The final stage of work

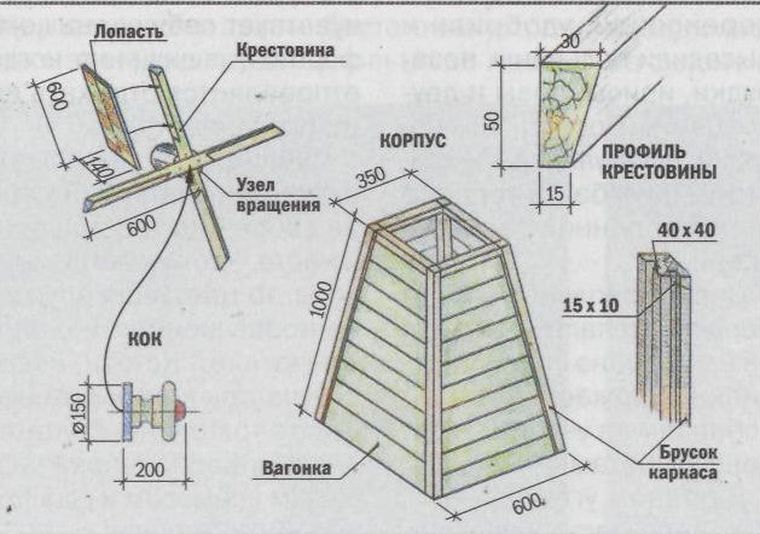

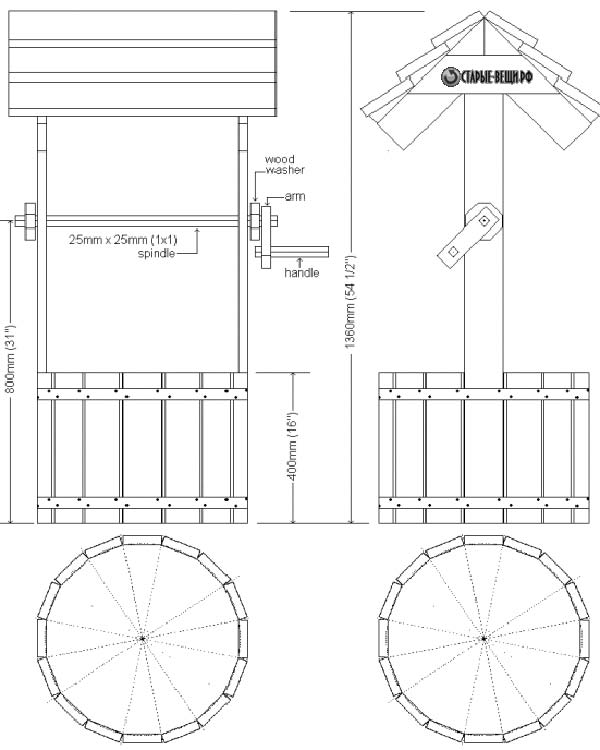

We turn to the manufacture of millstones. Lovers of minimalism can simply screw 2 boards to a wooden plate, drill a hole and thread the shaft for the blades. But, in order for the blades to rotate during the wind, the installation of bearings is necessary. To do this, we need the same 2 wooden plates, but large holes need to be drilled in them, for the size of the bearings, it can be 1 mm smaller.

Then we cut it in half and make small holes at the top for self-tapping screws so that they can be connected and disassembled if the bearings become unusable. After that we glue a small board from below so that the shaft is at a slight angle and the blades do not rub against the mill, you need to put a small block in front of the board. The resulting structure must be fixed to the plate to which the roof will be attached, after which we insert the bearings into the structure.

Now we need a threaded shaft and 4 nuts. We insert the shaft into the bearings and fix it with nuts. We glue / screw the wood lining to the roof and our millstones are almost ready. Then we put the millstones and the roof opposite each other at the same level (put bars under the roof), mark the place of contact of the shaft in the roof and make a hole. Then we grease with glue and fix the plate with the shaft to the mill, and then - the roof to the plate with screws from below (therefore, it should protrude beyond the mill).

Manufacturing of blades is the same. Large blades can be cut out of plywood and secured to the shaft with a nut. A more complex option - we drill holes in the blades, insert threaded shafts onto the glue. Then a square is needed, we drill a number of holes in it:

- 4 - from the side, at the points of attachment of the blades;

- 4 - perpendicular to the existing ones, for fastening the threaded cylinders, into which the shafts will be fastened along the thread;

- central - for fixing the blades on a large shaft.

We insert the cylinders into the holes and twist the blades into them until they stop. In this case, you can adjust the angle of inclination and change depending on the wind. After that, all parts are lubricated with a primer and paint for outdoor use.

Now we know how to make a decorative mill for a garden with our own hands. When looking at different photos of garden mills, new ideas and solutions may arise. In the manufacture of metal we use metal scissors and screws / rivets.

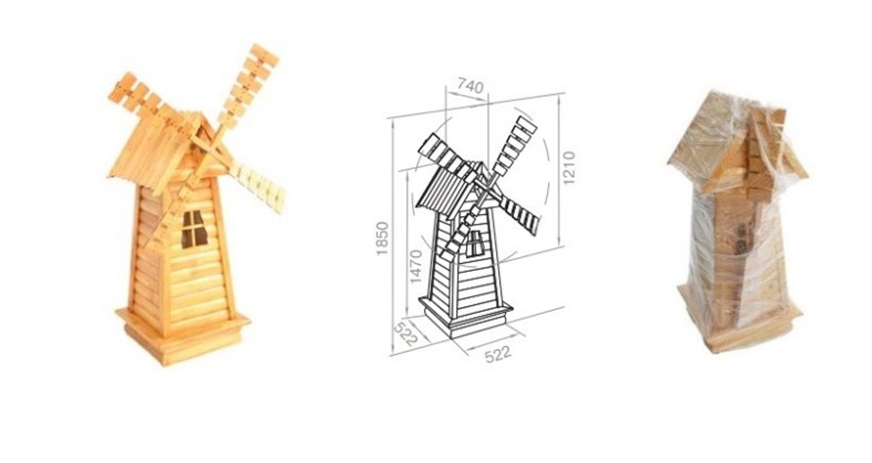

Garden mill device

Most of these decorative objects consist of the following parts:

- platform;

- base;

- frame;

- roof;

- rotation mechanism;

- blades.

