the surface.

Using a body degreaser

If you need to get rid of the remaining adhesive from the plastic surface, you can use a car body degreaser. However, before this, the surface is treated with a solvent in order to soften the composition slightly. If the degreaser does not work, you will have to use a mechanical removal method.

White spirit, nephras, solvent

Silicone sealant can be removed with solvent, nefras or white spirit. To get rid of traces of glue, moisten a cloth with detergent and then wipe the surface with it. After 2-3 minutes after that, the remnants of the product must be wiped off with a dry cloth or washed off with warm water.

Alcohols

To get rid of traces of adhesive with alcohol, do the following:

- apply an alcohol solution to the surface;

- leave the alcohol for 10-15 minutes;

- peel off the softened adhesive with a knife;

- wipe off the rest of the product with a damp sponge.

Sealant selection criteria

When choosing a sealant, attention should be paid to ensure that its technical characteristics correspond to the features of the operation of parts. During operation, vehicle units may heat up or be subjected to various kinds of loads.

Therefore, the properties of active substances in the composition of the product are considered important parameters for choosing a sealant:

During operation, vehicle units can heat up or be subjected to various kinds of loads. Therefore, the properties of active substances in the composition of the product are considered important parameters for choosing a sealant:

- viscosity level;

- heat resistance;

- the degree of resistance to high pressure and vibration loads;

- elasticity after hardening;

- durability of the resulting compound.

The presence of a dispenser and the need for a sealant gun also play a role in the choice of sealant.

In addition, motorists attach great importance to how much the product dries. For example, anaerobic compounds polymerize only when they are not exposed to oxygen. This means that the driver has time to calmly and without haste to apply the agent to the surface of the parts and connect them, without fear that the substance will solidify ahead of time.

Silicone sealants harden within 10 minutes, but do not require special application accuracy, so they can be used even by inexperienced drivers.

On the other hand, the use of silicone products is appropriate when filling deep gaps, while anaerobic compounds are able to fill irregularities no more than 0.5 cm deep.

You should not buy large amounts of the product - during storage, polymer substances lose their properties, which excludes the possibility of reuse.

Detailed recommendations on the use of seals, as well as information on how long the sealant dries, can be found in the instructions supplied by the manufacturer.

Application rules

The following recommendations of specialists with extensive experience will help to use modern sealing compounds as efficiently and competently as possible:

- The mating surfaces of the parts should be thoroughly cleaned, dried and degreased with a solvent or gasoline.

- Old seals must be removed carefully and without the use of abrasives, so as not to damage the surface.

- When applying sealant, it is necessary to control that the line is closed, and the layer does not exceed one millimeter. Tears can cause a lack of tightness, and the excess agent after squeezing out can clog the interior.

- The sealant must be allowed time to dry. Therefore, before connecting the parts, you should wait 10-15 minutes. Also, do not pinch the joints, tightening the fastening bolts as much as possible.

- The sealant must be completely cured before using the engine. The time and conditions required for this are highly individual. This data can be found on the original packaging or in the instructions.

Rating of the best sealants

To work with automotive optics, you need to purchase high-quality tools so as not to know problems with the functioning of lighting devices.

