How to drill pilot holes for screws

Learn to prevent plywood from cracking by making the correct fastener holes. Traditional taper shank screws require drilling a mounting recess for the smooth part and a guide channel for the threaded part, plus the head needs to be recessed. Perform these operations in one go with the combination tapered tip and adjustable countersink drill.

Drilling pattern for traditional screws.

Advice.

Use a steel screw of the same size to screw the brass screws into the thread made in the pilot hole.

Modern screws have a straight stem and a thinner top than the thread, so they don't need a mounting recess. It is convenient to drill pilot holes with the same combination equipment, but with a conventional drill, selected for each screw gauge.

Drilling diagram for modern screws.

Self-tapping screws with a drilling tip and countersinking ribs on the head, which make it possible to dispense with preliminary drilling in soft wood, often cause splits when screwed along plywood layers. Do not take risks and do not waste time replacing a cracked workpiece - make holes even for screws with a drill at least half the depth and especially near the edges and ends.

Advice.

Calculate the tightening torque by selecting the appropriate screwdriver mode. It is better to leave the cap sticking out slightly above the surface and tighten it with a screwdriver.

It is not necessary to determine the size of the pilot hole with an accuracy of fractions of a millimeter - it can be done "by eye".

The diameter is suitable if the attached drill covers the screw body and not the thread.

Making indentations for the caps near the edge of the plywood sheet, stick masking tape over the drilling site so as not to destroy the upper veneer.

When drilling pilot holes, fix the parts, preventing the workpiece from moving and, as a result, breaking off the drill.

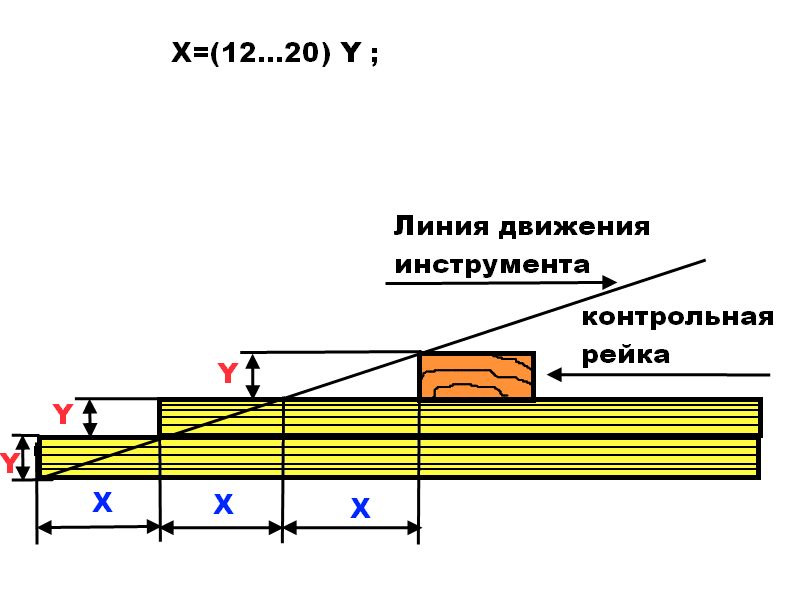

Any fastening of plywood parts will be accurate and reliable only if the workpieces are precisely adjusted. Make strictly perpendicular cuts on the workpieces. Always start by making a groove, and then adjust the comb to fit it.

It is very important that the floor in the apartment is warm and comfortable. Therefore, its installation begins with the laying of plywood, which will play the role of the base and will be able to ensure its stability and strength.

This material, which consists of several layers of veneer made from coniferous wood, is prone to various types of fastening. It can be mounted with screws, nails or bolts.

Pasting wallpaper on prepared plywood

- Date: 07-09-2015

- Views: 472

- Comments:

- Rating: 30

Wallpaper is one of the most common wall decoration materials. They differ in attractiveness, style, and gluing them does not cause any particular difficulties. Wallpaper can be glued even when the general repair is completely finished, without fear that the finishing materials of the floor or ceiling will be damaged. The canvases are demanding on the base, they can only be glued to a pre-leveled surface, since their small thickness will make any wall defects perfectly visible. Plywood is one of the alignment options. Such material is characterized by rigidity, strength, stability, its surface is as flat as possible. Is it possible to stick wallpaper on plywood? Yes, this option is sometimes used, although plywood requires preparatory work to make the wall as attractive as possible.

