F-4MB application news.

FEP

V

at present JSC "Plastpolymer" produces

pigment concentrates for

fluoroplastic-4MB (Teflon

Red, Orange,

yellow, green,

blue, purple,

Brown and black.

Concentrates

fluoroplastic pigments are produced in grades A and B and are intended for coloring

fluoroplastic-4MB in the process of extrusion when applying insulation of wires and

cables, as well as for coloring films, tubes and other products from F-4MB.

Pigment concentrates are produced in the form of colored cylindrical granules

shapes ranging from 2 to 4 mm in any direction. The product has

sanitary and epidemiological conclusion No. 78.01.06.224.P.001910.04.03,

issued by the Federal State Institution Center for Sanitary and Epidemiological Supervision in St. Petersburg on April 15, 2003.

The main indicators of concentrates are shown in the following table:

|

P / p No. |

Indicator name, units |

The norm of the indicator for the brand by |

|

|

F-4MB grade A |

F-4MB brand B |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

F-4MB (FEP) films are used abroad:

|

Aviation and space industry - fuselages, film coatings of wings and engine parts, backed up with polyamide film to insulate wires and cables); |

|

|

For coating rolls, solar collectors, sample bags, etc. |

|

|

Viewing windows in special purpose vehicles; |

|

|

Roofing material. |

Demand for F-4MB is growing in Russia:

|

Food and confectionery industry |

Anti-friction coatings for dough sheeters and non-stick coatings for baking. |

|

Automotive |

Sleeve bearing protection. |

Cooperation proposals of our laboratory .

Solar protection

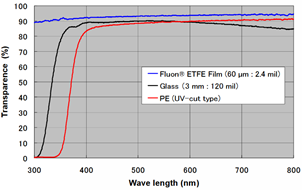

Renewable solar energy is one of the fastest growing industries today. The specificity of the operation of solar panels provides for a constant, maximum possible exposure to the entire spectrum of sunlight. At the same time, the most advantageous arrangement of the modules is low-cloud sandy deserts with an abrasive nature of the effect of winds and storms. To protect solar cell modules from both the front and back surfaces, ETFE films with a thickness of 25 µm or more are used. Compared to ETFE glass, the films are more transparent and incomparably lighter, which reduces installation and logistics costs, as well as contributes to the safe execution of coating work. ETFE protective barrier films compete very well in this application with a wide range of plastics used: polyvinyl fluoride (PVF), PVDF, PET and others. Recently, ETFE films have often been used in combination with other polymer layers such as PET and / or ethylene vinyl acetate (EVA), which improves electrical breakdown resistance and interlayer adhesion, resulting in a highly competitive product. The surface micro-lenticular modification ETFE is capable of imparting anti-glare to the film, which additionally increases the collection of solar energy by the PV modules of buildings. In some cases, ETFE film encapsulates, along with solar cells, inverters - LED and OLED elements used in the concept of building smart homes and autonomous facades.

The flexibility of ETFE protection facilitates the creation of portable photovoltaic converters capable of powering various gadgets or specialized portable electronics.

For more information on properties, applications and comparisons of PTFE-40 / ETFE films, see the article “Innovative PTFE-40 or ETFE Films” from our library.