ABRO WS 904

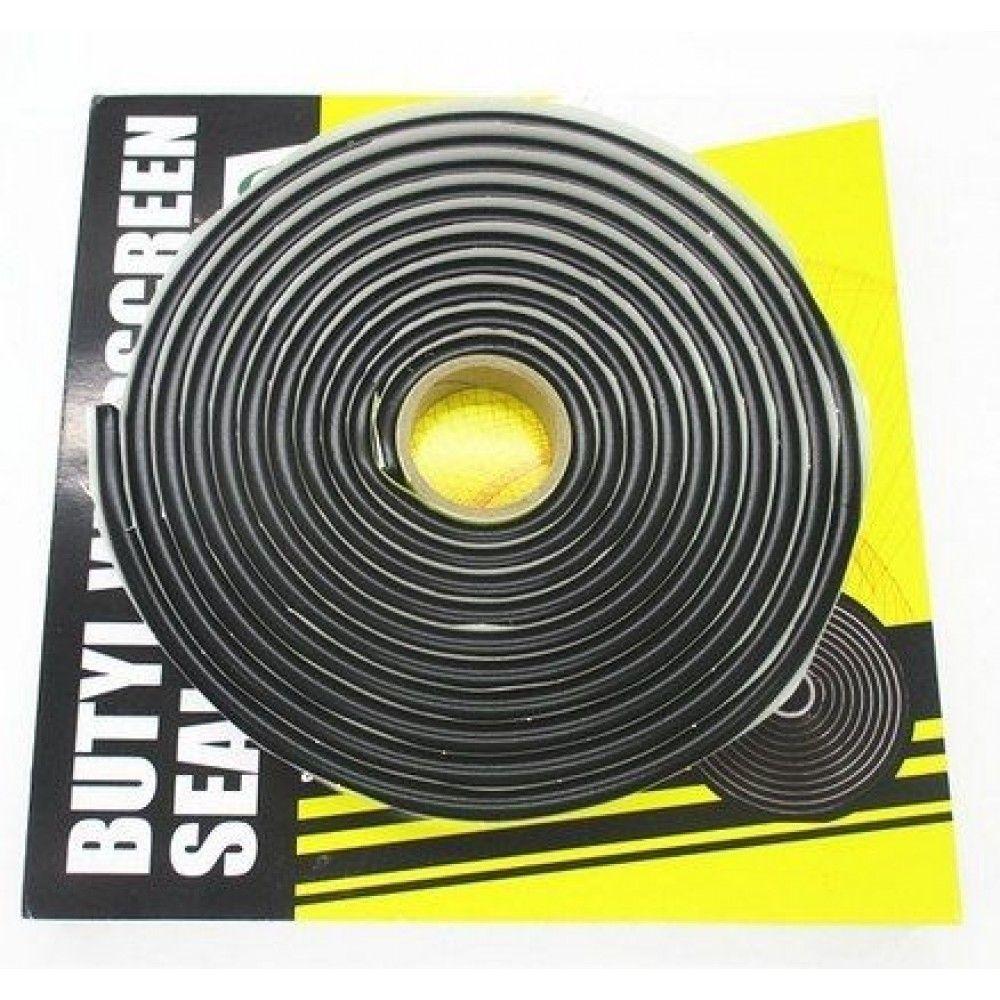

Sealant ABRO WS 904 - one of the most popular on the request of users. It is realized in the form of adhesive tape in rolls of different sizes, made on the basis of vulcanized polyisobutylene - a derivative of artificial rubber.

This butyl headlight sealant is highly flexible and easy to use - you just need to cut a piece of tape to the desired size, stretch and stick to the surface. A few seconds are enough to connect the ends of the tape to each other - the polymerization process takes place quickly. At low ambient temperatures, it is recommended to additionally warm up the sealant with a building hair dryer.

The advantages of the ABRO WS 904 tape are as follows:

- low consumption - there is enough packaging to completely seal the set of headlights;

- ease of installation - the tape does not stick to your hands, is pliable, easily cut off, stretched to achieve the desired thickness without effort;

- high degree of adhesion to most materials;

- lack of toxic secretions and unpleasant odor;

- strength, long service life after hardening, reliability and complete tightness of the seams.

Dow Corning 7091

It is recommended to purchase this sealant when working with dissimilar materials that have unequal coefficients of thermal expansion. It is able to create high-quality joints at the junctions of glass to metal, glass to plastic, metal to plastic, therefore it is perfect for the installation and repair of automotive optics.

Dow Corning 7091 Silicone Sealant is a one-pack, ready-to-use product that combines high strength with flexibility. The sealant is suitable not only for working with car headlights, but also for installing LED lamps, various electronic devices and complex mechanisms. After polymerization, the formed seam will reliably seal the joint, while it does not collapse from temperature extremes and can be operated at -55 ... + 185 degrees. The sealant is easy to post-process if required and is a good dielectric.

DoneDeal DD6870

DoneDeal DD6870 composition refers to polyurethane sealants, includes urethane groups, refined petroleum products, various polymers, adhesion promoters and other additives.

It can be used for installation and sealing purposes:

- headlights;

- glasses;

- lanterns;

- lamps;

- hatches;

- instead of gaskets.