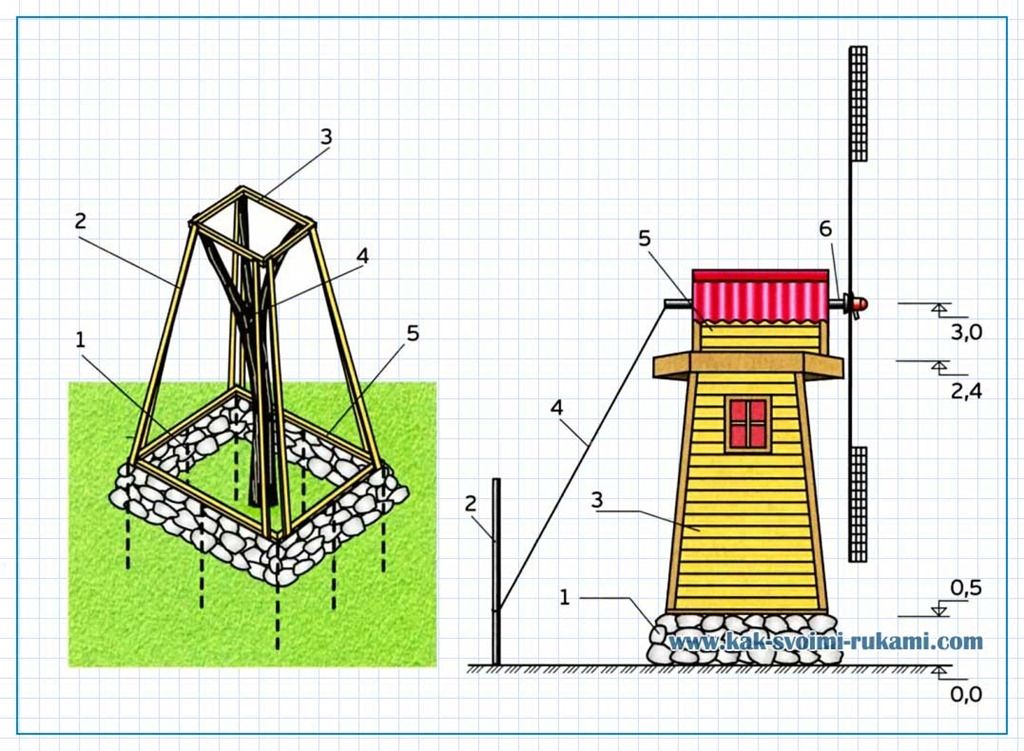

The platform is where the garden mill will be installed. The structure can, of course, be simply put on the ground in a garden or in a flower bed, but then it will not last long - the dampness will do its job and render the decor object unusable. Therefore, it is advisable to build a platform of concrete or stone. The last option will be prettier.

Garden mill with a platform made in the form of flat stones

Some gardeners use plastic pipes instead of a platform, fixed to the base of the mill and dug into the ground during installation.

Base - The bottom of the mill itself, usually wider for better stability. The most stringent requirements must be imposed on the quality of the base processing - this part of the structure is most in contact with damp earth and plants.

The frame is the main part of the decorative object, the walls of the mill. It is assembled from boards, plywood, slats, lining, small logs and many other materials. In addition, the frame has a decorative function and is often decorated with windows, doors, balconies and other small elements.

An example of decoration with various decorative elements like fences and windows

The roof is the upper part of the structure. Usually assembled from slats, planks or lining. In some cases, plastic is used, especially for rounded roofs, which are difficult to make from wood. In its color, this part of the mill should stand out from the frame.

