Path of tiles and ceramic tiles

Remains of tiles after construction or renovation may well be used for laying paths in the garden. Moreover, not only whole tiles will be used, but also individual pieces.

Whole paths can be arranged both as an independent material, and in combination with facing brick or natural stone.

Pieces of ceramics and tiles can be laid out in a beautiful mosaic or in the form of a thematic picture. However, this will take a lot of perseverance and a lot of time. But the result will please.

To decorate the tracks from this material, proceed as follows:

- By established standards, they dig a trench 10 centimeters deep for the track. Crushed stone is poured onto the bottom in a thin even layer and carefully tamped.

- To strengthen the base and give it strength, reinforcement is made from a thick metal mesh.

- A concrete solution is prepared, the track is poured and leveled. The pattern or pattern of tile pieces is started to be laid when the cement composition starts to set slightly. To make the work go faster, the drawing is laid out in advance next to the track. Then it is only transferred to solidified concrete.

- After laying the tiles, the seams are rubbed.

If whole tiles and pieces are laid out, then large elements should be placed along the edge and in the center, and the space between them should be filled with smaller ones.

As borders, you can use glass bottles with sand, turned upside down, as in the photo.

Recycled tire material

Due to the environmental situation, the use of recycled materials has become relevant, and even, it would seem, such a small thing as laying rubber material on garden paths helps save the planet from garbage.

Modern rubber coating is available in rolls up to 1.5 m wide, tiles of various configurations and colors, and crumbs. But since working with a self-leveling rubber crumb coating requires special skills and equipment, it is better to use a roll or tile for self-installation. And since the rubber flooring requires a solid base, this material is well suited for renovating concrete paths.

The relatively high cost is offset by a long service life: up to 50 years without loss of color and quality.

The garden path is a very important part of the design of the summer cottage and the types of coverage and decor described above do not exhaust the topic. The coverings are perfectly combined with each other, creating a unique story for each individual cottage or garden

Therefore, it is extremely important to find a balance between aesthetics and budget, strengths and desires so that not only the appearance of garden paths, but also the process of work on creation itself, brings joy and pleasure.

Garden path material

In general, there are a lot of options for arranging paths on a personal plot, but before work on the marking and arrangement begins, it is necessary to decide on the material. The most popular are garden paths:

- From stone - either processed material (pebbles, quartzite and others) or unprocessed material (limestone, shale, sandstone and others) is used. Yes, natural stone will cost you a pretty penny, but you can also use concrete paving stone - it is now produced in different shapes and sizes. The stone path on the personal plot is resistant to climatic and physical influences, and has a long service life.

- From clinker bricks - this material will be the best solution for arranging exclusively "pedestrian" zones on a personal plot.Only small areas can be laid out with clinker bricks and you need to know some of the features of the material in question:

- a high level of wear resistance is distinguished by a clinker brick made by vibro-compaction;

- that clinker brick, which was obtained by the method of vibrocasting, is distinguished by its decorative appearance.

Recently, water-repellent and high-strength clinker bricks have appeared on the building materials market - these are the qualities that make it optimal for laying out garden paths.

- Made of wood. This material is distinguished by a high level of environmental friendliness and the ability to use original design solutions for arranging a personal plot. Most often, wooden paths are guides to a specific, localized resting place. You can lay the tracks from pre-prepared fragments, you can use dies from a tree trunk - in any case, the selected material will need to be treated with specific solutions (antiseptic, UV and moisture resistant).

In addition to the materials listed, you can use plastic flooring for arranging garden paths. This is the most modern material that can be used for laying paths - you just need to lay the fragments of the flooring in a certain order and you will get a beautiful, bright path with an original design. Many people doubt its reliability - plastic can hardly be called a wear-resistant material, but you can replace a damaged fragment at any time. It is worth remembering only one rule for laying plastic fragments as a path on a personal plot - it is necessary to provide free space between the fragment itself and the ground / ground.