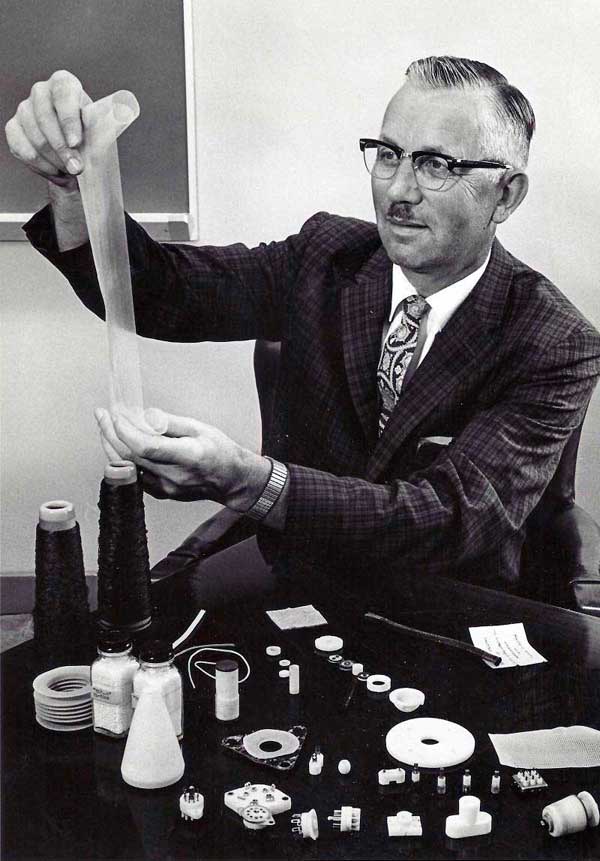

A bit of history

The discoverer of Teflon is the American scientist Roy Plunkett, who in 1938, as an employee of Kinetic Chemicals, witnessed the polymerization of gaseous tetrafluoroethylene and its transformation into a solid substance resembling paraffin. The resulting material showed amazing properties at that time, so it was immediately registered as a development of the Kinetic Chemicals company, which in 1949 became part of the DuPont corporation.

Teflon first came to the Soviet Union during the Second World War. The teflon ring was part of the design of the turret rotation system for American-made tanks that came to the USSR under Lend-Lease. The Soviet designers were impressed by the fact that instead of lubricant, a fluoroplastic gasket was used to rotate the turret of a foreign tank. After getting acquainted with the technical characteristics of the material, it was decided to establish its own production. For a long time, the use of fluoroplastic in industry, as well as the technology of its production in the Soviet Union, were classified.

Application of F-40 (ETFE) films

A very significant place in the sales of ETFE films is explained by a wide range of purposes and a number of technical advantages over conventional films, glass and polycarbonate sheets. Film manufacturers offer a variety of ETFE grades, differing in thickness, surface finish and additives for the following applications:

- Architecture;

- Agricultural and greenhouse applications;

- Solar panels protection;

- Electronics: printed circuit boards and semiconductors;

- Construction: interior decoration of premises;

- Industry: cable tape insulation;

- Medical industry.

Buy fluoroplastic film and tape

LLC Prompostavka produces and sells high-quality films and tapes made of fluoroplastic. We have a very wide range of these products. Buyers will be able to buy our products on favorable terms and at competitive prices. Our staff will help you choose the PTFE tape or film that meets your requirements. Leave a request on the website and our managers will call you back.

| Fluoroplastic film - 4 GOST 24222-80 | |||

|---|---|---|---|

| P / p No. | Name | Width, mm | Thickness, mm |

| 1 | "KO" - condenser oriented | 10 – 120 | 0,010 – 0,040 |

| 2 | "EO" - electrical insulating oriented | 10 – 120 | 0,010 – 0,100 |

| 3 | "EN" - electrical insulating non-oriented | 10 – 120 | 0,020 – 0,150 |

| 4 | "IO" - insulating oriented | 10 – 120 | 0,020 – 0,100 |

| 5 | "IN" - insulating non-oriented | 10 – 120 | 0,060 – 0,200 |

| 6 | "PN" - cushioning tape | 10 – 120 | 0,2 – 3,0 |

| Rolled film from F - 4 (TU 6-05-986-79) | ||

|---|---|---|

| Length, mm | Width, mm | Thickness, mm |

| not less than 500 | 450±15 | 0,13±0,05; 0,20±0,05; 0,30±0,05; 0,40±0,05 |

| Application of films and tapes made of fluoroplastic - 4 | |||

|---|---|---|---|

| P / p No. | Name | Brand | Appointment |

| 1 | Condenser film oriented | F - 4 "KO" | For the manufacture of capacitors operating at temperatures from - 269 to +260 ºС |