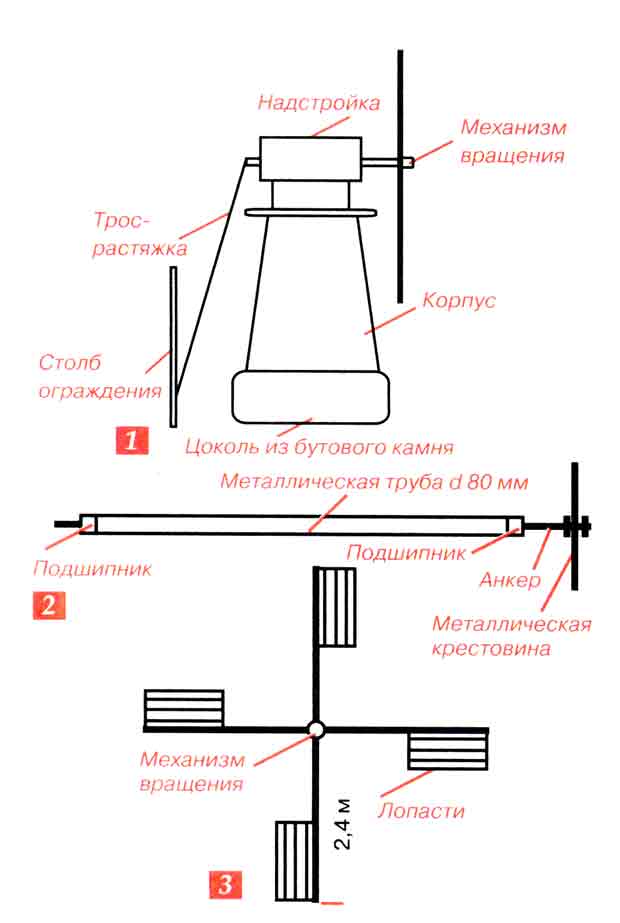

Inside the roof there is a rotation mechanism - an axle on two ball bearings. In most cases, it passes through the entire structure; this location option is reliable and stable. The mechanism can be supplemented by connecting the roof of the mill to the frame on a vertical axis and adding a sail - then the structure will not only turn the blades, but also turn in the direction of the wind.

An example of a drawing with the simplest moving mechanism

The windmill sail is indicated by a red arrow

The blades, also known as wings, are the second most important decorative element of the mill. Assembled from plywood, planks and thin bars

The main condition is that all blades must have the same mass and be balanced, then the mill will last a long time and without problems. Examples of different design options for mill wings are shown in the pictures below.

Garden mills with beautiful decorative wings

For the manufacture of decorative mills, metal is sometimes used, in which case its shape differs from wooden

Do-it-yourself mill for the garden - photo

The best environment for wood crafts is a green lawn.

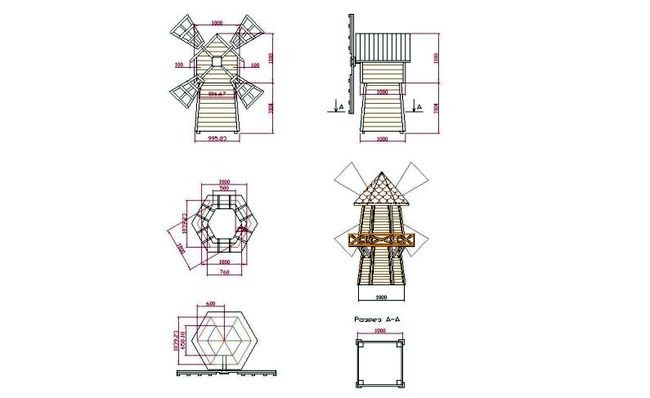

Table. Types of decorative mills for the garden.

| View | Description |

|---|---|

|

With quadrangular walls |

Quite a simple construction. The walls are rectangular, straight or inclined. Usually such a mill ends with a gable roof, but there are other designs as well. An excellent option for those gardeners who do not have much experience with wood. |

|

With hexagonal walls |

More complex construction. Requires a fairly high accuracy in cutting out parts of the desired size and giving them bevels. It is not uncommon for the walls of such a hexagonal mill to taper towards the top. It ends with a dome or polygonal roof. Compared to the previous version, other things being equal, it is more attractive. |

|

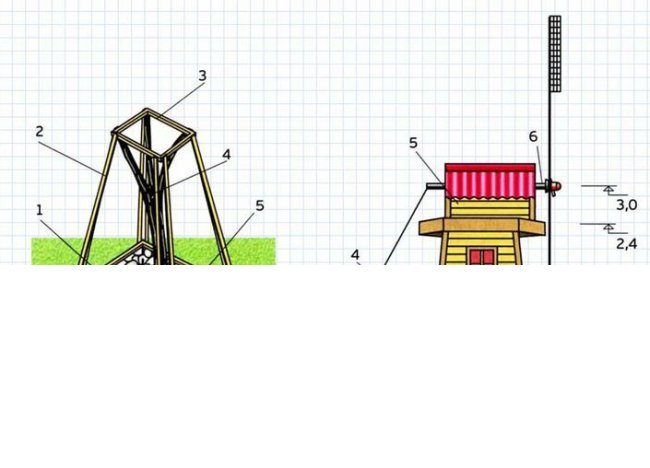

Windmill |

The decorative windmill has the simplest design due to the absence of cladding and a complex roof. In addition to decoration, it helps to determine the direction and strength of the wind on the site. In addition to wood, a windmill can be made of steel profiles, if it is easier and more convenient for you to work with them. |

Manufacturing of a wooden structure

A wooden mill will not be as durable as a stone one, however, the product looks completely different and creates a different mood. It may seem to some that it is much easier to assemble a structure from a tree, but this is not entirely true. Carpentry skills are indispensable.

Wood products do not tolerate high humidity, therefore, the mill must be brought indoors for the winter. This will help to avoid rotting and darkening of the array.

Required materials and tools

You can make a wooden mill from the remains of building material or buy everything you need in the store. Any trimming of solid wood and lumber will do.

Materials:

- wooden beam;

- moisture resistant plywood;

- wood for decoration;

- blade rail;

- roofing material

- nails, bolts, screws of different sizes;

- threaded rod;

- varnish for wood or drying oil.

Instruments:

- saw, hacksaw or jigsaw;

- drill or screwdriver;

- Sander;

- sandpaper;

- hammer;

- brush;

- roulette.

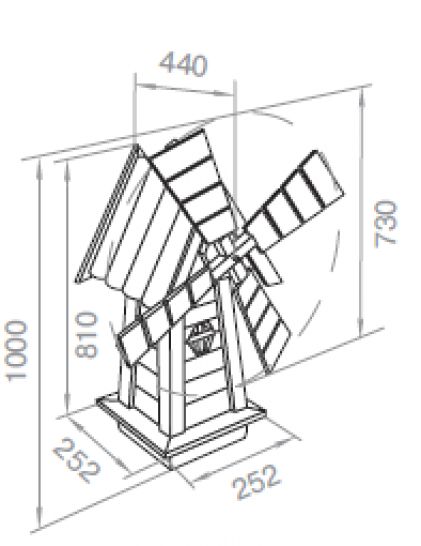

Foundation - is it needed?

