Adhesive handling and consumption

For Super glue PVA-M the instruction is present on the bottle. It is quite simple and understandable to every person, therefore, without experience in construction and repair, it will not be difficult to deal with the operation of this composition.

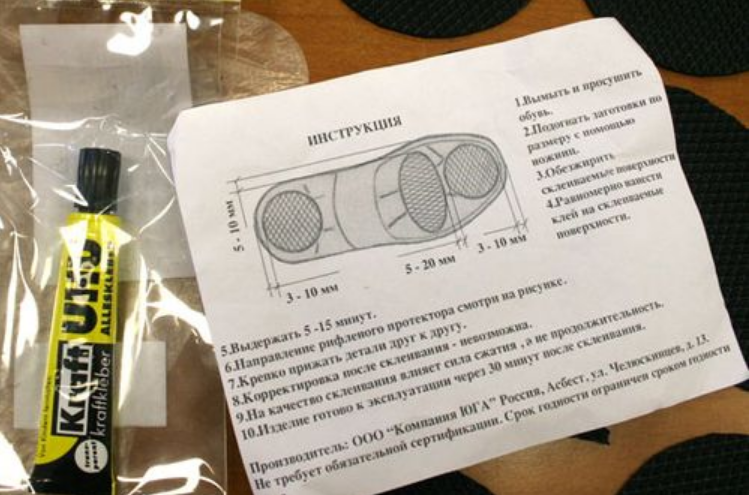

The gluing of surfaces is carried out in this way:

- Cleaning work surfaces from dust and dirt and removing moisture from them.

- Priming prepared surfaces.

- Spreading the adhesive over the area using a spatula or roller.

- Pressing the surfaces tightly against each other (this is done by hand or with a special press).

The consumption of the product depends on the thickness of the applied layer and the surface itself. On average, this figure ranges from 60 to 120 g / m2.

How to make PVA glue at home - Khimprom in miniature

To learn how to make PVA glue at home, you need to purchase a minimum set of glue ingredients. For 1 liter of aqueous solution you will need:

- Wheat flour, white, well sifted - 100 grams;

- Ethyl alcohol, you can technical - 20-30 grams;

- Fine gelatin, it is also called "photographic" - 5-10 grams;

- Common glycerin - 5-10 grams;

- Organic coloring pigment, light tones - as required.

Preliminary preparation is needed to prepare an aqueous solution of gelatin - it is diluted from a ratio of 10 grams of water to 1 gram of dry gelatin and left to "soak" for a day. If the jelly is too thick (the quality of the gelatin may vary), it can be diluted with hot water and mixed thoroughly. Further chemical manipulations will be carried out the next day.

We need two enamelled vessels, and one must be structurally combined with the other. The fact is that homemade PVA must be boiled in a water bath. Pour the gelatin solution and water into a smaller container, place it in a large bowl of water and set it on high heat.

It is required to bring the gelatin-water mixture to a boil and only then gradually add flour. The process is similar to the preparation of semolina porridge - if you want this dish to turn out without lumps, you need to stir constantly. Only now the semolina is cooked quickly, and it will take at least an hour to completely dissolve the flour in water with gelatin (and all the time you have to stir our glue brew with a wooden spoon, but what did you want?).

When the required consistency of thick sour cream is reached, it's time to add alcohol, glycerin and dye. After adding these components, homemade PVA must still be held in a water bath for 30 minutes, without stopping to stir thoroughly. Then it remains to cool the resulting composition and make sure of its adhesive qualities in the repair business. A properly prepared glue has a shelf life of at least 6 months in liquid form, if you do not forget to carefully seal the neck and do not expose the container to frost.

In the photo - how to make PVA glue at home,.

Photo of mixing pva glue at home,.

