Main characteristics

Heat-resistant glue has a special composition and unique properties that distinguish this material from other adhesive mixtures. There are several main characteristics.

- Good elasticity. It allows you to create an even veneer.

- Refractoriness. A good level of fire resistance is most important for finishing stove and fireplace structures.

- Resistant to temperature extremes. During the operation of furnace structures, it is impossible to avoid temperature changes, especially if the furnace is located outside the building. The adhesive solution creates a certain protective layer between the fireplace and the tile material, which prevents deformation of the cladding.

The composition of heat-resistant mixtures includes the following components, which may differ in quantity and quality in one form or another of hot melt glue:

- plasticizers (for external finishing with ceramic tiles, it is necessary to select solutions with a high content of plasticizers);

- synthetic additives (necessary to improve the refractory properties of the adhesive);

- cement-sand mortar;

- chamotte;

- mineral components.

Making heat-resistant tile adhesive with your own hands

For finishing with decorative tiles no more thick than ordinary tiles, use clay, cement and river sand in a ratio of 1: 1: 3

It is important to choose the right components

Particular attention is paid to clay, with which some difficulties may arise. It is checked as follows:

- Twisted between the palms into a tourniquet.

- The resulting tourniquet is wrapped around the cylindrical object.

- The condition of the clay is assessed by the cracks formed. If only the top layer of the rope is torn, then the clay is oily and sand must be added to it. The composition is considered normal if the breaks are evenly distributed over the entire length of the rope and are 1 / 3-1 / 4 of its thickness. Deeper breaks (from ½ thickness) indicate that the clay is skinny and requires a grease.

The fatty material is prepared independently:

- cut off the plastic canister;

- cover 1/5 of it with finely ground clay;

- pour in water, mix;

- waiting for precipitation;

- decant half of the supernatant;

- the sediment is allowed to brew and used as a fatty agent.

Clay, cement and river sand are mixed dry, poured with water and kneaded by hand. The resulting solution should be of a uniform consistency and normal viscosity (the trail from raking a properly prepared composition does not break and does not float). 200 g of sodium chloride are added. The adhesive is ready to use.