A small wooden mill with a decorative function does not need a foundation. The mobility of the structure will allow it to be rearranged at will in any part of the garden.

In the case when the stability of the future building is in doubt, four legs from a beam pointed at the ends are used as a foundation, which are attached on one side to the bottom of the support platform, and on the other are stuck into the ground.

If you are planning a solid building with a utility room or a children's playground inside, then you cannot do without a foundation. This will prevent the mill from overturning. In this case, a shallow foundation is made along the perimeter of future walls.

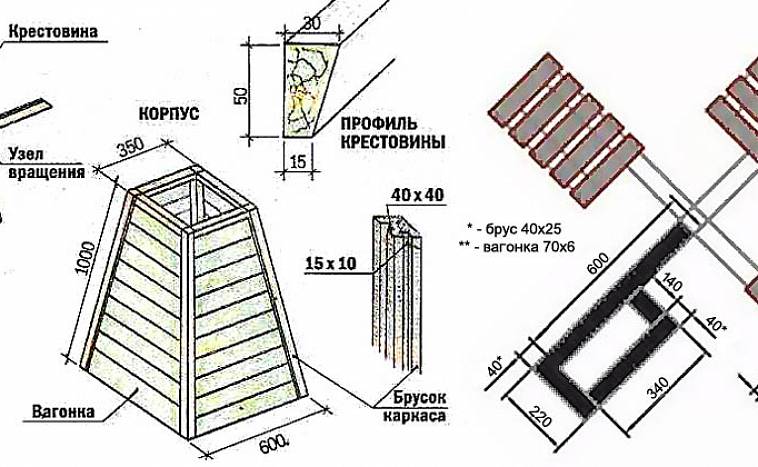

Support platform

The support platform will give stability to the mill. A square of the required size is assembled from a bar. For rigidity, you can additionally connect opposite corners cross-to-cross.

If desired, the area of the support platform can be larger than the base of the mill. This will protect the structure from falling in strong winds and can serve as an additional platform for placing decor, for example, a wooden fence.

Manufacturing of the case

The simplest case for a mill is a trapezoid box. To the support platform, using self-tapping screws, four bars of the same length are vertically attached. At the top, the edges are additionally connected with a bar horizontally

Symmetry is important when assembling

The edges of the resulting structure are sheathed with wood. You can use almost any material. Eurolining, block house or imitation of a bar looks good.

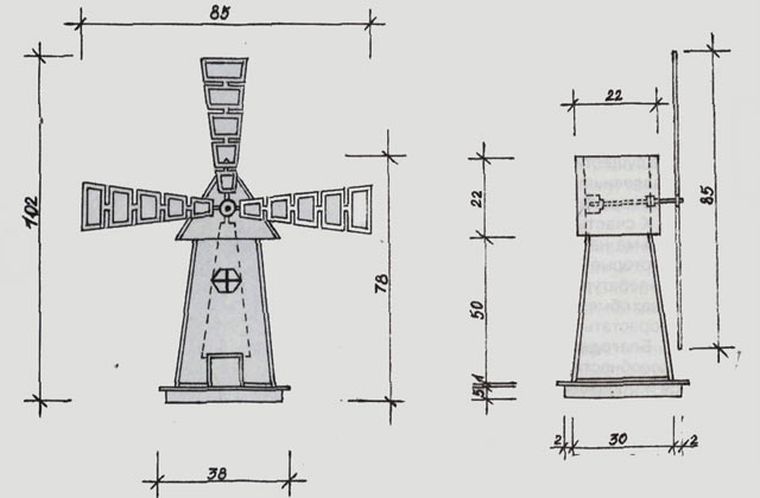

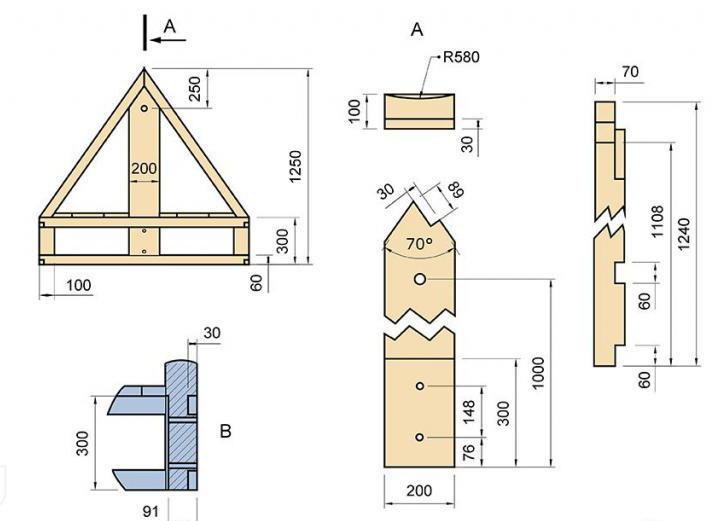

Roof arrangement and blade assembly

The roof can be either gable or hipped. The second option is best used for large structures, and for a small one, a gable roof is ideal.

We knock together two ends in the form of a triangle from a bar. Once upon a time, large flour mills were covered with real fired clay roofing tiles. A decorative analogue can be the same material that was used for the base, trimming the colored profiled sheet, or modern antique tiles. A slope of plywood is pre-laid under the roofing material.

The finished roof is put on the mill body and fixed from the inside with long self-tapping screws.