| 2 | Oriented electrical insulating film | F - 4 "EO" | For insulating wires and cables; electrical insulating material in high and ultrahigh frequency technology. |

| Non-oriented insulating film | F - 4 "EN" | ||

| 3 | Oriented insulating film | F - 4 "IO" | For interlayer electrical insulation in devices, assembly units, parts. |

| Non-oriented insulating film | F - 4 "IN" | ||

| 4 | Gasket tape | F - 4 "PN" | For the manufacture of cushioning and insulating material used at temperatures from -269 to 250 ° C |

| 5 | Rolled non-oriented film | F - 4 "VN" | For the manufacture of blanks for sealing devices, for use as a heat-insulating material operating in aggressive environments at temperatures up to + 260 ° C |

Non-oriented cushioning tape made of fluoroplastic - 4.

PN grade (GOST 24222-80)

The strip is made mechanically from fluoroplastic-4 blanks, pressed with subsequent heat treatment from fluoroplastic-4 powder, grades "P" and "PN" (GOST 10007-80).

The tape is resistant to all media, except for gaseous fluorine, chlorine trifluoride, alkali metal melts. The operating temperature range of the tape operation is from minus 269 ° С to plus 260 ° С.

| Belt dimensions | ||

|---|---|---|

| Thickness, mm | Width, mm | Length, m, not less |

| 0,2±0,020 | 40±0,3 — 140±0,3 | 0.2 for each thickness |

| 0,3±0,030 | 40±0,3 — 140±0,3 | |

| 0,4±0,040 | 40±0,3 — 140±0,3 | |

| 0,4±0,060 | 40±0,3 — 140±0,3 | |

| 0,8±0,080 | 40±0,3 — 140±0,3 | |

| 1,0±0,100 | 40±0,3 — 140±0,3 | |

| 1,2±0,120 | 40±0,3 — 140±0,3 | |

| 1,4±0,140 | 40±0,3 — 140±0,3 | |

| 1,6±0,160 | 40±0,3 — 140±0,3 | |

| 1,8±0,180 | 40±0,3 — 140±0,3 | |

| 2,0±0,200 | 40±0,3 — 140±0,3 | |

| 2,2±0,220 | 40±0,3 — 140±0,3 | |

| 2,4±0,240 | 40±0,3 — 140±0,3 | |

| 2,6±0,260 | 40±0,3 — 140±0,3 | |

| 2,8±0,280 | 40±0,3 — 140±0,3 | |

| 3,0±0,300 | 40±0,3 — 140±0,3 |

NOTE:

The tape of the "PN" brand with a thickness of 0.5 and 0.7 mm is made with maximum deviations of ± 0.07 mm with a width of 60 mm.

By agreement between the consumer and the manufacturer, it is possible to manufacture a tape with dimensions that are not

indicated in the table.

PTFE tapes

grades F4K15M5 - L and F4K15M5 - L - EA. TU 6-0505-138-80

Belts of grades F4K15M5-L and F4K15M5-L-EA are intended for the manufacture of anti-friction parts: overhead guides for metal-cutting machines, sliding bearings, etc., used in machine-tool and other machine-building industries.

F4K15M5-L tape is produced by planing a cylindrical blank from compositions F4K15M5 according to TU 6-05-1413-76.

The tape of the F4K15M5-L-EA brand is obtained by processing the tape of the F4K15M5-L brand from both sides with a glow discharge.

F4K15M5 – L – EA tape can be attached to metal substrates with various adhesives (for example, adhesives based on epoxy resin K – 153A or B, etc.).

The guaranteed shelf life of the F4K15M5-L tape is 3 years from the date of manufacture.