Mixtures for the device of individual elements of the furnace

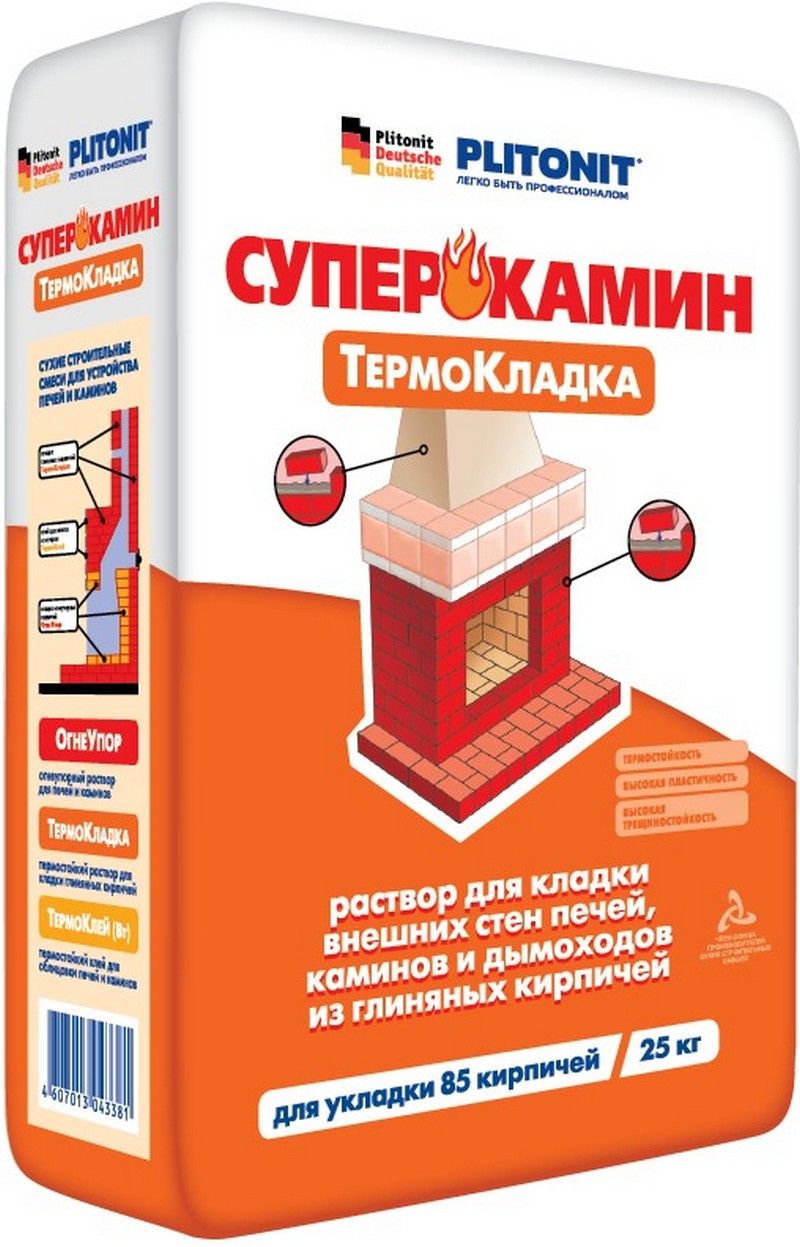

There are two main requirements for kiln mixtures: thermal stability and elasticity. These qualities will allow you to fully operate the device without fear of the formation of chips and cracks at the time of heating. Mortars are made based on components such as cement, lime, gypsum, etc. There are also mixed formulations with several binders. For each individual part of the fireplace, you need to select the appropriate mixture:

- the foundation is erected using a lime-based material or a cement-lime component. If it is too wet under the base, then use cement-based mixtures;

- the chimney is laid out on lime or lime-gypsum mortar. To make the mixture harden faster, you can add gypsum to it;

- the building is constructed from a mixture of sand, clay and water.

If any of these elements require increased strength, cement must be added to the main composition.

What should be a heat-resistant adhesive mixture?

Most often, tile adhesive is sold in powder form.

But in extreme times, you can see jelly-like compositions.Their advantage is that they are ready to use. The composition of any tile glue contains:

It is chamotte fibers that provide heat resistance and hardness to the masonry. In fact, because the oven brick must be glued exactly the first time. In the event of shear, the adhesive loses its characteristics. For exterior cladding, tile adhesive with the highest plasticity is used. If, for example, you need to glue clay tiles on the fireplace, then you should take consistencies with a significant number of plasticizers.

They significantly increase adhesion.

When choosing a heat-resistant glue, you should take into account some of its qualities:

Durability

When buying, you should pay attention to the service life of the tile mortar. The bigger it is, the better.

Linear expansion

The presence of this property will not allow us to crack with a sharp change in temperature.

Moisture resistance. Such quality is needed for glue, especially when the fireplace or stove is located in a room with the highest humidity or outdoors.

Environmental friendliness. If heat-resistant glue is used for facing a fireplace or stove, it will be constantly heated. Therefore, such a tiled consistency is not obliged to emit any harmful substances.

Heat exchange. The higher this indicator, the better the heat transfer will be. But such structures are built for the most part for heating.

Which glue is better?

On sale you can see a large assortment of similar products. But more often, consumers choose such mixtures:

Terracotta mix

- Profix This is the best choice for tiled chimneys. Tile adhesive is fire-resistant, sets extremely quickly, which makes it possible to significantly reduce the working life.

- K The base of this tile adhesive is aluminate cement and modern synthetic admixtures. Therefore, it has great thermal stability and is not afraid of a sharp temperature drop.

- Ivsil termix This product is distinguished by the highest elasticity.

With its help, they not only create the installation of fireplaces, but also decorate the facade of the buildings, decorate the kitchen areas next to the stoves and ovens.

- Hercules This tile adhesive is used for both cladding and masonry. It has shown beautiful properties in various areas of finishing and construction processes.

- Polimin P11 Effective heat-resistant consistency will allow you to glue not only clay tiles, but also to use for leveling the walls. It perfectly withstands temperature changes, indicates excellent performance even on problem areas of the surface.

Choosing a heat-resistant adhesive for lining stoves and fireplaces

Adhesive for facing stoves and fireplaces must be resistant to temperature extremes, ductile and durable. Ordinary tile adhesive will not withstand the heat effects of fire, and as a result, the surface will deform.

Criterias of choice

When choosing an adhesive for cladding, you need to take into account the following indicators:

- Heat resistance - indicated on the packaging of the glue. Heat-resistant glue must withstand up to 120 ° C;

- High degree of adhesion;

- Security;

- Moisture resistance (criterion is important if the stove is located outdoors or in a room with high humidity);

- Elasticity;

- Durability. The longer the life of the glue, the better it is.