The propeller is assembled in the same way as for a stone mill. A hairpin is installed in one of the edges of the base, only in the case of a stone it was walled up in the masonry, and here it is fixed with nuts. Similar to the previous version, the blades are put on the other side of the stud and fixed.

Decorative finishing

The wood mill has a variety of decorative finishes. Flowers and greenery look good next to her. Alternatively, turn the building into a flower garden. To do this, its base must contain a box for earth, where marigolds, phloxes, petunias or any other annual garden plants are planted in spring.

The finished mill must be impregnated with a protective solution and painted, or coated with linseed oil or varnish. If you walk on the wood with a stain before that, you can emphasize the structures of the tree. Each additional layer will darken the surface of the mill.

Where is it better to place and what to combine with

Garden mills come in a variety of sizes. An object of this type can be placed slightly away from the high fence, which will create the effect of a fortress. If your garden has a small pond or lake, then a mill structure will perfectly complement this composition. Try not to overload it with large items.

A mill lined with stone will look great, besides, such designs can be supplemented with old-style garden wheelbarrows, sophisticated benches, mini-bridges over a pond or tall lanterns. Clay animal figurines can also be harmoniously used to complement the overall composition.

Read how to use amphorae in landscaping.

Artificial nests with chicks, storks with long legs, herons are perfect.Little gnomes, located at the structure or accompanying a stone path to it, will be able to transfer to the atmosphere of a fairy-tale forest and will also brighten this complex.

At the mill itself or nearby, you can place wooden containers in which small flowers of bright colors can be planted. Contrast can be achieved this way, especially if the design is dark chocolate. Shades such as fuchsia, white, yellow are perfect, you can even combine several colors.

Tips before starting work

-

- Before proceeding with the construction, you need to consider the rules. The first step is to choose a location. It should be clearly visible and in harmony with the surrounding environment. That is, putting a mill right under the house is not particularly logical, but at a distance, so that one can observe it, is what you need.

- The second point: we will make a mill out of wood. There will be no problems with the compatibility of this natural material with other elements of landscape design.

Wooden style of decoration of the local area

Advice! If there are no ideas where exactly to place the mill, in the design of the site, you can use such a direction as landscape. It provides for the independent placement of decorative elements on the site, at a certain distance. They may not be connected at all with each other.

Beautiful building in the center of the garden

-

-

- The style of the mill on the site is the best possible way to emphasize the country style that is gaining popularity. The structure can be installed near the gazebo, if it is made in the form of a stylized hut.

- If an oriental style is visible in the design of the site, then you simply cannot do without a water mill. It can be harmoniously located near a shop or pagoda. You should not mount it in the far corner of the garden, as it will surely become the centerpiece of the decor on the site and should decorate, and not be hidden away.

- You should also be very careful when choosing a location if moving blades are planned. This is possible even for the decorative mill, which we are planning to create. That is, it is not necessary to place it too close to trees and any buildings.

-

Internal mechanism

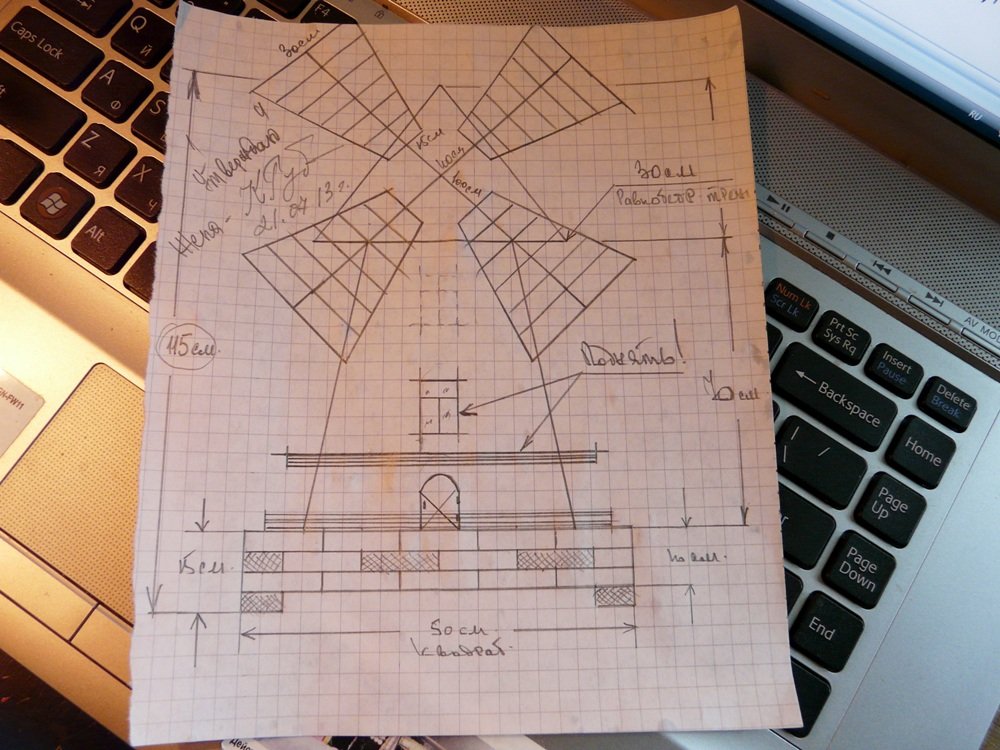

25. Now we need to make the structure for the blades of the mill.

As you may have noticed, a decorative windmill for a summer cottage is not an easy project, but it is worth the effort and time.

So, you need to make two flat wooden squares with holes inside, as shown in the photo, and drill holes in the right places.