The guaranteed shelf life of the F4K15M5 – L – EA tape is 1 year from the date of manufacture (glow discharge treatment).

| Sizes of tapes from compositions | ||

|---|---|---|

| Dimensions (edit) | Brand | |

| F4K15M5-L | F4K15M5-L-EA | |

| Thickness, mm | 1,0 — 3,0 | 1 |

| Thickness tolerance, mm | ±0,15 | ±0,15 |

| Width, mm | 60 — 140 | 140 |

| Width tolerance, mm | -1 | -1 |

| Length, m | not less than 0.6 | not less than 1.0 |

NOTE:

By agreement with the consumer, tape of the F4K15M5-L-EA brand is manufactured with a thickness of 1.0 to 2.5 mm and a width of 25 to 140 mm.

Features of PTFE film

The PTFE web is presented in the form of a translucent or matte white material. It is a polymer product, chemical formula - PTFE (polytetrafluoroethylene). Often referred to as Teflon sheeting.

The polymer is produced by extrusion. A workpiece is made of fluoroplastic powder. It is also called a pill. Then the top layer is removed from it, which is rolled through the rollers to the required size. The resulting material is cut to the desired width and wound onto spools.

Fluoroplastic sticky oil-resistant film is supplied to consumers in rolls of various lengths:

- 50 meters;

- 100 meters;

- 250 meters.

Has a thickness of 0.005 to 0.1 mm. The width of the fabric made of fluoroplastic f 4d can be from 10 mm to 120 mm. Strength and elasticity are distinguished from the quality characteristics.

The fluoroplastic polymer complies with safety and environmental requirements: it does not burn, does not explode, does not require special conditions during its processing and storage.

Shows excellent performance when working in aggressive environments.

The shelf life of the material is 20 years.

Greenhouse and greenhouse construction

The most widespread greenhouse coverings in the world are polymer films: Southern Europe, Arab countries. Greenhouse complexes in Israel and North. Africa occupies 190,000 hectares; of which 168,000 hectares are covered with polymer films; the other part is glass or polymer sheets. In Asian countries, the area of greenhouses is ~ 380,000 ha - China, 60,000 ha - Japan and 2,200 ha Korea. The coverage of these greenhouses is almost 100% - polymer films. Russia today is ~ 60% dependent on the import of greenhouse vegetables (China, Turkey). Now the country has about 1900 hectares of greenhouses and the pace of their construction is low. The use of modern ETFE material in greenhouse and greenhouse business is hindered by the high cost per square meter, reaching 1080 rubles with an optimal thickness of 100 microns. Nevertheless, Tander CJSC, which has its own sales system - a chain of food stores “Magnit”, has built the most modern greenhouse complex LLC “Greenhouse complex“ Green Line ”with an area of 90 hectares using the Japanese ETFE F-Clean film! The choice of covering material was facilitated by a significant increase in the yield of vegetable crops and savings on metal structures.

Wide range of climatic conditions

Greenhouses using ETFE have already proven their worth in the Far North.On the other hand, the material is successfully used in the construction of buildings in the hot conditions of deserts and humid tropical climates.

Transparency in the visible and UV spectra

Glass and polyethylene transmit only 5% of the solar spectrum necessary for the plant. The maximum transparency of ETFE is 95%, and in the ultraviolet range it is over 90%. Full spectrum light, especially UV-A, plays an important role in plant health. In the natural environment, under the influence of ultraviolet radiation, the plant produces a greater amount of protective biologically active compounds - beta-carotene, anthocyanins and glycosides. They provide color, flavor and nutritional value to plants. In addition, ultraviolet light inhibits the development of many microorganisms, including fungi and bacteria that cause plant diseases in greenhouses. The main consequence of the higher transparency of ETFE films in greenhouses is undoubtedly the taste of vegetables and fruits in open field!