The choice of glue also depends on the finishing material. A different adhesive must be used for each substrate. Therefore, you need to read in the instructions for the adhesive mixture about the interaction with specific materials. Heat-resistant adhesive is applied to the surface in a thin layer. Therefore, if the surface is uneven and the differences are large, then it is better to use thick heat-resistant glue to level the base.

And here is one of the ways of tiling.

Top 5 brands

The adhesive mixture is produced by many construction companies and firms. Basically, they use the same ingredients in the composition, but the quality of production can vary greatly.

To buy the best heat-resistant tile adhesive, you can pay attention to the popular brands of mortars:

- Ceresit CM 17.Suitable for cladding made of different materials (except marble).

- Stove-maker. Contains a mixture of sand, cement, additives (mineral, synthetic). Cladding works can be carried out at temperatures from -10 ° C to 35 ° C.

- Triumph. The composition includes silicate fillers for the viscosity of the mixture. The main plus of the mixture is the minimum layer thickness. Such glue can be used in rooms where additional loads cannot be created on the supporting structures.

- Ivsil Termix. This adhesive can withstand temperatures up to 250 ° C. The basis is aluminate cement. The composition also includes profile chemical fillers.

- Paladium Palatermo. It showed itself perfectly when facing with natural or artificial stone, porcelain stoneware, clinker tiles. The solution remains viable for 3 hours.

Knowing the requirements that apply to heat-resistant adhesive mixtures will help you not to make a mistake when choosing a solution for masonry or facing fireplaces and stoves. Otherwise, an error can lead to deformation of the base, as well as destruction or delamination of the material.

How to make it yourself?

Experts identify several types of hot melt glue that you can make yourself at home. They all have different compositions and properties.

Clay composition

This solution includes filler, water, and clay. Most often, clay hot glue is used for the construction of furnace structures.

For cladding, it is practically not used. This is due to the effect of high temperature on the structure of the clay, on which cracks appear in this case.

Fillers such as wood chips, chippings or sand can be used to prevent material degradation.

The composition of the mixture depends on the degree of fat content of the clay used, which, in turn, depends on the amount of sand. If the sandy component in the clay is less than 15%, it will turn out to be too oily. Normally, raw materials should contain 15-20% sand.

To determine fat content, you can use the following methods:

- Crush the clay in your hand. If it is oily, then the grains of sand will not be felt between the fingers.

- Roll up a ball from raw materials and dry it. The greasy clay will crack. If the ball retains its spherical shape, then the raw materials are lean.

The filler together with the clay is added to the mixture in a ratio of 1: 4 (if fatty raw materials are used), 1:25 (if lean clay is used) and 1: 3 (for normal material). The quantity and quality of raw materials in the composition of the mixture will determine its heat resistance.

Experts advise adding a small amount of salt to the clay hot melt glue.

To increase the thermal stability of the solution, chamotte powder can be added to it. This recommendation is useful for those who will use charcoal for heating.

Cement-clay mixture

The mixture is prepared from sand (part), chalk, clay and cement (part). The finished composition has high adhesion properties.

The cement is first thoroughly mixed with other ingredients without the use of clay. After that, clay pulp is added to the prepared substance.

After mixing, you can add a little liquid glass to the mass. The ready-made glue is suitable for finishing surfaces with tiles and large-sized slabs.

For laying ordinary tiles, it is advisable to use simpler solutions based on sand, cement, clay and a small amount of salt.

Mortar

This mixture is prepared from sand and lime in a ratio of 3 to 1. The disadvantages of such hot melt glue include long-term preservation of humidity in the room where it was used.

In addition, this heat-resistant mortar is undesirable for installing tiles on stove structures.

If the lime mixture will be applied to the lime coating, it is advisable to knock it down to prevent the newly applied layer from peeling off.

Cement mortar

The cement composition is most often used for finishing with tiled elements of horizontal surfaces.When it dries, its strength becomes less than that of a clay mixture, so hot-cement glue is used for finishing substrates that are not subject to regular stress.

The composition is prepared from 3 parts of sand and 1 part of cement. It is recommended to mix it using a construction mixer.

It should be borne in mind that the cement slurry quickly shrinks, so it must be constantly stirred.