Further, following the photographs, you need to cut them in half.

Now, for two parts, you need to make a base of three pieces of boards (on the outer ones you need to drill two holes) and fasten them with glue, setting them in a vice.

And then place it on a solid base.

Note that it should also have 4 screw holes.

The final step in making the base for the internal structure of the mill is to install a support cut at an angle to make the structure look like a slide.

26. Now you can install the tops of the squares with the hole using the screws. But do not fasten them too tightly.

27. Next, you will need a threaded stainless steel rod and nuts and washers. Follow the instructions to properly mount the "cannon" structure.

28. In the hemisphere, you need to make a hole through which the rod could rotate freely. But to choose the right place for it, take the support panel, attach a wooden ring to it and set the "gun" inside to the wall (to the ring). Putting the half-ball at the same height as the height of the support panel and the ring, on the side where the rod is higher, mark the place where the rod and the half-ball meet and make a hole in it.

29. Now you need to glue the ring to the hemisphere, rewinding the resulting "helmet" with tape for strength, for a while.

thirty.It's time to install the support panel (use a screw to attach it in the center to the top cover of the frame), the "gun" in the middle and the "helmet", after removing the adhesive tape from it, when the glue dries, so that the rod comes out through the half-ball prepared for it hole.

31. Screw the support plate to the ring from below - the holes are already prepared for this.

Wind blades

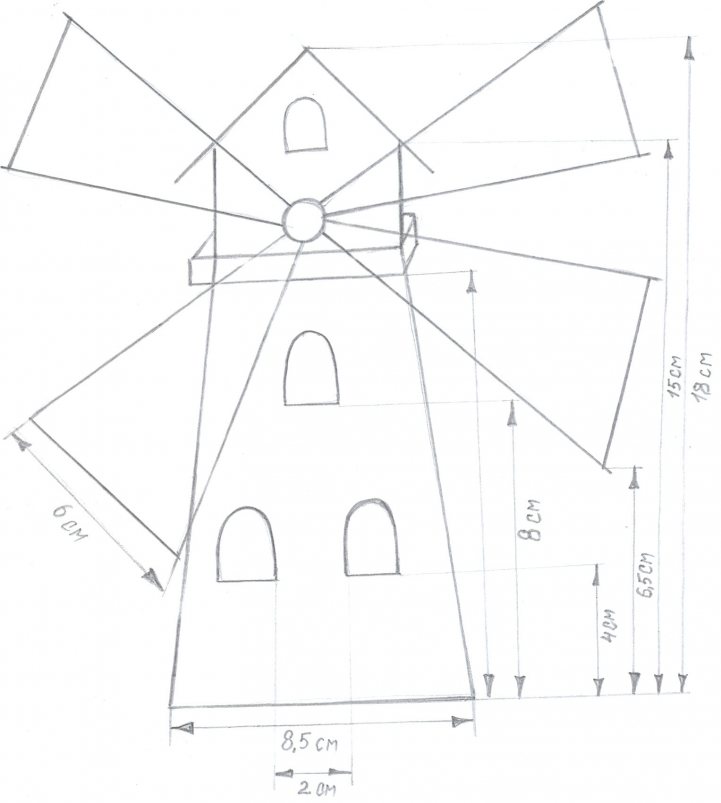

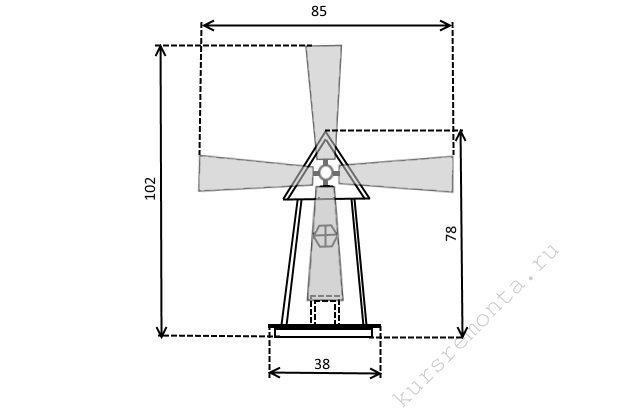

The blades are the main part that makes the mill a mill. There is no need to bother about their design, we still make a decorative mill. But simply knocking down the structure of the boards and hanging it on the building will be too little. Consideration should be given to parameters such as the size and width of the blades, their weight and inclination from the axis. It depends on these parameters how the blades will take on the wind and spin.

Windmill blades must be calculated

It is especially important to pay attention to size and weight. The following materials can be used to create the blades:

The following materials can be used to create the blades:

- Wooden lath with plywood - considered lightweight and practical at the same time;

- Wooden beams and dense polyethylene film;

- Thin wooden slats are attached to an axle that rotates the blades.

At the last stage, you need to install the axle and reinforced beams inside the structure, then put on and fix the blades.

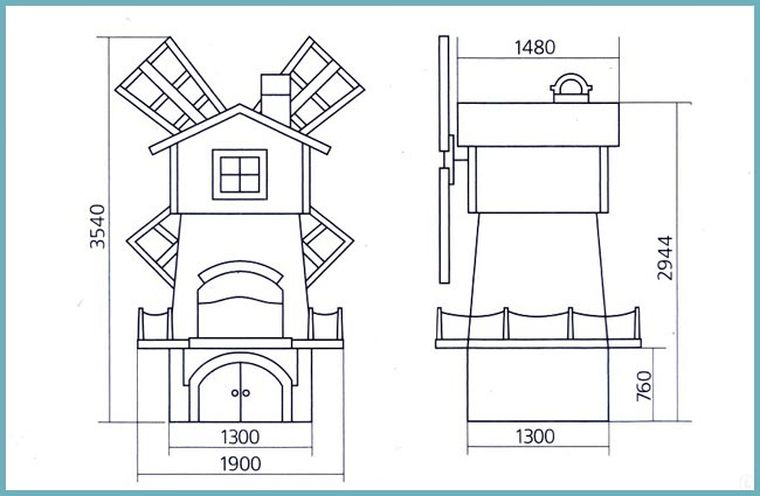

What elements does the structure consist of?