Durability

In traditional film greenhouses, the film has to be replaced every 3-5 years, since its light transmittance and strength characteristics decrease as a result of aging. The test results show that the light transmittance of ETFE film decreases by only 5% after 20 years of use with a warranty of more than 30 years. In the aging tests carried out by Dyneon, after 10 thousand hours of exposure to UV radiation (Xenontest 150 test), no signs of optical damage to ETFE were detected. In this regard, the Japanese firm AGC estimates the beginning of the destruction of the carbon chain to be over a hundred years.

Maintainability

In case of mechanical damage to the film with a sharp object or bird's beak, it can be easily repaired with a special tape made on the basis of the same film.

Anti-drop effect

It consists in the absence of the formation of condensate drops on the surface of a specially treated film, capable of falling on plants (one of the reasons for the disease of seedlings with powdery mildew).

Self-cleaning greenhouses

The high strength of the material in combination with the optimal angle of inclination of the roof and the surface anti-adhesive effect does not allow the accumulation of sediments. The material is also not damaged by hail. Dirt, foliage, pollen and dust slide off ETFE better than other plastics. Dirt-repellent properties depend on the value of the surface tension of the material, the lower it is, the more anti-adhesive surface. The range of surface tension reduction is as follows: polyamide (PA) polyethylene terephthalate (PET), polyetheretherketone (PEEK), polyethylene (PE), polyvinylidene fluoride (PVDF), fluoroplast-40 (ETFE), fluoroplast-4 (PTFE).

Gas separation properties of films

|

Film brand |

Film thickness, microns |

Gas permeability, P × 108, cm3 × cm / (cm2 × s × atm) |

Selectivity |

|

|

He |

CH4 |

He / CH4 |

||

|

F-2M |

50 -100 |

34,4 |

3,7 |

10,2 |

| F-10 | 10 | 2,6 | ||

|

F-3M |

50-100 |

7,14 |

458 |

|

|

F-4MB |

50-100 |

3,52 |

4,72×10-2 |

74 |

Due to the increased fire resistance, chemical resistance,

excellent electrical and mechanical performance over a wide range

temperatures, films made of fluoropolymers have also found application in areas

making increased demands on reliability, durability,

fire safety. Such requirements, in particular, exist in

aviation and space industries.

Our achievements in the production of fluoroplastic films

In the production of fluoroplastic (f-4) films, there has always been a problem of obtaining ultra-thin and wide films. Until now, TU 6-11-5751766-1-88 operates according to which the maximum width of film materials with a thickness of 0.04 mm and more does not exceed 290 mm. In this case, gouging technology is used without subsequent orientation, which significantly affects the physical and mechanical properties of such films for the worse. According to foreign data, non-oriented films from F-4 with a thickness of 0.1 mm are planed with a width of up to 500 mm, and with a thickness of 0.2 mm and up to 1500 mm. At the same time, unique equipment for gouging and special equipment for hydro-compacting of workpieces of large length and diameter is used.

We also carry out chemical activation of the surface of a fluoroplastic film made of F4, F4K20

Chemical activation of the film surface allows the fluoroplastic to be glued to other surfaces. It is not possible to glue fluoroplastic without chemical activation.

Surface-activated fluoroplastic film:

What it is?

PTFE film is an extruded polymer material. Fluoroplastic powder is used as a base. A blank is made of it, in professional slang it is called a "pill". The technological process involves careful monitoring of the homogeneity of the material. According to state standards, not the slightest sign of impregnation of foreign substances is allowed.

The film has high strength, elasticity and resistance to aggressive environments. In the manufacturing process, the technology of the cold method is used. Wide shavings, similar to long strips, are cut from the blanks and rolled. This reduces the thickness of the belts, gives the material strength in length and width. Then the film is rolled into rolls. A similar method is used to produce fluoroplastic tape.

Special properties and application examples of TPFP films

PTFE film

F-40

Special properties:

Resistant to acids, alkalis and organic solvents, radiation resistant, resistant to destabilizing factors in the group

hardness 3u, moisture resistant, good dielectric.