The sealant dries completely within 15–30 minutes after application, has a high strength of seams, good adhesion to most materials, does not crack under the influence of vibration or shock. The product is characterized by moisture resistance, works without loss of properties in the temperature range from -60 to +270 degrees.

3M PU 590

Sealant 3M PU 590 is produced in the USA, has a polyurethane base, is packed in convenient tubes of 300-600 g. It does not tolerate a strong rise in temperatures (it can withstand up to +100 degrees), therefore it is not used on heated vehicle parts. The product polymerizes quickly (in 25–30 minutes), does not react to the action of acids, alkalis, solvents, is resistant to moisture and UV radiation, reliably connects even dissimilar materials. Once cured, the sealed joint can be painted over with most car paints.

Emfimastic PB

This brand of adhesive sealant is produced in France, contains polyurethane groups and various additives. Efirmastika glues homogeneous and dissimilar materials as reliably as possible, ideal for the installation and repair of automotive optics. The composition is odorless, hardens in half an hour, does not shrink, does not crack over time. It is not harmful to humans, does not have an unpleasant odor, and can even be used indoors. A hand or air gun is required to apply this elastic sealant.

Review of popular sealants

The modern market offers a wide range of sealants for gluing headlamp glass, but not all of them are of high quality and reliability. We have compiled for you a list of proven compounds that have the necessary characteristics and are time-tested.

- ABRO WS-904 is considered a favorite in the market. The composition is sold in the form of a tape rolled into a roll. This sealant has excellent adhesive properties, dries instantly, holds its shape, does not stick to hands and is generally easy to use. The market value of ABRO WS-904 varies from 400 to 700 rubles per roll. One roll is enough for 2 sets of headlights.

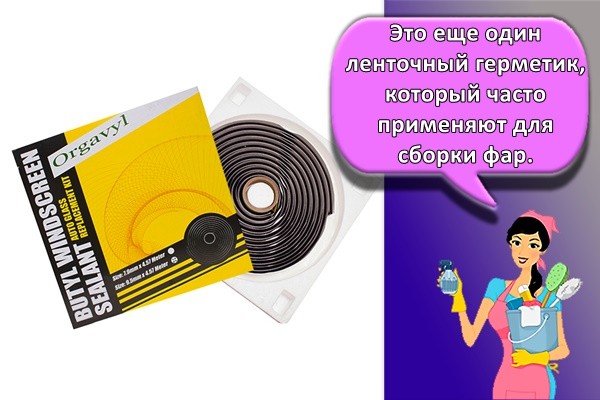

- Orgavyl. Butyl sealant for the assembly of American-made car headlights is an analogue of the Abro tape and has similar properties, but it will cost the car enthusiast 200-400 rubles more.

- Dow Corning 7091 is a one-component silicone sealant.The material is suitable for bonding glass to both plastic and metal. The composition has a high degree of elasticity and strength, quickly hardens and is easy to use. Car enthusiasts especially appreciate it for its resistance to high and low temperatures (from -55 to +185 ° C). The manufacturer offers three colors of the composition (black, white and gray) and several packaging options - 310 ml, 20 l and 250 kg, the last two options are more suitable for car services and repair shops. A small tube will cost around 800-850 rubles.

- Efimastica PB (Emfimastic PB) - French-made one-component polyurethane-based adhesive sealant. Provides strong adhesion, holds its shape well and does not smell. The composition hardens within 30 minutes. Packaged in tubes of 300 and 600 g, a small tube will cost about 500 rubles. To work, you will need to additionally purchase a pneumatic or manual gun, as well as thoroughly clean and degrease the surfaces.

-

3M PU 590 - polyurethane adhesive sealant, which is produced in the USA and specializes in gluing glass on vehicles. The composition glues any surfaces and hardens in 25-40 minutes. In addition, it can be painted in any color. The disadvantages of the composition include its instability to high temperatures (over 100 ° C).

Packaged in tubes of 300 and 600 grams, a three-hundred-gram tube will cost 450-550 rubles.

- DoneDeal - transparent silicone sealant from an American manufacturer. The composition adheres well to glass and plastic, hardens quickly (within 15 minutes), has a high level of resistance to moisture and chemicals and fuels, and does not lose its properties in the temperature range from -60 ° C to + 260 ° C. Despite the fact that DoneDeal is a universal car sealant, there are negative reviews on the network that when the headlights were glued after a while, a sediment appeared on the inside of the glass that could not be removed, and the glass had to be changed.