In addition to the materials listed, you can use plastic flooring for arranging garden paths. This is the most modern material that can be used for laying paths - you just need to lay the fragments of the flooring in a certain order and you will get a beautiful, bright path with an original design. Many people doubt its reliability - plastic can hardly be called a wear-resistant material, but you can replace a damaged fragment at any time. It is worth remembering only one rule for laying plastic fragments as a path on a personal plot - it is necessary to provide free space between the fragment itself and the ground / ground.

The easiest way is to say "I will make a path on a personal plot with my own hands" and decide on the material. What's next? It turns out that there are clear technologies for the process of arranging garden paths from various materials - they need to be studied before starting work.

Concrete preparation and mixing

Based on the calculations, a mixture of cement is compiled, sand and gravel, to which water and plasticizers are added. The composition is kneaded and brought to a homogeneous creamy consistency of medium viscosity.

Crushed stone is used in medium fractions, 10-20 mm in size. When constructing paths with increased load, it is recommended to take crushed stone with a fraction of 40 mm.

It is advisable to mix it with a concrete mixer, especially for a large amount of work. If there is no concrete mixer, then you will have to make the mortar by hand. To do this, all the components are poured into the container and thoroughly mixed with a shovel, after which water is poured into the mixture and mixed again until a homogeneous mass is obtained.

Mixing the solution.

It is advisable to use plasticizers in small quantities in order to make it more convenient to distribute the fill over the trench. Excessively with additives can reduce the strength of the concrete grade.

The simplest plasticizer additive can be prepared independently using the following starting materials:

- silicate glue;

- slaked lime;

- PVA;

- any detergent.

Instead of silicate glue, you can use liquid glass, and laundry detergent or laundry soap is suitable as a detergent.

If the paths are planned to be colored, then pigment dyes of the required color must be diluted with the concrete mixture.

How to make from saw cuts?

For garden paths, logs with a longitudinal or transverse cut are used. Both options allow you to save on the construction of such structures. The use of saw cuts is also justified by the fact that material of this type is easier to lay. These paths are appropriate in a rustic landscape. The gaps between the cuts are usually filled with crushed stone, gravel or soil. In the latter case, lawn grass is additionally planted.

Material preparation

To lay tracks from cuts you will need:

- level;

- twine (any large thread);

- gloves;

- roulette;

- brush;

- chainsaw;

- mallet;

- shovel.

It is also necessary to prepare equipment for compaction of the earth. For these purposes, you can use improvised means. Before laying garden paths, it is recommended to clean the bark from the cuts. This helps to extend the life of the material. Small diameter workpieces should be placed between larger stumps.

In addition, the wood must be treated to prevent rotting before laying. For this, drying oil or antifungal agents are first applied to the material. After drying, that part of the saw cut that will be hidden under the ground is additionally treated with resin. In this case, it is recommended to use a mixture of bitumen and gasoline. If necessary, copper sulfate can be applied to the top of the stumps. This material ages the wood.

Larch

It is considered the best option for making garden paths. Larch, with proper preparation, will last at least 30 years. However, this material is expensive.

Beech

Beech, like larch with oak, is a hardwood. Therefore, the material has a long service life.

Pine

Pine is used less often, since the service life of this material does not exceed seven years. In addition, hemp exudes a sticky resin in the first year.

Birch

Birch is an average option. In terms of service life, the material is slightly superior to pine, but it costs significantly less than larch or oak.

How to pack?

For the manufacture of garden paths, beams with a height of 150-200 millimeters are suitable. At the same time, it is not recommended to take logs with a diameter of less than 100 millimeters, since such a workpiece will eventually come out of the ground.

Markup

Before applying the markings, it is necessary to draw up a detailed plan of the garden plot in advance and mark the center lines of the paths on the drawing. Next, you should decide on the width of the passages. For comfortable movement on the site, this parameter should be more than 80 centimeters. If the tracks will be used by one person, then the width is 35 centimeters or more.

After that, the center lines are marked on the site, along which the pegs are hammered. A twine is then drawn between the latter, which marks the future paths and defines the zones for excavation of the earth.

Trench

When digging a trench, you need to focus on the size of the wooden blank. When calculating the depth of the pit, you should take the height of the hemp, add 50-100 millimeters. The width of the trench is selected based on the dimensions of the future track.

