Gas tank restoration

The restoration of the fuel tank is required when dents appear, corrosion and in a number of other cases.

Removing dents

As a result of mechanical stress, dents can form on the gas tank, which will interfere with the normal operation of the float. As a result, the fuel level in the tank will be displayed incorrectly on the dashboard. In addition, dents can significantly reduce the volume of the tank.

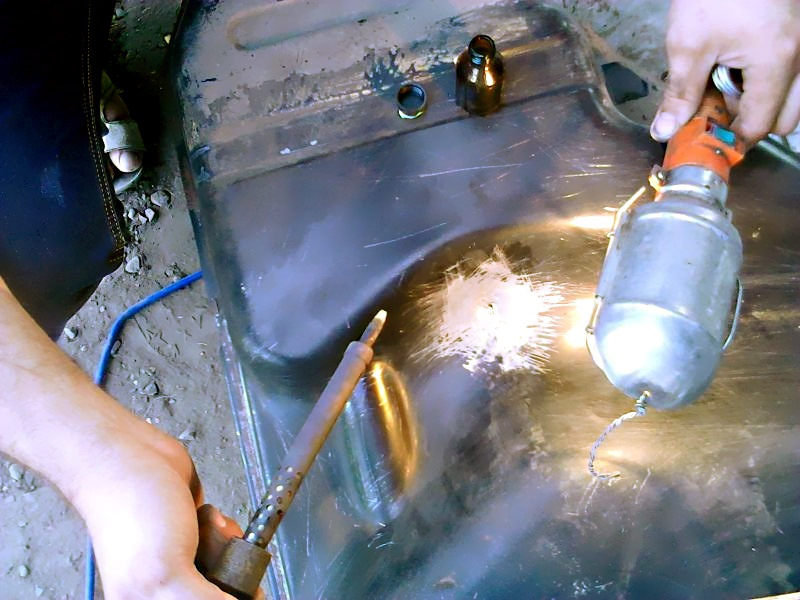

Repairing dents involves filling an empty tank with compressed air under pressure. The work should be done very carefully. If the pressure is too high, the tank may split at the seams and need to be replaced.

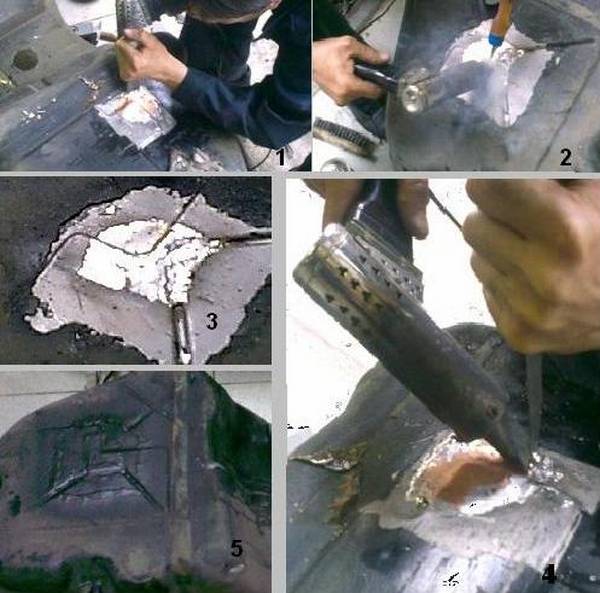

Dents can be removed by welding. After dismantling the tank to the damaged place weld on a suitable element that will allow back blows to be applied to it. After straightening, this element is cut off.

You can also contact a bodybuilder or use a spotter.

You can remove dents with compressed air under pressure.

If a dent has formed under the hole of the fuel pump, then you can, after disconnecting the pump, try to press on this place through the adapter. This procedure should be performed carefully so as not to damage the opening of the gas pump.

If the dent does not affect the operation of the fuel sensor, and the decrease in the volume of the tank is not critical, you can do without repair.

Corrosion protection

When using low-quality fuel, water may enter the tank. This, in turn, can lead to corrosion of the metal gas tank. Moreover, other impurities contained in the fuel can lead to malfunction of the injection pump (for diesel engines) and shorten the life of the fuel tank.

The main reason for the corrosion of the gas tank is the use of low-quality fuel.