Almost all models of decorative mills consist of the same parts. They can differ from each other in the technology of installation, for example: objects made of plywood are built according to one scheme, and from metal or brick according to another. List of building parts:

- concrete or brick platform;

- lightweight foundation - elevation above the platform;

- frame of the building;

- roof of different shapes;

- part for rotation;

- balanced blades.

There are not many structural elements, but they all perform different functions. Therefore, it is necessary to know for what purpose this or that part of the mill is used. Description of the structure in detail:

- Platform. If you place the decor object on the ground, then after a short time the building will collapse, since moisture destroys the wood material. The platform should be made of concrete or brick - this is the launch pad on which the object will be erected.

- Foundation. This structural element is constructed of bricks. That is, you need to make a small foundation that will protect the building from dampness. The base is also intended for good stability of the decorative item.

- Mill skeleton. This is an equally important part. The frame is mainly made of timber or logs. The skeleton of the roof must be done correctly, taking into account the location of the windows and doors. Then the structure is sheathed with plywood or other material.

- Roof. Oftentimes, owners opt for rounded hexagonal roofs because the mill is essentially rounded. However, any roof option is allowed. A soft roof is used as a roof covering.

- Detail of rotation. This element is usually installed from the inside of the roof and consists of bicycle bearings and an axle. The structure is connected with blades, which begin to rotate due to gusts of wind. The rotation mechanism can also be connected to all elements of the mill, and not only the blades will rotate, but the entire structure will rotate. But for this, a sail is mounted on the axle. Bicycle bearings are also recommended.

- Wings (blades). The structure is constructed from any available materials, but it is easier to make from plywood or planks. When attaching the wings to the axle, you need to take care of the balancing and symmetry of all four parts.

What is a windmill for today?

Before you decide to choose a place where a self-made windmill will be installed in the future, you should definitely keep in mind that the structure may have a different purpose.

Firstly, a DIY windmill can hide some of the least pretty places in your home, like a manhole.

Secondly, most mills, which, in principle, can be made without any problems by their own efforts, are quite simply made of lightweight materials, which makes it possible to significantly reduce their size.

Thirdly, many owners of country houses decide to turn the drawings of the mill in real life into a house for their children to play. True, this requires a slightly enlarged structure, but there is definitely nothing possible.

The main thing to pay attention to is that it is as stable as possible and with an open entrance.

Of course, having decided to make a mill for the garden, one can subsequently find a huge number of a wide variety of uses for it, as a component of modern landscape design.

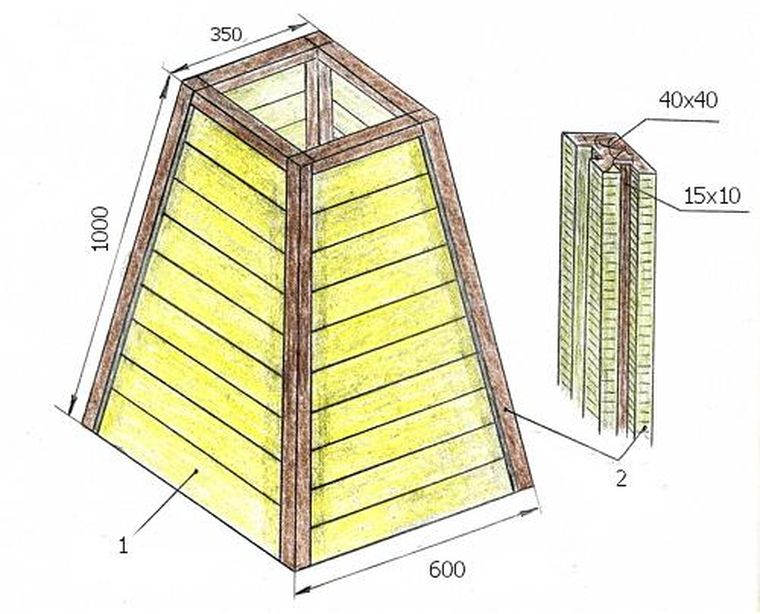

Frame

Next moment. Since a wooden mill will be quite simple in design, it is advisable to lay its frame at the same time. To do this, you need to take into account the scale of the product, install the most massive beam. If there is a pine tree among the harvested pile of logs, it is best to use it. Pine is not so afraid of water.

We proceed to the installation of a frame made of a reliable wooden bar. Actually, we have two crowns: the lower one is the base of the case; and an upper, lighter and smaller one - the base of the roof. The ideal ratio of the scale of the lower and upper rims is 1: 1.5, that is, the lower rim is one and a half times higher than the upper one. These dimensions are needed to create a trapezoid - the classic shape of a medieval windmill.

Both frames must be connected with strong vertical boards that play the role of racks. Boards need to be led at a certain, well-formed angle, depending on the length of the posts. They will rest against the lower frame. You can use nails or wood glue to strengthen it. Which is better? Mixtures based on conventional PVA work well, such as Titebond II. But it is cheaper to stay on the Moment-Stolyar glue.

The other end must be aligned with the top frame. The boards should also be reinforced with poles or a thin beam. Thus, the frame of the decorative mill will be made.