Wall marking scheme before wallpapering.

When decorating walls with plywood, it must be remembered that wood is subject to thermal and moisture expansion. Therefore, it is necessary to choose only moisture-resistant plates; during installation, ensure special gaps. You can take any wallpaper for plywood, but their texture will affect the quality of the wall preparation. The best option is non-woven wallpaper, which perfectly mask irregularities and joints. But with thin paper wallpaper you will have to tinker a little, the plywood wall should acquire an ideal appearance. Only then can you start work.

Attention should also be paid to the glue, which should be designed specifically for working with wooden surfaces. Before gluing, a primer is applied to the surface

Necessary tools for wallpapering walls.

To quickly and efficiently glue wallpaper on plywood, you need to prepare materials such as:

- waterproof primer;

- putty (alkyd enamel for rough and non-waterproof plywood);

- brushes and rollers;

- metal spatula;

- serpyanka tape, metal perforated corners;

- wallpaper glue;

- wallpaper;

- metal ruler;

- simple pencil;

- knife with replaceable blades.

How to glue plywood

Most modern floor coverings are laid on top of the substrate rather than directly on the concrete. One of the most popular types of backing is plywood.

It attracts with ease of installation and affordable price, and one should not forget about the important fact that it is a natural material. Its popularity is evidenced by the fact that manufacturers have begun producing a moisture-resistant type for use in bathrooms.

Also, the grinded grade on one side is gaining great popularity, which facilitates installation under the final floor covering.

Choosing the right substrate is not enough, the main thing is to choose a good glue for gluing plywood to concrete. It depends on him how firmly the sheets will hold on the floor, how quickly everything will dry out and it will be possible to move from preliminary work to final ones.

Types of glue

The huge assortment presented on the shelves of hardware stores can be divided into several main types:

- water based;

- polyurethane;

- epoxy.

These types of glue for plywood on a concrete floor differ in price, composition, consumption and drying time.

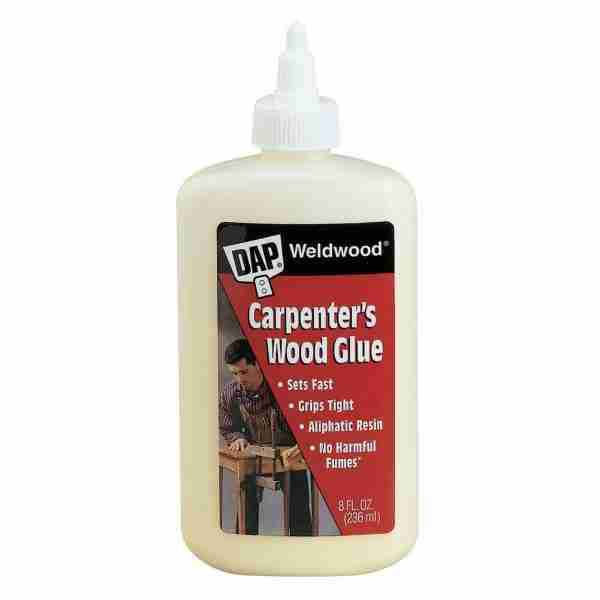

PVA glue for plywood

But besides the pros, it also has its drawbacks:

- dries for a long time (for large volumes up to 7 days);

- suitable only for interior work in heated rooms (there is an option marked D with frost-resistant additives, but its price is much higher);

- the fastening of the base to the flooring is not very strong, therefore, until completely dry, the sheets must be screwed with self-tapping screws;

- when using this type of glue, the floor must be sufficiently flat, the difference cannot be more than 2 mm.

Polyurethane adhesive is characterized by high strength, toughness and ductility. It can be either two-component or solid.

Two-component plywood adhesive on concrete floors has a high viscosity (applied with a comb trowel). This is both an advantage and a disadvantage. On the one hand, it is grasped literally in half an hour, and on the other hand, it cannot be cooked in a large portion "in reserve", as it quickly dries up and becomes unusable.

The one-piece version dries much longer, so it does not freeze during installation. Complete drying takes 36 - 48 hours, and the strength of the resulting layer is superior to concrete, and can withstand drops up to +55 ° C.

Installation of plywood on glue

The disadvantages include:

- high toxicity, but harmful substances are released only during installation, after hardening it becomes safe;

- too fast solidification of two-component mixtures, which creates inconvenience in the process.