The situation is aggravated in the cold season - when water gets into the fuel system, it can simply freeze. As the temperature rises, it will melt and enter the engine. This can lead to more serious consequences.

Corrosion arising from the presence of water or humid air in the tank (with constant operation of an incomplete tank) leads to a leak and subsequent repair or complete replacement of the gas tank.

Internal tank treatment

To protect the tank material from corrosion, you can use special agents to remove rust and form a protective layer. You can also cut open the tank, clean it and cover it with a protective layer.

When using special agents, the tank is cleaned of rust and covered with a substance that, after drying, forms a polymer layer.

To protect the tank material from corrosion, special polymer compounds are used.

To prevent the appearance and development of corrosion, do not leave the fuel tank empty or with a minimum of fuel. You can use a special paint that is resistant to gasoline and acid called "liquid plastics". After it dries, a strong polymer film forms. It should be noted that this method is permissible only with a minimal risk of mechanical stress on the gas tank. Otherwise, the polymer layer will simply peel off.

In addition, the fuel tank can be protected from corrosion by chemical etching followed by galvanizing.

To protect the tank from corrosion from the outside, it must be dismantled, cleaned of rust, treated with a rust converter and covered with primer. After drying, mastic is applied to the surface of the tank.

New technologies have many advantages

One of these elements is a plastic gas tank, which has undeniable advantages over its metal counterpart:

The weight.Plastic products are usually about 3 kg lighter than metal structures. This indicator is especially taken into account in the world of auto and motor sports, in the production of sports cars and motorcycles, where there is a stubborn struggle with excess weight;

Anti-corrosion resistance. Corrosion does not threaten plastic products, unlike metal ones. No matter how the metal is processed from the outside, all the same, an aggressive external environment makes its way to the structure of the substance, causing irreparable damage to it. The same problem is inherent in the internal space, the destroyed surface fills the fuel with metal particles that contaminate filters and other elements of the fuel system of the machine;

Security. A plastic gas tank is easily deformed and takes an impact compared to iron, which, as a result of hard contact with other rigid elements of the car's structure, can spark a spark, which, in turn, is fraught with fuel ignition at best. Perhaps, and a more sad result, when mixing in certain proportions of fuel vapors with air, an explosion is possible;

Manufacturing cost. With an established scheme for the production of this plastic product, its price comes out much lower than that of iron products. So, the use of a plastic tank in the design of Lada Kalina made it possible to reduce the cost of the car. It is also known that many other manufacturers use polypropylene products, for example, Hyundai, Ford, Renault, Nissan and many other well-known brands.

The photo shows a plastic gas tank. Let's talk about its cons

Refurbishment and repair of a gas tank

In modern passenger cars, the fuel tank is usually installed in the rear lower part of the body. This is due to both the requirements for adjusting the center of gravity of the machine and the safety of the controls. However, with this arrangement, the tank body is constantly exposed to road dirt and chemicals, which in turn leads to corrosion.

Through the hatch, the fuel enters the neck, and then flows directly into the container of the tank itself.

Safety requirements

When repairing a fuel tank, basic safety requirements must be observed:

- It is imperative to make sure that the machine is securely fixed in one place.

- Start work only after completely emptying, rinsing and drying the tank.

- Determine the advisability of dismantling the tank - sometimes you can carry out repair work without removing it.

It is most convenient to drain gasoline using special pumping units.

Dismantling the fuel tank

In most cases, the gas tank must be removed for repair. The fuel level should be kept to a minimum. For dismantling you will need:

- flat and Phillips screwdrivers;

- ratchets;

- pliers.

The dismantling itself is carried out as follows:

- The pressure in the fuel system is released - the power plug is disconnected from the fuel pump. Usually the pump is located in the gas tank itself, and you can get to it through the passenger compartment by lifting the back seat.

- The car is driven into the inspection pit or raised from the rear by a jack.

- From the bottom of the tank, loosening the clamps with a screwdriver, unscrew all the hoses.

- From the side of the rear beam, in any sequence, unscrew the two bolts securing the tank to the bottom of the body. In this case, you should hold the gas tank so that it does not fall.

- The tank is carefully pulled out from under the car.