In the photo - why is pva glue made,

Purpose of medical glue

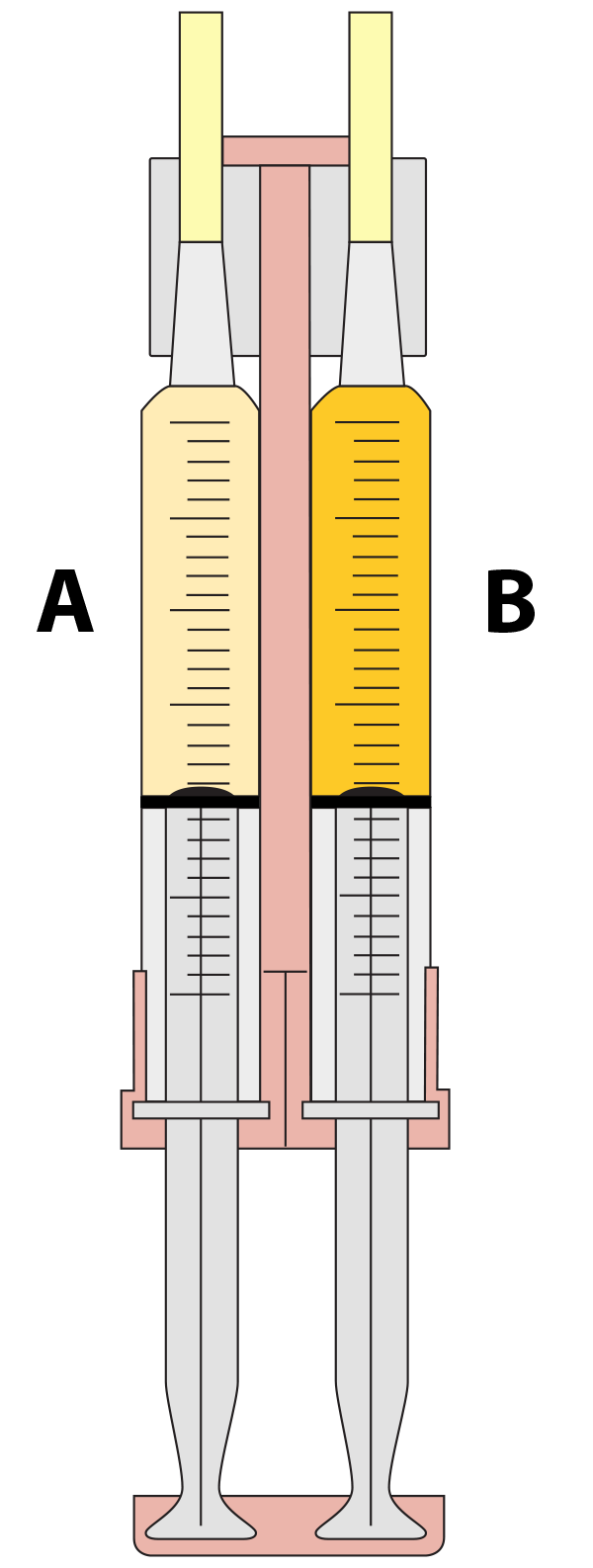

Fig. 1

Fig. 1

Medical device for gluing fabrics with filler (KRYOFIT glue):

- Eliminates the disadvantages associated with suturing

- Reduces the duration of operations

- Accelerates the natural process of hemocoagulation

- Limits or eliminates capillary and resistive bleeding

- Prevents primary and secondary liquorrhea

- Seals anatomical cavities (for fixing organic tissues: liver, lungs, kidneys, brain)

- Simplifies the surgical technique for stopping bleeding

"CRYOFIT" can be used in general, cardiovascular, thoracic, plastic and burn surgery, traumatology, neurosurgery to achieve reliable and effective hemostasis, accelerate fixation and wound healing.

Varieties and their technical characteristics

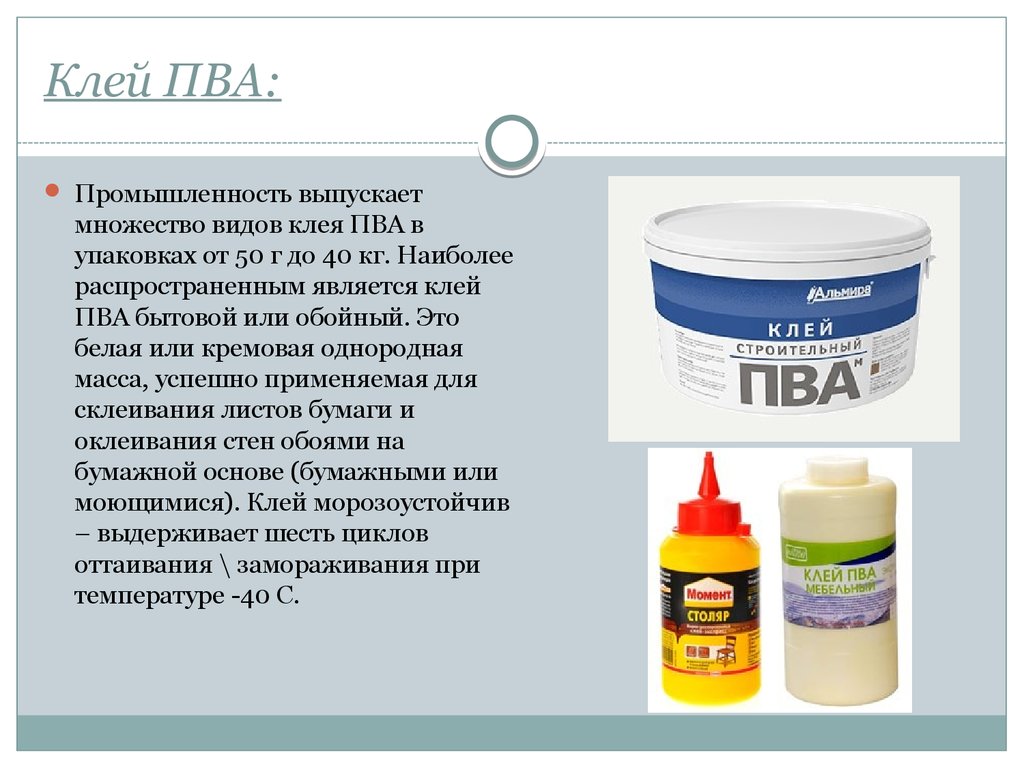

PVA glue is widespread in everyday life and construction. Both a schoolboy, a professional carpenter and a housewife use polyvinyl acetate. Depending on the type of activity, polyvinyl acetate is divided into types:

Stationery (PVA - K). Popular in kindergartens and schools. The consistency is thick, white mass, with the formation of a surface film. Non-toxic, not resistant to frost and high humidity. It is used in working with paper and all its varieties.