Epoxy adhesive for plywood on concrete floors also consists of two components that must be mixed before installation.Complete drying occurs in 4 - 5 days, but you can walk on the plywood surface in a day.

Read the topic: how to properly lay plywood on a concrete floor.

When laying, harmful substances are also released into the air (due to the alcohol base, the smell is saturated and sharp), so you need to work in accordance with safety precautions. Safety goggles, gloves and a respirator must be present, regardless of what glue you glued the plywood to the concrete floor.

But there are some general rules:

- First, the concrete must be cleaned of the remains of construction debris and other contaminants (if necessary, vacuum or wet cleaning).

- It is advisable to prime it before work - this will reduce the consumption of raw materials and improve adhesion to the surface. For these purposes, both a primer (ordinary or water-repellent, for damp rooms) and the glue itself are suitable. It must be diluted and applied in a thin layer to the prepared surface.

- Although additional fastening requires only PVA and its water-based analogs, when working with the rest, for better adhesion, it is also advisable to press the sheets with something to the floor (put under pressure) until completely dry.

- It is best to cut the sheets into 0.5x0.5 squares, so they will fit better without creating cavities in uneven areas. Such squares are laid in a checkerboard pattern, or simply with an offset.

- A technological gap of 2 - 5 mm must be left between the sheets.

- Depending on the condition of the surface (cracks, irregularities, dirt) and the selected type of glue, the consumption will be 0.5 - 1.5 kilograms per square meter.

Laying plywood on a concrete floor

On the PVA label, they often write "consumption from 0.25 kilograms per square meter", but one should not be encouraged. With this type of glue, it is necessary to cover not only the concrete base, but also to apply it to the sheet. Therefore, when calculating the consumption, the numbers indicated on the label should be multiplied by two.

How to glue plywood together

Plywood consists of several layers of wood veneer, their number can vary from 3 to 20. In production, gluing is performed using urea or phenol-formaldehyde compounds, using pressing.

The best option for gluing finished plywood is considered to be adhesives that are already present in the material. But this is not a prerequisite. If the sheet is not water-repellent, aqueous formulations can be used. For non-absorbent products, epoxy or plywood can be used.

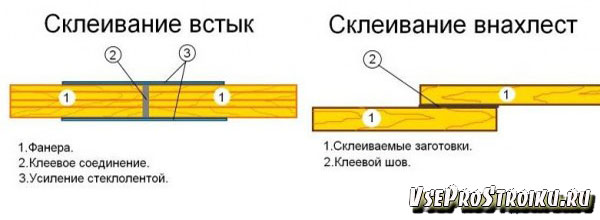

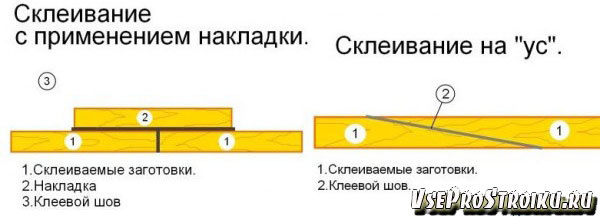

Bonding can occur end-to-end or on a mustache. In any case, the adhesive must be applied to both surfaces. After that, the sheets are pressed tightly against each other and left in this position until dry. Excess must be removed immediately.

Review - what kind of glue to glue plywood to various substrates

However, to achieve a better result, it is better to use a specialized wood glue.

Moment STOLYAR PVA Universal - one of the most suitable options according to the criterion "price-quality". This multi-purpose adhesive provides strong and durable bonding of plywood, fiberboard, MDF and chipboard.

The composition has good viscosity, and after drying forms a colorless elastic seam.

Working with PVA glue Joiner is easy and convenient: just apply a thin layer of glue on one of the surfaces to be glued, firmly press the parts together and fix with clamps or improvised means for 20 minutes.

Note! If moisture-resistant glue Moment STOLYAR Super PVA D3 should be used for gluing sheets of moisture-resistant plywood. It is even suitable for the manufacture of furniture for kitchens, bathrooms and other rooms with high humidity.

Glue laying of plywood on a concrete screed.

In most cases, plywood is used to create a base for parquet or laminate on a concrete screed.