Reasons for the appearance of cracks in the gas tank

On most vehicles, the gas tank is located at the rear (right, left, under the rear seat). This design feature is due to the safety for passengers and the driver. In addition, vehicle handling is improved. However, the rear part of the body is quite often exposed to external damage during the operation of the car, as a result of which the gas tank also suffers.

Metal corrosion, which is an inevitable process, is also considered to be a significant cause of damage. The more mileage a car has, the higher the likelihood of this kind of problem. Power system malfunctions are less common. Since a rarefied pressure is created in the middle of the tank as fuel is consumed, this affects the condition of its walls. During operation, small cracks may appear on them, as a result of which increase, a leak occurs. This situation indicates the need to repair the gas tank.

Corrosion is one of the causes of damage to the gas tank.

What to do if a reservoir leaks

The appearance of a crack, hole or any other type of damage to the gas tank is inherent not only in domestically produced cars, but also in foreign cars. When the tightness of the tank is broken, it is necessary to fix the problem as soon as possible. Operating a vehicle with such a malfunction can lead to disastrous consequences, and the danger threatens not only those in the car, but also those around them. Due to the fact that the fuel tank is a simple structure, it will not be difficult to restore the tightness. However, much depends on the degree of damage and the feasibility of such an event. Since gas tanks are made of different materials, different repair methods are used.

Cons of plastic versus iron

Despite the relevance of modernizing the gas tank, the transition from iron to plastic was slowed down for a number of reasons. At the beginning of 2000, new environmental standards were issued, into which plastic fuel tanks did not fit, due to the fact that, despite all the tightness of the structure, the leakage of fuel into the environment was more than 20 milligrams per day. Most of the losses occurred on the outside fuel intake lines. At present, the problem has been overcome by shifting the elements of the fuel delivery system to the tank, and by using a multilayer structure. This modernization has reduced the likelihood of fuel leakage to zero, the main thing is that your hands do not shake when refueling the car.

Today, about 70% of new cars are equipped with plastic gas tanks, but the problems that cause inconvenience to the owners remain unresolved:

- The noise from the fuel tank disturbs the sound atmosphere in the vehicle interior. Of course, if a person drives cars of the VAZ family, such as VAZ 2107 or VAZ 2110, then this nuance will be unimportant to him. At the same time, this discomfort is very annoying to the owners of Hyundai Sonata and Kia Sid;

- Internal pressure regulation. Due to the fact that plastic lends itself well to deformation, each change in pressure leads to contraction and expansion of the container. These actions lead to fractures of the joints on the neck under the lock of the hatch cover or in other similar mates.

Despite possible troubles, most drivers install plastic gas tanks on their cars. The advantages of these products outweigh the disadvantages. For owners of Mitsubishi Pajero, the anti-corrosion resistance of plastic is relevant. The owners of the VAZ 2114 are interested in the economic component, because the maintenance and repair of a plastic gas tank is cheaper than a metal one.

How to put the gas cap back on line

You can pay attention to a malfunction of the gas tank cap if, when it is opened, a noise effect is noted associated with the suction of air into the container. Repairing the gas cap of the often plastic leash

You can replace it with ties that hold the wires together. For work, you need three clamps. Insert one of them into the lug of the fuel tank cap and tighten the tight loop. Connect the second clamp to it. In the loop of the gas tank flap, make a small hole to which to tie the loop knot.The second end of the clamp will be tied to it, located on the gas tank cover

Repairing a gas tank cap is often a plastic leash. You can replace it with ties that hold the wires together. For work, you need three clamps. Insert one of them into the lug of the fuel tank cap and tighten the tight loop. Connect the second clamp to it. In the loop of the gas tank flap, make a small hole to which to tie the loop knot. The second end of the clamp will be tied to it, located on the gas tank cap.

Knowledge of the peculiarities of repairing a fuel tank is extremely useful for the driver. Understanding the repair issues, not a single motorist will be taken by surprise, even far from civilization.

How to glue the gas tank of a car?