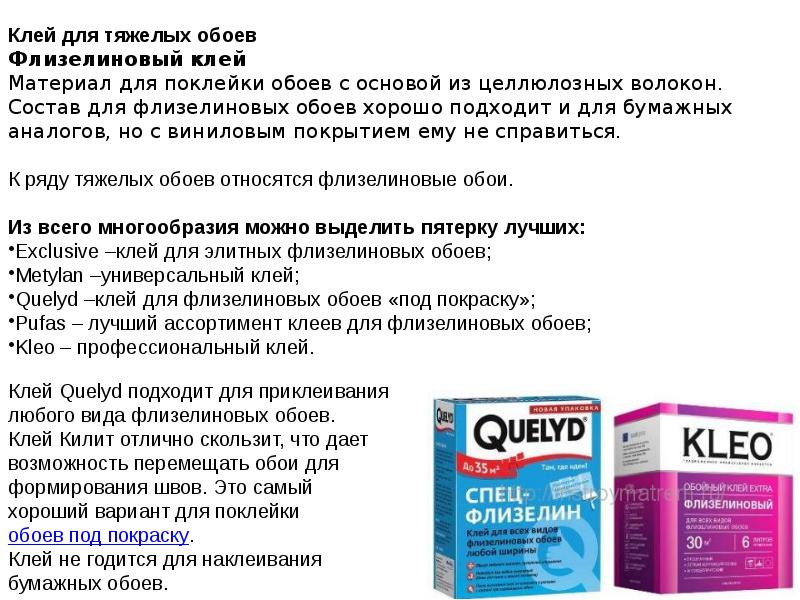

Wallpaper (household). It is used for gluing paper, vinyl, non-woven and textile wallpapers. Creates a reliable adhesion to concrete, plasterboard or combined surfaces. The glue is resistant to frost down to -40 degrees.

PVA-MB (universal). Bonds various types of materials. It is used in water-based building and finishing mixtures. Withstands temperatures up to -20 degrees.

PVA-M is a cheap modification of the universal glue. Only holds paper and wood together. Not recommended for use on glass and porcelain surfaces.

Polyvinyl acetate dispersion - adhesive emulsion, improved for adhesion to surfaces. It is divided into two types: plasticized and without plasticizers. It is found in household chemicals, packaging products, water-dispersion paints and mortars.

Dispersion glue is used in textile, footwear and other industries. Also used in the manufacture of tobacco products - for cigarette filters. Possesses frost and moisture resistance. Has a creamy yellow tint and a viscous consistency.

Class d waterproof adhesive. It is used in the construction and repair of wooden products, furniture manufacturing. The range of moisture resistance is from d1 to d4.

The most optimal for gluing on wood, fiberboard, chipboard and cork is PVA d3 glue. It stands for polyvinyl acetate dispersion emulsion of 3 degrees of moisture resistance. The consistency is transparent, thick and viscous. It can be used in rooms with a high degree of air humidity.