Experts recommend adding no more than 100 g of powder to 1 bucket of solution. Laying a mosaic or stone on such hot melt glue can negatively affect the appearance of the future coating.

Kiln brick

Usually, two types of bricks are used - these are fireclay or ceramic refractory bricks. If the stove is built in a bathhouse, then fireclay bricks are no longer suitable here, ceramic refractory and clinker ones are used.

By components, the structure can be divided as follows:

- foundation;

- facing;

- firebox;

- chimney;

- smoke circulation.

First-class bricks are needed on the foundation, clinker bricks are best used in a region with constant and severe frosts. The mortar in this case is suitable for lime or cement, it has good strength.

The firebox itself should be laid from fireclay bricks, the solution is similar - fireclay.

The chimney is equipped with refractory bricks, a composition with clay is used.

The chimney is built of grade 1 bricks or clinker bricks in combination with hollow bricks (in places with a harsh climate).

Important! The mortar for the chimney masonry must be resistant to the effects of various acids; it must be borne in mind that its parts are subject to different thermal loads. For the source of the pipe, a clay-chamotte solution is recommended

The head and neck of the chimney are laid out with a more durable material with the addition of slaked lime and / or cement

For the source of the pipe, a clay-chamotte solution is recommended. The head and neck of the chimney are laid out with a more durable material with the addition of slaked lime and / or cement.

Overview of manufacturers of heat-resistant adhesives

At present, it is rather difficult to navigate in all the variety of refractory mortars offered by manufacturers. In order not to be mistaken in choosing a quality material, we offer a list of manufacturers whose products are in special demand among domestic consumers:

- Ceresite. The manufacturer produces heat-resistant dry mixes consisting exclusively of natural ingredients. They can withstand a temperature load of up to 1200 degrees due to the addition of kaolin refractory components to the composition of the solutions. Adhesive mixtures for Ceresit tiles have proven themselves well among other manufacturers;

- Polyplast. The products of this manufacturer contain special mineral additives that guarantee the resistance of the material to the direct effects of fire. Plastic solutions are able to withstand significant temperature drops of 300-500 degrees;

- Terracotta. Heat-resistant mixtures include fireclay dust and clay, which, when heated, behaves in the same way as ceramic or fireclay bricks. The heat-resistant solution is able to withstand heating up to 500-600 degrees.

Heat-resistant tile adhesive - a special type of mixture suitable for cladding surfaces exposed to high-temperature heating

When purchasing a refractory composition, you should pay attention to the technical characteristics of the solution, the type of base, as well as the scope of operation of the solution.

The choice of heat-resistant glue for masonry stoves and fireplaces

Masonry adhesive for stoves and fireplaces can withstand an average of 850 ° C to 1200 ° C. In some cases, up to 1400 ° C and even higher. The packaging always indicates whether the glue is intended for laying an open firebox or not.

The composition includes special additives, plasticizers, additives that provide strength and heat resistance. The mixture retains working properties and remains viable for 60 minutes.

Criterias of choice

When buying heat-resistant glue for stoves and fireplaces, a person needs to take into account the following criteria:

- Frost resistance. Freezing temperatures can cause the glue to crack. Therefore, this indicator is important if there is a possibility that in winter the residents will live in the premises inconstantly;

- The mode of operation of the stove or fireplace. If they are often melted and then extinguished, then the load on the masonry material will be greater than during continuous operation of the device;

- Ability to withstand additional loads.

According to these criteria, you can choose glue for stoves and fireplaces. From the huge assortment, you need to opt for the masonry mortar that best suits the operating conditions.

Top 5 brands

The most popular brands of masonry adhesives are:

- Terracotta is a dry mixture of gray color. The solution is very flexible. After applying the glue, you can adjust the position of the laying material for another 15 minutes.

- Scanmix Fire (gray) - withstands up to 1200 ° C. It is resistant to the appearance of cracks at the seams, quickly hardens, is environmentally friendly and has a high degree of adhesion.

- Polymine is resistant to negative temperatures and moisture. Used for substrates that may undergo deformation.

- Ceresit Flex CM 16 is safe, elastic and prevents deformation of the laying material. A distinctive feature of the mixture is that uneven material can be laid on it.

- Master "Peach" - withstands short-term exposure to 1200 ° C. The mixture is resistant to moisture and frost. The solution is flexible and durable. It can be used for masonry outside and inside the stove.

v class = 'yarpp-related yarpp-related-none'>