Waterproofing and base

After preparing the trench, work is carried out in the following order:

- A waterproofing material is covered at the bottom (you can use a plastic wrap that covers the greenhouses).

- The film is covered with a layer of gravel or fine gravel necessary to create drainage. The latter protects the wood from constant contact with moisture. The height of the drainage layer is half the depth of the trench.

- Crushed stone (gravel) after filling is well rammed.

- The drainage layer is leveled.

If a curb is provided along the path, then this structure is erected before the cuts are laid. In this case, both wood and bricks, sheet metal, stones and other materials are used. After installing the curb, a layer of sand is poured, in the same volume as the drainage. Then the base of the future path is watered abundantly with water.

Styling

Cuts are laid according to a previously prepared drawing. To prevent the wood from walking underfoot, the stumps at the base are reinforced with pegs (you can use metal ones). After that, the material is rammed and leveled with a mallet. The voids between the stumps are filled with earth or rubble.

Preparatory stage

You can independently, even without extensive construction experience, build a path in your country house.To do this, carefully follow all instructions. When you understand which path you want, you need to decide on the materials and other nuances that do not directly relate to construction work.

Localization and markup

When choosing a place, consider the following points:

- The width and smoothness of turns should be such that two people could easily miss each other or a loaded wheelbarrow would pass.

- The route should be such that access to all parts of the yard is provided, even in bad weather.

- The building should be no closer than 2 m from the trees, since the root system can violate the integrity of the masonry.

- It is necessary to coordinate the irrigation system so that water does not flood the surface of the path, otherwise it will be washed out and destroyed. If there is no opportunity to coordinate, then you need to make a slight slope and ditches for water to drain.

To mark the future building, take wooden pegs, a tape measure and a rope. Place pegs 3–4 m apart around the perimeter, and increase the number of pegs at turns.

When choosing raw materials for masonry, choose one of these types:

- paving bricks or tiles;

- clinker;

- masonry ceramic;

- paving stones.

Keep in mind that broken brick can be used for the pedestrian zone, but if it will be in harmony with the rest of the design of the site.

When deciding on the parameters of the brick, rely on the type of pattern of the future track, as well as its length and width.

When determining the required type, be guided by the following principle:

- calculate the amount of materials that will exactly fit along the width of the structure when laying;

- calculate the length in the same way;

- calculate the optimal ratio of raw materials sizes so that after laying there is a minimum of unused raw materials, and the amount of necessary debris is minimal.

Taking all factors into account, draw up a design project, while trying to identify all the parameters as accurately as possible. The correctness of the drawing will help to avoid shortcomings at the construction stage, and knowledge of the dimensions of the future building and the dimensions of the materials directly affects the aesthetics of the structure.

Requirements for paving bricks

So, for laying paths in a garden plot, you can use bricks that meet the following conditions:

- Strength;

- High density;

- Resistant to moisture.

Best of all, for paving paths, special, paving bricks or clinker bricks are suitable. The path paved with these types of bricks will last a very long time.

Bricks, which have the ability to absorb a large amount of moisture, are subject to rapid destruction as a result of frost.

Since the moisture in the brick freezes and destroys it from the inside. However, if you have a different brand of brick left, do not be upset. For example, if you are interested in how to lay out a brick track with your own hands, and at the same time I mean:

- red brick path;

- DIY broken brick path;

- DIY old brick paths and so on.

Then, such a brick can also be used, it is only recommended to immerse it in a hydrophobic solution before laying. As a result, the bricks change their properties, as the material becomes water-repellent.

And yet, if clinker bricks can be laid on a sand cushion, then it is recommended to place ordinary bricks on a concrete cushion. That is, in a mixture of sand and cement at the rate of three to five parts of sand per one part of cement.

True, with this method of installation without the use of hydrophobic solutions, the risk of efflorescence increases.

The first stage of work - preparation and leveling of the site

You should first prepare a path for a brick.

Determine the exact location of the site on which the brick will be laid.

Mark the outline of the future track with pegs and twine. Next, we proceed to excavation. That is, remove the sod, soil, to a depth of fifteen centimeters.

Next, you should level and tamp the surface of the site. It is imperative to form a slight slope for water flow, about five millimeters per meter.

