In the modern world, the design of a metal staircase has a direct impact on the perception of the overall design of a room. Therefore, when choosing a solution, they are guided not only by technical parameters, but also by aesthetic characteristics, especially since the qualities of the source material make it possible to create systems with a configuration of any complexity.

Device options

Modern models have good durability and functionality, successfully fitting into almost all interiors. However, the design also has a direct impact on the appearance. The basis, as a rule, is a steel frame, which is responsible for the durability and reliability of the entire system.

Using kosour

This design of a metal staircase is considered the most popular, as it has many advantages, including a respectable appearance. A metal ladder, if desired, can be assembled with your own hands.

For manufacturing, special profiles or composite bent beams are used. The number of stringers is determined by the possible load-bearing capacity and aesthetic considerations.

- The products are visually compact and lightweight, therefore they are perfect for buildings where there are no huge rooms intended for stairwells.

- Due to their ability to withstand quite serious loads, structures of this type can be used not only in private houses, but also in public buildings.

- When the device is installed, it becomes possible to design systems with massive decorative elements. That is, if necessary, the wave can really add any accessories.

Note! When the configuration of the interior is simple enough, it is difficult to offer anything better than the traditional marching stairs on kosoura. All methods of execution of important units are fully worked out.

Bowstring systems

Products of this kind have bearing elements in the form of guide planes placed on the sides of each march. They differ from previous analogs in the way of fixing the steps: the steps are inserted directly into the inclined posts. In some cases, the design of metal ladders of this type may imply the presence of only one ladder bowstring.

- The sufficient strength of the inclined supports gives a certain freedom to the master of design, allowing the product to be adapted to the peculiarities of almost any interior.

- Versatility is achieved due to the fact that metal bases are ideal for the manufacture of not only straight stairs, but also for the production of screw counterparts.

- Numerous design options are aimed primarily at calculating the massiveness of the entire system as a whole.

Attention! Although these products are quite simple to manufacture, assembly still requires a certain level of professionalism and some skills. However, making them with your own hands is easier than other analogues.

Steps on the bolts

Such structures of metal stairs are actually devoid of supporting supports, so they look unusually light.

This also gives rise to a list of numerous advantages that are not inherent in other systems.

- The correct placement of the winder steps is ensured, which is rather difficult to perform with other manufacturing technologies, and this adds up to safety.

- The interior of the dwelling is not overloaded, but at the same time the appearance of the room is improved.

- Extremely easy maintenance, because after installation there are no poorly accessible places for cleaning.

- The presence of a significant area at the bottom makes it possible to rationally use the internal space of the house.

- Any part, if necessary, is replaced without any difficulties, by removing several elements.

Important! In many situations, the bearing capacity of the side planes is not enough for the device of this system, this applies primarily to wooden and plasterboard partitions, as well as thin brick walls.

Carrying out basic actions

The parts used are cut to specific dimensions. This can be done using an angle grinder. (grinders)... To facilitate operations, you can buy a universal jig, which allows you to maintain the required angles.

Welded works

At the heart of all operations with metal is welding, which allows the connection of elements. Only after fully familiarizing yourself with the instructions, you can proceed to the practical part.

It will also not hurt to study safety precautions when carrying out welding work.

- Do not operate in a closed room. It is necessary to provide air ventilation. It is advisable to perform most of the operations in an open space.

- Clothing with sleeves should be used, as a fairly strong ultraviolet radiation is emitted during the combustion process.

- Pants must be put directly on the shoes so that the molten metal particles cannot burn through it.

- A protective mask must be used without fail, otherwise it is quite possible to get a corneal burn.

- Do not use simple gloves. It is necessary to use special leggings made of dense fabric.

Note! When making stairs and metal structures of a different type, you should adhere to the above rules and recommendations, then you will be able to avoid unpleasant episodes.

Mounting on bolts

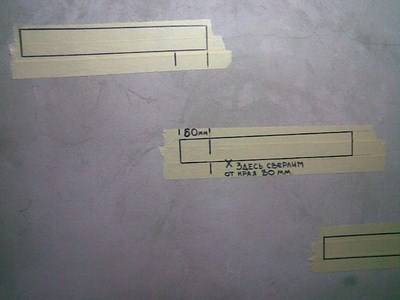

It is important to know that when constructing a staircase in this way, the rises find themselves on top of each other: the front edge rests on the back. Thus, after installation, the actual dimensions of the steps are reduced by about 5 centimeters.

Below is an instruction to assemble the structure yourself.

- A bowstring is installed on the inside, and steps are rigidly fixed to it so that there is no opportunity for lateral displacement.

- The installation of support balusters is being carried out, which play the role of a supporting element, withstanding the second part of the mass of the entire system and moving people.

- Fixing is done using metal brackets located on the floor beams.

- A handrail is attached to the vertical balusters, which is an additional support for the bolts.

- When connecting the elements with bolts, a steel crossbar is used, and the bolt itself is already fixed to it.

Recommendation! If the steps are to be mounted directly into the side plane of the building, then holes of the required diameter should be made first, and then elastic spacers should be placed in them to eliminate possible squeaks.

Classification methods

Products may be categorized according to various factors.

- Based on the trajectory of movement, circular, straight, screw, elliptical, rotary or curvilinear structures are distinguished.

- Based on the location, you can designate outdoor, garden and indoor systems.

- Depending on the intensity of operation, there are decorative, entrance, fire, evacuation and front stairs.

- As for the layout, it allows you to select single-march or multi-march products.

Finally

To better understand the process of making metal stairs, you need to carefully watch the video in this article. Having devoted very little time to the study of this topic, you can easily spoil the whole structure, and the price of metal elements is quite high.Also, a lot of time will be wasted (also learn about the benefits of telescopic stepladders).