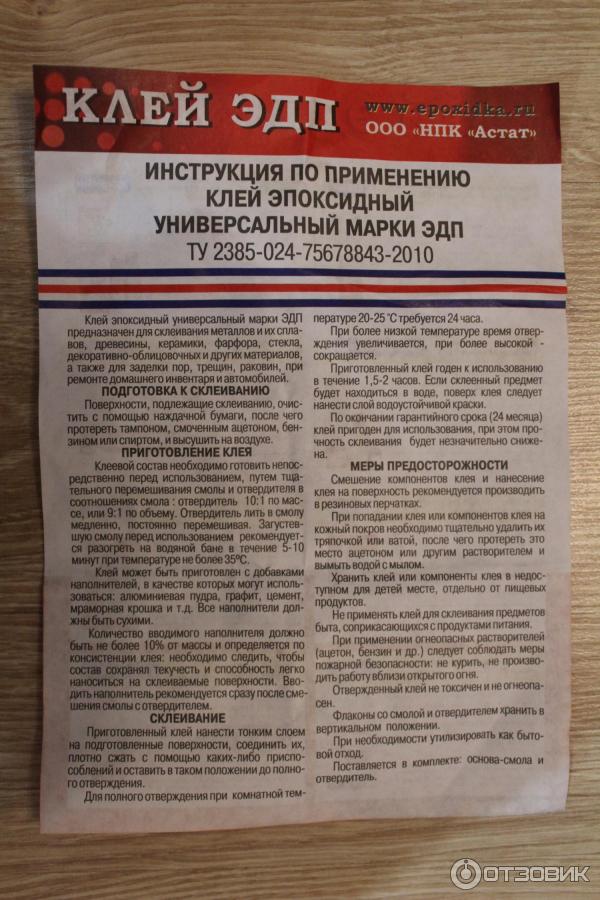

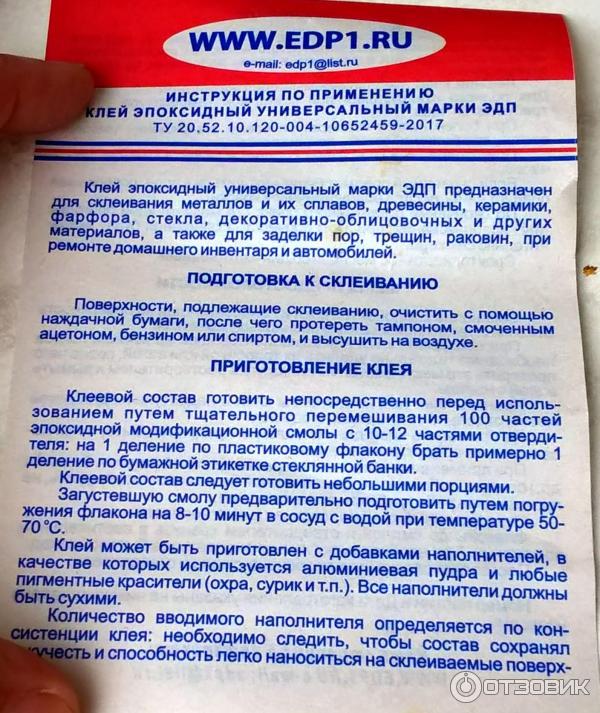

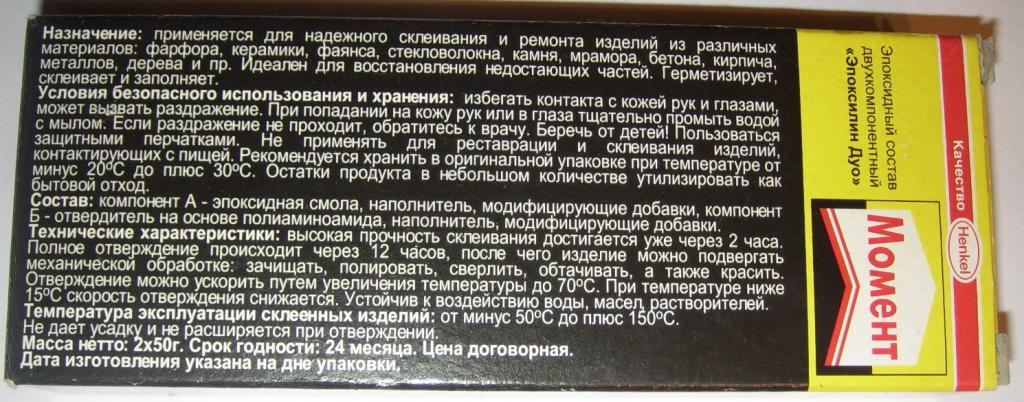

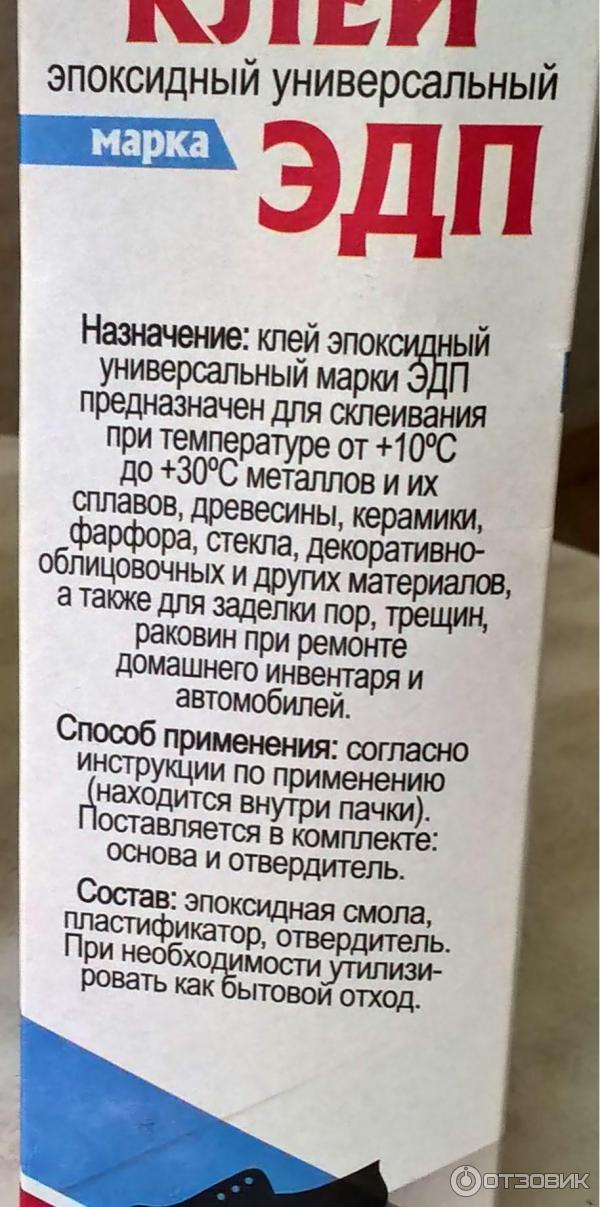

Safety measures

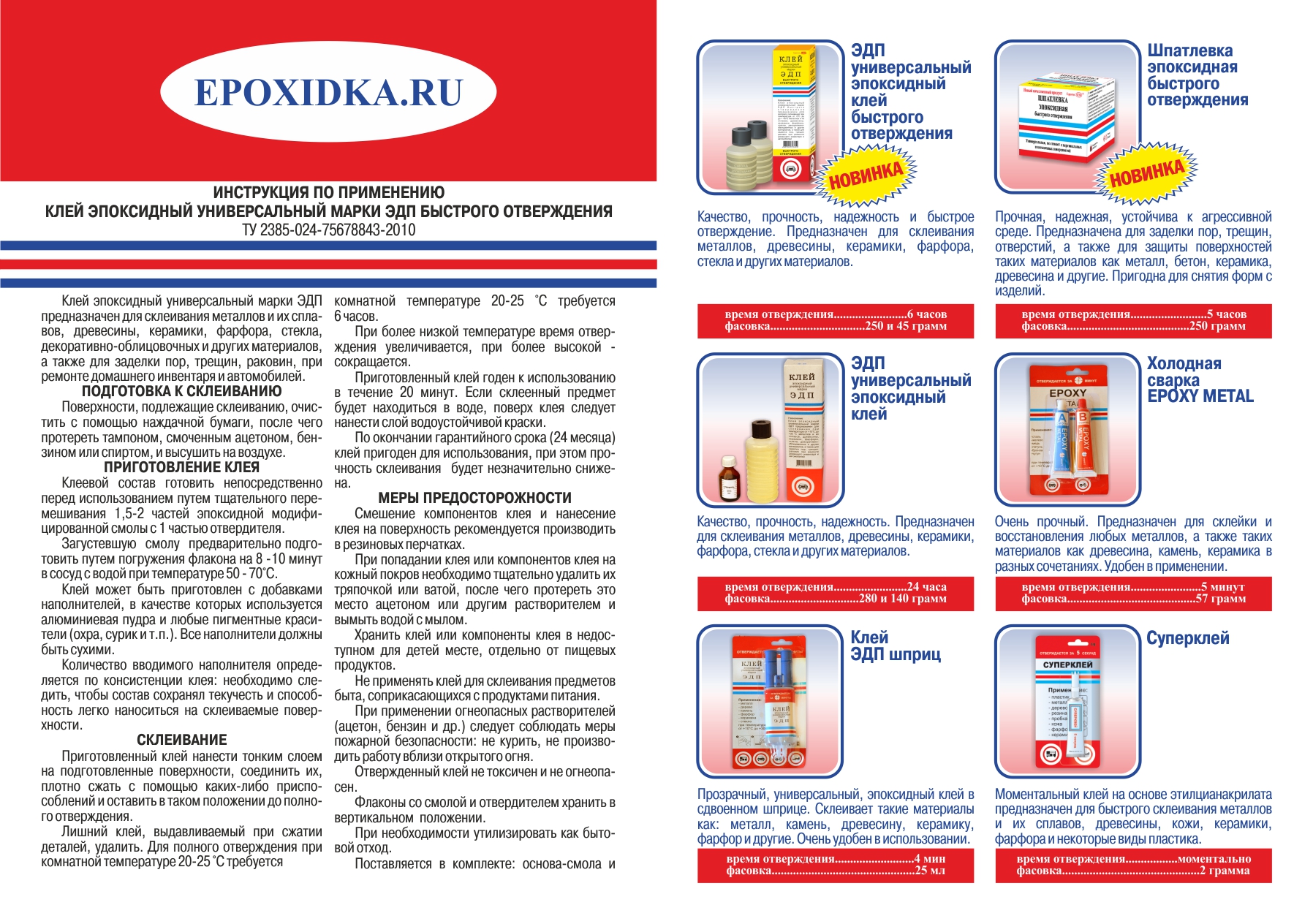

When working with a line of epoxy adhesives, you should not only carefully adhere to the attached instructions, but also observe safety measures. Given the harmfulness of the substance, it is imperative to adhere to these rules. They are as follows:

- Do not allow the resin to come into contact with unprotected skin on the hand. In addition to serious allergic reactions, getting the glue on the skin, given the speed of polymerization, brings painful sensations. If the resin comes into contact with the skin, wash it off immediately with soapy water.

- For protection from dust and harmful toxic fumes, use a respirator mask with a charcoal filter.

- All work with glue is carried out in a well-ventilated area.

- Use rubber gloves when mixing resin with hardener.

- Do not mix resinous substances in a container that will later be used for food or food storage.

- If the paste or glue is difficult to squeeze out of the tube, the tube can be slightly warmed up under hot running water. Do not use a water bath, microwave oven or ovens for this purpose, otherwise the resin will boil and become unusable.

Review of famous brands

There are seven well-known glue manufacturers.

Decart

For a durable gluing of wood, cardboard and paper, experts advise using Decart adhesives. They are manufactured using traditional technology and are therefore quite reliable. Most often, Decart products are bought for schoolchildren, lovers of needlework or for office workers.

Among the features of the glue mixture, they highlight the speed of drying and ease of use when gluing objects.

VGT