In order to ensure a strong connection and prevent the further formation of peeling and squeaking of the floor, special two-component compounds should be used for these purposes - STAUF PUK-446, SikaBond-PU 2K, IBOLA R 200 glue, etc.

These and other types of two-component, hard-elastic polyurethane adhesives are ideal for gluing plywood, chipboard and OSB boards to concrete substrates.

Note! Before gluing plywood onto a concrete screed, the base must be thoroughly dried and cleaned of dust. The surface must be pre-treated with a primer

An elastic two-component adhesive is also suitable for laying tiles on plywood. Thick, moisture resistant plywood is often used as a more durable alternative to drywall when constructing boxes.

The polyurethane adhesive will firmly adhere the tiles to the plywood base, but care must be taken to seal the joints so that moisture does not come into contact with the wood.

We glue the linoleum to the plywood base.

For these purposes, water-dispersion compositions are the best suited - Homakoll 208, Forbo Eurocol 522, etc.

Dispersion adhesive is specially formulated for bonding linoleum and other rolls of flooring to plywood, concrete and other substrates.

The glue is completely ready for use, you just need to mix the composition thoroughly before use.

Dispersion adhesive is applied directly to the prepared substrate using a notched trowel, after which the floor covering is laid.

Compositions

All plywood adhesives are divided into 2 main types according to their composition.

- Animals. These are dry casein (curd), protein (based on animal blood) and combined (with the combination of the first 2 types).

- Synthetic. They are based on various formaldehyde resins. This type is usually transparent in color, resistant to fungi and mold.

Consider the most common types of adhesives.

Polyurethane

Such compositions are made on the basis of a solvent, therefore, they have a very pungent unpleasant odor. They are toxic, their application must necessarily be carried out using protective equipment - gloves and a respirator.

However, these inconveniences are felt only during work - after drying, the smell disappears, in the future, harmful substances are no longer released.

And also in this case, the polymerization time is limited - work with the composition must be carried out quite quickly. Such glue can be solid or 2-component. Both varieties are very durable and flexible. They have excellent moisture resistance, sound insulation, UV resistance and dry quickly after application to the surface.

Water based

Aqueous formulations are the safest to use. A bright representative is the well-known PVA glue. Such glue has a low cost, is absolutely non-toxic, practically odorless, easy to apply.

Dispersive

These adhesives contain fine resin particles that are insoluble in water. The consistency of the glue can be liquid or in the form of a thick paste. Its adhesion level is quite high, it is resistant and can withstand significant loads. Another advantage is the use of such a composition over a wide temperature range from –30 to +70 degrees Celsius.

Alcoholic

This species contains artificial resins, rubber and various solvents. It is very easy to use, resistant to moisture, and has a high drying rate.

The disadvantages of such compositions are the release of volatile harmful substances and strong flammability.

Two-component

Any formulations based on 2 active ingredients set quickly, are strong and give strong adhesion to surfaces. The chemical reactions when the formulations are mixed provide a very high connection reliability. To strengthen them, you do not need to additionally use hardware (dowels, screws).

Work instructions

Before gluing plywood, you need to prepare the following tools:

Before gluing, the plywood parts are sanded.

- foam roller;

- clamps;

- hammer.

Materials:

- blanks;

- sanding paper;

- nails.

Plywood is glued, working in this order:

- The surface of plywood sheets is cleaned of dust and dirt is washed off it. Remove the laminate layer from the laminated material using sanding paper.

- The sheets are thoroughly dried.