Today there are two options for gluing

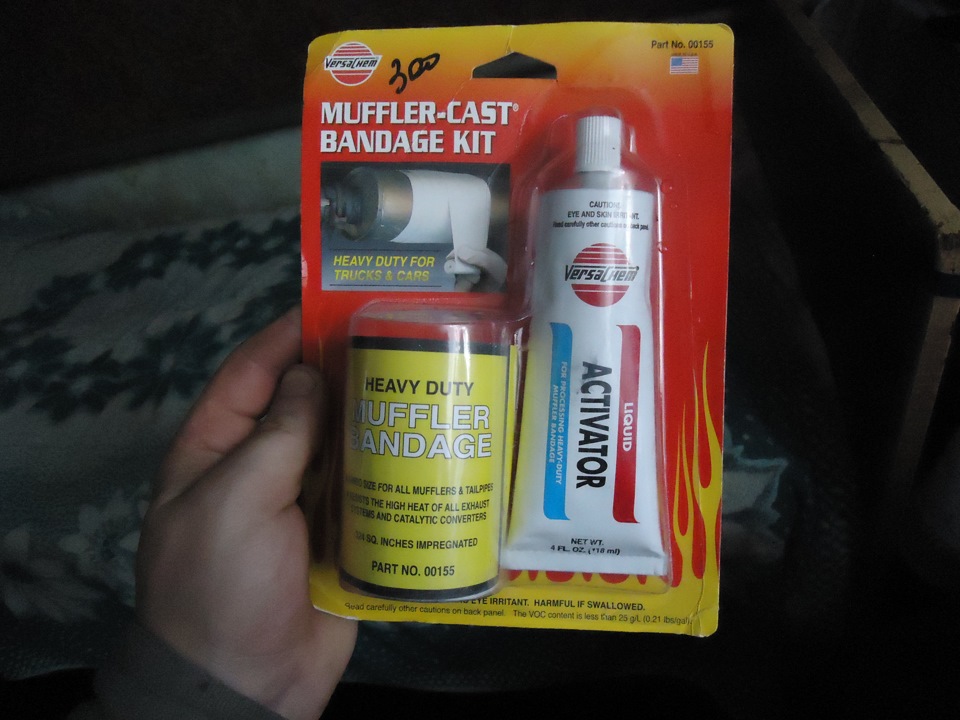

- Using cold welding to seal the crack and hole;

- Epoxy glue or popularly called fiberglass. Better to buy a two-component.

Each method is good in its own way. Of course, you can find other ways to eliminate leaks in the gas tank, but they are less effective than the above.

Tools and related equipment

- Several sheets of sanding paper;

- Half a liter of acetone;

Epoxy resin;

Fiberglass.

First, we purchase all the above materials, carefully read the conditions of the instructions for use.

Troubleshooting Algorithm

- We drive the car to a viewing pit or overpass;

- We outline the place of leakage with chalk;

We dismantle the fuel tank from the car;

Pour out the remnants of gasoline or diesel fuel;

We dry it in the open air, since the vapors of the chemical reagent are explosive;

Using rags and soapy water, we externally clean the gas tank from resin residues, dirt, and other impurities;

To clean difficult chemical compounds, we use coarse sandpaper;

Degrease the surface of the gas tank with acetone. This procedure must be carried out several times, since the quality of gluing the material of the gas tank depends on how well the degreasing is carried out;

Preparation phase and epoxy bonding

For gluing, it is necessary to use glue of a viscous consistency, otherwise the effect may not be achieved.

- We cut scraps of fiberglass so that they protrude 1-2 cm more than the perimeter of the crack or other damage. We saturate the scraps of fabric carefully in an eboksitka;

- Gently apply fiberglass to the surface of the gas tank so that no air bubbles remain, otherwise eliminate the imperfections;

Remove excess glue and resin with a rag;

Smooths the glass strip with a small piece of plastic to keep the platform flat;

After that, we proceed to the imposition of the second ball, we carry out a similar procedure. Depending on the degree of damage to the gas tank, it is determined with the number of balls of fiberglass. Accordingly, minimal damage will require a minimum number of balls of fiberglass, deeper areas of damage will require more balls.

Note to the driver, it must be remembered that the quality of the rest of the structure depends on how the first layer is laid.

Each subsequent layer should be slightly wider than the previous one and with an interval of 15-20 minutes.

In addition, the last layer is additionally impregnated with aluminum powder, which can be purchased at a car dealership.

After a day, the structure will completely dry out and harden. You can process it with fine sanding paper.

We proceed to painting or priming, depending on the need.