Some people during the repair work in the apartment are engaged in laying parquet. For bonding parquet boards, it is better to use an adhesive made by VGT. This firm specializes in the creation of adhesives that are ideal for working with wood. It is also used to glue carpet and linoleum to the floor surface. These materials adhere reliably to plastics, glass, concrete and wood.

Polax

Adhesives made by Polax are used for laying on linoleum or tile floor surfaces. The distinctive features of this glue include the following:

- does not contain any solvents;

- does not shrink after hardening;

- provides a strong connection of treated surfaces;

- completely safe.

ASP 8A

It is a one-component acrylic compound often used by builders during work. ASP 8A has a high level of adhesion to materials such as tiles, drywall, PVC, brick, concrete and wood. It does not contain solvents and therefore does not leave an odor after application.

Axton

Axton's adhesive is considered a common method for attaching roll materials to flooring. Most often it is used to attach carpet with linoleum to the surface. Axton is odorless and can therefore be used in residential environments. It is also suitable for outdoor use, as it is resistant to high levels of humidity and low temperatures.

"Rainbow-18"

It is a construction adhesive that is suitable not only for smooth, but also for porous substrates. "Rainbow-18" is used for attaching carpets, ceramic tiles, linoleum, polystyrene and even metal. These materials adhere securely to wood, plasterboard, plaster and concrete.

MasterTeks

It is one of the most effective assembly adhesives used by many builders. MasterTeks differs from most other compounds in its increased elasticity, resistance to moisture and low temperature indicators. Suitable for fastening large and massive structures.

Specifications and properties of various varieties

There are several brands of KS glue. All of them are used for indoor and outdoor renovation. Each type of product differs in both general and inherent properties only.