TOP-best sealants

According to experts and domestic motorists, today the following means are recognized as the best sealing compounds for repairing motor vehicles:

ABRO red

The composition in a 32 gram tube is suitable for replacing any seals. It is distinguished by excellent elasticity, resistance to high temperatures, pressure, stretching and compression. In addition, the finished layer can take any shape and also exhibit resistance to fuel and / or oil.

Done Deal Muffler Cement

Ceramic material ideal for exhaust system repairs. The tool actively prevents exhaust gases from seeping through burnt-out holes in the exhaust pipes. The sealant resists high temperatures and pulsations well.

Permatex Ultra BLACK

Gasket "Ultra BLACK" black 95 g, Permatex. This composition is a silicone mixture of the gasket, which demonstrates excellent elasticity and elasticity after curing, as well as excellent resistance to high temperatures and the effects of motor oils.

Kazan

Sealing agent for vehicles that allows you to quickly eliminate leaks of technical fluids. The composition perfectly seals, takes the desired shape, resists high temperatures, pulsations and mechanical damage well.

Dirko HT

Fast acting automotive sealant used to mate parts exposed to high temperatures (up to 300 ° C).

How to apply headlight sealant correctly?

Not every car enthusiast can make minor headlight repairs on his own, although this, in principle, is not so difficult. But there are a number of rules, just reading which, you can cope with this task quickly and without any particular problems. Below we will take a closer look at several ways to solve situations when your headlights were damaged on the road and require urgent repair.

So, the main question is - how can we still repair the headlight on the road? First of all, it is necessary to take into account that if some type of sealant has already been applied to the headlights, then the first layer should be removed. Otherwise, the substance will simply not grab.

If a stone or any other object hit the headlight on the way, as a result of which a crack appeared or the headlight was completely broken, then it is most rational to use liquid sealants. For this, a spare tube can be stored permanently in the vehicle.

Before use, degrease the surface and apply the substance to the crack joint. Be sure to remember that all this should be done only when the headlights are turned off.

You will also need to wait until the substance has completely solidified.

If you just need to ensure the impermeability of an unbroken headlight, then a sealant in the form of a tape will be optimal. Consider the application of one of the most common types of sealant - Abro WS-904:

- measure the required length of the seam for sealing;

- we measure out the required amount of tape and cut off;

- if necessary, you can stretch the sealant in width so that it completely covers the seam;

- degrease the surface with any alcohol-containing product;

- we apply the material so that it completely fills all the gaps and cracks;

- we fix the elements to be connected and hold it for a minute;

- if the procedure is carried out outdoors in winter, it is recommended to warm up the sealant a little with a hairdryer.

All repairs with proper use of the material will take about 20 minutes.

Types of body sealants

The process of sealing surfaces during body repair is complicated by the need to create high-quality seams that reliably protect parts from external influences. This goal can be achieved using various forms of issuing funds:

- sprayers. They are applied by means of a mechanical or pneumatic sealant gun when processing rolled seams, interior surfaces of doors and trunk. There are different colors - white, gray and black;

- under the brush. They are used to seal joints in the bumper, luggage and engine compartments. It comes in white, gray, beige and black;

- in the form of self-adhesive tape. Simple and easy to use product that does not require drying. Allows painting immediately after sealing.

The most popular body sealants are:

Body 999 - based on synthetic rubber and organic resins. Available in tubes and cans. Designed for processing steel surfaces of internal elements of the car. It is characterized by good adhesion and resistance to cracking due to its high elasticity of the joint. It is applied to degreased surfaces with an anti-silicone part with a brush. Drying time 30 minutes. Upon completion of polymerization, the seam can be painted.

Terostat 9100 is a flexible and fast drying polyurethane based sealant. It is applied with a sealant gun on a dry, pre-cleaned and degreased surface. After application, the sealing layer is leveled with water or gasoline. Remove excess funds with a spatula.

Views

The chemical composition of the sealant can be as follows:

- Anaerobic;

- Silicone;

- Polyurethane;

- High temperature.