Application:

For the manufacture of electrical insulating gaskets and electrical insulation of wires, film roofing.

PTFE film

F-10

Special properties:

Possesses unique chemical resistance, in

including in particularly aggressive environments in combination with increased

elasticity.

The film is a good dielectric,

transparent.

Application:

Elastic containers, membranes, protective

covers.

PTFE film

F-50

Special properties:

High electrical insulating properties, resistant to aggressive environments at elevated temperatures.

Application:

For anti-adhesive and anti-corrosion protection, insulation of wires, lining of containers, as a separating anti-adhesive layer

with vacuum autoclave molding.

Aeronautical engineering

Film F-10 it is applied for

production of elastic compensation tanks, fuel tanks, products

special purpose.

Film F-50

- for the manufacture of insulation for electrical wiring in aircraft.

Construction

Film F-40

- roofing, solar collectors (translucent materials),

coverings for greenhouses, greenhouses, lining of swimming

pools, cabins for

tanning.

Filled with

F-2M film - facing material.

Tfuel-energy

complex

Film F-2M

used in power plants using wind and sea energy

Film F-40

- metallized with aluminum and silver for parabolic solar mirrors

collectors.

Radio engineering and electronics

Electret

film F-4MB-2, capacitor film F-2M, piezo and pyroelements (F-2ME) in

touch switches, microphones, sensors, etc.

Mechanical engineering and instrument making

Protective

rubber o-ring shells, figured gaskets, transparent shells

emitters, membrane compensators.

Cable

industry

Chemical protection

Lining

smoke boxes and gas pipelines.

Protection

working surfaces from aggressive environments, atmospheric influences,

ultraviolet and radiation.

Package

Medicines,

containers for the preservation of blood and bone marrow, chemical reagents, valuable devices,

sampling bags, food.

Sports, tourism

Lookout

windows in tents for operation at temperatures up to - 60 ºС. Sail windows

windsurfing.

Our laboratory carries out developments of fluoroplastic

films for specific orders, in accordance with the Technical Specifications,

developed by us:

-

TU 2245-043-00203521-98

"Fluoroplastic film - 4MB" -

TU 2245-062-00203521-2000

"Film from fluoroplastic-10" -

TU 2245-075-00203521-2001

"Film from fluoroplastic - 2M" -

TU 2245-082-00203521-2003

"Film from fluoroplastic - 40E" -

TU 2245-078-00203521-2007

"Film from fluoroplastic - 3M"

If you are interested in our products, we

always ready

answer your questions about properties, characteristics and

the use of films made of thermoplastic fluoroplastics.

Areas in which fluoroplastic is used

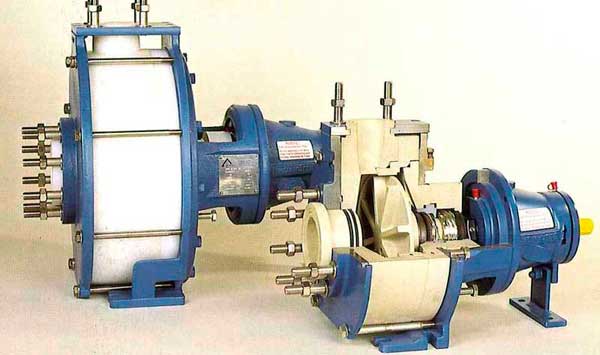

Today Teflon is used in almost all areas of economic activity. It is actively used in medicine, pharmaceuticals, energy and construction, automobile and aircraft structures. The use of fluoroplastic in the food industry is widespread. Fillers for high-temperature membrane filters, heat-resistant gaskets of various types, critical elements of shut-off and control valves, valves and pumping equipment in the chemical industry are made from it.