"Artel"

The main properties of the Artel brand KS construction adhesive is that it:

- heat and frost resistant;

- environmentally friendly;

- has no smell;

- elastic.

It is not for nothing that the Artel brand of glue is used for gluing block parquet, wooden flooring, ceramic tiles, and linoleum to the floor. Use a beige-brown mass in order to clad the exterior and interior walls of houses with natural and artificial stone. Suitable for lining stoves and fireplaces. The optimum air temperature during the period of repairs using a pasty construction agent should vary between 5-35 degrees above zero. The finished composition can be purchased in specialized stores with a volume of 9 kilograms.

"Optimist"

This type of KS glue is more suitable for floor coverings. It holds well linoleum based on jute, fabric and felt, while the glue seam will be strong. Use an adhesive mass for pasting stoves and fireplaces. Glue can be used to seal seams, cracks. By adding the composition to cement mortars, the heat resistance of the building material is increased. The glue line reaches its maximum strength after 3 days. They offer a ready-to-use composition in 18 kg buckets.

KS-3 "Malva"

White moisture-resistant adhesive mass is considered ideal when laying parquet, linoleum of various types on the floor.The paste is easily applied to the surface and sets after 24 hours. Before use, the composition is thoroughly mixed and applied with a spatula to both glued surfaces. Then you need to roll it in with a roller. Excess paste coming out of the seams is immediately removed.

Farvest

KS glue is heat-resistant and suitable for gluing tiles. With the help of an adhesive mass, she is lined with not only the floor, walls, but also stoves, fireplaces. Thanks to high-tech additives to liquid soda glass, the glue is used for surfaces inside the building, as well as outside. Withstands the composition even of natural and artificial stones of a large size.

"Pulse"

The improved adhesive properties of the adhesive allow it to be used widely during renovation and construction. The pasty composition of the composition allows you to quickly and reliably glue surfaces of different structure.

You can stick tiles on surfaces that are slightly heated. The glue begins to harden after 25 minutes. Therefore, it is possible to correct the incorrect masonry after the surfaces are smeared with a building compound. After all, the tool belongs to heat-resistant. It is used for ennobling warm floors.

"Universal"

Construction universal adhesive KS with mineral fillers is necessary when working on wall cladding, both internal and external. With it, you can easily and firmly glue the floor with tiles, linoleum, parquet. The adhesion strength does not depend on whether there are residues of old paint or other coating on the surfaces. The adhesive is resistant to alkaline solutions. Hence the use of funds for the repair of canteens, kitchens in children's institutions, hospitals, and catering establishments.

The coating is firmly glued to fibrous, chipboard, concrete and aerated concrete. Suitable for underfloor heating installation. Cladding is securely held on stoves and fireplaces, if you use the universal KS. When laying stoves, sealing cracks, seams, it is an irreplaceable material. It can be added to grout using slab masonry material.

Types of PVA glue

Today there is more than one composition of PVA glue. Varieties are classified based on specifications, industry and other factors.

The following types of PVA are found on store shelves:

- Super (PVA-M). It contains additional components, due to which, after the glue dries, the strength is significantly increased. It is recommended to use for household needs, gluing any wallpaper, installing tiles. It is packed in small tubes with a spout and a lid, thanks to which, if desired, they can be made a thin seam in order to glue lagging elements or restore small damaged areas.

- Stationery (PVA-K). It is actively used in everyday life, as a rule, for children's crafts. The product is available in liquid or dry form. In the first case, it is poured into small bottles, in the second, a pencil is formed into a solid PVA glue.

- Universal (PVA-MB). The composition is always ready for joining cardboard, leather, wood and glass products. Ideal for processing carpets, linoleum, serpyanka, etc. The mixture is sold more often in buckets.