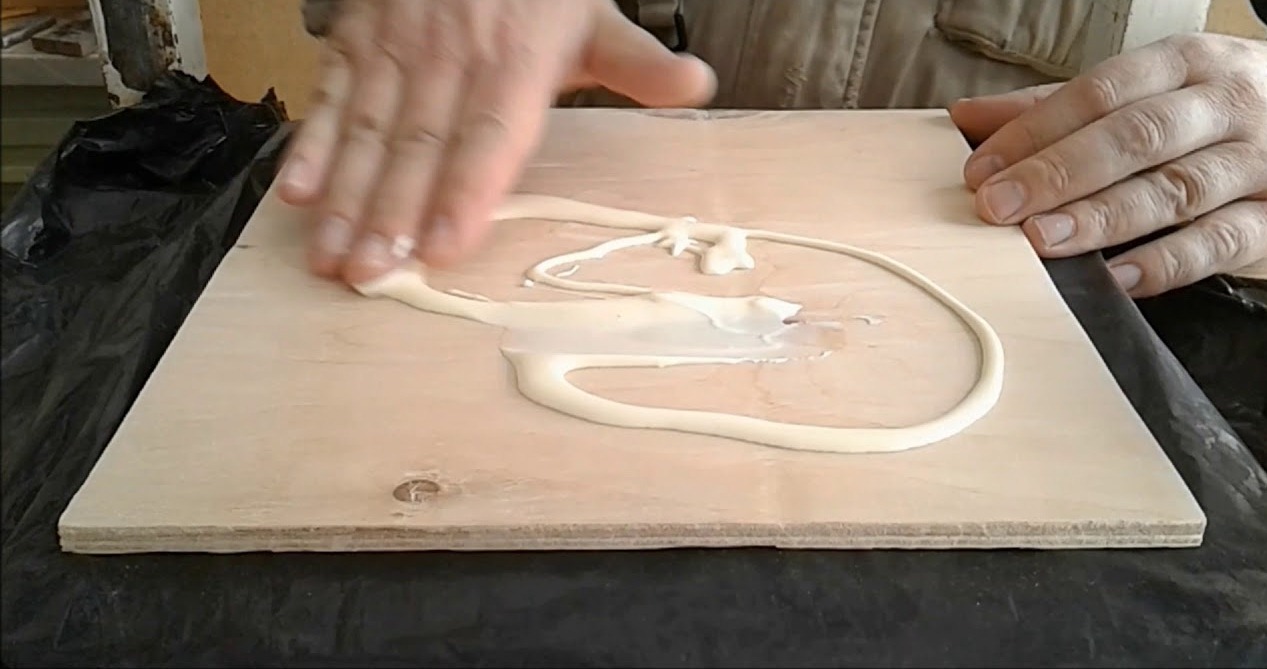

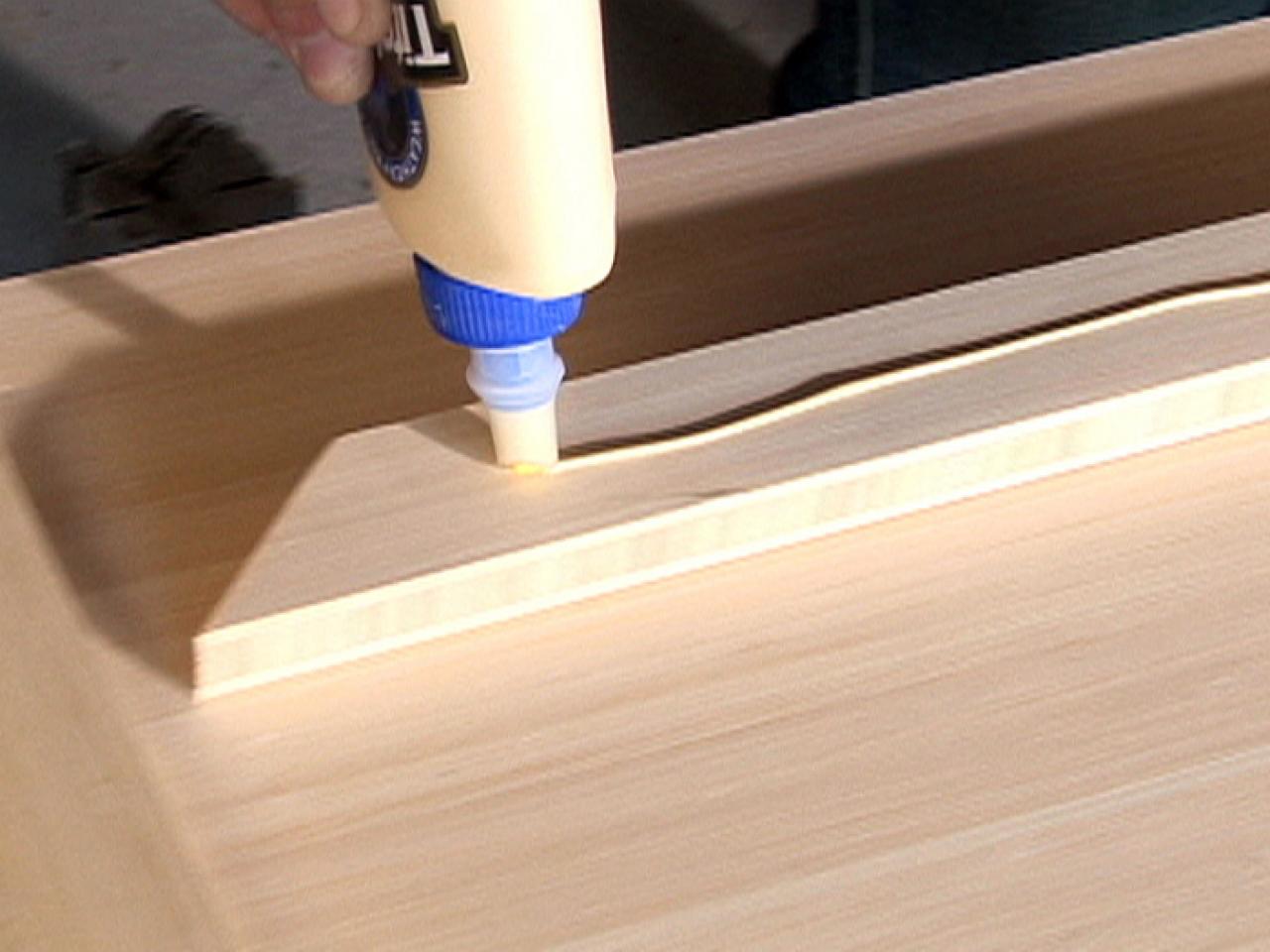

- Use a roller to distribute the glue in an even layer on the surface to be glued.

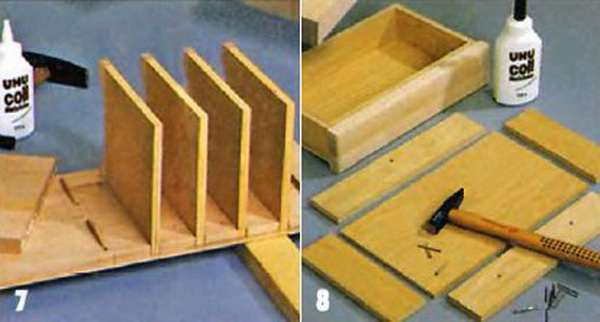

- With the help of clamps, the plywood parts are tightly pressed against one another. The protruding excess glue is carefully removed so that they do not fall on the front side of the product with a knife and rags.

- Details of large sizes, if necessary, are additionally connected with nails, evenly distributing them over the surface in increments of 40-50 cm.

- After the glue mass dries, the clamps are carefully removed.

If you need to glue plywood to a metal part, it is recommended to use epoxy glue. Tools required:

- brush;

- emery;

- clamps.

Materials:

Types of plywood gluing.

- plywood and metal parts;

- epoxy adhesive.

They work in the following order:

- The workpieces are sanded, then the parts are freed from sawdust and dust.

- Apply the epoxy mass evenly to clean and dry surfaces with a brush.

- The workpieces are aligned and fixed with clamps, the excess glue is removed.

- After the seam dries, the parts are released from the clamps. If the plywood sheet has delaminated, then you can glue its layers by laying them with paper.

In its upper and lower parts, threaded holes are made and the workpieces to be glued are fixed at the stop with bolts through the gasket. The bolt pitch should correspond to 10 workpiece thicknesses. Spacers between bolts and plywood should be 3 times the thickness of the part. The edges of the channels are bolted through the bosses. Pressing in is carried out evenly, with a medium tightening, so that enough glue remains in the seam.

Plywood can be used in interior decoration, to create items for home or country interiors. To work, you need to know how to connect plywood parts. Before gluing plywood, you should carefully study the instructions, choose an adhesive composition, prepare everything you need to work with the material. With a well-made seam, self-made products will look attractive and retain their strength for a long time.

The procedure for gluing plywood yourself is as follows:

Treatment of joints and the bordering surface of the material in order to degrease and remove residual dust and dirt.

If you want to glue laminated sheets together, the next step is to sand the material to get rid of the slippery laminated surface over the entire joint area. Or make it rougher.

Before gluing, take care of high-quality drying of the sheets.

Apply the adhesive to the adhesive surface with a roller to make the product evenly more even.

Apply special clamps to ensure a fixed and snug fit of the bonded parts

Attention! When gluing large parts, an additional connection is required using self-tapping screws and / or nails.