If you plan to plant a brick on a concrete solution, then the path should first be covered with plastic wrap to protect the brick from moisture from below.

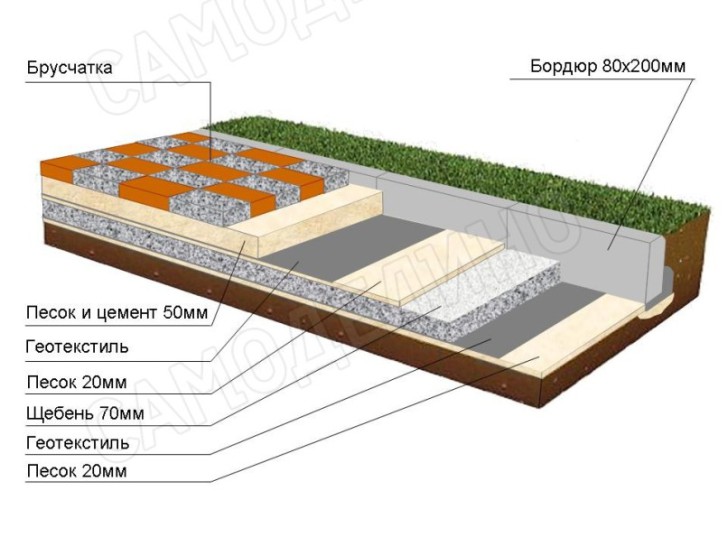

The procedure for laying materials under a regular brick:

- Level and compact a thin layer of sand;

- Moisture-proof material (geotextile);

- Fine gravel or crushed stone, up to seven centimeters high, level, tamp;

- Pour a thin layer of sand onto crushed stone, level and tamp;

- Moisture-proof material;

- Dry mixture of sand and cement, at a rate of three to one, up to five centimeters.

In order to make it easier to level the surface, lay two pipes or battens on the level. Then pour a dry mixture between them and align along the pipes.

A brick is laid on top and tamped with a wooden or rubber tool. The distance between the bricks is from two to four millimeters.

It is recommended to fill small spaces with pieces of brick after a solid brick has been laid, forming a certain pattern.

At the end, the gaps between the bricks are filled with a sand-cement mixture.

Installation without waterproofing

In the event that you have a special paving brick, then it can be laid without a concrete pad and waterproofing material.

This method of laying bricks is the simplest and easiest. Plus it is also cheap. However, there is also a minus - if the base is poorly prepared, then the track may deform.

At the same time, such a track can be disassembled and repaired without waste.

Plan ahead for the water drain so that it does not accumulate under the brick path. It is advisable to plan longitudinal and transverse slopes.

The procedure for laying materials under paving bricks:

- Pour a layer of sand on the tamped surface, up to seven centimeters, and moisten it with water from a hose;

- Not earlier than in three hours, proceed with the sealing of the base. With the help of special means, the surface of the path should be tamped, leveled and rolled;

- Fill in a layer of gravel, from ten to twenty centimeters. Align and compact it;

- The last, leveling layer is to fill up with ordinary, water-washed, clean sand.

The brick is simply laid on a sand cushion and the seams are covered with sand. Do not lay the film so that rainwater can freely seep through the sand and be absorbed into the soil.

A layer of gravel or crushed stone is poured onto the prepared section of the track for an amortization cushion and leveling. On top of which a layer of sand is laid.

In principle, if this is a budget option, then you can only get by with a layer of sand. A pre-prepared brick is laid on a sand cushion.

Thus, you can lay out brick paths in the country or in your personal plot without special costs.

How to mount the formwork

Edged boards or thick plywood sheets with an even inner surface are used as formwork.

If the formwork is planned to be removable, then before its construction it is recommended to treat the inner surface of the boards with a special lubricant - thanks to it, later the formwork can be disassembled easily and quickly.

If there is no lubrication, then used machine oil can be used.

The step-by-step instructions for the formwork device can be presented as follows:

- Planks are installed in trenches on a previously prepared base. The formwork can be installed all at once or gradually, as the boards are released, the height should be equal to the height of the planned path. The horizontalness of the structure must be checked with a building level.