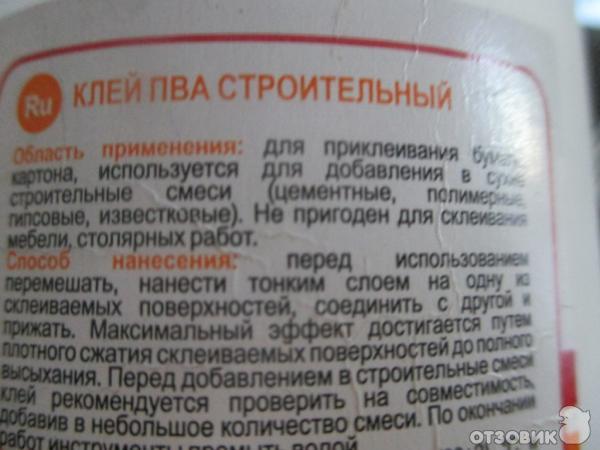

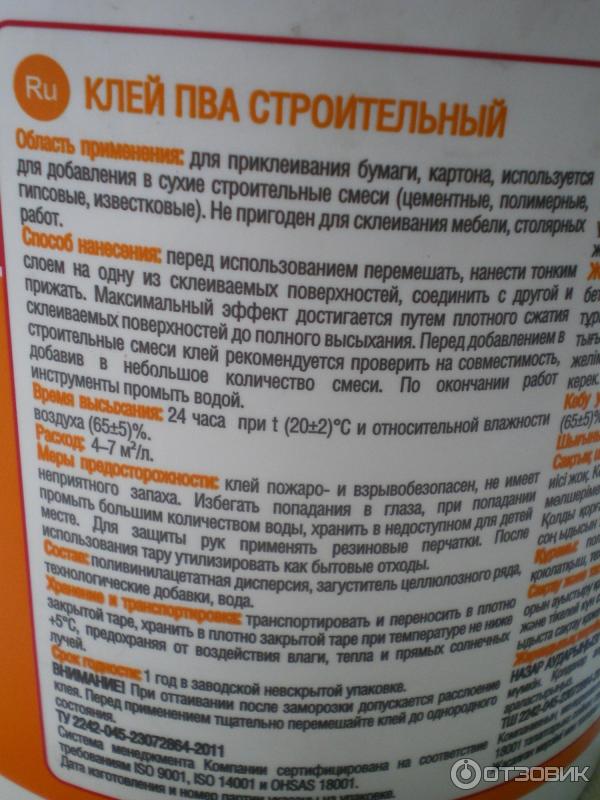

- Construction (waterproof PVA emulsion) with polymerizing particles is intended more for compaction of building mixtures, but it can also be used as an independent tool for working with durable and heavy materials. In stores, this glue is found both in small tubes and in cans or buckets.

- Household (wallpaper). This variety provides good adhesion to concrete, brick, drywall and plaster. Also suitable for gluing heavy cloths and work with paper, foam rubber, textiles. The product is sold, as a rule, in large buckets or jars.

Specifications

Polymer glue is a colorless liquid with a uniform texture and characteristic odor.The material is based on high quality synthetic resin diluted with organic compounds.

Due to this composition, Dragon glue has the following characteristics:

- elastic;

- creates a strong seam;

- incombustible;

- moisture resistant;

- suitable for use over a wide temperature range.

Due to its increased elasticity, Dragon is able to adhere materials even to an uneven (rough) surface. This material is used in bathrooms and kitchens. When working with universal polymer glue, it is recommended to heat the created seam. This effect increases the strength of the hitch. During cold weather, the properties of the glue do not change after hardening. However, for the material to dry completely, the ambient temperature must be greater than zero degrees. In this case, the glue creates a reliable bond within 15-20 minutes.

The consumption of glue varies within a fairly wide range. The processing of one square meter may require from 10 to 500 grams of polymer material. This indicator directly depends on the type of surface on which the composition is applied. The maximum amount of glue is consumed when objects with a rough surface are connected.

Tips & Tricks

People who constantly use glue stick share tips for buying and using:

When buying, you should sniff a pencil

If even a slight hint of chemicals is felt, the purchase should be abandoned.

The glue stick should have a homogeneous mass without lumps.

When buying glue, you need to pay attention to the lid. It should curl well or fit snugly

The tightness of the tube will extend the life of the pencil.

If in the process of work the glue stick remained open for a long time and its top layer dried out, it is not difficult to restore working qualities. You just need to close the pencil tightly and leave it for 5 hours. The hardened layer will return to its original properties.

And the last piece of advice for lovers of glue sticks - stay tuned. Chameleon pencils with disappearing color and pencils with a triangular sticker are on sale. They are much more convenient to use than their colorless round predecessors.

Share link:

Characteristics and purpose

Of all the polyvinyl acetate adhesives, super PVA has the highest adhesive ability, the declared tensile strength is more than 50 kg / cm2. The biological safety characteristic meets the increased requirements. Withstands up to 6 freeze / thaw cycles. The addition of this amount of plasticizer made it easier to mix with water. At the same time, the emulsion does not precipitate.

Variety of PVA super glue

In descending order, we present the following areas of recommended use:

- wood;

- shoes and leather;

- cardboard;

- polygraphy;

- package;

- repair work.

Yes, it is the tree in the first place. Woodworking companies often choose this adhesive as their main glue.

The use of PVA glue in the woodworking industry

In Soviet times, DF51 / 15V was used in the tobacco industry (!).

Tobacco industry

The addition of this adhesive to the cement mortar improves the waterproofing properties of the screed and increases the adhesion when gluing tiles.

But recommendation does not mean that there is no better analogue. For example, for gluing shoes and leather, Super NN polyurethane glue is more suitable. It has a more elastic glue line.

To get a transparent adhesive for polycarbonate, some manufacturers went for a trick. During the manufacturing process, they add ethyl cyancrylate to the emulsion. Small amounts of this additive increase the optical properties of the glue line, but impair its elasticity. Such a product is produced under the brand name glue moment super PVA. But according to an objective assessment, over other adhesives for polycarbonate, it wins only in price.

The main varieties of PVA glue

Since the scope of application of PVA is determined by the type of its composition, among the varieties are distinguished:

- household (wallpaper);

- stationery (PVA-K);

- universal (PVA-MB);

- Super glue;

- building.

Household glue is used for paper and paper-based wallpaper. The properties of the composition make it possible to use it for wallpaper, which is glued to plastered walls, concrete or wooden surfaces. In consistency, the composition is a milky-white liquid, which can have a beige tint and a faint odor. The composition is non-toxic, therefore it is safely used in residential premises. With prolonged use, the glue turns yellow. The composition has a shelf life: the glue, suitable for use, is liquid and homogeneous. PVA with an expired shelf life is taken in lumps, which makes it impossible to apply it to the surface. If the glue is expired, then when the composition is squeezed out of the container, a clear liquid will flow first. The seam formed using household PVA can withstand a temperature drop of up to -40 ° Celsius.

The PVA superglue contains additives that increase its strength after polymerization. You can use the composition by repairing the surface laid with ceramic tiles. For several unsticked elements, it makes no sense to prepare a cement composition; it will replace it with PVA superglue, which can firmly fix the tile on the concrete surface. The substance, like the previous version, can withstand fluctuations up to -40 degrees, so its use is allowed in unheated rooms or on the street.