Machines and mechanisms

The structural properties of Teflon are used in the production of vehicles, machines, mechanisms, in machine tool building and the aviation industry. In units subject to high loads, sliding elements and bearings are used, consisting of a metal base covered with Teflon.

During the operation of the mechanism, the fluoroplastic leaves a thin film on the surface with which it comes into contact, due to which it is possible to significantly reduce the coefficient of friction.

For the same reason, finely dispersed fluoroplastic is sometimes added to the composition of lubricants. A thin layer of Teflon coating that forms on the rubbing surfaces of the elements during operation allows the mechanism to continue to work for some time if the lubricant for some reason has ceased to flow into the system. In addition, Teflon glands and sealing elements are a must in high pressure piping and hydraulic systems in most machine designs.

Medicine and pharmaceuticals

PTFE has good compatibility with the human body, therefore it is successfully used for the manufacture of prostheses in surgery, cardiology and dentistry. Artificial substitutes for blood vessels of the circulatory system and heart valves are made from fluoroplastic. Now Teflon has replaced titanium, the use of which for the manufacture of prostheses previously imposed a number of restrictions on human life.

Food industry

The use of fluoroplastic in the food industry is also noteworthy. It is used as an inner liner for pipelines and for stuffing box seals in pumps handling various raw liquids such as sunflower oil, lecithin, fat and dairy masses.

Non-stick coatings for cooking containers are also made of Teflon.

The Tefal cookware with a non-stick surface has become very popular.

Chemistry

In the chemical industry, the use of fluoroplastic is widespread for the manufacture of parts for shut-off and control valves and sealing elements of vessels and pipelines transporting liquid solutions with a high degree of chemical aggression. Due to its ability to withstand the effects of chemically active substances, the material is used in column-type reactors, extractors and various containers as a lining for surfaces in contact with an aggressive medium.

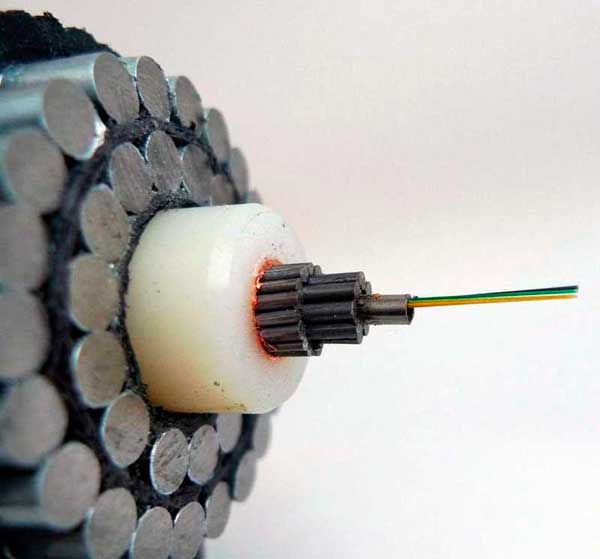

electrical and Electronics

In electrical engineering, instrument making and electronics, fluoroplastic is used as a dielectric.Teflon sheeting is an essential component of today's high quality cable products. Insulating fluoroplastic materials are used for the production of coils, capacitors and boards. PTFE insulation is able to withstand the effects of high-temperature corrosive environments.

Construction

Fluoroplastic plates are the most important parts of the structures of sliding supports of critical structures, such as bridges, galleries, overpasses, overpasses and other spans. In regions with a high level of seismic activity, Teflon gaskets are used in the places where the floor beams rest on the columns, as well as in the nodes for installing the columns on the foundations in order to ensure the possibility of free movement of the building frame elements of the building frame.

Manufacture of clothing and specialty fabrics

The thinnest film that forms during the deformation of Teflon raw materials serves as a coating for special types of fabric.

This fabric is used for sewing high-tech clothing with water-repellent and windproof properties.

At the same time, the porous material does not trap the natural vapors of the human body. Most modern sports and outdoor clothing has a thin Teflon coating.