We apply cold welding in the same way as above. Despite the advanced technology in the form of welding, many drivers prefer the old proven and durable methods. So, the question of how to seal the gas tank has already been disassembled.You can carry out a similar procedure both in a garage and at a car service, depending on your decision.

Quite a frequent occurrence that can catch the driver in the most unforeseen situation. Failure of the gas tank is a serious problem that needs to be at least partially eliminated at the scene of the accident. This will allow the vehicle to be transported to the nearest service centerwhere it will be possible to carry out a major inspection and repair. Do-it-yourself gas tank repair is not too difficult for people with some knowledge about this.

The location of the gas tank is the lower right corner of the rear sector of the vehicle. This is due to the provision of safety for the driver and passengers, as well as the formation of the correct center of gravity in the car, which makes it possible to improve its handling. However, the lower area most often suffers from constant physical impact, which leads to multiple damage to all mechanisms located here. The fuel tank is no exception.

Ways to repair a fuel storage tank

There are several ways to troubleshoot. Most of them are applicable in extreme conditions, which will avoid spending additional funds on.

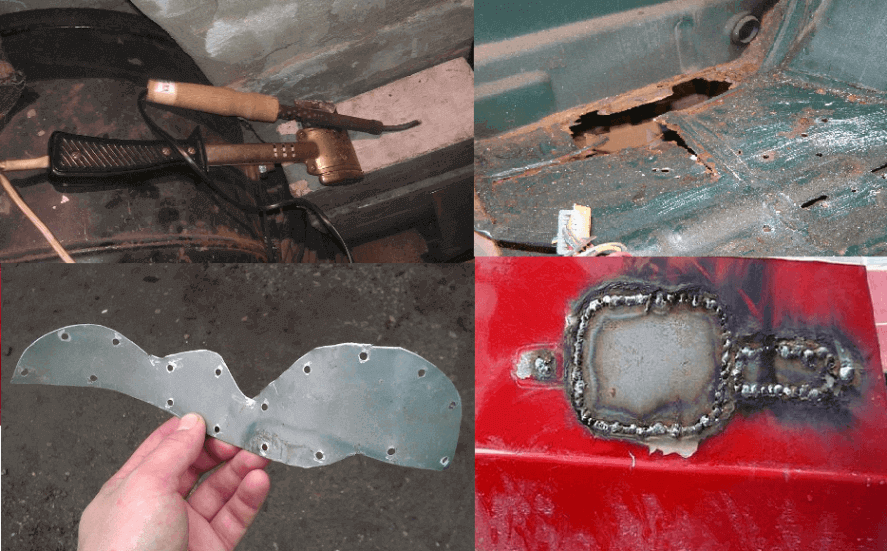

Installing the patch with a nut bolt and rubber washer

... First, you need to expand the tank hole to a size corresponding to the bolt with the help of available tools. A washer with a rubber gasket is put on its narrow part. Then the whole structure is inserted into the hole through the neck. On the outside, a cuff with a washer is installed and tightened with a nut.

The rubber must be petrol resistant. Not every driver has such material stored in the car. A camera from any truck is suitable as a replacement. This patch is considered to be quite durable. When contacting a service station, you can wait. This method is often used by truckers who spend most of their time on the road. A good patch can last over five years.

Use for elimination of damage to glue "Moment" or any of its analogs

... The method is relevant for not very serious damage. To create a patch, you need a piece of thick but pliable cloth dampened with glue. It is required to press it firmly to the place of damage and hold it for some time. After the main gluing, the patch should be treated with nitro paint from the repair kit. This is a temporary measure to get to the nearest service station.

The video shows the repair of a hole in the gas tank:

Temporary replacement of the gas tank for any bottle.

The method is suitable for the breakdown of the fuel capacity of cars of the carburetor type. A plastic or any other container is filled with gasoline, a hose from the fuel pump to the fuel tank is immersed in it. The container should be securely fastened so that it does not overturn and lead to negative consequences. This method will easily help the driver get out of a difficult situation.

Elimination of damage with laundry soap

... The method is considered effective only in case of superficial problems.

Sealing the crack area with epoxy glue and fiberglass

... The gluing site must be thoroughly cleaned and dried, the gasoline must be drained. Clean the work area with sandpaper, degrease and dry again. A piece of fiberglass must be glued to the place of damage. After completely dry, stick another patch of the same type. The number of layers must be at least three. When gluing the last layer, a plasticizer should be used, which can be aluminum powder.