It is interesting: Autonomous gasification of the house: we look at it from all sides

General description and features

One of the most effective and efficient means that are used to fix different surfaces is fish glue. It is obtained from the swim bladders of fish. Most often, representatives of the Sturgeon family are used for this. These include stellate sturgeon, beluga, sturgeon. It is also possible to use other fish - in particular, catfish.

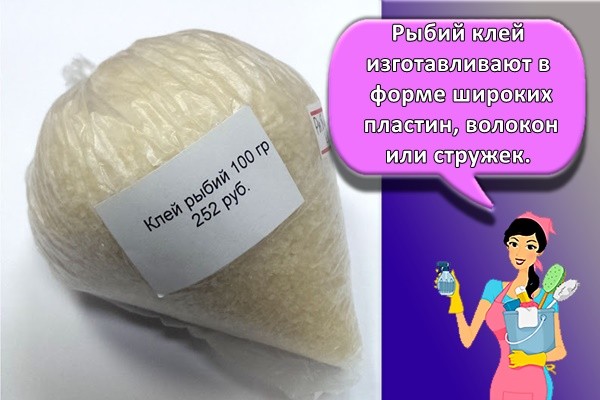

Fish glue is made in the form of wide plates, fibers or shavings. They can vary in thickness. It is best to use natural glue in the form of plates. They are fragments of the walls of the swim bladders. A lower quality composition is made from the scales of bony fish. It is a thin plate of hard consistency, which can have different shapes. In addition, glue is often brewed from heads and other waste from the fishing industry. The properties of the substance are due to the presence of collagen in the composition of these products.

In some cases, fish glue is obtained from broth, which is prepared by melting fat with the addition of water. In this case, after removing the solid residue, a thick broth accumulates in the container. A small amount of alum is added to it for purification and poured into molds. After the jelly has solidified, it is cut into tiles and dried.

This type of glue cannot be considered very popular. However, there are several areas of production in which it is actively used. These include the following:

- Winemaking. With the help of glue, impurities and sediments are absorbed in the wine material. Thanks to this, they can be quickly removed.

- Restoration. Fish glue is used as a base for paints and artistic primer. It is used when restoring old canvases. Also, the substance is used for the restoration of furniture, mosaics and frescoes.

- Making musical instruments. In this case, only high quality and expensive types of glue are used. This is due to the specifics of production.

- Light industry. Fish glue is often used to decorate clothing.

- Furniture and joinery production. The substance is used for the manufacture of mass products.

The benefits of fish glue include the following:

- lack of smell and taste;

- resistance to moisture;

- lack of color;

- excellent bonding mechanical parameters.

At the same time, the glue also has a number of disadvantages:

- lack of heat resistance - the maximum permissible heating temperature is considered to be 80 degrees; at higher parameters, the composition begins to collapse;

- high price;

- the risk of destruction under the influence of mold, parasites, pathogenic bacteria.

General description and purpose

CMC glue is produced at chemical plants on the basis of cellulose. If you decipher the abbreviation CMC itself, you get the word - carboxymethyl cellulose. In addition to the cellulose processing product, the glue contains anti-caking agents and antifungal agents. All components, although they are of synthetic origin, do not harm health.

CMC is intended for gluing various types of wallpaper to any surface (concrete, with plaster, wood). Several types of glue are produced. They differ in the percentage of sodium salt of carboxymethyl cellulose (the higher this indicator, the greater the adhesive ability of the glue).

CMC is mixed into cement mixtures and gypsum fillers to increase their strength. This product is used in various industrial sectors. The glue looks like a free-flowing powdery white powder. If the CMC has a yellow color, it means that the product has expired long ago.

CMC is the most demanded product for repair, and all thanks to its ease of use and low cost. Before use, the glue is diluted with water at the dosage indicated in the instructions. Then it is left to swell (depending on the type of CMC) for 15 minutes or 2-3 hours. The finished mixture resembles a colorless, gelatinous, viscous mass. The solution never forms clots or lumps, has no smell, does not leave yellowish streaks on the wallpaper. The pot life of a 4% mixture is as much as seven days.

Precautionary measures

The components included in Dragon have a negative impact on human health. When working with polymeric materials (especially in cases where interior decoration is being carried out), it is recommended to wear a respirator and gloves. With prolonged inhalation of the vapors that the glue creates, dysfunction of the central nervous system or kidneys is possible. Also, poisoning of the body, characterized by attacks of nausea and headache, is not excluded.

When working with polymeric materials, contact of the adhesive with the skin should be avoided. This product rarely causes allergic reactions. But such cases cannot be ruled out. If the glue gets on the mucous membranes, the latter must be immediately rinsed with plenty of water. After completing installation or repair work, the rollers should be cleaned with solvent or acetone. Hands can be washed with regular soap under running water.

PVA glue GOST

According to the rules, it must have the following features:

- It looks like a milky white homogeneous mixture that does not have a pronounced odor.

- After drying, it forms a transparent viscous film.

- With the use of PVA glue, the seam of the products comes out strong and elastic.

- Water resistant formulations contain a polyvinyl acetate emulsion that enhances the bonding properties of polyvinyl acetate.

According to GOST, it should not contain toxins and have a strong odor. During use, its white color turns into transparent and after drying it is impossible to return it to its original appearance.

Due to the fact that PVA glue is safe, it can be used in kindergartens, creative circles and schools. It is distinguished and appreciated by fire safety, as well as unpretentious use, since no special clothing is needed to work with this glue.