How to build a mill?

Initially, you must create for yourself drawings of a future mill for a summer residence. There are many types of mills, but we will figure out with you how to build a log mill with our own hands.

This mill is inexpensive and easy to make. So, we offer you a plan for the construction of the mill:

You need to take two shovel handles, assemble them side by side and tighten them with bolts. Be sure to make sure that the remaining blanks should be slightly longer than the future mill. The designated cups should be at a sixty-degree angle, as we are talking about a hexagonal mill now.

Put the combined cuttings on the sloping wedge. Saw the cups under the frame with an electric saw. After that, turn them over the other side and drill again, but this time from the other side. The mill base is ready. Repeat this procedure until you have the required number of logs for your mill.

Very carefully you need to cut 6 identical logs in half. You get one with cups, which will be on top of the base, and the other without, necessary for the bottom of the base.

The logs need to be connected together with pins. You can also do this with wood glue. Assemble a hexagonal base from two planks and insert the studs at the corners of the next log house. String the previously prepared halves of the logs without cups onto hairpins.

Gradually push the logs onto the studs, creating the correct frame. Inside you can make holes for windows or doors.

Attach long and thin sticks to the corners, which are the future walls of the mill.

Next, you need to sheathe the walls of the mill with small slats, also varnishing.

Drill a hole for the axle at the ends of the roof.

Take three sticks and cut them out. They will become the frame of the blades - one in the center and two side ones. On the middle, form a rounded hairpin to fit the blade onto the axle. After that, nail the pieces of the frame onto the slats and cut them out in the desired shape.

Grind the wings of the mill and place them on the axle. Place the finished mill in the required area of the summer cottage.

Sheathing

Now the important task is to carefully sheathe the frame. In this case, you need to make a small decorative window, a door. At this stage, the roof is created, the blades. Plywood is used in the first stage of cladding. On top of it is a pre-sanded board.

Advice! The block house looks attractive. This imitation of log masonry is easy to install. Its decorative effect is very attractive.

Sturdy concrete footrest

Garden mill construction scheme

At this stage, you can paint and varnish the main body, since when the blades are attached, this is inconvenient to do.

Construction of a stone mill

The indisputable advantage of the stone mill is its durability. With minimal maintenance, it will stand on the site for more than a dozen years. The disadvantages include the complexity of moving, as well as dismantling, therefore, the construction should be considered thorough.

Required materials and tools

Construction starts with a project. Having decided on the size and appearance of the future structure, you need to draw a plan. This will allow you to calculate the required amount of materials.

Materials:

- brick or broken fragments for the foundation;

- cement and sand;

- natural stone or tiles for cladding;

- sheet metal or wooden slats for making blades;

- threaded rod; nails, bolts, nuts, screws of various sizes.

Instruments:

- mixer and bucket for mixing the solution;

- putty knife;

- Master OK;

- roulette;

- level;

- if the blades are made of wood, then you will need a saw, hacksaw or jigsaw.

Foundation

A stone mill will need a foundation, this is the only way to ensure that the building does not float with the ground in spring or during rain.

The depth of the bookmark depends on the overall dimensions. For a small mill with a height of 1-1.5 m, a hole is dug 40 by 40 cm, about 30 cm deep, reinforcement is laid inside and poured with a cement-sand mortar. The foundation should dry out for several days, after which construction can continue.

Building a house

Inside, the finished house will not be empty, so you need to prepare the base. It is most convenient to use a brick or its fragments. It is necessary to fold the masonry of the desired shape. The size and proportions can be any, but it is better to make the mill in the form of a trapezoid or cone. For the bond, the same cement-sand mortar is used. The structure must be flat, therefore, during construction, a level is used.

In the process of laying bricks, a threaded rod is walled into the base for further fastening of the blades. A plate is welded onto it in advance or a large nut is screwed onto it, with which it hooks onto the brickwork.

At the same stage, other technical holes are provided in the base of the mill, because when the solution hardens, it will no longer be possible to change the design. Of course, you can try to drill the masonry, but in this case, a split of the entire base is not excluded.

The shape of the roof depends on the shape of the house. For a cylindrical base in the form of a tower, a traditional cone-shaped roof is suitable, the covering of which is made of cladding material, and for a rectangle, a conventional gable roof.

How to decorate

The mill can be decorated with natural or artificial stone. Tiles made in the form of small bricks look best. A building lined with such material will look like a reduced copy of a real old mill. The outer layer should be laid on a moisture-resistant glue, avoiding voids.The better the work is done, the less moisture will penetrate inside, and the mill will retain its good appearance longer.

Propeller manufacturing

The blades rotating under the influence of the wind are the most recognizable part of the mill, however, when making a decorative version, they can be motionless.

There are several ways to assemble a propeller.

First option:

- Two circles with a diameter of 15-25 cm are cut out of plywood, and a hole for a hairpin is made in the center with a drill.

- Blades are assembled separately from the rack. In order for the wind to spin the propeller and rotate the millstones, in a real mill they are slightly angled, which allows air currents to be captured.

- Both parts are treated with an antiseptic and painted over.

- The blades at the same distance from each other are clamped between two plywood circles using glue or bolts.

- The finished propeller is put on the stud, the nut is screwed on both sides.

Second option:

- Two long strips, with the help of glue, are connected cross to cross.

- A hole for the stud is made in the center of the intersection.

- Rails in the form of a blade are nailed to each edge.

- The finished propeller is put on the stud and secured with nuts.

If desired, the blades can be cut from sheet metal. In this case, sharp edges must be processed, and the parts must be welded together. A decorative stone mill with a metal propeller looks more harmonious, but the iron must be painted to avoid rust.