Remove excess glue with a rag or knife.

After the adhesive is completely dry, remove the clamps.

Are you ready to start solving the problem in practice?

Then prepare the following materials and tools:

- Nails and / or screws;

- A sander with an appropriate attachment or sander paper;

- Clamps;

- Hammer;

- Rags;

- Glue;

- Roller.

Alcohol glue

If you need to do the work quickly, then one-component glue is used for laying, which is also called alcohol. It is based on artificial resins and solvents, so it has a strong pungent odor that requires the use of a respirator during work and long-term ventilation of the room. Before applying it, the concrete screed must be primed.Additional fastening is desirable. But at the same time, this glue has a number of advantages:

- dries up under normal conditions after three days;

- due to its consistency, it fills in cracks and does not leave voids, thereby compacting the rough base;

- does not crack during operation, due to its high elasticity when cured.

Has a higher flow rate per square meter than dispersive. It takes about one and a half kilograms.

Bonding Basics

Production technology

Speaking about gluing plywood sheets, most often they mean either the production technology of the material itself, or the connection of several fragments in the manufacture of various products

We will talk in detail about the splicing of sheets a little below, and in this section we will try to pay attention to the intricacies of the production process

Most often, veneer gluing for plywood production is carried out using a hot dry method. The following technological schemes are relevant today:

- The connection of the prepared veneer plates is carried out using a press while maintaining a constant pressure in the working gap. This technology is used for the production of slabs, the thickness of which does not exceed 8 mm.

. - Alternate gluing of veneer at constant pressure with heat treatment. Thicker plywood is made by alternate joining - usually from 10 to 18 mm

. - Multi-stage gluing of workpieces with cooling of the press after each operation makes it possible to increase a significant thickness of the plate. This technique is used for the manufacture of a sheet with a thickness of 20 mm or more.

.

However, these technological schemes are of interest only to those who plan to engage in the industrial production of veneer panels.

For us, first of all, it will be important to know how you can connect several pieces of plywood with your own hands, without the use of presses and thermostats.

Used adhesives

When choosing how to glue plywood, you should carefully study all the available options. There are many formulations on the modern market, and therefore it is worth choosing exactly the one that will best meet our requirements.

The bulk of plywood adhesives is presented in two categories - protein (animal) and synthetic. We will talk about the most popular varieties from each category.

Protein groups include the following groups:

- Casein

- are made from cottage cheese that has passed the degreasing procedure. Adhesives are sold in the form of a dry powder, dissolve in water and mix thoroughly before work. - Albumin

- made from protein obtained from animal blood. The dry component is mixed with water in a ratio of 1: 9. The glue curls up at a temperature of 70 0 С, therefore albumin compounds are used for hot gluing. -

Combined

- combine components of casein and albumin compositions.

Synthetic adhesives are mainly represented by resinous substances. The most commonly used:

Urea-formaldehyde resins (KF-MT, KF-Zh, etc.).

They provide a colorless seam, therefore they are practically irreplaceable in the manufacture of decorative elements that imitate natural wood.

Almost any glue for gluing plywood includes:

- The main adhesive.

- Solvent.

- The filler is wood dust or flour.

- Additives that control the cure rate and ensure maximum adhesion.

- Plasticizers.

- Antiseptics.

Substances such as acids or ammonium chloride are used as hardeners, and tannins (formalin, copper salts, etc.) are introduced into the composition to ensure resistance to wetting.  Photo - fast-hardening composition in a tube.

Photo - fast-hardening composition in a tube.

In order for the glue to retain its adhesive properties for the longest possible time, either ethyl alcohol or acetone is used to dissolve the adhesive component.

Adhesive requirements

Many bonding technologies, such as bonding on plywood with a mustache, can only be realized if high quality adhesives are used.

It is for this reason that the following requirements are put forward for most types of plywood adhesives:

- High quality joining of materials.

- Ease of use at home.

- The absence of volatile toxins in the finished product after the composition has dried.

- Resistant to moisture.

- Not susceptible to degradation by bacteria and fungi.

It is very important that the adhesive during application does not destroy the wood veneer or change its color. The democratic price is also important, since when working actively with plywood, the glue is consumed quite quickly.

The democratic price is also important, because when actively working with plywood, the glue is consumed quite quickly.