Anaerobic sealants

They harden when two parts are pressed against each other. Oxygen is not required for hardening, so if you apply such a sealant to half of the part, you can not be afraid of quick hardening. Operating temperature range from -85 to +175 ° C.

Silicone compounds

When using a silicone sealant, the result is an elastic gasket seam. In appearance, after drying, it looks like a non-rubber gasket. Heat-resistant material, not afraid of high temperatures. Silicone sealants are not used near oil, gasoline, antifreeze and other chemicals that can corrode rubber. Not for repairing radiators, gearboxes.

Polyurethane

They have increased adhesion (ability to stick to the surface) and moisture resistance. It is often used by professionals in workshops and service stations for the repair and gluing of headlights.

High temperature

Heat-resistant compounds are designed to work in places with high temperature conditions. Maintain an upper limit of 375 ° C. They are sold in different packages and types (spray, powder, paste). Sealants of this type dry out relatively slowly, over 12-14 hours.

Review of popular brands

There are several popular brands that are often used to repair car headlights.

Abro WS-904

Abro is the most popular manufacturer of sealants. The product is produced and sold in the form of a tape that is rolled into a small roll. Abro WS-904 contains butyl alcohol, thanks to which the product dries quickly. Other advantages of the sealant include the following:

- cheapness;

- resistance to temperature extremes;

- resistance to dampness.

Orgavyl

This is another tape sealant often used to assemble headlights. In terms of its qualities, such a tape is very similar to the products manufactured by "Abro". However, Orgavyl formulations cost an order of magnitude more.

Dow Corning 7091

It is a one-component silicone sealant suitable for bonding metal, plastic and glass products. The features of Dow Corning 7091 include ease of use, high curing rate, good strength and elasticity. This composition is popular among motorists due to its resistance to temperature extremes.

"Efimastica"

It is a polyurethane one-component adhesive that adheres firmly to parts and does not have an unpleasant odor. After application "Efimastica" dries up within half an hour. The product is sold in small tubes, the volume of which is 300-400 grams. It is necessary to apply such a composition to cleaned and degreased surfaces.

3M PU 590

It is an American adhesive that is used to glue glass and headlights on cars. The advantages of 3M PU 590 include a fast curing speed, since the composition dries completely within twenty minutes. The sealant also has disadvantages, which include poor resistance to high temperatures.

DoneDeal

Another American sealant, which contains components for reliable bonding of plastic or glass. DoneDeal cures quickly after use and copes with sudden temperature changes. The only serious disadvantage of the adhesive is that after use, a thin layer of sediment remains on the surface.

KOITO HOT Melt

People looking to purchase a professional headlight sealant should take a look at KOITO HOT Melt. Sealant is used for repackaging, retrofitting and restoration of car headlights

KOITO HOT Melt cleans well from the surface. For example, at room temperature, you can peel it off with your fingers.