- Layers of sand and crushed stone (if necessary) are poured onto the pre-rammed bottom.

- Lay a mesh of reinforced rods.

- Every 2-2.5 m across the trench, boards up to 20 mm thick are installed, which will take the main load when pouring. They will also function as expansion joints, thanks to which they do not crack at temperature extremes.

The formwork should protrude 5-10 cm above the ground.

If you want to arrange curved paths, then instead of boards, plywood or plastic panels are used, which are easy to bend in the desired direction.

In order to save energy and reduce material costs, the formwork can be assembled in parts.

Edged boards are suitable for formwork.

Choice of material - varieties of tiles

For paving garden aisles, materials are chosen depending on the passability. For wide paths where vehicles can pass, strong surfaces are needed. Narrow paths are decorated with light tiles.

Highest quality and most durable track - bounded on both sides by curbs pre-installed on the concrete mix

A natural stone

Stone garden paths are a classic. The stone will fit in any landscape design, it all depends on the shape and color of the stone:

- durable granite with a variety of textures are offered in the form of tiles and bricks;

- marble strikes with a variety of shades, is more often used in the form of natural cuts of blocks;

- slate for laying is chosen hard, quartzite, the palette of shades is wide from gray to marsh, salmon pink to carmine;

- quartzite is harder than shale, rougher, cut to tiles or paving stones;

- shungite is even, smooth, gray as asphalt, sometimes there are pieces with shiny quartz veins;

- sandstone is cut into bars and tiles of various formats, the moisture saturation is higher than that of other stones, but it is very decorative, the rough texture creates an anti-slip effect;

- limestone is quartz rocks that form layered deposits, textured, color from yellow to reddish.

Stone tiles with a relief surface look elegant and expensive

A combination of stones with a rough and smooth surface is allowed. The best option is to lay sandstone and marble together.

Fake diamond

For paving paths in the country, clinker bricks and concrete tiles are used. The clinker is made of plastic clay, it looks like a solid brick, it comes in shades of brown and red-brown.

Clinker paving stones are one of the most durable materials for paths in the country.

Porcelain stoneware differs in texture, color, produced:

- in the form of tiles of various formats;

- torn plates imitating natural pieces of stone.

Most often you can find porcelain stoneware tiles of medium and large formats.

Garden path made of porcelain stoneware tiles with imitation of natural stone

When working with tiled stone, it is recommended to install the curbs on the paths after installation in order to reduce the number of trimmings.

Concrete

Concrete is made smooth or with an anti-slip surface (hardened concrete is treated with sand). They imitate the texture of limestone, clinker. Concrete tile paths in the country are an economical design option. For self-production of fragments, ready-made forms are used.

Concrete tiles are produced in different sizes, textures and thicknesses.

In case of self-production, concrete tiles are poured right on the spot

Polymers and plastics

Modern manufacturers offer many types of decking - artificial deck boards or parquet. Paths made of such tiles look like wooden flooring, they are not afraid of moisture, temperature contrast.

Garden deck or parquet - these are panels with a pattern made from a mixture of plastic and wood flour

The plastic cover of the modules is suitable for the construction of paths and the design of recreation areas

Lawn tile grids are created in the form of modules, they are usually green, easy to install, and will preserve the green carpet.

A plastic lattice path can be made directly across the lawn or laid on a sand cushion and filled with fine gravel

Where does the track begin

Each work is of two types: with the help of some uncle (uncle) or with your own hands. The choice is up to the owners.

But in any case, the track begins with a markup. You can draw on paper (or using a computer program), and if the area of the site is not large, then directly on the ground.

The main routes of movement are between the house, outbuildings and the exit from the site, therefore they are determined first of all.

After marking the main paths, they move on to those that connect recreation areas, playgrounds, and a summer kitchen.

And then paths are outlined leading to the plantings, the irrigation connection point, to separately located plantings, when needed.

Basis for the track

To prevent the path from sinking into the ground, it is necessary to prepare a substrate for paving slabs. This preparatory phase should by no means be ignored. The foundation is being laid in several stages... The first thing to do is to dig a small hole. It is necessary to remove approximately 20 centimeters from the ground. For this purpose, a bayonet shovel is the best fit.