Repair of plastic gas tanks and metal gas tanks by cold welding

... The very fight against holes. Damage is removed with epoxy. The first stage of work is grouting the surface with sandpaper.Then, in a separate bowl, the epoxy resin is mixed with the hardener until a homogeneous mass is obtained. If heating is required, the container can be placed on the engine. This method also uses a fabric patch. Soak it liberally with the mixture and apply it to the hole in the fuel tank. Let dry well. This patch is very strong and can last a long time.

How to properly glue a plastic gas tank?

Significantly lightening vehicle design is an extremely necessary operation when it comes to creating motorcycles for a variety of races.

By reducing the weight of the gas tank, engineers achieve a significant reduction in the total weight of the motorcycle, which has an extremely positive effect on its maneuverability, acceleration speed and the duration of the journey from refueling to refueling.

A plastic gas tank has sufficient ductility to successfully withstand various mechanical loads. In addition, it can easily be given the desired shape and configuration, which has a positive effect on the manufacturing process of this component.

It should be noted right away that leaks occur extremely rarely in a gas tank of a seamless type. Rust and any types of corrosion are also completely out of the question. When a plastic tank is damaged, there are certain manufacturer-tested and recommended methods for restoring it.

What material is a car gas tank made of

Fuel tanks are a dangerous structural element of a vehicle. The safety of using the vehicle depends on its tightness. In addition, leaks from the gas tank reduce fuel economy and affect the environment.

Fuel tanks are made of metal (steel or aluminum) and plastic. Steel tanks are more often installed on trucks and cars running on methane. Gasoline engines are produced complete with an aluminum firebox. Plastic fuel tanks are suitable for all types of fuel, inexpensive, easy to maintain and repair. The share of cars with a synthetic tank is 2/3 of the total.

Repair of a gas tank on the road

Trouble with a gas tank can also occur on the road, when it is impossible to get to the garage or car service.

If a rather large hole is found in the tank, it can be closed with a bolt and nut. A piece of thick rubber should be placed between them.

Small holes (for example, when small stones get into the weld seam) can be temporarily sealed with a piece of cloth impregnated with the usual "Moment" or other similar glue. For faster drying, nitro paint is sprayed onto the fabric (it is usually included in the repair kit of a modern car).

It is extremely dangerous to continue driving with a punctured gas tank.

Causes of damage to the gas tank

Manufacturers usually place the gas tank at the back of the car, and depending on the car model, it can be located on the right, left or in the middle. This solution allows you to maximize the safety of people in the cabin. In addition, placing the fuel container at the rear of the vehicle improves handling. At the same time, such an arrangement of the gas tank exposes it to external influences (mechanical, chemical, natural), which can lead to cracks and holes.

This element of the fuel system can be made of metal or composite material, conventionally called plastic. Regardless of the type of material used, holes, cracks or microcracks may appear on the tank body, through which fuel will flow. If the damage is significant, the fuel will be spilled abundantly and a stain will form under the vehicle.

The fuel tank can be made of metal or composite material

When microcracks form in the passenger compartment or trunk, a fuel smell appears, and a wet spot appears around the damage. Another sign of failure of this element of the power system is increased fuel consumption. In any case, it is necessary to look for the place of the leak and determine the cause of its appearance, and only then proceed to elimination.

There are several reasons leading to fuel tank malfunctions:

-

Mechanical damage. Given the location of this element and the condition of our roads, there is a high probability of hitting the gas tank, resulting in a hole or crack.

-

Corrosion. Although quality metal is used to create the gas tank, it can corrode over time. Usually old cars are susceptible to this, but if in a new car the tank is made of low-quality metal, then it also rusts quickly. Outside, corrosion of the tank occurs due to the effects of moisture, as well as corrosive substances falling on its walls. Low-quality fuel may contain water and this causes the development of corrosion from the inside.

- Power system malfunctions. As the amount of fuel in the tank decreases, in the event of a faulty power supply system, a rarefied pressure is created in it. This leads to the appearance of microcracks on the walls, which can subsequently damage them.

If leaks of a gas tank are detected, such a vehicle cannot be operated and the malfunction must be urgently eliminated.