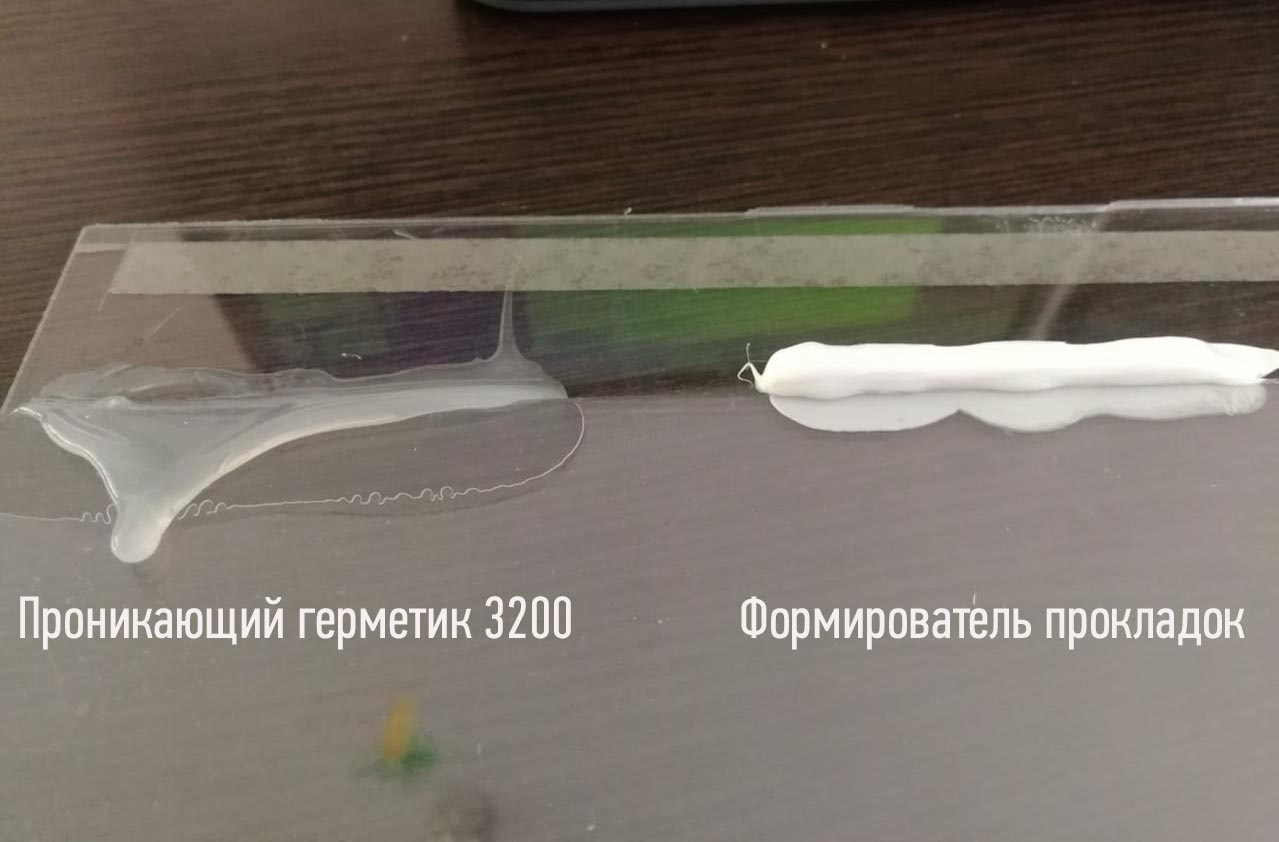

Permatex Flowable Silicone

It is a cold-curing silicone compound that is used for bonding glass, plastic and even wood. Permatex Flowable Silicone is also used in car headlight repairs to bond broken glass. Among the advantages of such a sealant is the fact that it penetrates into thin cracks and other hard-to-reach areas.

Varieties

Depending on the consistency, the following glass sealants are distinguished:

- pasty. Sold in banks. As a rule, to use them, you need to dilute the composition with a special substance that comes with the kit;

- liquid. They are one-component mixtures and can be used immediately after opening.

DoneDeal Liquid Silicone Headlamp Sealant

Depending on the material at the base of the composition, the following sealants for car headlights are distinguished:

silicone. The silicone helps to form a flexible adhesive backing to replace the broken one.Used to glue headlights, sunroofs and some other auto accessories. It is based on silicon - an organic type of rubber, to which vulcanizing components are added, allowing the mixture to acquire elasticity. Once cured, the sealant becomes flexible like rubber. The properties of the substance make it possible to seal cracks up to 6 mm deep. The composition will withstand temperatures up to +250 degrees. However, it is unstable to the effects of gasoline or antifreeze, which is why it is not used to repair gearboxes, radiators and other auto parts;

Permatex 81730 silicone sealant

- anaerobic. They are distinguished by the possibility of long-term preservation of their properties in conditions of air access. In the absence of oxygen exposure, they quickly become solid. They can be used to glue flanges and threaded connections. Unlike silicone models, they are resistant to fuel. However, they can be operated in the temperature range from -80 to +175 degrees;

- polyurethane. They are used for sealing seams, as well as for gluing headlamp glasses. Differ in water resistance. However, they cannot be used to ensure the tightness of dismountable parts and joints;

Isistem Polyurethane Headlamp Sealant

heat resistant. These glass bonding models are designed for use in harsh environments. After hardening, they retain their qualities up to a temperature of +375 degrees. It takes up to 12 hours to strengthen the composition. Also sold are heat-resistant mixtures that can be used to glue the headlights, in the form of two-component compounds.