The next stage is the installation of wooden boards, which will act as guides. Everyone can make a substrate with their own hands. This is not difficult. The sand is poured into the recess, after which it is distributed evenly over the surface using a straight board.

Important! There is usually a layer of clay under the topsoil. If you lay paving slabs on clay, then after the first frost it will swell

Therefore, a sand cushion is a necessary component of a quality trail.

Layer cake for laying paving slabs

If the path is located close to a residential building, then you need to think about the drainage of rainwater. The easiest way to implement it is by tilting the walkway (away from home). The thickness of the sand layer must be at least 15 cm.

It is very easy to calculate the amount of sand that will be required to organize the substrate along the entire length of the track. One cubic meter of sand covers about 7 square meters. The sand must be tamped down, after which you can proceed to the next stage.

Of stone

Of tightly fitted stones

Of tightly fitted stones

The stone paths in the country house will look very impressive. You can make them from stones that were left after construction. Also, stones that were left unused in the alpine slide are suitable. Such boulders will have an uneven, "ragged" shape, which is exactly what is needed to create picturesque paths.

- Original garden paths First, you need to calculate how many stones are needed to arrange the path. This can be done in a number of ways. You can pre-arrange the boulders in the form of a path to see if there are enough stones or not.

- The place where the path is supposed to be made must be sprinkled with sand. It will become a kind of stone cushion. The sand must be well tamped.

- The stones need processing. They are all too different in shape, so it is unlikely that they will be able to successfully dock without additional work. In work, you can use both a grinder and less powerful tools. Irregularities on the surface of the stones can also be slightly smoothed out. You can also do this manually. When the stones are ready, it remains only to lay them so that they create a single mosaic.

When the stones are laid, the seams between them can be repaired. If the seams remain, the path may begin to grow over time. However, this also has its own special charm, because such a path will look as natural as possible.

In order to seal openings between stones, you can use a standard mixture of sand and cement.Country paths using stones and other similar materials have been known for a very long time. After all, the stone was used in ancient civilizations. It made it possible to hide the unaesthetic appearance of soil and dirt and to give the streets and roads a noble civilization.

20 - Clinker brick path

Clinker is a very environmentally friendly material with high strength. Paving paths with clinker has long been popular in Europe, and now it has become "number one" in Russia. Clinker tiles such as Gresmanc Aldonza or clinker bricks have an incredibly rich variety of shades, therefore, by laying them in a mosaic pattern, you can get an interesting visual effect and a very respectable look.

In fact, clinker is just a ceramic brick, but it is made from a special type of clay mined in the north of Europe. Firing of such bricks takes place using a particularly complex technology, usually also in factories in Europe. This explains the cost of this material. However, the cost pays off a hundredfold during operation, here the GresmancTambora clinker is a very high-quality and durable material

In addition, it is frost-resistant, which is very important for our realities.

Clinker paths are laid in the same way as in the version with simple bricks. For durability, it is recommended to fasten the structure with cement mortar, and use heavy stone bricks or concrete blocks as a curb.

Advantages, disadvantages and types used

In favor of the construction of a track from used bricks, the following says:

- the ability to free the territory from the remnants of construction;

- cheapness;

- ease of installation, allowing you to perform the necessary work without the involvement of professionals;

- environmental friendliness;

- good drainage properties;

- ease of dismantling, if necessary, and quick restoration of the surface of the site.

However, with all this, brick is mostly a wall material, which means that it will collapse in the open air, being exposed to moisture and frost. To extend the service life of a broken brick walkway, it is recommended:

- use sand-lime brick if possible;

- treat stones with a hydrophobic solution or waterproof varnish;

- if clay bricks are used, then before laying the bricks should be treated with a hydrophobic solution twice, immersing each fragment in the solution.

The purpose of this treatment is to give the stone frost resistance and moisture resistance. The period of validity of the water repellent agent is 5 years, at the end of this period the treatment must be renewed.

When paving a garden path with your own hands, simple laying methods are recommended:

- longitudinal layout;

- transverse layout with the location of the seams perpendicular to the direction of the track;

- chaotic layout (in the presence of multi-colored elements) with any method of laying relative to the direction;

- herringbone laying, when the paving elements are located at right angles to each other, while the pattern is often oriented along the direction of movement;

- braid (a pattern imitating weaving is formed by alternating longitudinal and transverse elements);

- alternating horizontal and vertical lines.

Subtleties of working with old material

If you need to save a budget, you can get away with the low cost of using broken brick. The process of laying a garden path from fragments has some features. As a rule, pieces of ordinary red brick are used.

So, for such a masonry, you will need, in addition to the standard set of tools, a grinder with a diamond wheel to process uneven edges.

So, you will also need to fence the perimeter, expose the stakes and make a 25-30 cm depression. The process of creating a base is identical to the usual version. The most time consuming part of this job is laying out the broken parts so that they form a flat, smooth surface.To do this, you need to choose larger pieces, with at least one flat surface and a rubber mallet, drive them into the base. In this case, the depth of such driving will be different. In this case, you will need to resort to the help of the building level more often. Try to keep the gaps between the elements no more than 2-3 mm.

Building a path in the country with your own hands is a rather laborious process. Nevertheless, you can independently do this layer of work and get a satisfactory result that will be both practical and design attractive. To do this, study the options for patterns, purchase the necessary material, draw up a drawing and follow the step-by-step instructions. And remember: in any job, your safety is paramount.

Advantages and disadvantages

Choosing a brick has a number of advantages: installation will be simple, raw materials are commercially available, and inexpensive, besides, you can use both whole brick and its fragments. True, such a design will not differ in durability and under the constant influence of precipitation and temperature changes, parts will begin to crumble in 2-3 years.

Use bricks to create a path on your site

Use bricks to create a path on your site

To make the structure less subject to destruction processes, you can treat the parts of the masonry with a special moisture-repellent substance, take clinker bricks during construction, or buy imitation tiles. In this case, the processing of raw materials must be carried out by complete immersion in the substance, and this stage must be repeated at least 2-3 times. This will increase resistance to moisture and frost.

It is also important to remember that the service life of moisture-repellent substances is usually about 5 years. After the expiration of this time, you will need to repeat the treatment again.

The effect of the varnish depends on how intensively the building is used.

Clinker stone is characterized by a high level of moisture resistance and therefore is not susceptible to degradation. It is more durable and more attractive in appearance, however, its price is higher than usual.

How to use broken brick

When planning how to use broken brick in the country, home craftsmen find interesting solutions, such as:

- paving beautiful garden sidewalks;

- creating borders;

- decoration of flower beds and high beds.

Also, when deciding how you can use broken brick, it is recommended to use recycled material in the construction of gabions and the arrangement of foundations for alpine slides. Most gardeners are fond of decorating tall vegetable beds, the design of which provides for the formation of a powerful drainage layer, where different-sized fragments of the battle can also be effectively used. With the help of waste products, it is easy to build high-quality drainage when planting trees and shrubs.

As experienced tilers note, the use of unsightly material can give quite original results. For example, from a product that is not suitable for construction, you can arrange a path curb by placing the specimens on the edge at an angle of 45 °. To get a unique masterpiece in the form of a garden path with an original masonry pattern, you can organize a composition of battle and a whole brick.

Which tile to choose?

Pedestrian paths are important objects in the country, providing free movement within the site. For their organization, paving slabs are most often used. This material has a number of important advantages, such as:

- environmental friendliness,

- reliability;

- durability.

Important! To lay such a track, the site must have a sufficient amount of free space.

This is a very important point, since in a limited area it is much more difficult to install the path, and its appearance will be less attractive. Experienced craftsmen do not recommend styling in rainy weather.

Variety of tile tracks

How to choose a tile? When choosing this building material, you need to pay attention to the purpose of the future track. If this area is exclusively pedestrian, then for its construction, products with a thickness of 40 mm can be used.

From a more voluminous tile, you can lay out paths for the passage of vehicles.

You also need to pay attention to the shape of the tiles. The complexity of its installation depends on this factor.

Products of a rectangular shape are the most expedient, since it is the easiest of them to make a track.